Double-process combined denitration interlocking control system for tail gas treatment of waste incineration plant

A technology for waste incineration and exhaust gas treatment, which is applied in general control systems, control/regulation systems, electrical program control, etc., and can solve problems such as frequent start and stop of SCR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, content of the present invention is described further:

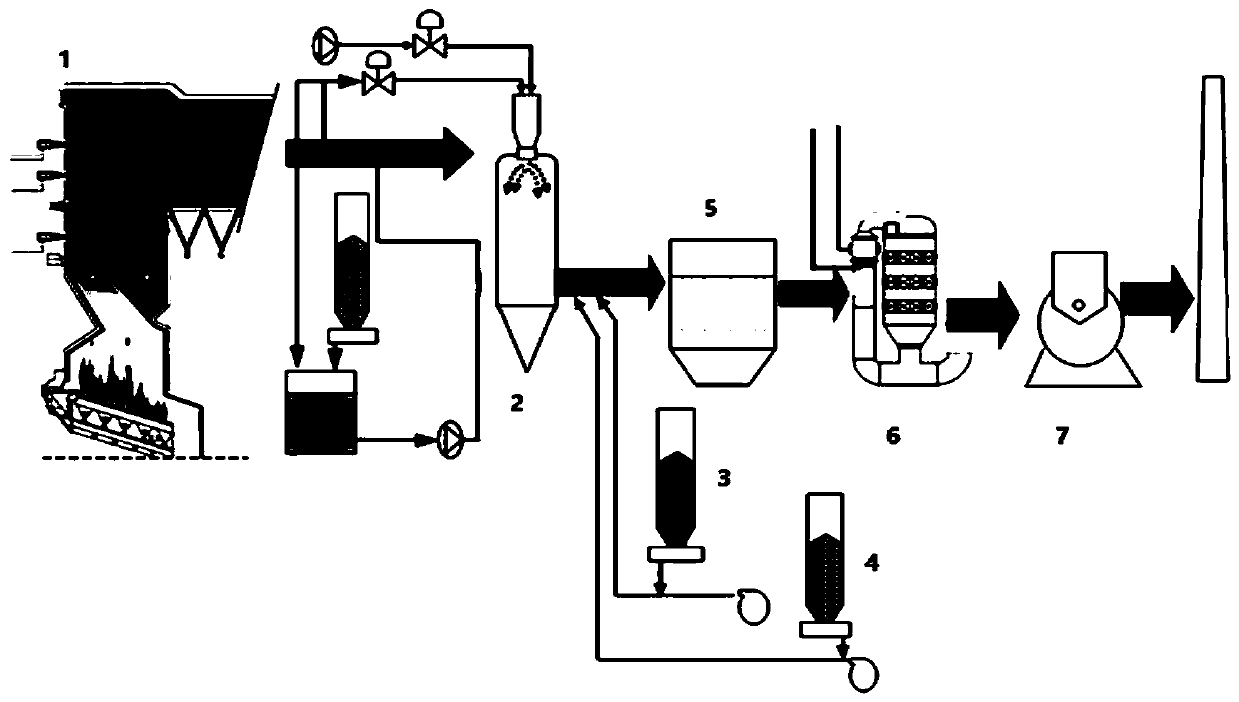

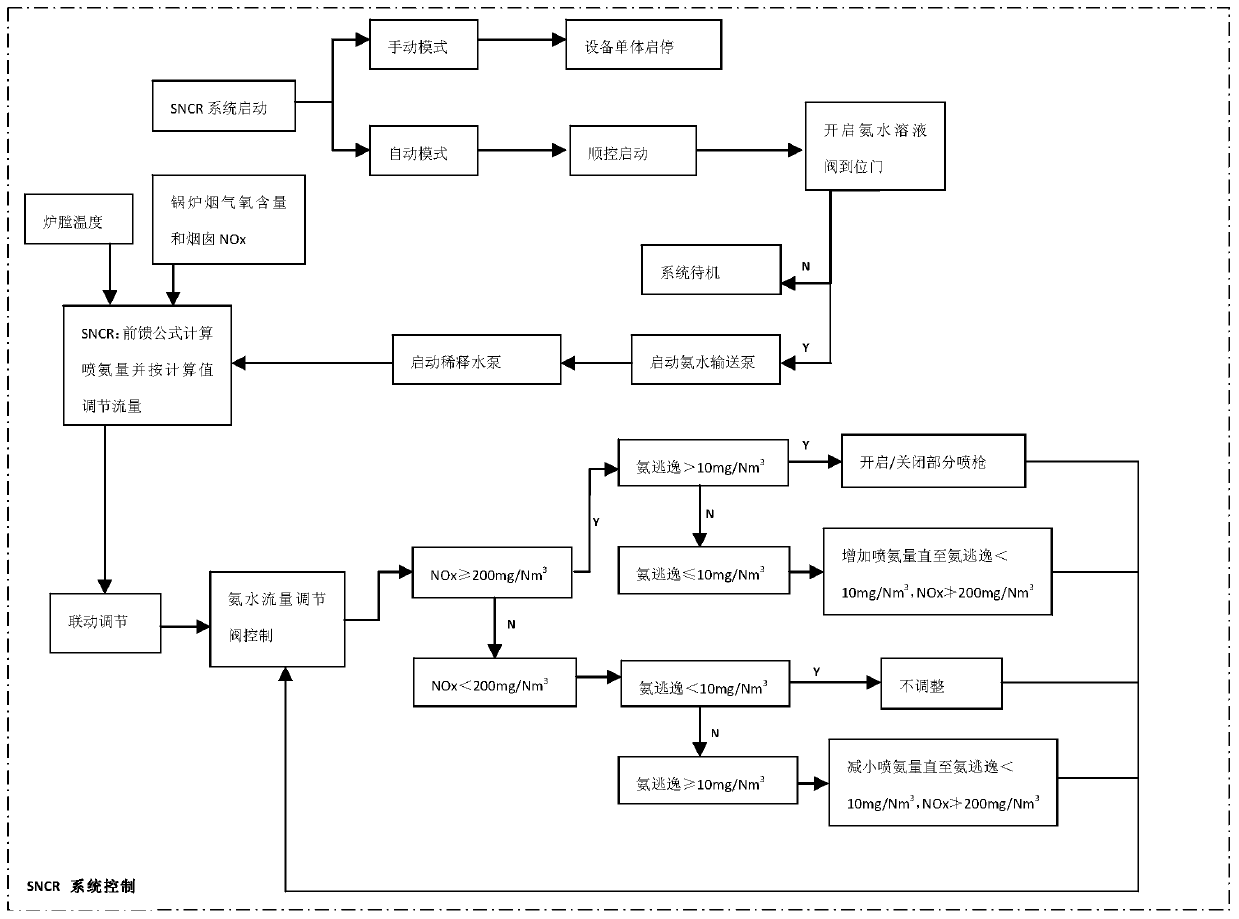

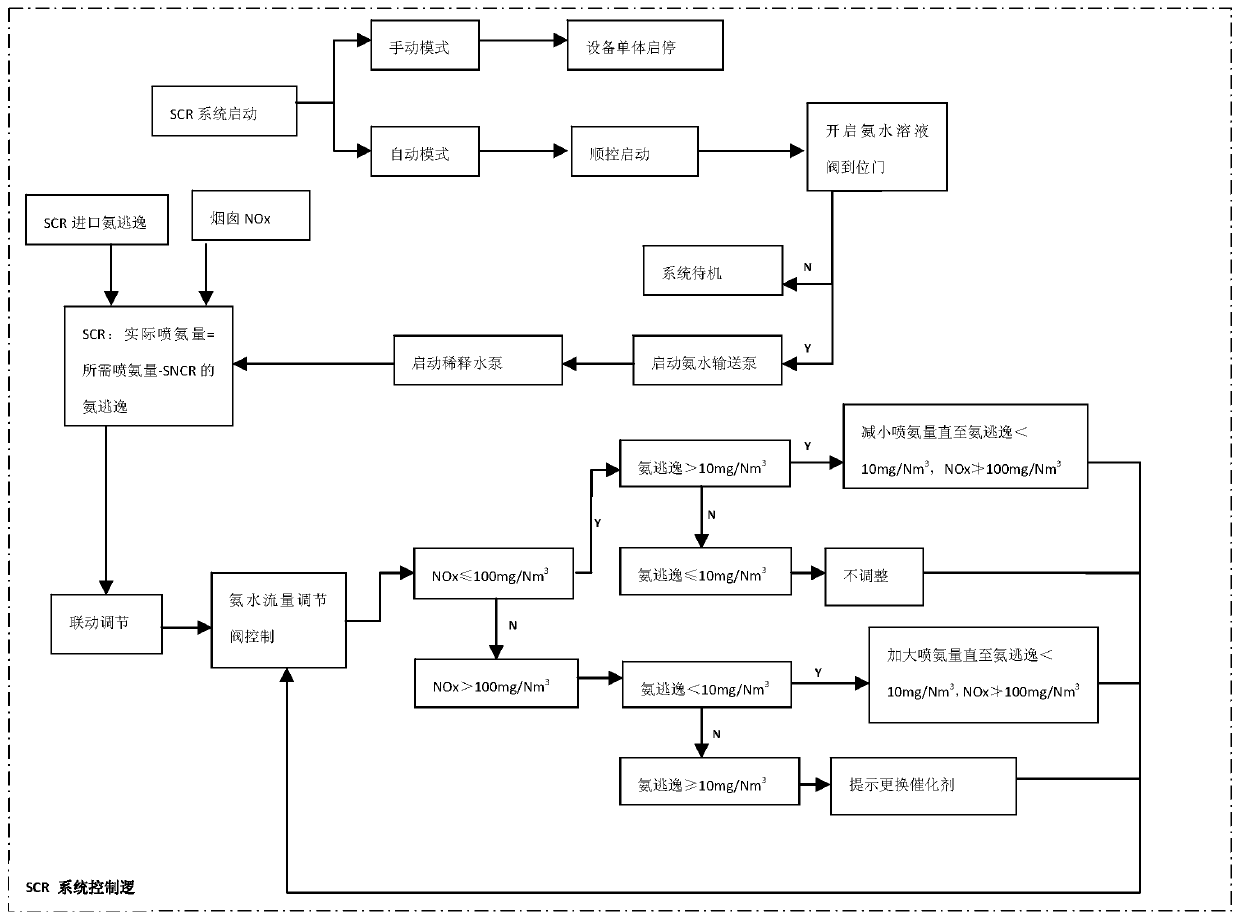

[0036] Such as figure 1 Shown is a dual-process automatic combined denitrification (SNCR+SCR) system diagram, which generally cooperates with other exhaust gas purification processes. The specific configuration is: 1. SNCR system; 2. Semi-dry deacidification system; 3. Activated carbon injection system; 4. Slaked lime injection system; 5. Bag filter system; 6. SCR system; 7. Induced fan system.

[0037] First, the SNCR system 1 atomizes 5% ammonia water through compressed air and sprays it into the boiler furnace for denitrification. The denitrification efficiency is optimized through feed-forward control to ensure the lowest ammonia escape. After coming out of the filter, it enters the semi-dry deacidification tower in the semi-dry deacidification system 2 for deacidification. In the flue of the bag filter entering the bag filter system 5, the activated carbon inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com