The method for preparing potassium chloride and magnesium sulfate by using kainite

A kind of technology of magnesianite and potassium chloride, applied in the direction of magnesium sulfate, alkali metal chloride, etc., can solve the problems that potassium chloride and/or magnesium sulfate have no relevant reports, so as to improve the separation efficiency of nanofiltration and improve the Recycling rate, effect of ensuring high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

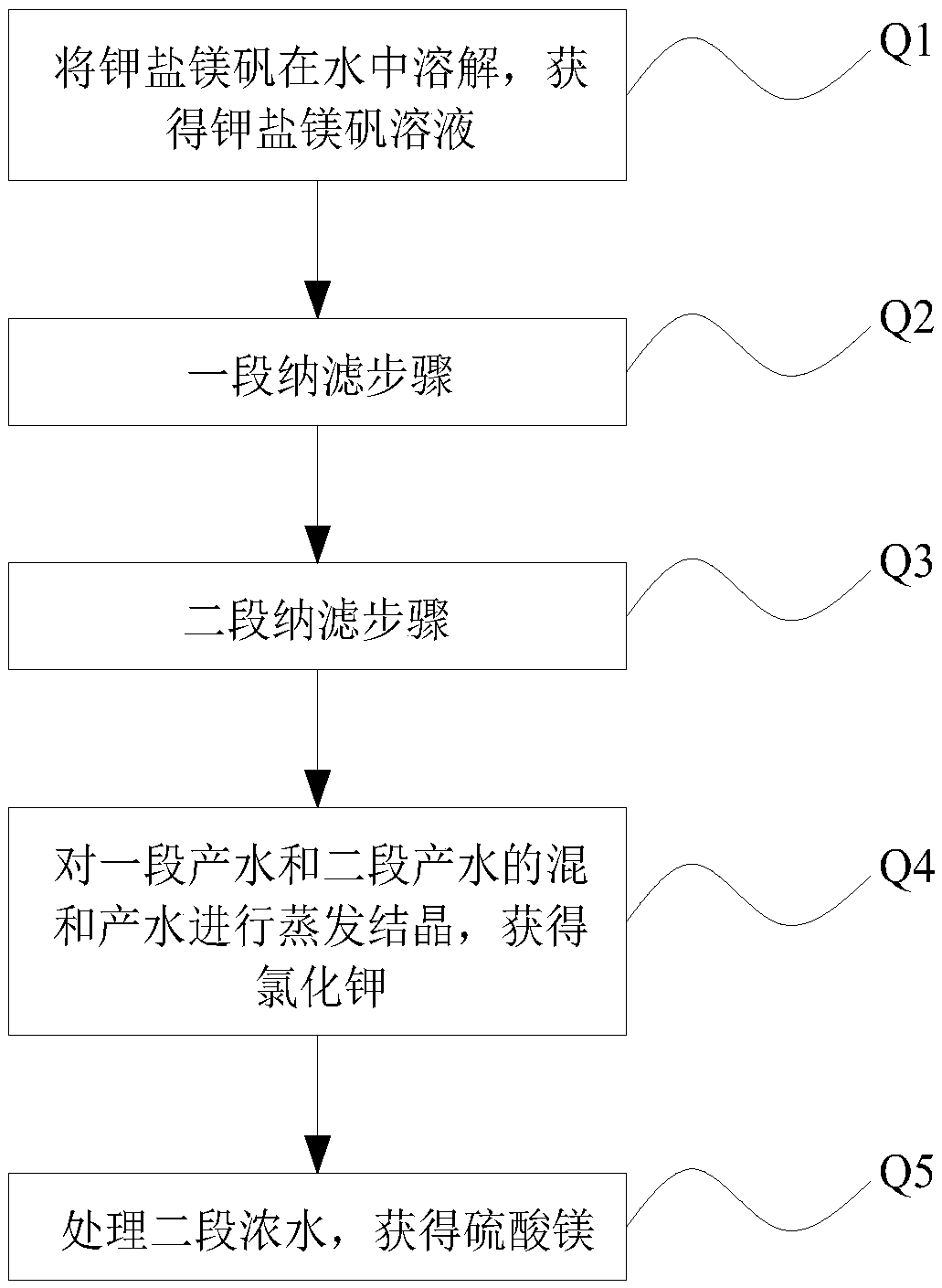

[0032] This embodiment discloses a method for preparing potassium chloride and magnesium sulfate by using magnesia. The method for preparing potassium chloride and magnesium sulfate by using magnesia according to this embodiment includes the following steps:

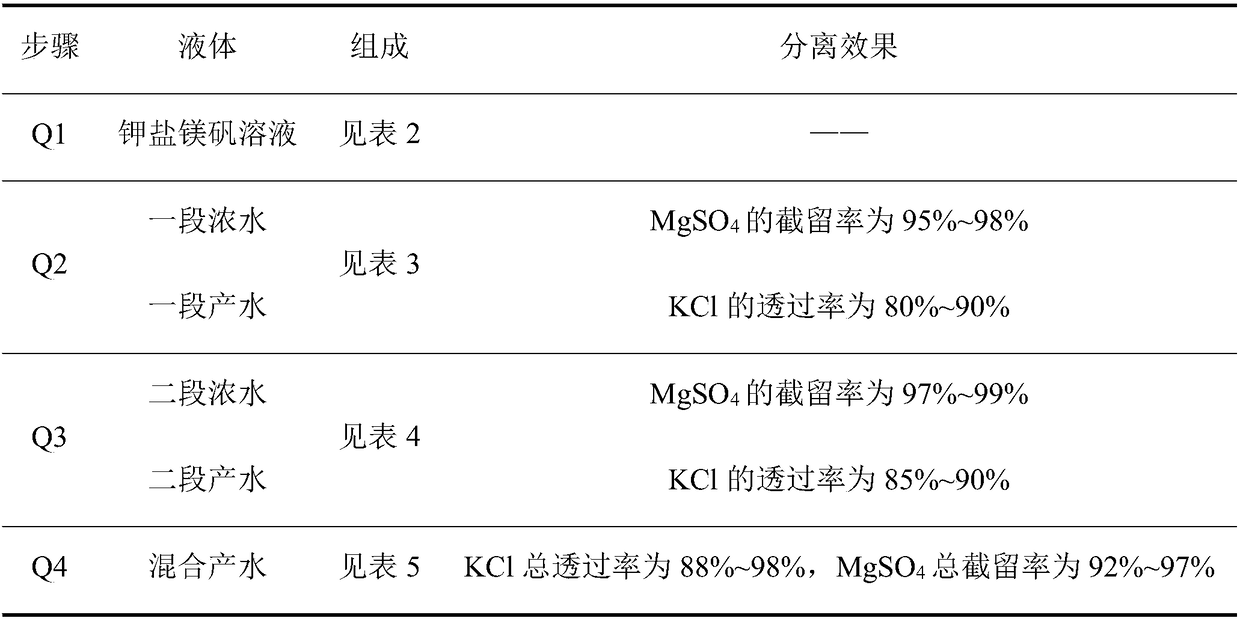

[0033] S1. Dissolve the potassium magnesia in water to obtain a potassium magnesia solution.

[0034] In the potassium salt magnesia solution, the concentration of KCl is 15g / L~35g / L, MgSO 4 The concentration is 30g / L~60g / L.

[0035] S2, one-stage nanofiltration step: a nanofiltration membrane system is used to perform one-stage nanofiltration treatment on the potassium magnesia solution to obtain one-stage concentrated water and one-stage product water.

[0036] Specifically, the nanofiltration membrane system includes a first nanofiltration membrane module, and a first concentrated water tank and a first produced water tank connected to the first nanofiltration membrane module; the first concentrated water tank is used to store...

Embodiment 2

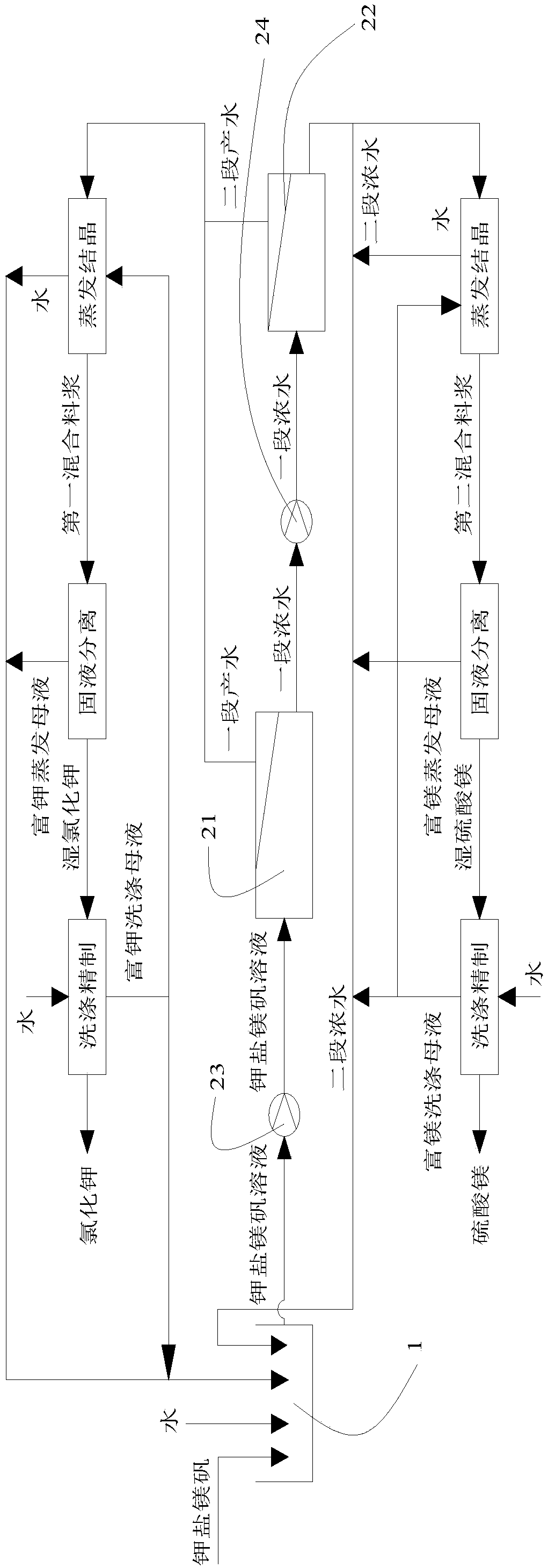

[0043] This embodiment discloses another preferred method for preparing potassium chloride and magnesium sulfate using potassium magnesia, specifically refer to figure 1 , The device on which it is based includes a dissolution tank 1 and a nanofiltration membrane system connected in sequence; specifically, the nanofiltration membrane system includes a first nanofiltration membrane module 21, a first concentrated water tank connected to the first nanofiltration membrane module 21 ( (Not shown in the figure) and the first produced water tank (not shown in the figure), the second nanofiltration membrane module 22 connected to the first concentrated water tank, and the second concentrated membrane module 22 connected to the second nanofiltration membrane module The water tank (not shown in the figure) and the second produced water tank (not shown in the figure).

[0044] Preferably, the aforementioned nanofiltration membrane system further includes a first booster pump 23 arranged bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com