Preparation method of chrysanthemum morifolium extract

A chrysanthemum flower extract and an extraction technology are applied in the field of preparation of chrysanthemum flower extract, which can solve the problems affecting powder yield and flavor, stickiness, environmental pollution, etc., and achieve rich effective components and aroma components, and improvement of stickiness phenomenon. The effect of sticky tower conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

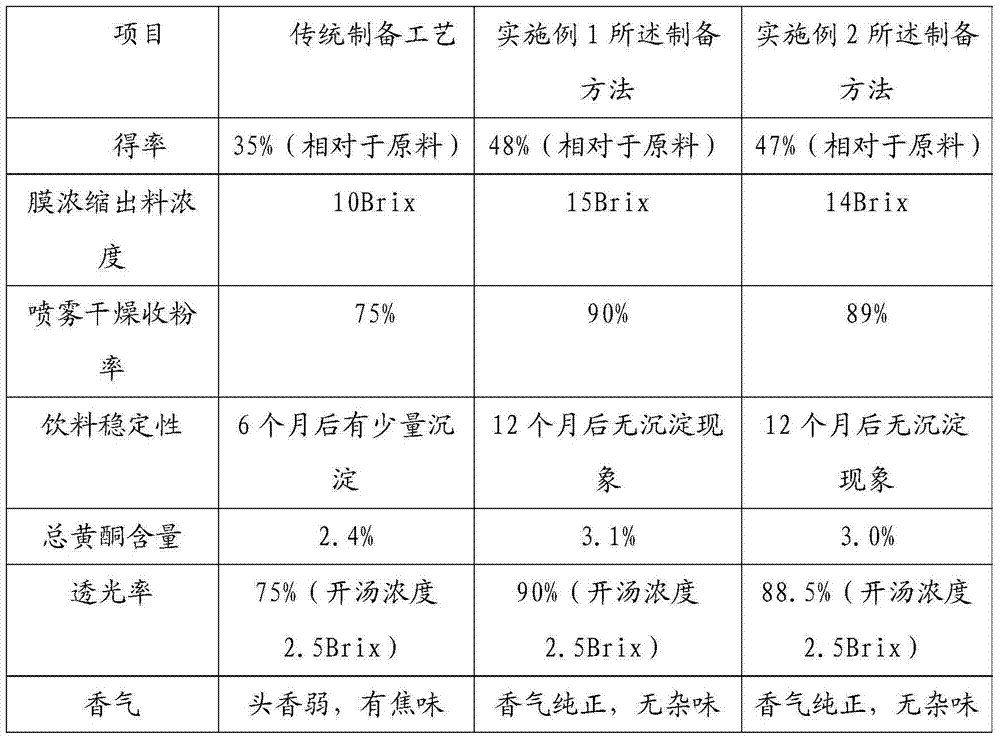

Examples

Embodiment 1

[0029] A kind of preparation method of chrysanthemum extract, carries out according to the following steps successively:

[0030] 1) Pulverization: take Chrysanthemum chrysanthemum as raw material, and pulverize the raw material to 10 mesh through a pulverizer;

[0031] 2) Extraction: Put the crushed raw materials into the extraction tank and extract twice; among them, the first extraction, the amount of cellulase is 0.3% of the weight of raw materials, the amount of pectinase is 0.2% of the weight of raw materials, enzyme The hydrolysis temperature is controlled at 45°C, the enzymatic hydrolysis time: 60min, and the extraction water is 15 times the weight of the raw material; the second extraction temperature is controlled at 95°C, the extraction time: 30min, the extraction water is 10 times the weight of the raw material, After merging, enter the next process;

[0032] 3) Coarse filtration: After the combined extracts are coarsely filtered through a vibrating sieve, some la...

Embodiment 2

[0039] A kind of preparation method of chrysanthemum extract, carries out according to the following steps successively:

[0040] 1) Pulverization: take Chrysanthemum chrysanthemum as raw material, and pulverize the raw material to 40 mesh through a pulverizer;

[0041] 2) Extraction: Put the crushed raw materials into the extraction tank and extract twice; among them, the first extraction, the amount of cellulase is 0.3% of the weight of raw materials, the amount of pectinase is 0.2% of the weight of raw materials, enzyme The hydrolysis temperature is controlled at 55°C, the enzymatic hydrolysis time: 80min, and the extraction water is 10 times the weight of the raw material; the second extraction temperature is controlled at 98°C, the extraction time: 30min, the extraction water is 8 times the weight of the raw material, After merging, enter the next process;

[0042] 3) Coarse filtration: After the combined extracts are coarsely filtered through a vibrating sieve, some lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com