Hydroxylamine nitrate crystal preparation method

A technology of hydroxylamine nitrate and crystals, which is applied in the field of preparation of hydroxylamine nitrate crystals, can solve problems such as cumbersome steps, and achieve the effect of meeting the requirements of HAN concentration and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

[0024] Steps of the present invention:

[0025] (1) Weigh the raw materials barium nitrate and hydroxylamine sulfate according to the ratio of 1:1, and pour them into suitable three-necked bottles and beakers respectively;

[0026] (2) According to the ratio of adding 1500ml-2500ml distilled water per mole of barium nitrate, add an appropriate amount of distilled water into the three-necked bottle, raise the temperature to 60°C-70°C, and keep stirring until the barium nitrate is completely dissolved;

[0027] (3) According to the proportion of adding 500ml-1000ml distilled water per mole of HAS, add an appropriate amount of distilled water into the beaker, and keep stirring at room temperature until HAS is completely dissolved;

[0028] (4) Add the HAS aqueous solution to the barium nitrate aqueous solution at a rate of 1 drop / second to 3 drops / second, and the reaction system is always maintained at 60°C to 70°C. After the HAS aqueous solution is added dropwise, continue to m...

Embodiment 2

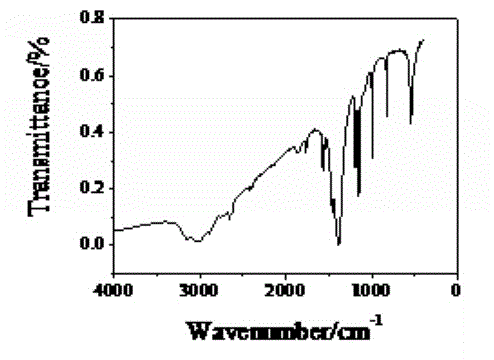

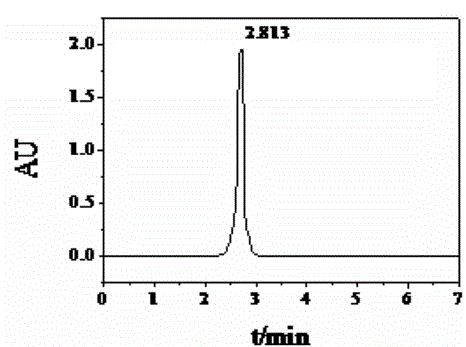

[0035] Prepare multiple batches of HAN crystals, and analyze them by infrared, liquid phase, and purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com