Power-improved diaphragm type carburetor

A diaphragm type carburetor and carburetor technology, applied in carburetors, engine components, machines/engines, etc., can solve problems such as poor oil supply of carburetors, achieve good control and reduce deformation , to avoid the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

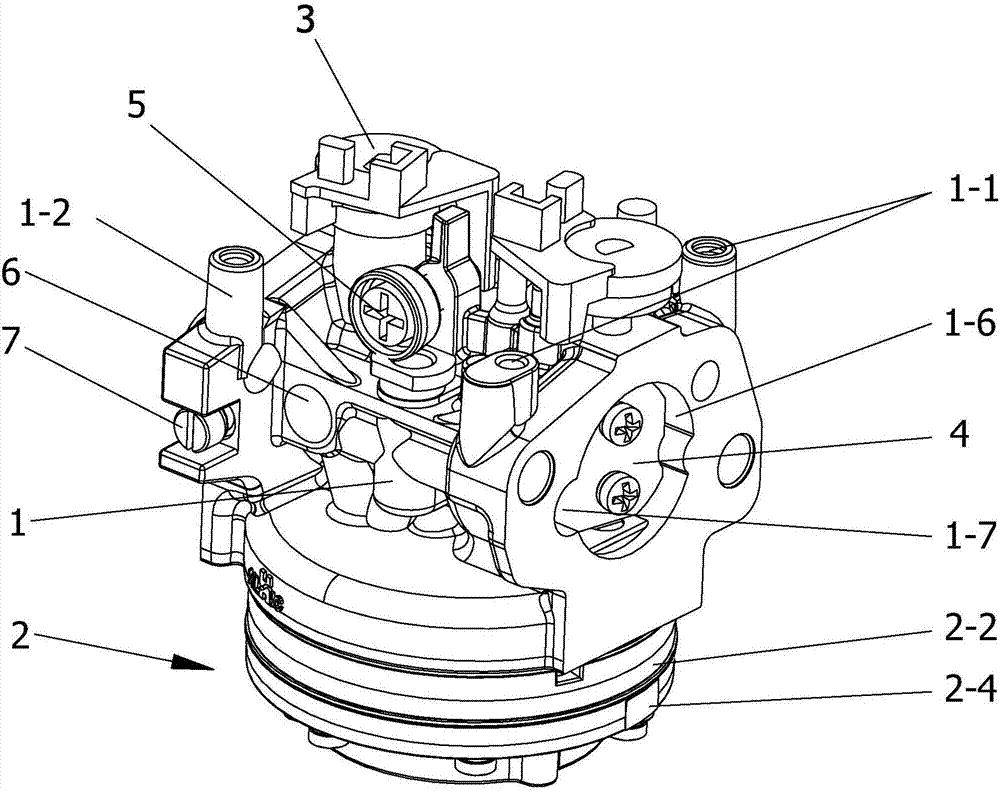

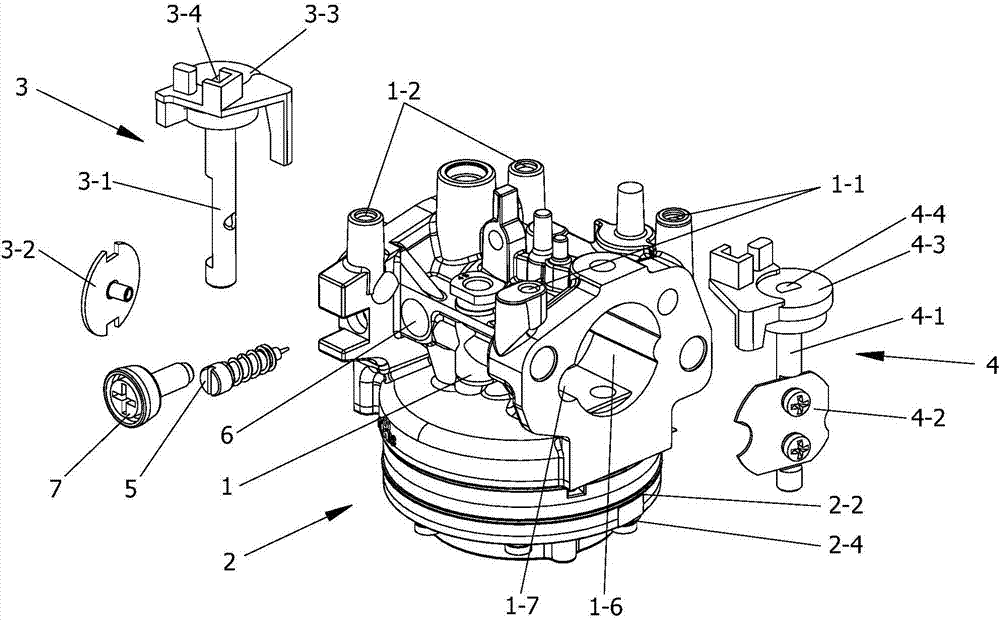

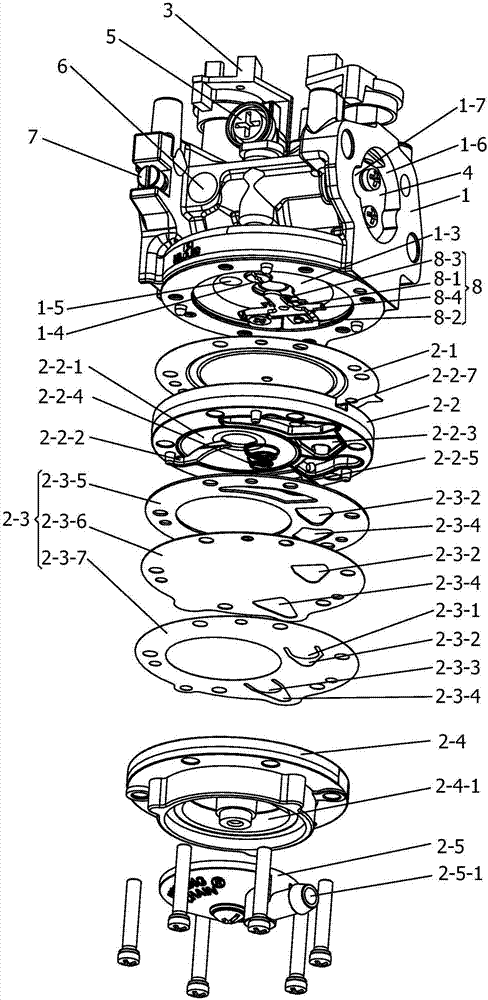

[0038] Such as Figure 1-7 As shown, a power-improved diaphragm carburetor provided by the present invention includes a carburetor body 1, and the upper body of the carburetor body 1 is provided with an air intake passage 1- 6. The air intake channel 1-6 is sequentially provided with a choke device 4 that can be rotated to adjust the intake air volume, a throat pipe 1-10 that can be rotated to adjust the volume of mixed gas in the air intake channel 1-6. The throttle device 3, the lower side of the carburetor body 1 is provided with a fuel injection chamber 1-3 for storing fuel, and the carburetor body 1 is provided with a fuel injection chamber 1-3 to facilitate the fuel injection in the fuel injection chamber 1-3. The fuel injection passage in the air passage 1-6, the lower part of the carburetor body 1 is equipped with a negative pressure adjustment device 2 for controlling the fuel tank to enter the fuel injection chamber 1-3, and the negative pressure adjustment device 2 ...

Embodiment 2

[0050] Such as Figure 8 , Figure 9 As shown, the difference between the second embodiment and the first embodiment is that the diaphragm 2-3 includes a sealing gasket 2-3-5 and a diaphragm three 2-3-8 arranged sequentially from top to bottom. The first notch 2-3-2 and the second notch 2-3-4 penetrate the sealing gasket 2-3-5 and the diaphragm three 2-3-8, the first movable valve 2-3-1 and the second movable valve The valve 2-3-3 is arranged on the diaphragm three 2-3-8.

Embodiment 3

[0052] Such as Figure 10 As shown, the difference between the third embodiment and the first embodiment is that the throttle valve 3-2 is controlled by a stepping motor, and the choke valve 4-2 is automatically controlled by a torsion spring connected with the rocker arm 3-3 of the throttle shaft. When the throttle valve 3-2 was fully opened, the choke valve 4-2 was also fully opened. Otherwise the throttle valve 3-2 is closed or the opening degree is small, and the choke valve 4-2 is also closed or the opening degree is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com