Classification grinding separation process for preselected coarse-grained concentrate of lean hematite

A technology of hematite and concentrate, which is applied in the classification and grinding process of pre-selection of coarse-grained concentrate of lean hematite, which can solve the problem of too fast wear of the grit chamber and the failure to guarantee the particle size of the overflow product, which affects the separation Problems such as normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

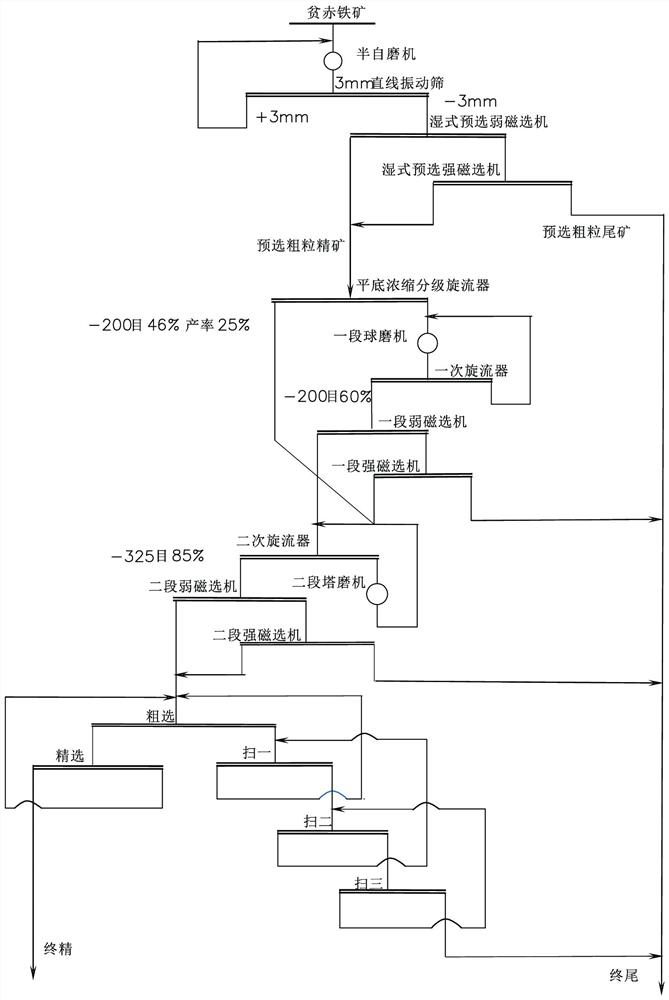

[0020] Such as figure 1 As shown, a kind of lean hematite pre-selection coarse-grained concentrate classification grinding process of the present invention, the poor hematite grade that is 25.56% is given to the coarse-grained wet pre-selection process after coarse crushing, specifically through the semi-autogenous mill Closed-circuit grinding composed of a linear vibrating screen with a screen hole size of 3 mm. The under-screen product with a particle size of 3-0 mm is separated in two consecutive stages by a wet pre-selection weak magnetic separator and a wet pre-selection strong magnetic separator. The pre-selected coarse-grained tailings with a grade of 7.86% and a yield of 22.67% can be obtained with a grade of 30.75% and a pre-selected coarse-grained concentrate with a concentration of 22.8%. , stage grinding, and stage strong magnetic tailing-reverse flotation process, which specifically include the following steps:

[0021] Step 1. Feed the pre-selected coarse-graine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com