Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Low linear expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

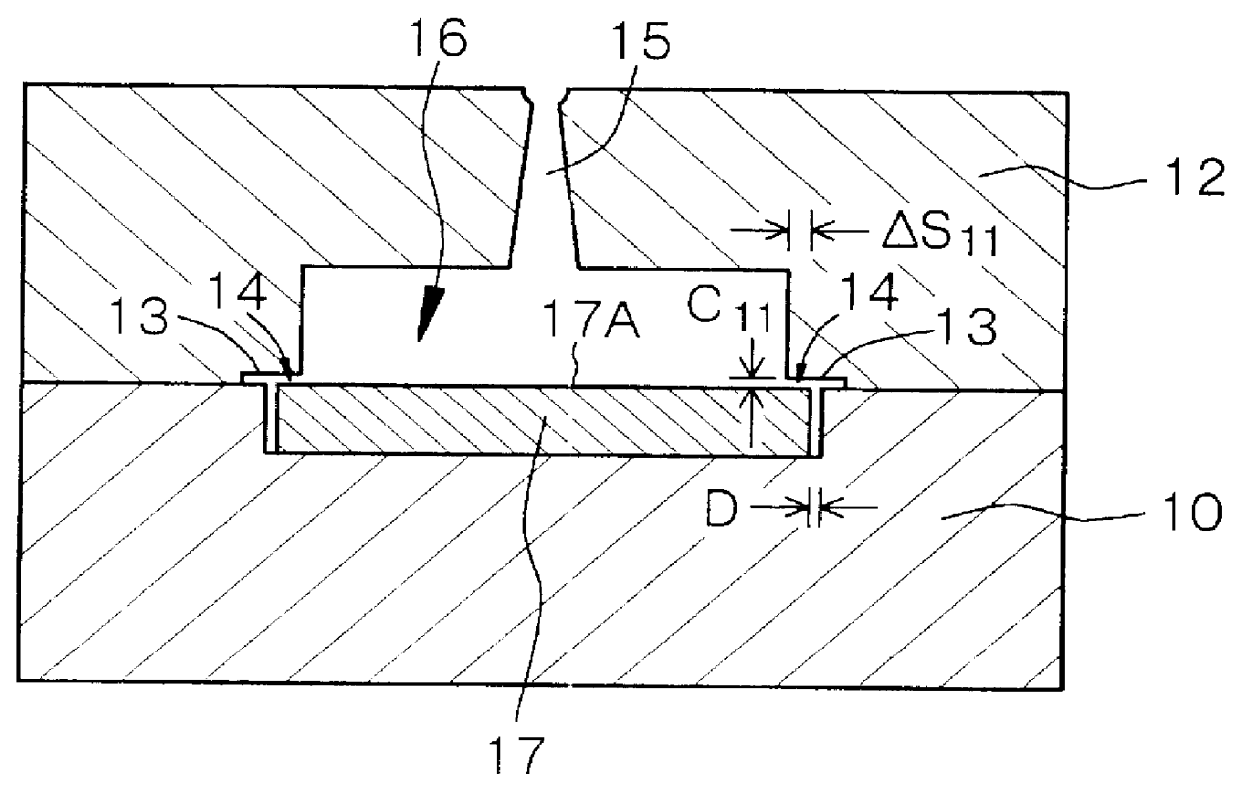

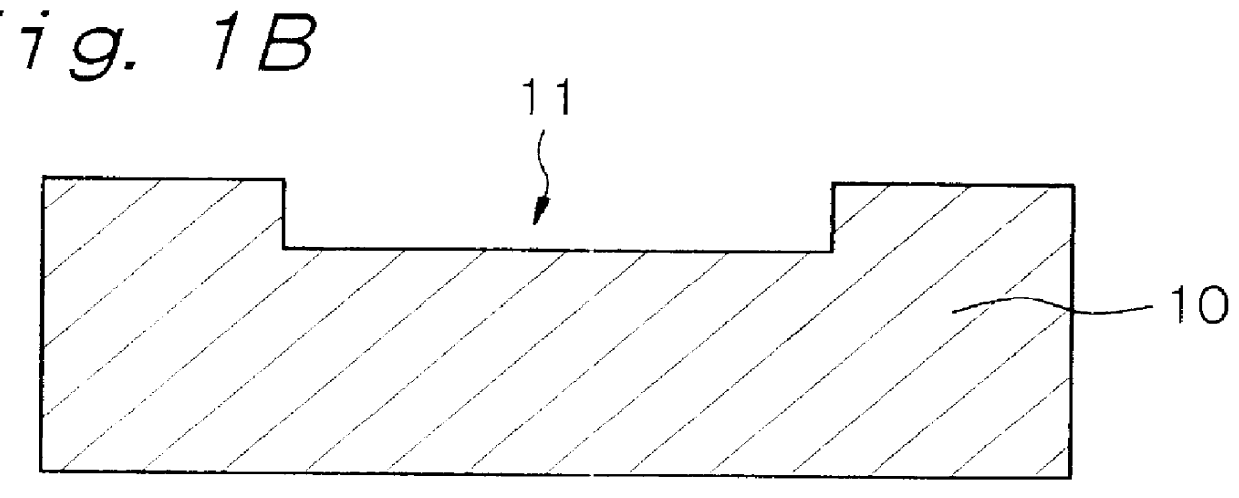

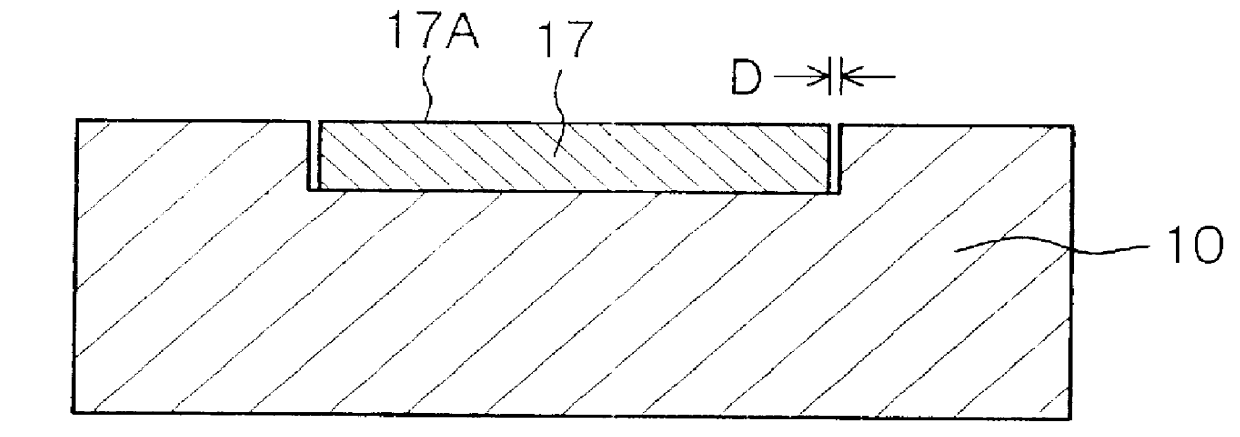

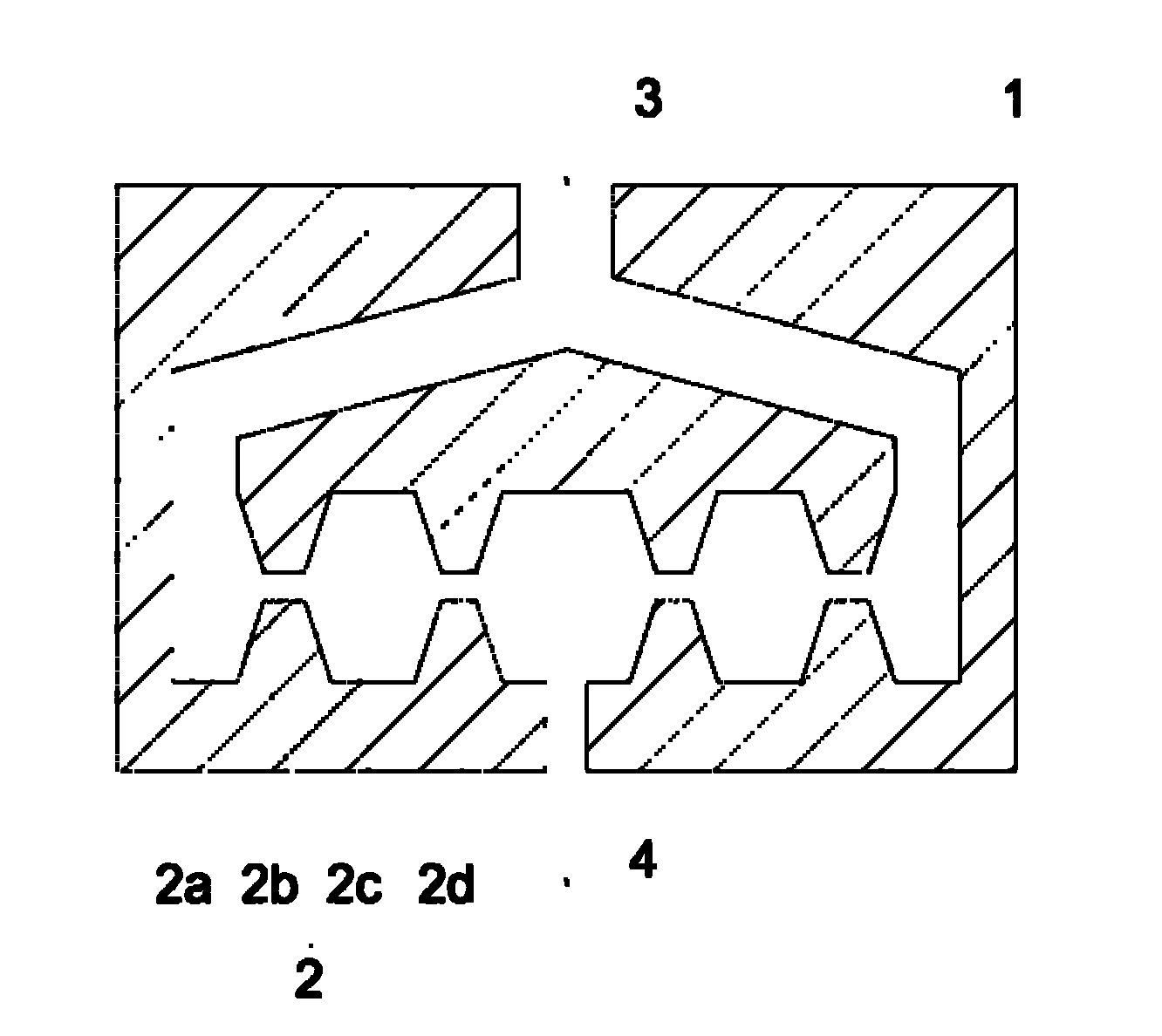

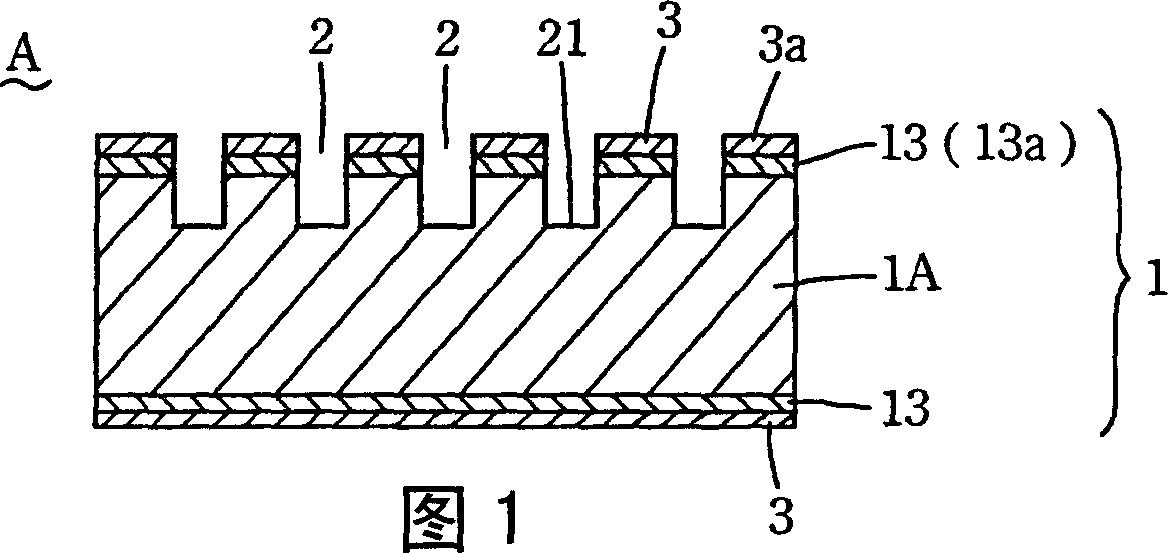

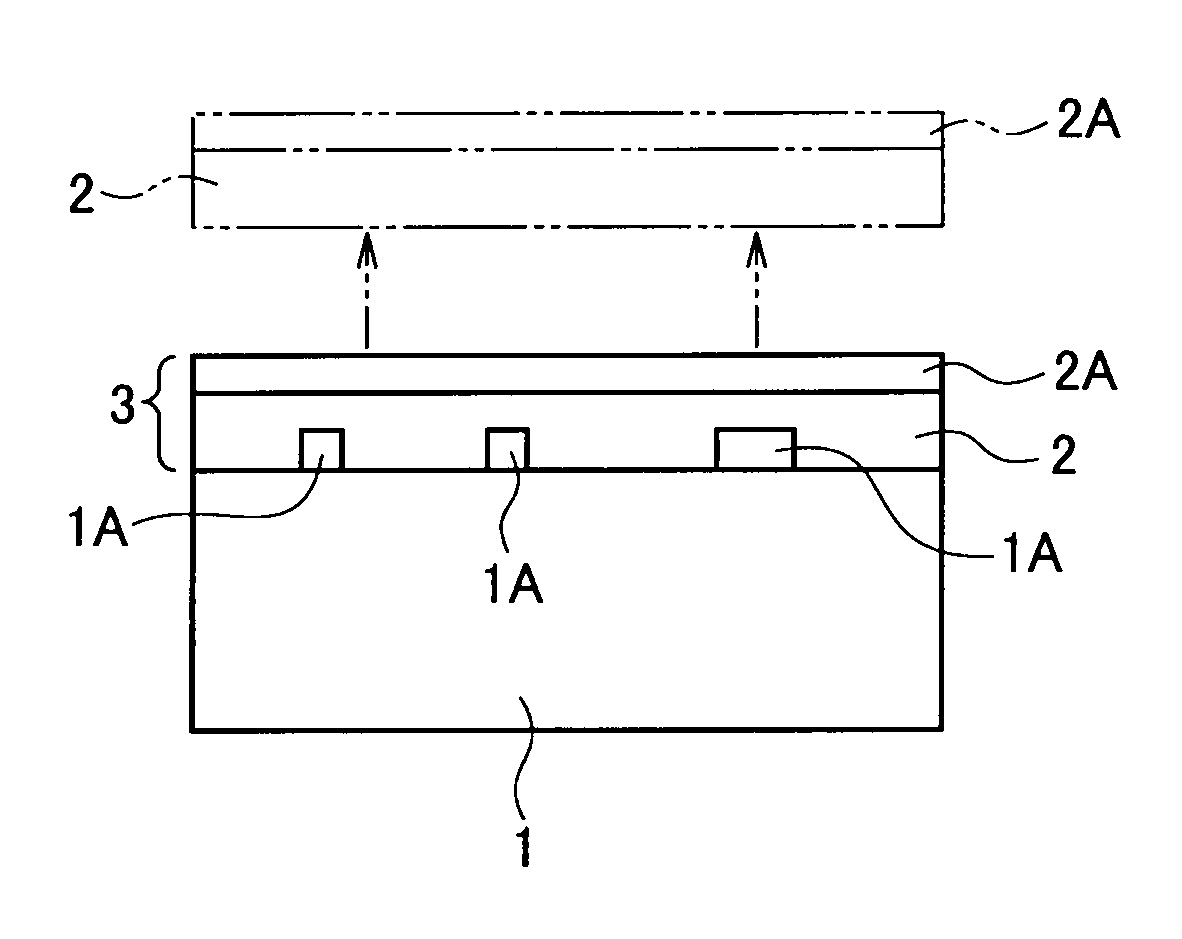

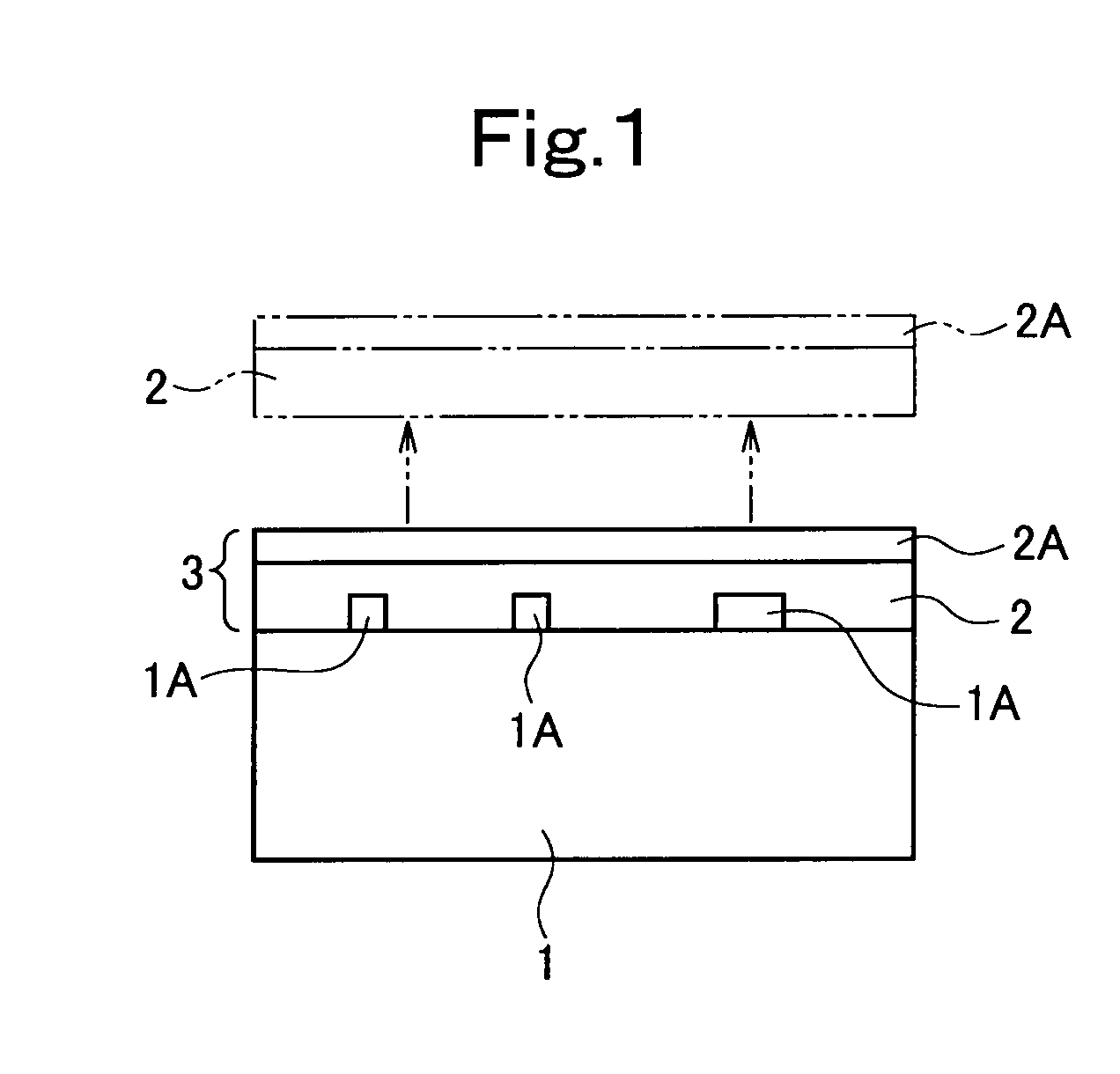

Mold assembly for molding thermoplastic resin and method of manufacturing molded article of thermoplastic resin

InactiveUS6165407AReduce residual stressReduce injection pressureConfectioneryOptical articlesMaterials scienceThermal conductivity

A mold assembly for molding a thermoplastic resin, which comprises; (a) a first mold member and a second mold member for manufacturing a molded article of a thermoplastic resin, (b) an insert block provided in the first mold member, said insert block constituting part of a cavity, having a thickness of 0.1 mm to 10 mm and being formed of a material having a thermal conductivity of 2x10-2 cal / cmxsecx DEG C. or less, and (c) a molten thermoplastic resin introduction portion provided in the second mold member, wherein an insert block covering portion is formed in the second mold member, and when the first mold member and the second mold member are clamped to each other, (A) a clearance between the insert block and the insert block covering portion is equal to, or less than, 0.03 mm, and (B) an amount of overlapping of the insert block and the insert block covering portion is equal to, or greater than, 0.5 mm.

Owner:MITSUBISHI ENG PLASTICS CORP

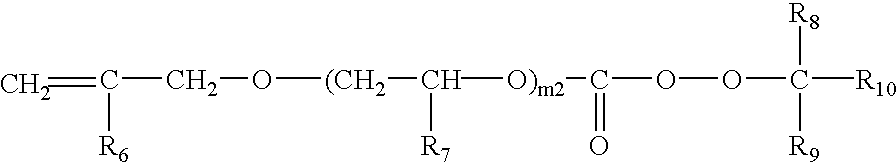

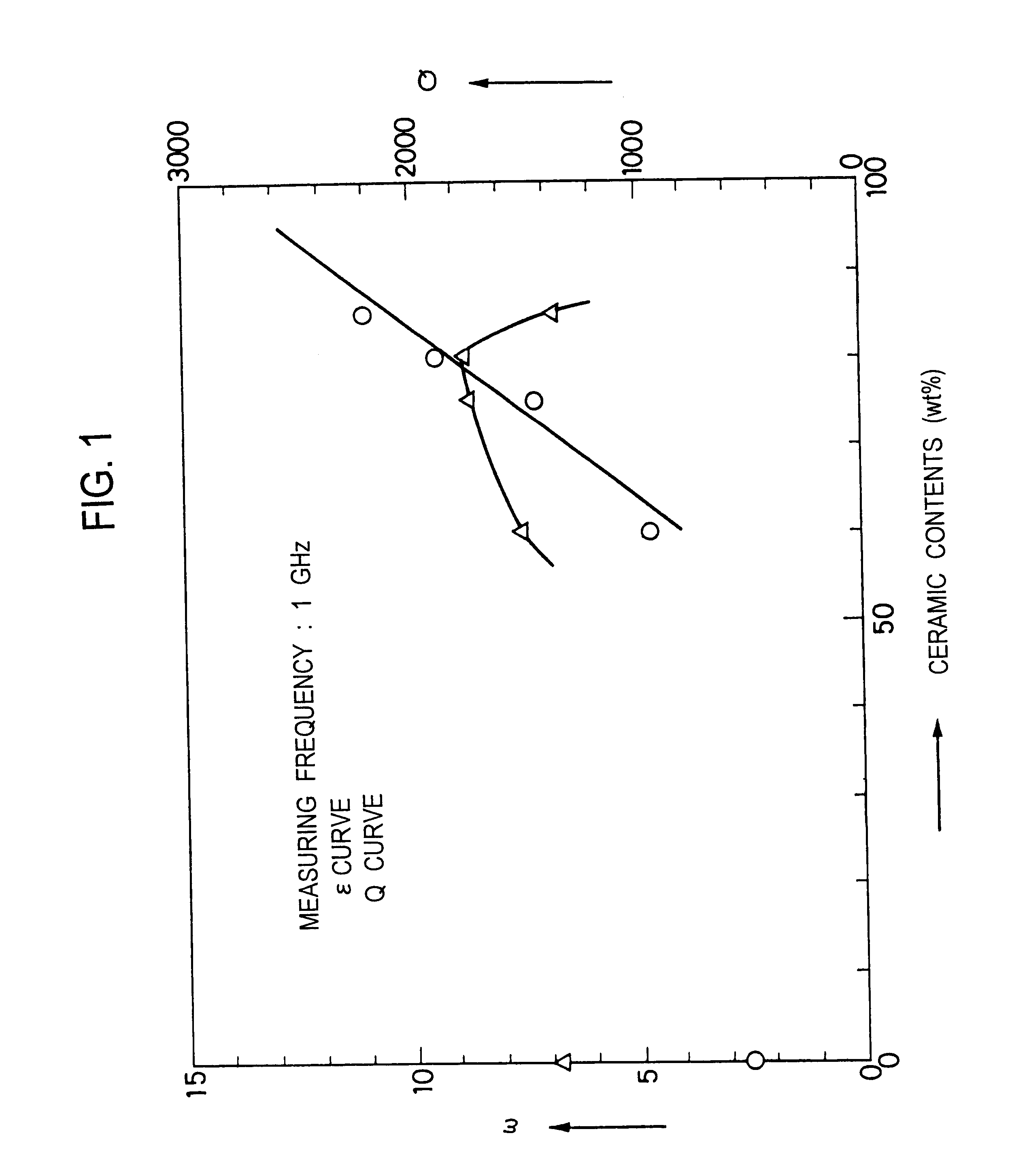

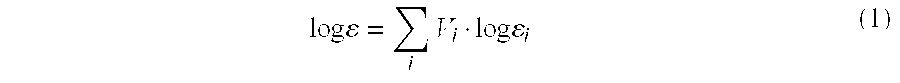

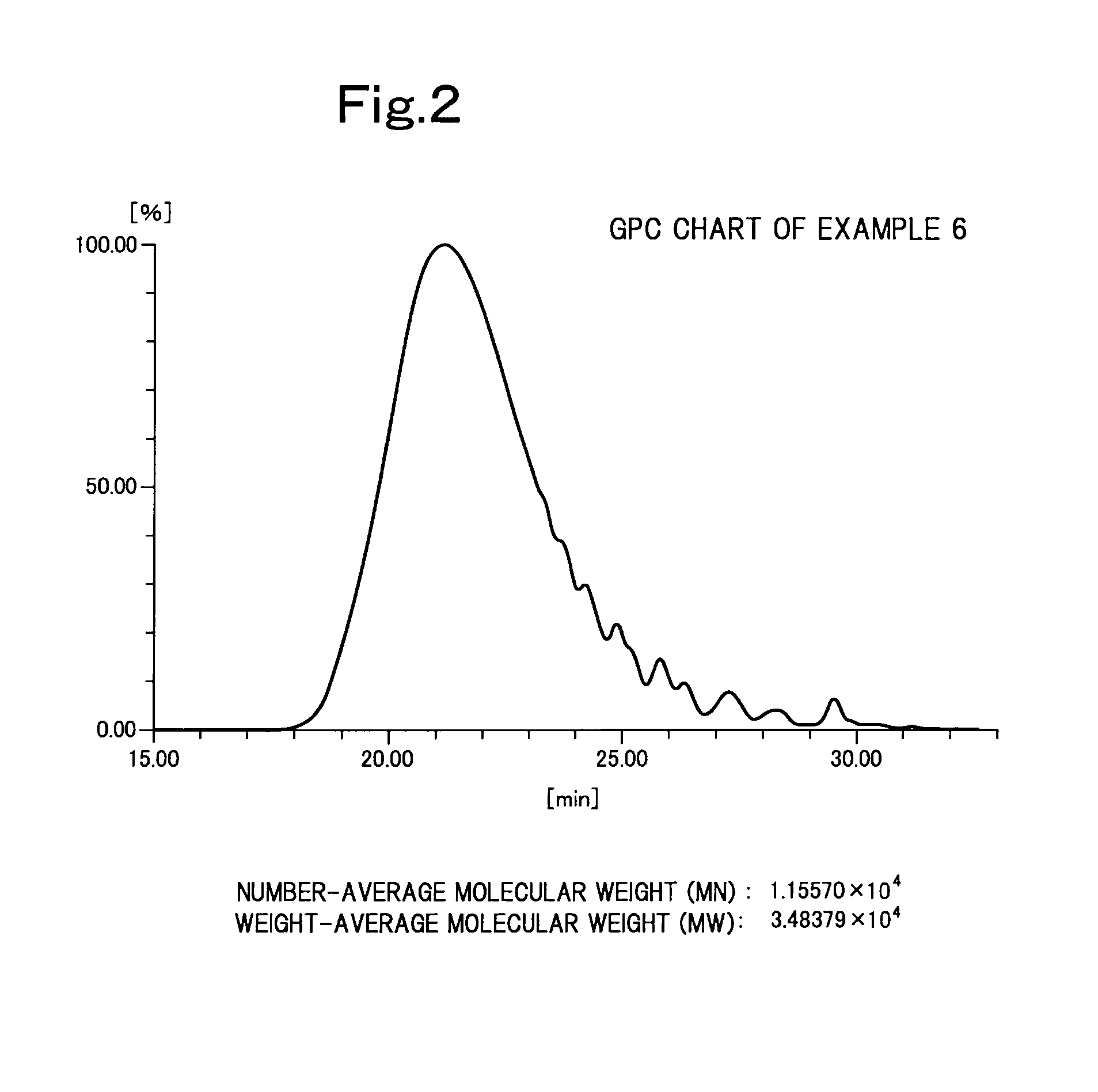

Composite dielectric material composition, and film, substrate, electronic part and molded article produced therefrom

InactiveUS6420476B1Acceptable performanceImprove performancePlastic/resin/waxes insulatorsOther chemical processesHydrogenHydrogen atom

The invention has for its object to provide a composite dielectric material having any desired dielectric constant selectable from a relatively wide range in a high-frequency band and a low dielectric loss tangent, and a film, substrate, electronic part or molded or otherwise formed article using the same. To accomplish this object, there is provided a composite dielectric material composition comprising a heat-resistant, low-dielectric polymeric material that is a resin composition comprising one or two or more resins having a weight-average absolute molecular weight of at least 1,000, wherein the sum of carbon atoms and hydrogen atoms in said composition is at least 99%, and some or all resin molecules have a chemical bond therebetween, and a filler. A film, substrate, electronic part or molded or otherwise formed article is obtained using this composition.

Owner:TDK CORPARATION +1

Calcium oxide-based ceramic core for casting titanium alloy and manufacturing method thereof

The invention discloses a calcium oxide-based ceramic core for casting titanium alloy and a manufacturing method of the calcium oxide-based ceramic core. The calcium oxide-based ceramic core comprises the following components by weight percent: 1.0-15.0% of zirconium dioxide, 0.5-10.0% of yttrium oxide, 0.05-0.1% of thorium oxide and the balance of calcium oxide, and the sum of the contents of the above the component is 100%. According to the ceramic core, the bending strength is 15-30Mpa at room temperature, the bending strength is 5-10Mpa at high temperature, the high-temperature deflection is 0.2-0.5%, the firing shrinkage ratio is 1-1.5%, and the porosity is 40-50%. Compared with the existing commercial alumina-based ceramic core and silicon oxide-based ceramic core, the calcium oxide-based ceramic core of the invention greatly reduces the reactivity with molten titanium, and has the advantages of high temperature resistance, easiness in core leach, low in cost and the like.

Owner:BEIHANG UNIV

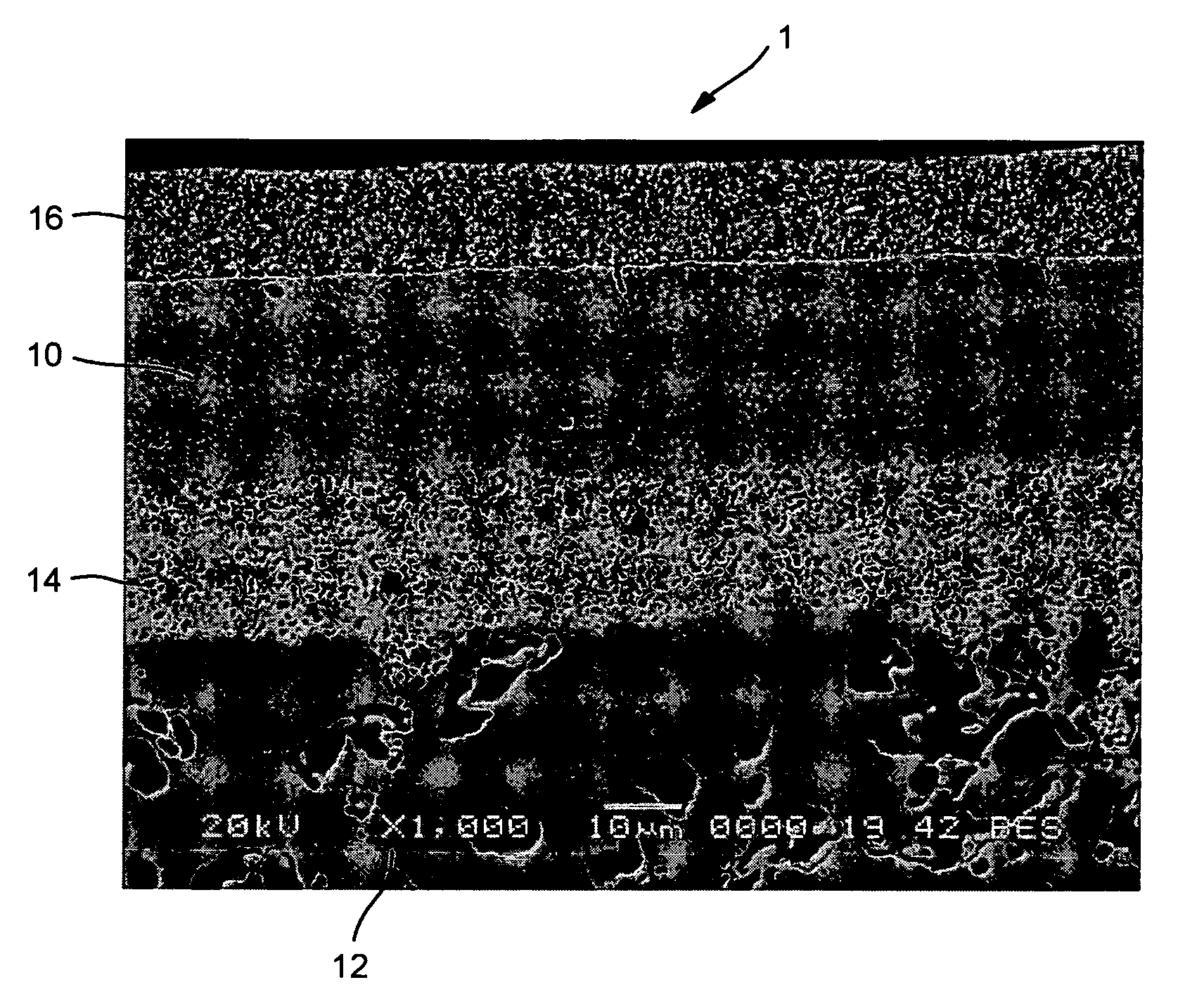

Composite oxygen ion transport membrane

ActiveUS7556676B2Closely matchedLow linear expansionSemi-permeable membranesMembranesCeriumOxygen ions

A composite oxygen ion transport membrane having a dense layer, a porous support layer, an optional intermediate porous layer located between the porous support layer and the dense layer and an optional surface exchange layer, overlying the dense layer. The dense layer has electronic and ionic phases. The ionic phase is composed of scandia doped, yttrium or cerium stabilized zirconia. The electronic phase is composed of a metallic oxide containing lanthanum, strontium, chromium, manganese and vanadium and optionally cerium. The porous support layer is composed of zirconia partially stabilized with yttrium, scandium, aluminum or cerium or mixtures thereof. The intermediate porous layer, if used, contains the same ionic and electronic phases as the dense layer. The surface exchange layer is formed of an electronic phase of a metallic oxide of lanthanum and strontium that also contains either manganese or iron and an ionic phase of scandia doped zirconia stabilized with yttrium or cerium.

Owner:PRAXAIR TECH INC

Fluoropolymer molding process and fluoropolymer molded product

InactiveUS20060122333A1Reduction factorComplex shapePrinted circuit manufacturePolymer scienceCompound (substance)

A fluoropolymer molding process is provided for molding a mixture of at least two of fluoropolymers having different melting points at a temperature that is at or above the melting point of the fluoropolymer with the lowest melting point and is less than the melting point of the fluoropolymer with the highest melting point, and the resultant fluoropolymer molded product has excellent resistance to chemical and gas permeation and a low coefficient of linear expansion.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD

Primer composition and coated article

InactiveUS20080280149A1Improve light resistanceGood weather resistanceLayered productsCoatingsPolymer scienceUltraviolet absorbance

A primer composition comprising (A) a vinyl polymer having hydrolyzable silyl groups and / or SiOH groups and organic UV-absorbing groups and (B) an organopolysiloxane cures into a primer layer having a coefficient of linear expansion equal to or less than 150×10−6 / ° C., which allows a polysiloxane hard coat to be applied thereon.

Owner:SHIN ETSU CHEM IND CO LTD

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

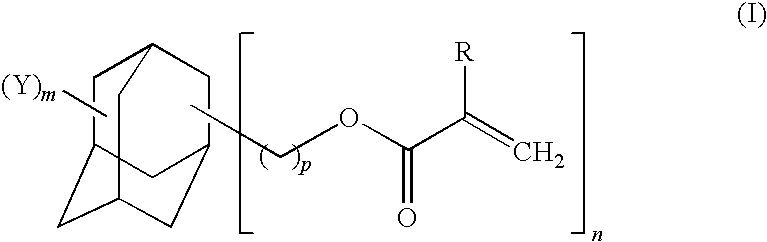

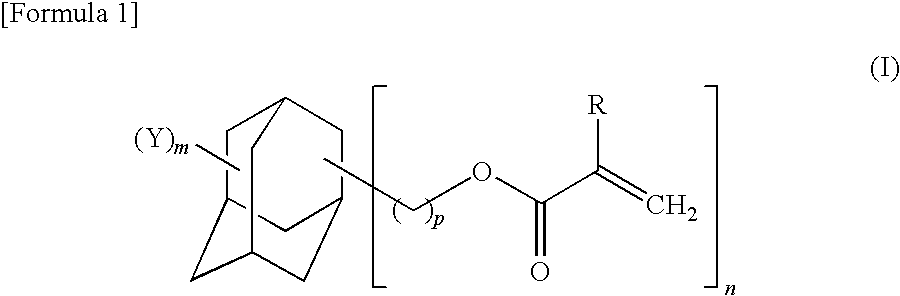

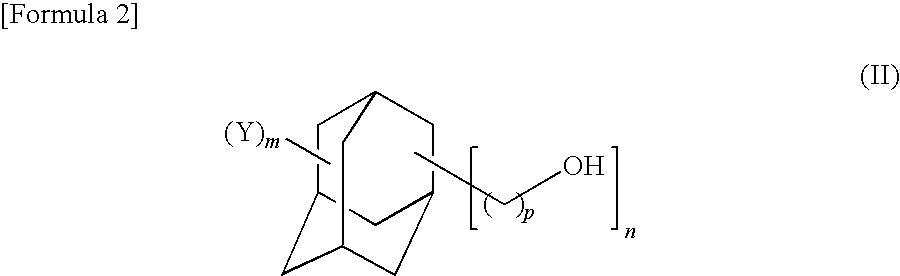

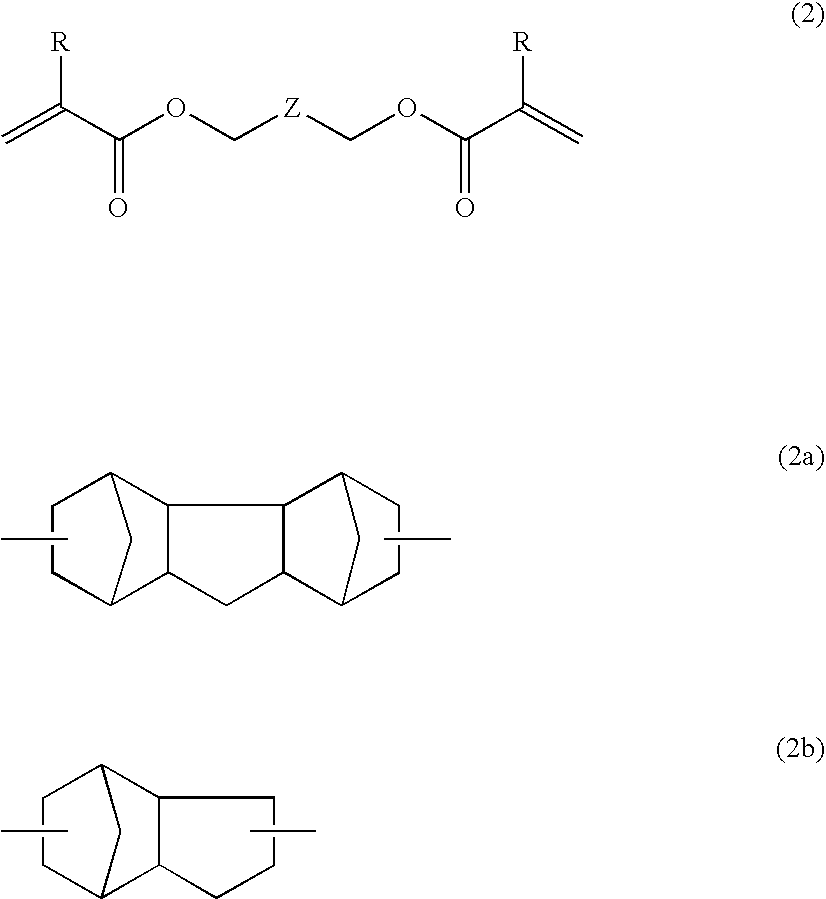

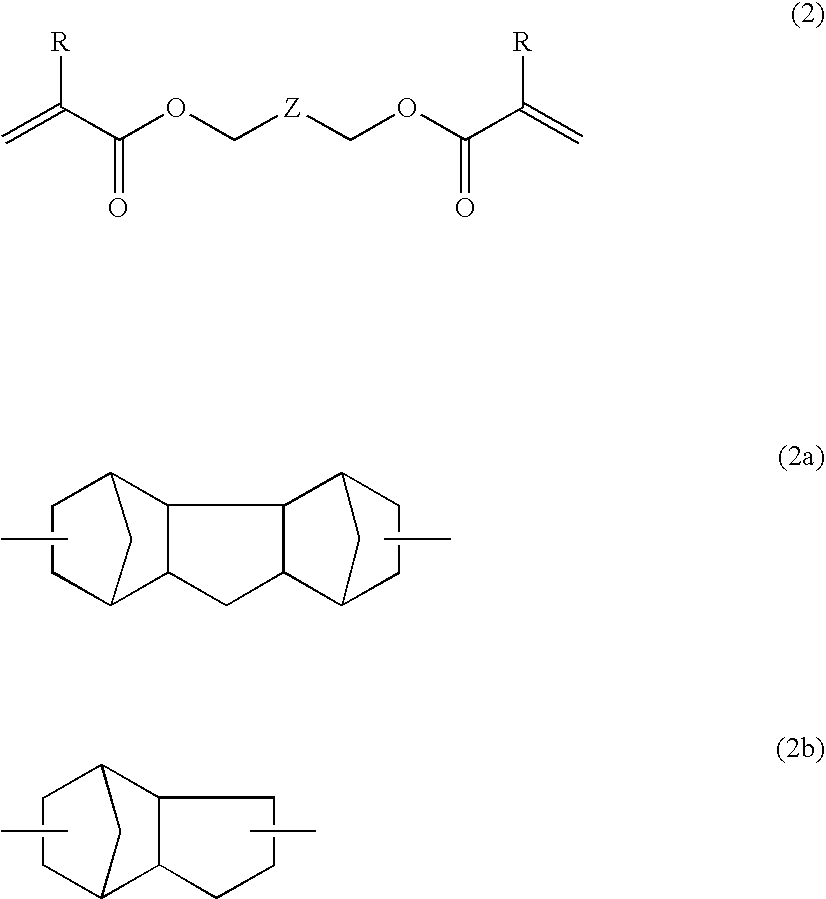

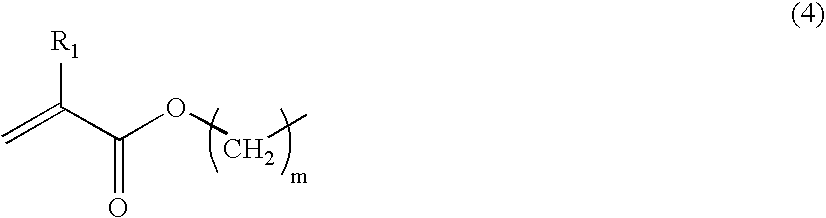

Adamantane derivative, process for production thereof, resin composition, and cured product of the resin composition

InactiveUS20100048757A1Improve heat resistanceImprove mechanical propertiesOrganic compound preparationCarboxylic acid esters preparationMethyl groupMechanical property

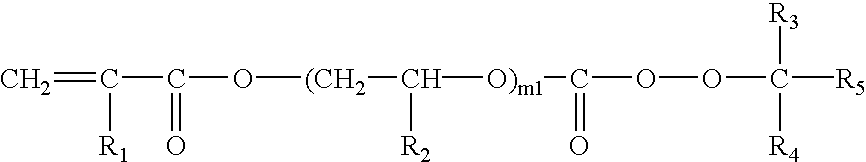

Disclosed herein is an adamantane derivative represented by the following general formula (I):(wherein R represents a hydrogen atom, a fluorine atom, a methyl group or a trifluoromethyl group; Y represents a hydrogen atom, a hydroxyl group, ═O formed by two Ys together, a carboxyl group, or a hydrocarbon group having 1 to 20 carbon atoms or a cyclic hydrocarbon group having 3 to 20 carbon atoms; m is 13 and n is 3, or m is 12 and n is 4; and p is an integer of one or more), a production method thereof, a resin composition containing the adamantane derivative, and a cured product thereof. The present invention provides a cured product advantageous as various coating agents, a microlens, a film condenser, a colored composition for a liquid crystal color filter, a pattern organizer formed in nanoimprinting, and the like, having transparency, heat resistance, good mechanical properties, low volume shrinkage, and low coefficient of linear expansion, as well as liquid adamantyl group-containing (meth)acrylates to produce the cured product, the production method thereof, and the resin composition.

Owner:IDEMITSU KOSAN CO LTD

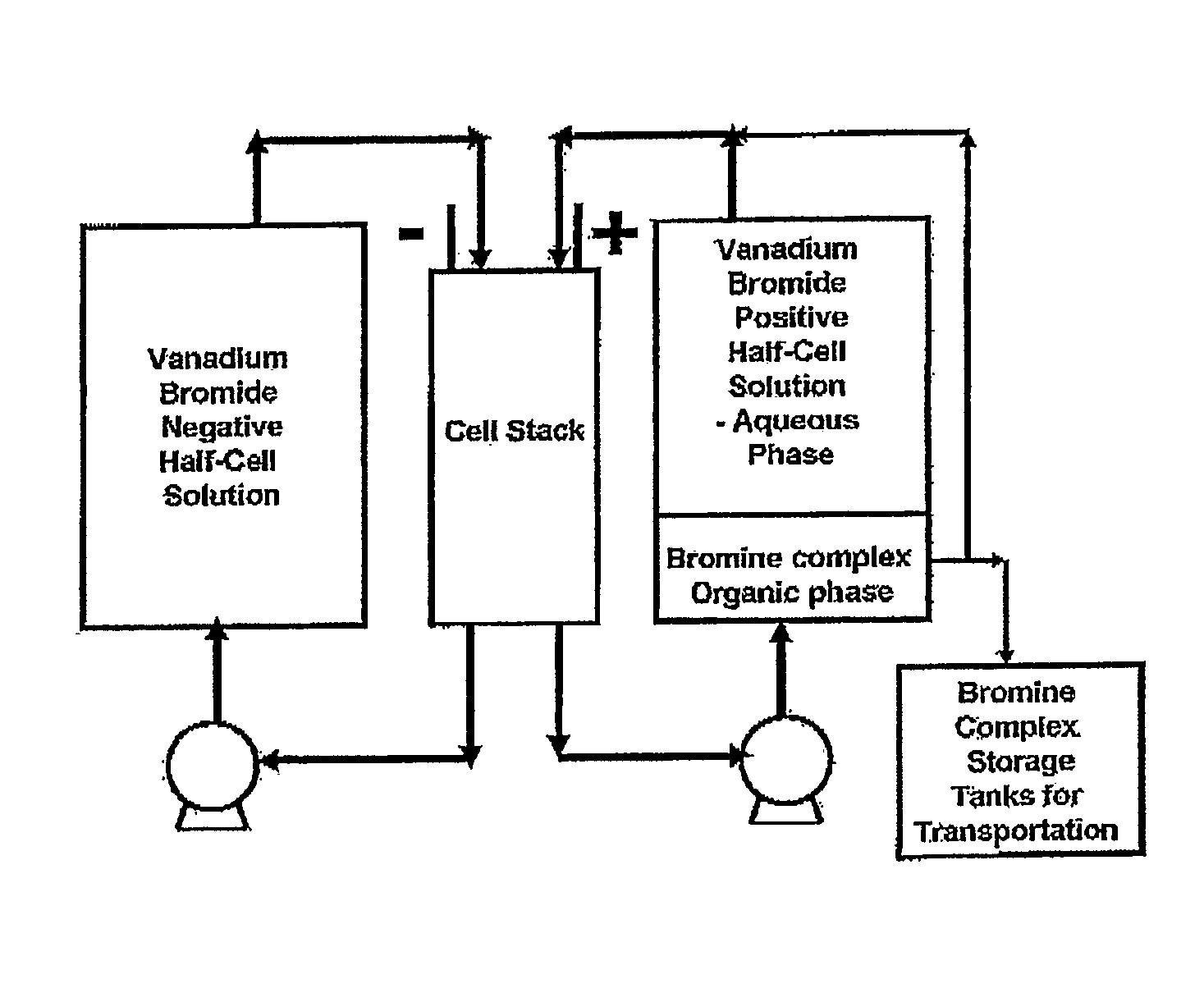

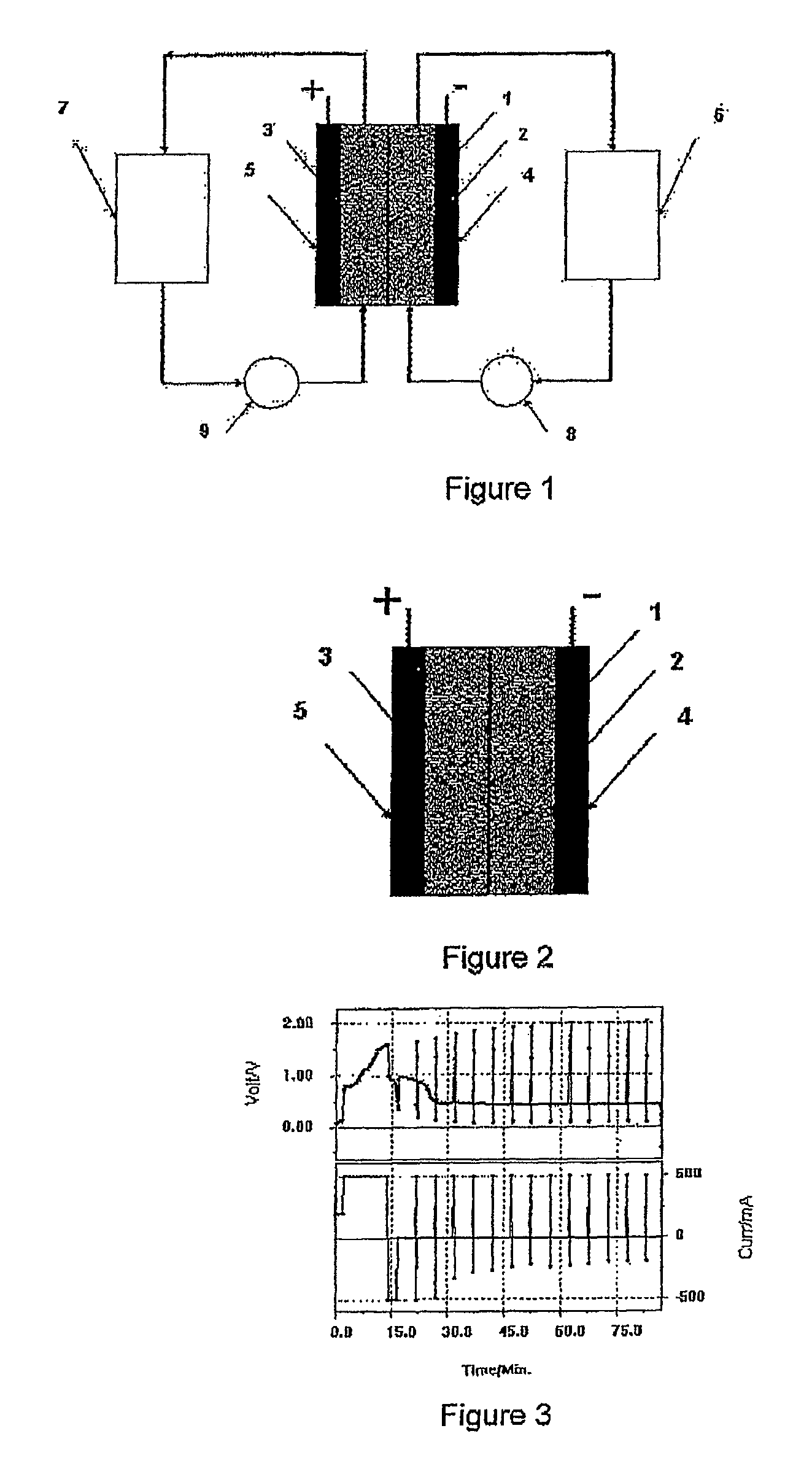

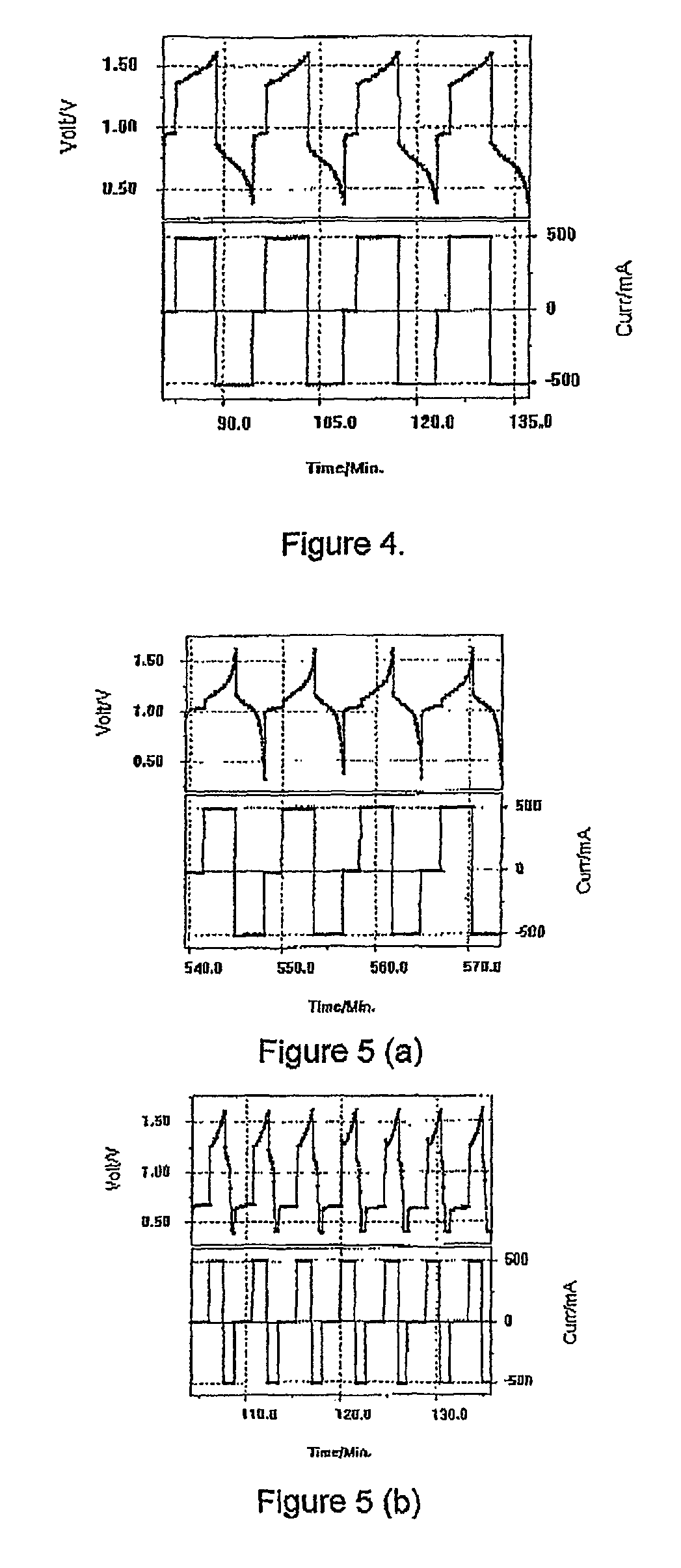

Perfluorinated membranes and improved electrolytes for redox cells and batteries

ActiveUS8541138B2Improve performanceLow linear expansionFinal product manufactureSecondary cellsVanadium redox batteryRedox

The present invention describes an improved membrane for Redox Flow Batteries, in particular for Vanadium Redox Batteries and energy storage systems and applications employing the Vanadium Redox Cells and Batteries. Redox Flow Batteries involve the use of two redox couple electrolytes separated by an ion exchange membrane that is the most important cell component.

Owner:NEWSOUTH INNOVATIONS PTY LTD

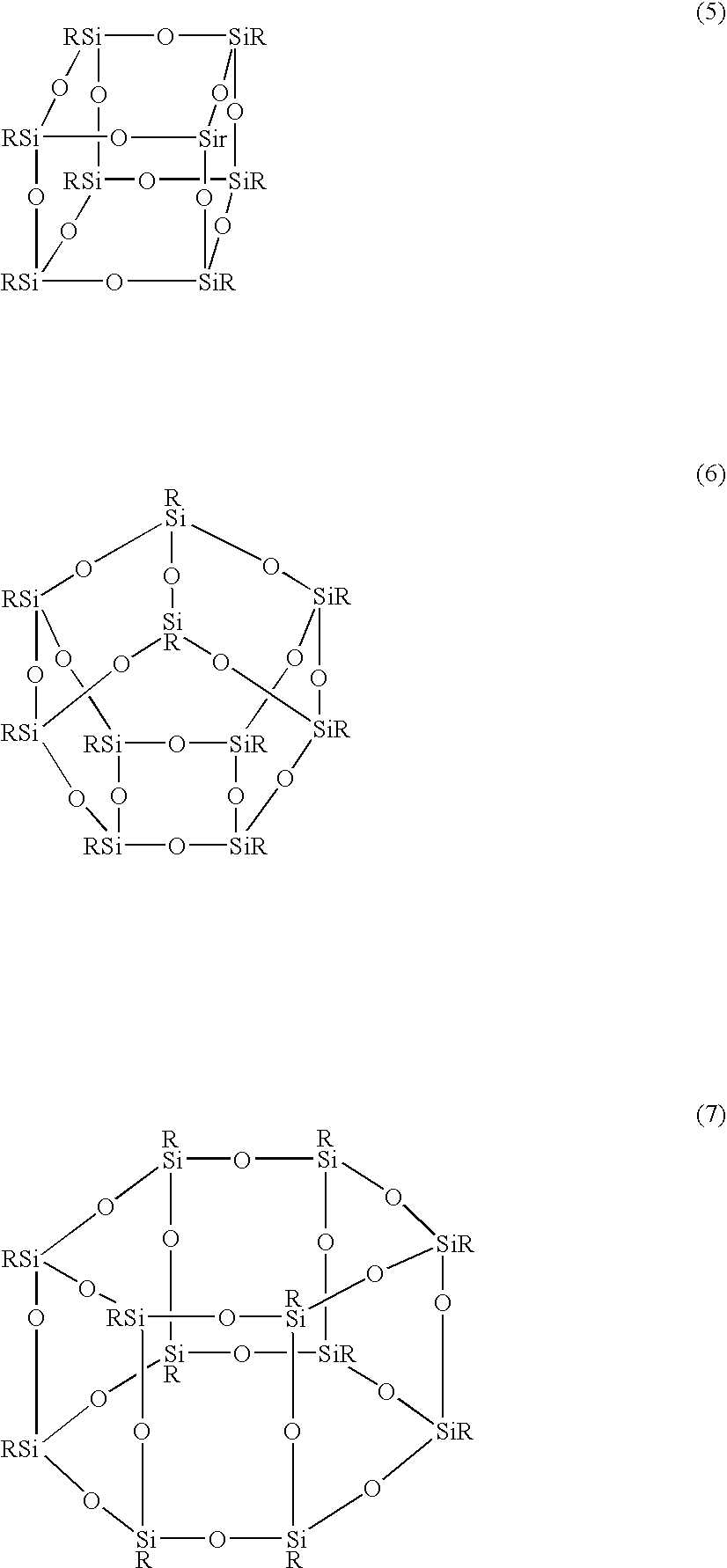

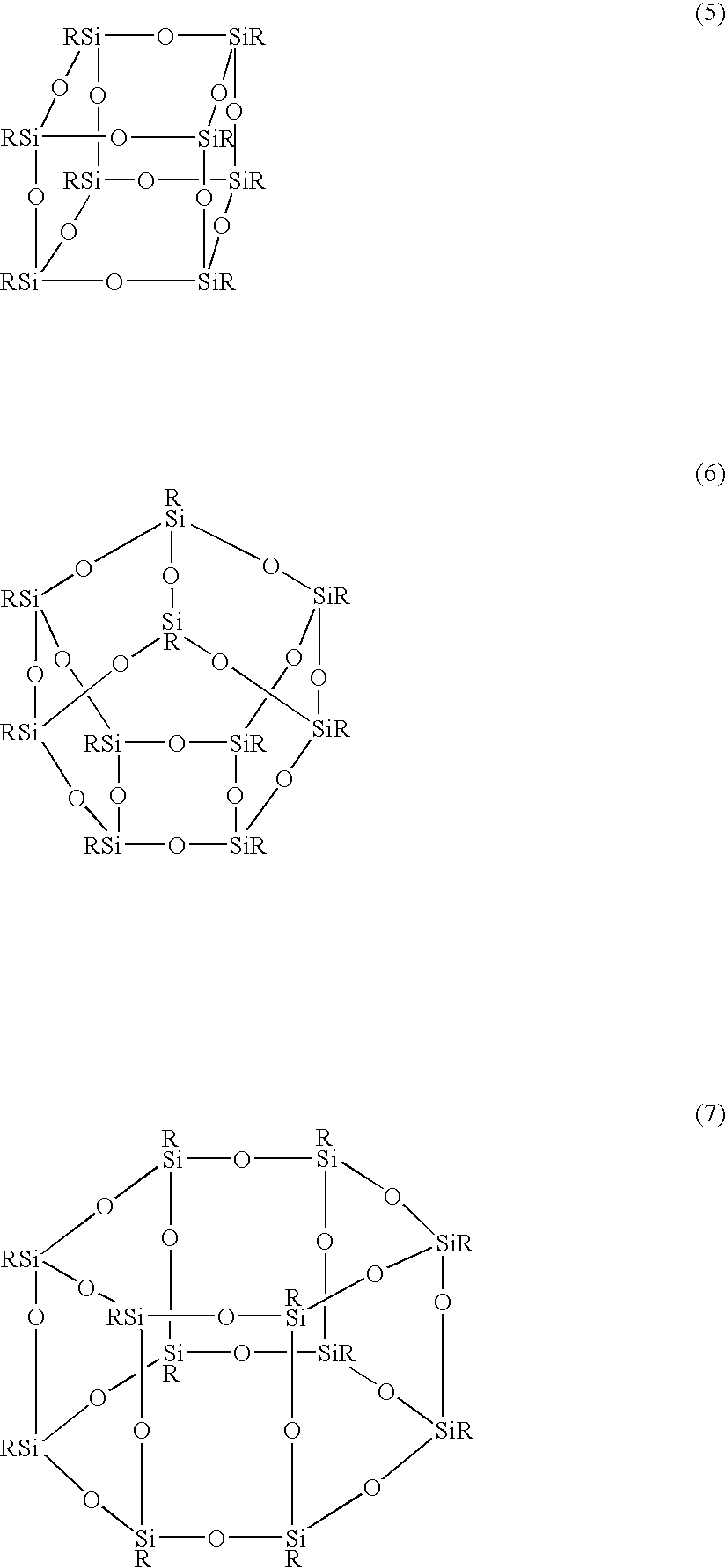

Silicone resin compositions and moldings thereof

InactiveUS20060052567A1Good dimensional stabilityLow water absorptionOptical elementsPolymer scienceMeth-

This invention relates to a silicone resin composition which exhibits high heat resistance, high transparency and high dimensional stability and thus can be suitably used for optical applications such as a lens, an optical disc, an optical fiber, a substrate for a plat panel display, a window material for an automobile, and the like. A silicone resin composition, which comprises a silicone resin comprising, as a primary component, a polyorganosilsesquioxane being represented by the formula: [RSiO3 / 2]n, wherein R represents an organic functional group having a (meth)acryloyl group, and n is 8, 10 or 12, and having a cage type structure in its structural unit, and an unsaturated compound having, in its molecule, at least one unsaturated group represented by —R3—CR4═CH2 or —CR4═CH2, wherein R3 represents an alkylene group, an alkylidene group or a —OCO— group and R4 represents a hydrogen atom or an alkyl group, and being capable of radically copolymerizing with the above silicone resin, in a weight proportion of 1:99 to 99:1.

Owner:NIPPON STEEL CHEMICAL CO LTD

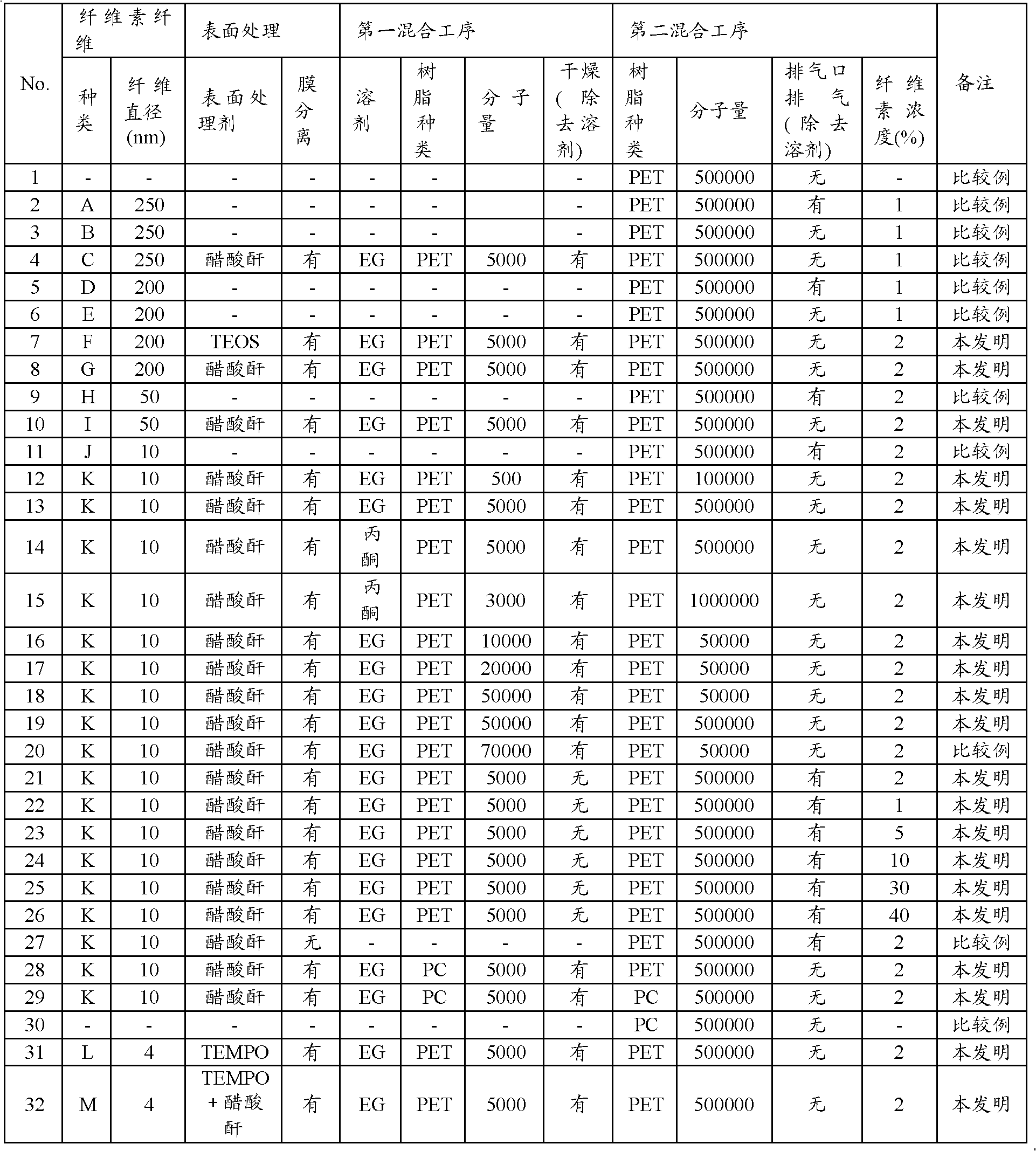

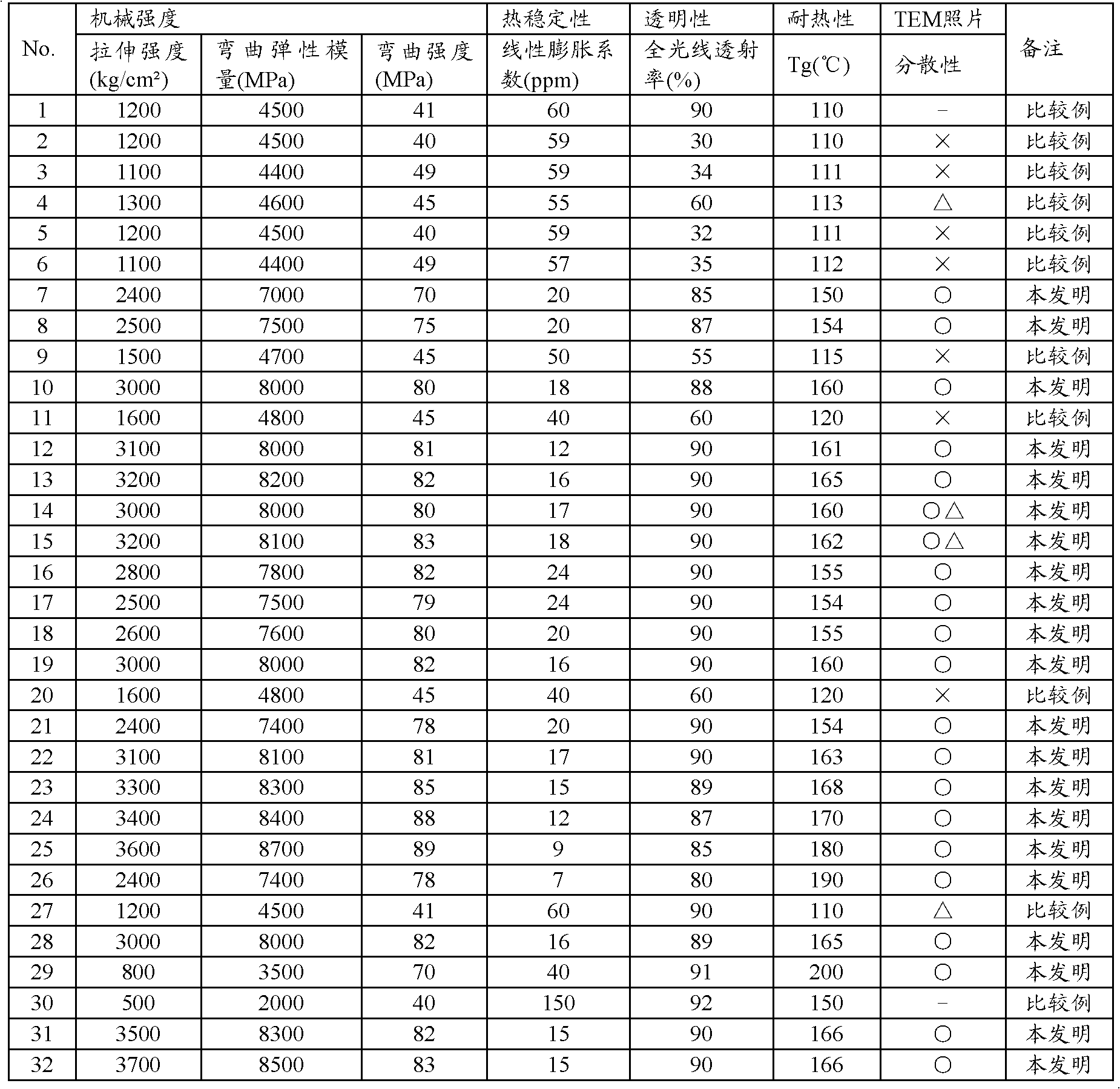

Method for producing cellulose fiber-containing resin material

Disclosed is a method for producing a highly transparent composite material, wherein MFC (microfibrillated cellulose) is uniformly dispersed in a thermoplastic resin, thereby improving the mechanical strength thereof and providing heat resistance thereto. A cellulose fiber dispersion liquid, in which cellulose fibers are uniformly dispersed, is produced by pulverizing cellulose into MFC at high concentration without gelatinizing the cellulose. Specifically disclosed is a method for producing a cellulose fiber-containing resin material that contains a thermoplastic resin and surface-treated cellulose fibers having an average fiber diameter of not less than 2 nm but not more than 200 nm. The method for producing a cellulose fiber-containing resin material is characterized by comprising a first mixing step in which the surface-treated cellulose fibers, an organic solvent and a first thermoplastic resin are mixed, and a second mixing step in which a second thermoplastic resin having a higher molecular weight than the first thermoplastic resin is additionally mixed into the resulting mixture.

Owner:KONICA MINOLTA INC

Liquid epoxy resin composition and semiconductor device

InactiveUS20050152773A1Improved humidity resistant reliabilityImprove toughnessSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

A liquid epoxy resin composition comprising (A) a liquid epoxy resin, (B) an aromatic amine curing agent, and (C) an inorganic filler having an average particle size of more than 5 μm in an amount of from 300 parts by weight to 1,000 parts by weight per 100 parts by weight of components (A) and (B) combined, has a low viscosity and a low coefficient of linear expansion and is suited for the encapsulation of semiconductor devices.

Owner:SHIN ETSU CHEM IND CO LTD

Paste composition and dielectric composition using the same

InactiveUS20060159927A1Easy to getImprove reliabilityPlastic/resin/waxes insulatorsFixed capacitor dielectricCapacitanceConstant composition

A paste composition contains an inorganic filler, a resin and a solvent, wherein the paste composition is characterized in that it contains one or more solvents of which the boiling point is 160° C. or higher and an inorganic filler of which the mean particle diameter is 5 μm or smaller, and the total content of the solvent is 25 wt % or less based on the total amount of the paste composition, and a dielectric composition contains an inorganic filler and resin, wherein the inorganic filler includes inorganic fillers of at least two kinds of mean particle diameter, and the greatest mean particle diameter of said mean particle diameters is 0.1-5 μm and is 3 times or more to the minimum mean particle diameter. It is possible to obtain a high dielectric constant composition of which linear expansion coefficient is low, and which has a large capacitance.

Owner:TORAY IND INC

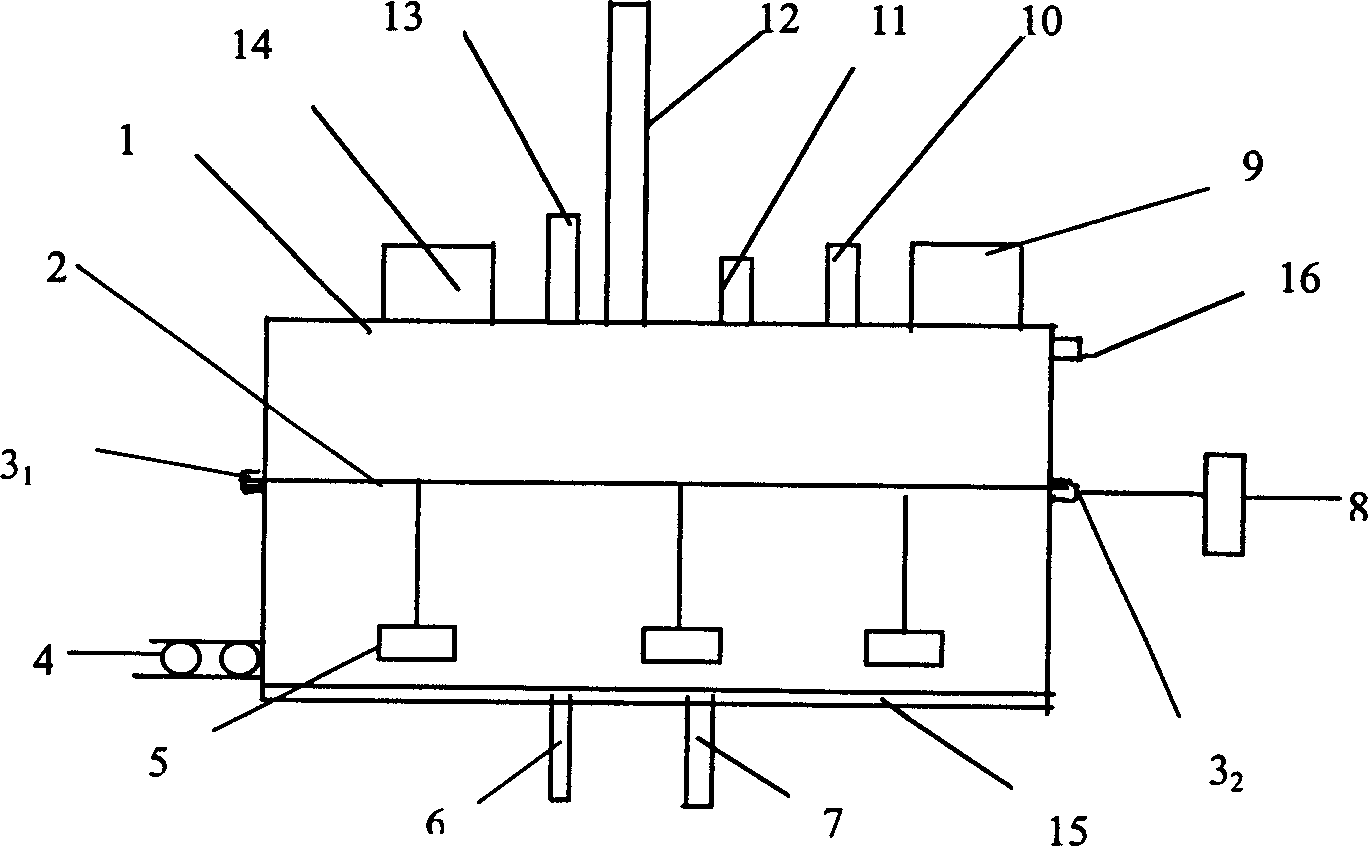

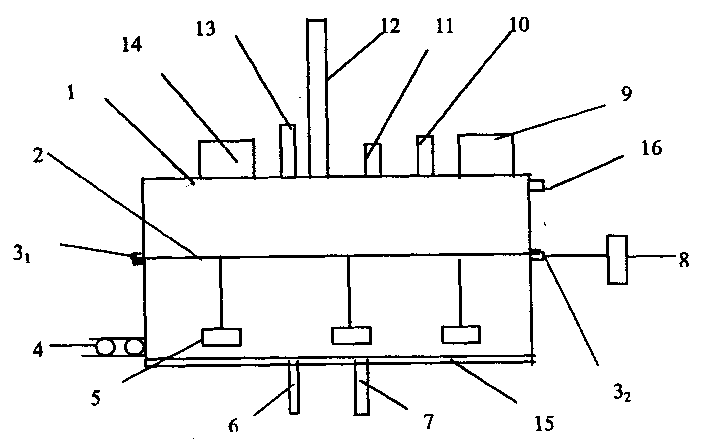

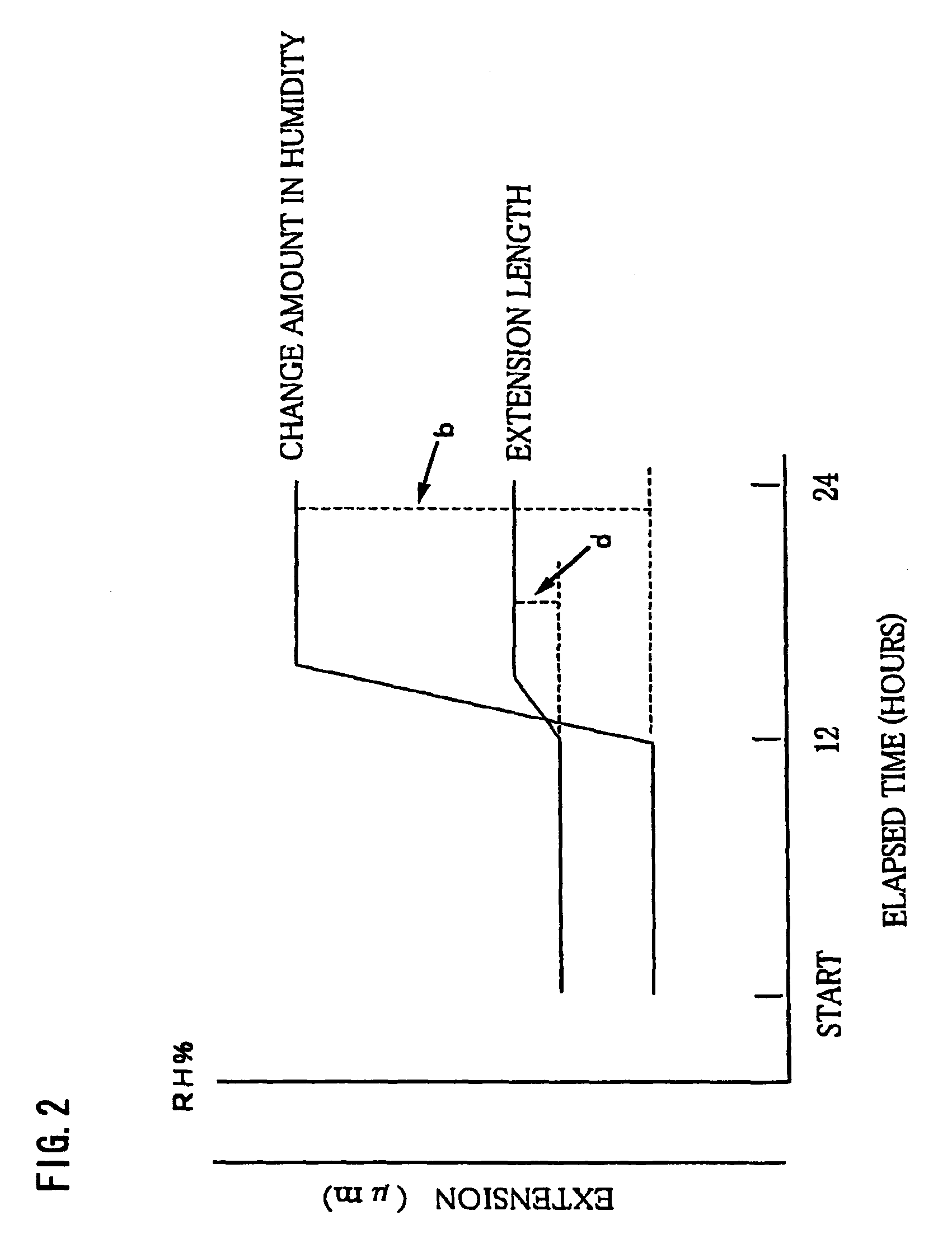

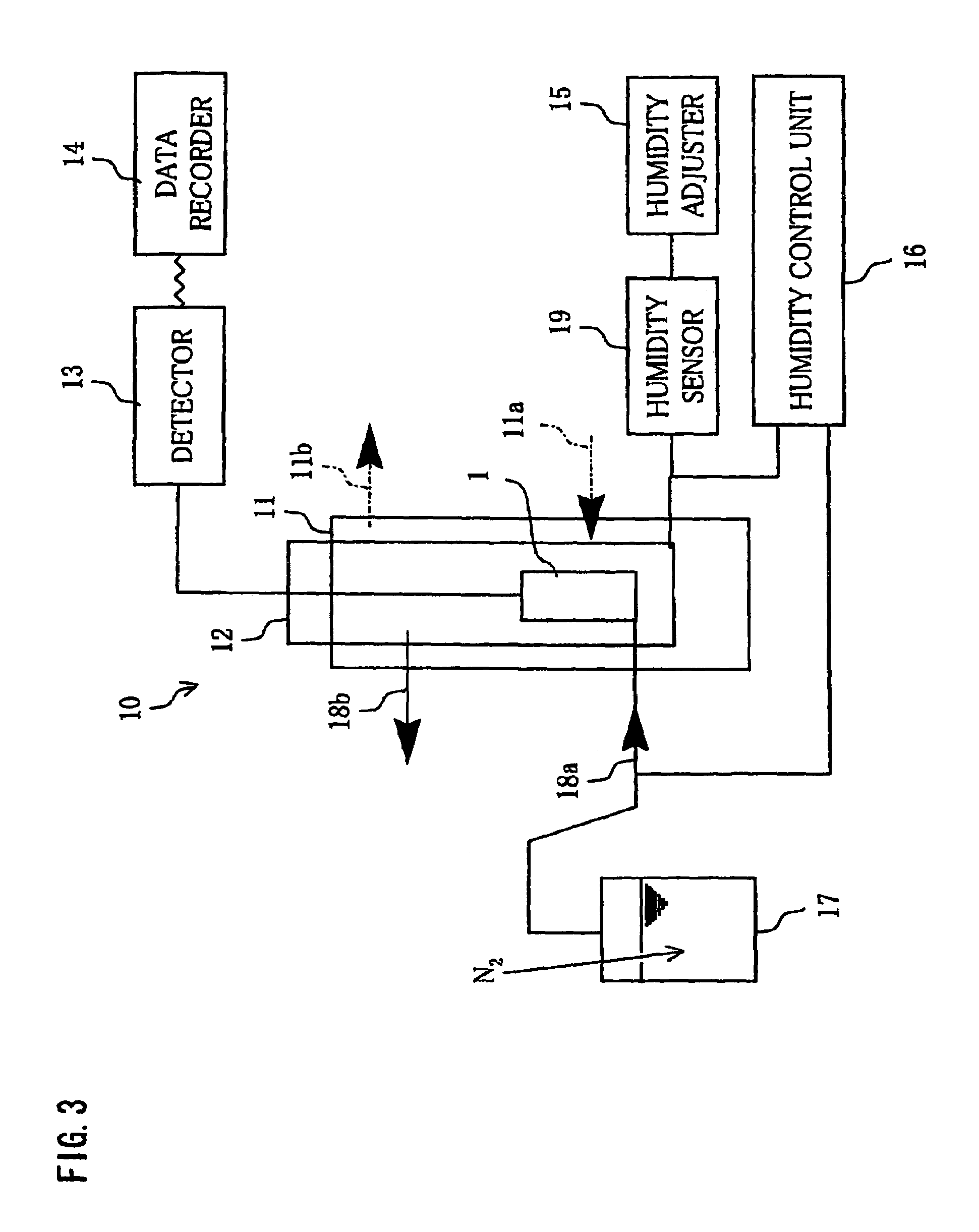

Preparation method of inorganic-organic composite particle and its special-purpose equipment

InactiveCN1515632AHigh hardnessHigh surface finishPigment treatment with macromolecular organic compoundsChemical LinkageInorganic particle

The present invention relates to a preparation method of inorganic-organic high-molecular composite particle and its special-purpose equipment. The inorganic particle can be directly reacted with organic high-molecular compound in a reactor still, under the action of mechanical energy and heat energy provided by reactor still the inorganic particle is reacted with organic high molecular to make chemical linkage, and one layer or several layers of organic high-molecular membranes can be formed on the surface of the particle so as to obtain the invented hydrophobic inorganic-organic high-molecular composite particle which can have an affinity for organic high-molecular material. Its special-purpose equipment is formed from horizontal reaction still with jacket, motor and control cabinet, etc.

Owner:WUHAN UNIV OF TECH

Polyimide film and laminate having metal layer and same

ActiveUS7267883B2Reduction factorHigh modulusSynthetic resin layered productsThin material handlingDynamic viscoelasticityPotassium hydroxide

A polyimide film of the present invention is a polyimide film having a dynamic viscoelasticity whose tan δ peak is located in a range of not less than 310° C. but not more than 410° C., and whose tan δ value at 300° C. is not more than 0.05, or a polyimide film prepared by copolymerizing (a) an acid dianhydride component including a biphenyltetracarboxylic dianhydride and a pyromellitic dianhydride, and (b) a diamine component, and the polyimide film having such an etching speed that one side thereof is etched with a 1N potassium hydroxide solution at an etching speed of 0.1 μm / minute (one side) or higher. The polyimide film of the present invention possesses film properties that are necessary for use in an electronic raw material for flexible printed circuit boards and the like, and is suitable as an electronic raw material.

Owner:KANEKA CORP

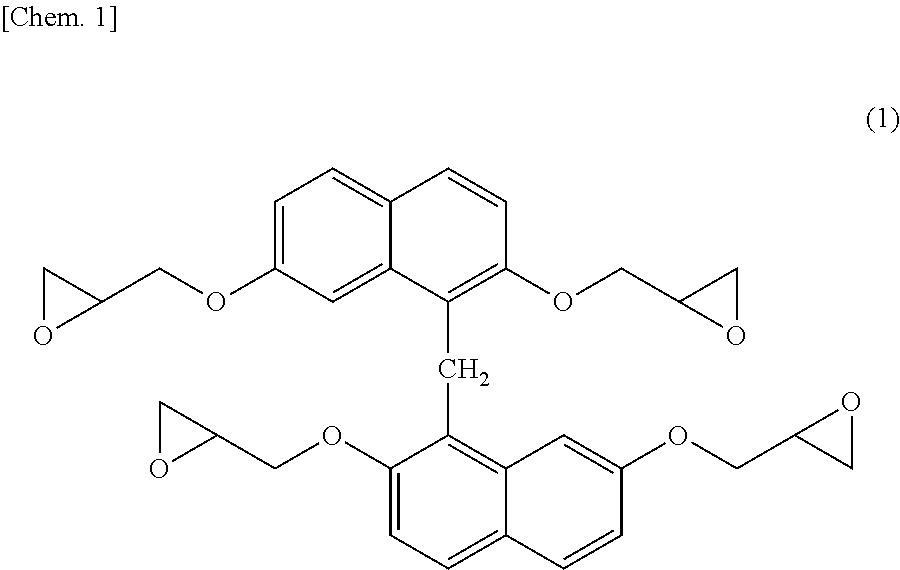

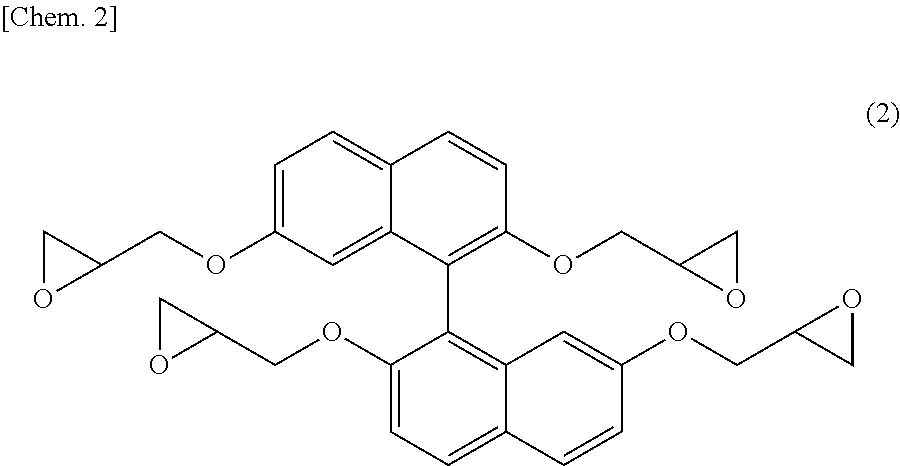

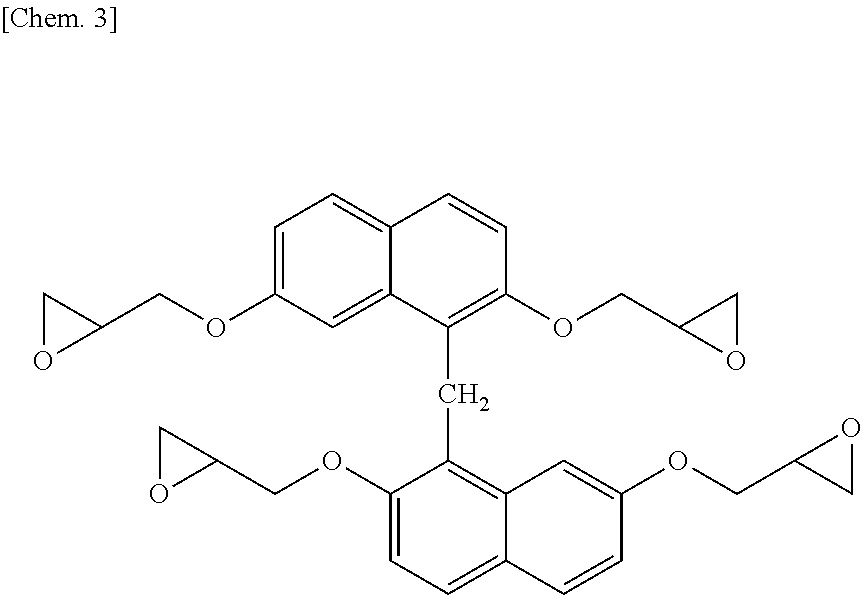

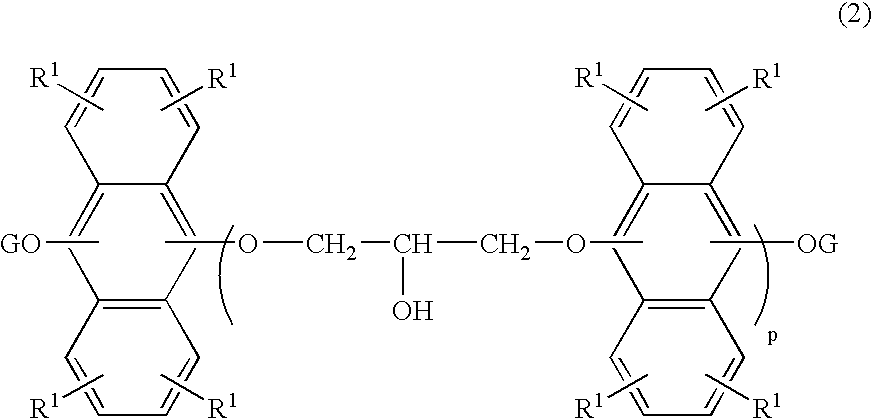

Epoxy resin composition, cured product, heat radiating material, and electronic member

ActiveUS20160122604A1Improve heat resistanceReduce absorptionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySilicon dioxide

The present invention provides an epoxy resin composition including 2,2′,7,7′-tetraglycidyloxy-1,1′-binaphthalene as an epoxy resin (A), and a filler (B). Further, the present invention provides an epoxy resin composition in which the filler (B) in the epoxy resin composition is a thermally conductive filler and an epoxy resin composition in which the filler (B) is silica. Further, the present invention provides a cured product produced by curing the epoxy resin composition of the present invention and a heat dissipation material and an electronic material each including the cured product.

Owner:DAINIPPON INK & CHEM INC

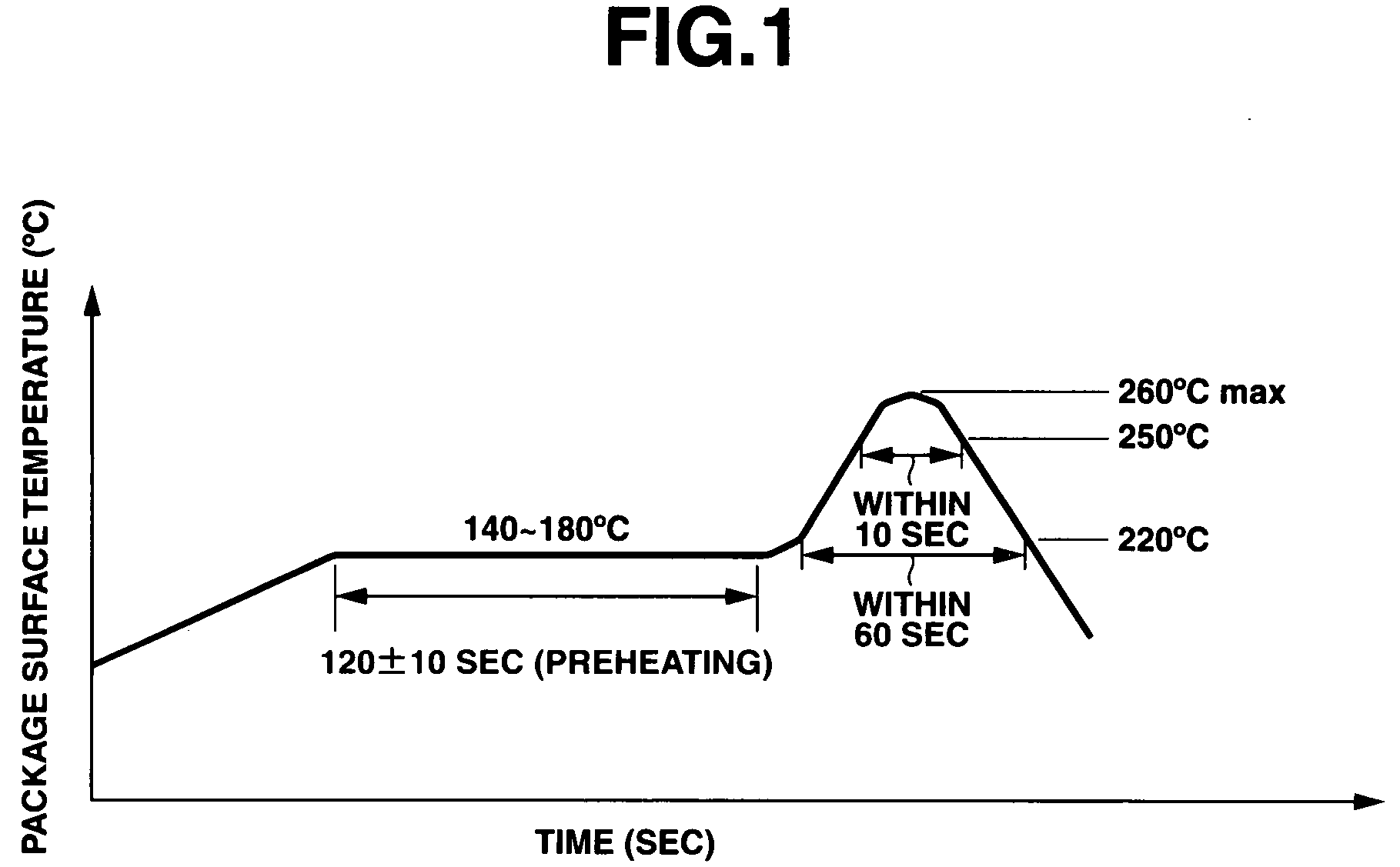

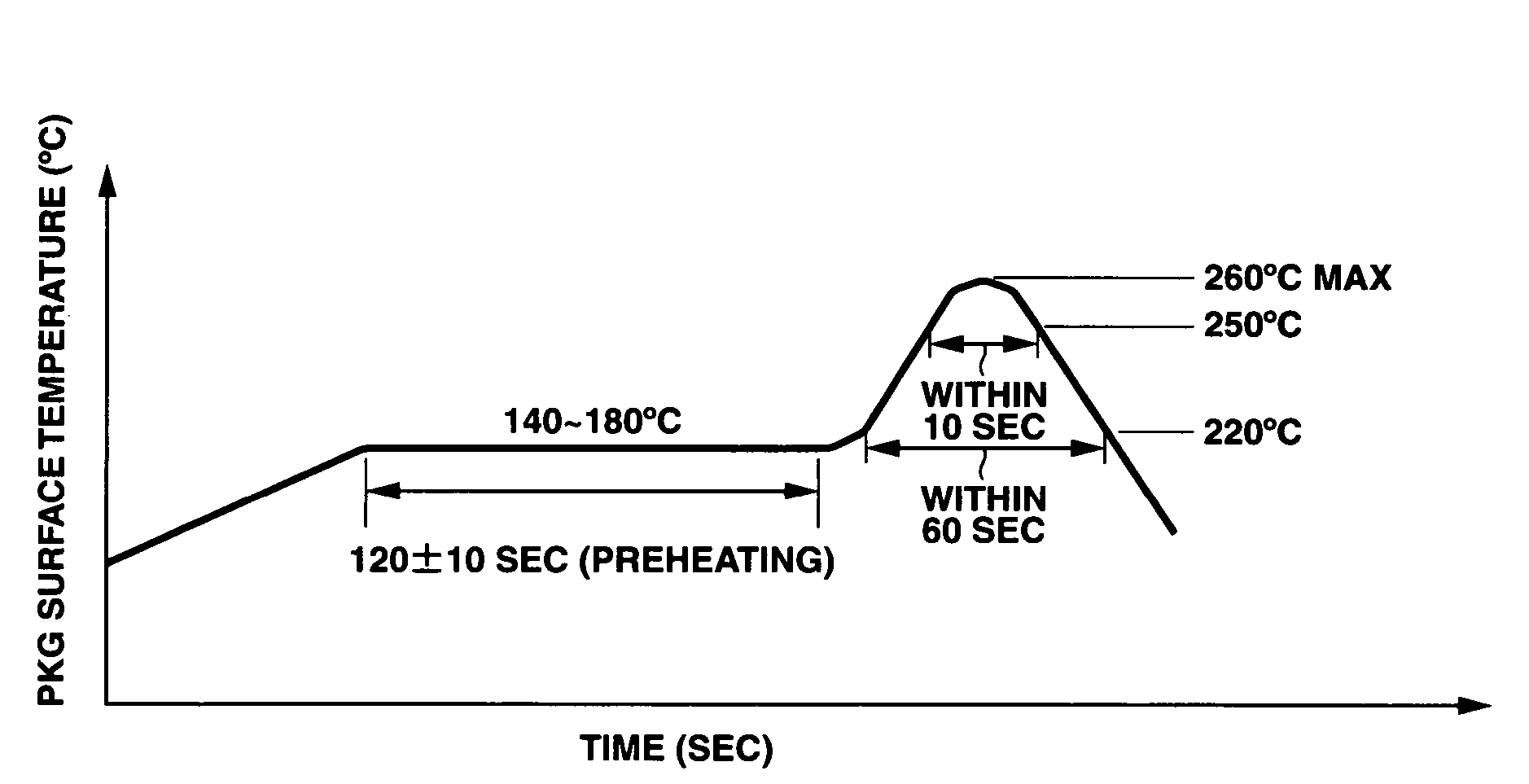

Semiconductor encapsulating epoxy resin composition and semiconductor device

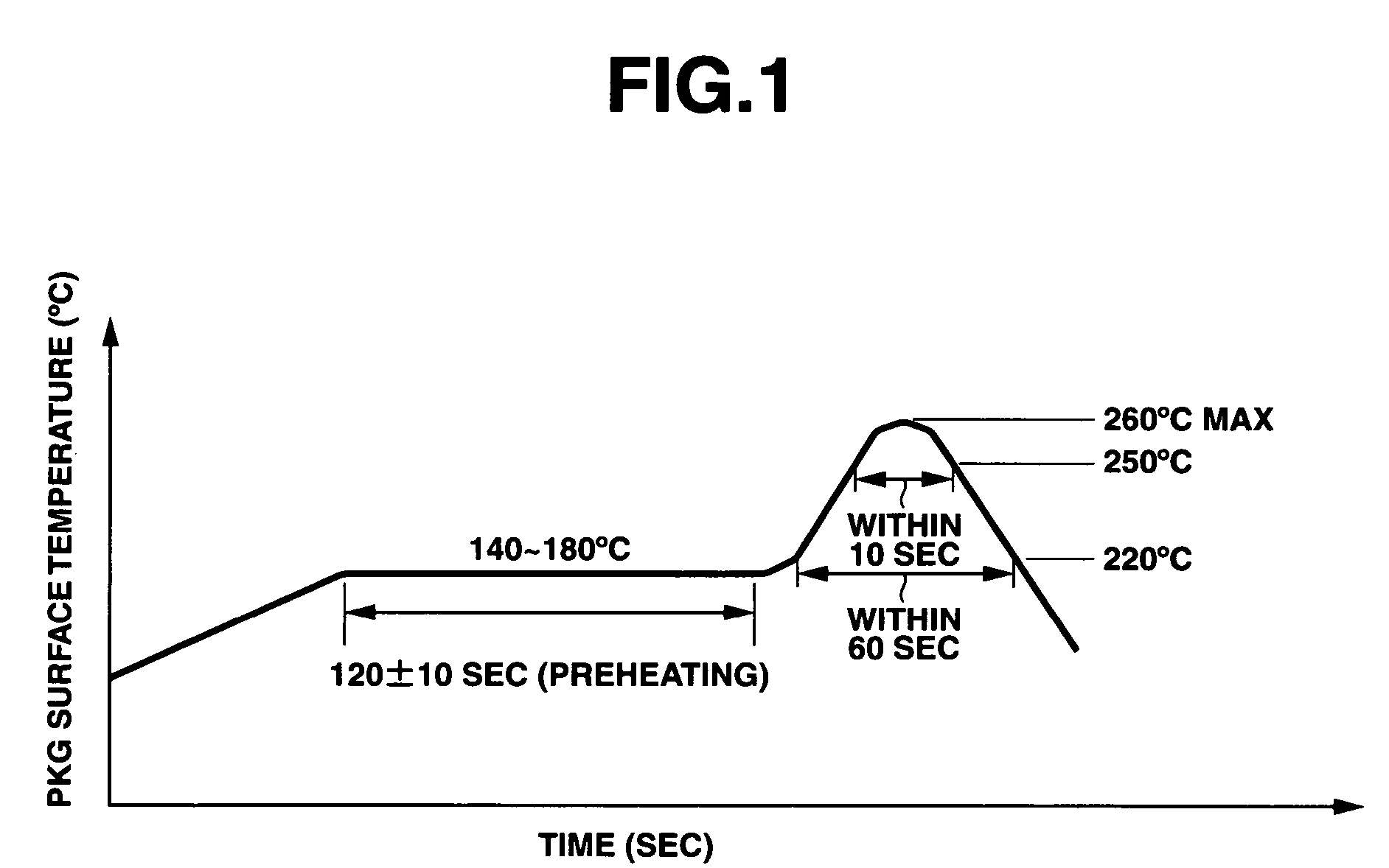

ActiveUS20060216519A1Low coefficient of linear expansionHigh TgSemiconductor/solid-state device detailsSynthetic resin layered productsChemistrySoldering

An epoxy resin composition comprising (A) at least one epoxy resin comprising (a) a naphthalene ring-containing epoxy resin having at least one substituted or unsubstituted naphthalene ring in a molecule and having an epoxy equivalent of 175 to 210, (B) a phenolic resin having at least one substituted or unsubstituted naphthalene ring in a molecule, and (C) an inorganic filler, the substituted or unsubstituted naphthalene ring of the epoxy resin (a) being contained in an amount of 45 to 60% by weight in the total amount of the epoxy resin (A) is best suited for semiconductor encapsulation because it has good flow, a low coefficient of linear expansion, a high Tg, minimal moisture absorption, and crack resistance upon lead-free soldering.

Owner:SHIN ETSU CHEM CO LTD

Magnesia castable and production process of slag baffling component for tundish

The invention discloses a magnesia castable and a production process of a slag baffling component for a tundish. The magnesia castable comprises the following raw materials in parts by weight: 70-95 parts of magnesia consisting of magnesia aggregate and magnesia fine powder, 4-15 parts of silica, 5-30 parts of waste magnesia-chrome brick consisting of waste magnesia-chrome brick aggregate and waste magnesia-chrome brick fine powder, 2-10 parts of silicon dioxide micropowder, 0.1-0.5 part of a composite additive, 0.01-0.1 part of organic fiber and 0.1-1 part of steel fiber. The slag baffling component for the tundish, which is produced from the magnesia castable provided by the invention, is long in service life, resistant to molten steel erosion, resistant to slag erosion and good in anti-peeling performance.

Owner:PUYANG REFRACTORIES GRP CO LTD

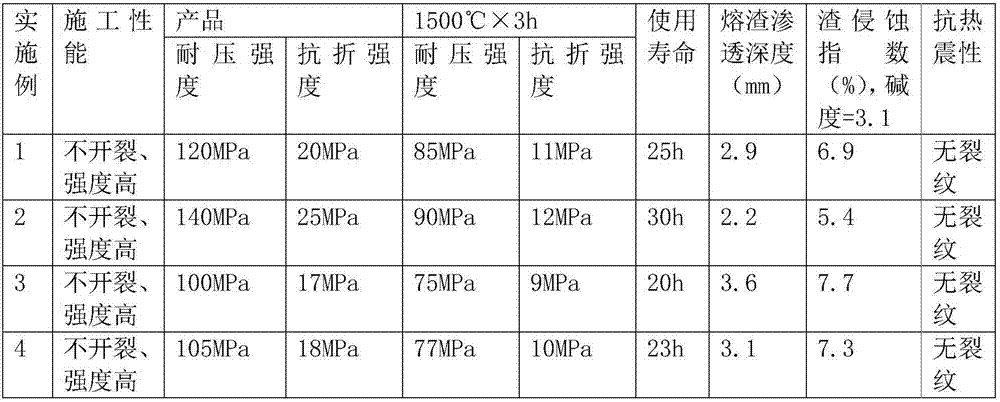

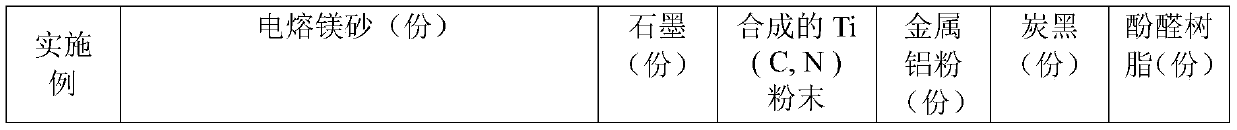

Low-carbon magnesia carbon brick with addition of titanium carbonitride and preparation method thereof

The invention relates to a low-carbon magnesia carbon brick with addition of titanium carbonitride. The magnesia carbon brick comprises the following raw materials in parts by weight: 20-30 parts of fused magnesite with the particle size being greater than 3 mm and not greater than 5 mm, 10-20 parts of fused magnesite with the particle size being greater than 1 mm and not greater than 3 mm, 10-20parts of fused magnesite with the particle size being greater than 0 mm and not greater than 1 mm, 10-20 parts of 200-mesh fused magnesite, 1-10 parts of 200-mesh synthetic Ti (C, N) powder, 1-10 parts of 200-mesh graphite, 1-10 parts of 200-mesh carbon black, 1-10 parts of 200-mesh aluminum powder and 1-10 parts of a binding agent. When the refined steel ladle slag line magnesia carbon brick is produced, titanium carbonitride is added into a magnesia carbon material, and after high-temperature carbon burying treatment, the titanium carbonitride is still uniformly distributed in a matrix and is subjected to solid solution with MgO to a certain extent.

Owner:海城利尔麦格西塔材料有限公司

Foam sheet for interior material of automobile and interior material of automobile

InactiveCN1833272AImprove sound absorptionValid conversionSound producing devicesThermal energyEther

A foam sheet for an interior material of an automobile formable in a specified shape while maintaining excellent sound absorbing performance, characterized in that hole parts opening to the surface thereof are formed in one surface of a denatured polyphenylene ether-based resin foam sheet with a continuous bubble fraction of 50% or higher. Thus, the foam sheet can develop excellent sound absorbing performance by smoothly guiding sound vibration energy to the continuous bubbles in the foam sheet (1) through the hole parts to vibrate the bubble walls of the continuous bubbles so as to transform the vibration energy into thermal energy.

Owner:SEKISUI PLASTICS CO LTD +1

Silicone resin compositions and molded articles thereof

InactiveUS7385017B2Good dimensional stabilityLow water absorptionOptical elementsMeth-Flat panel display

This invention relates to a silicone resin composition which exhibits high heat resistance, high transparency and high dimensional stability and thus can be suitably used for optical applications such as a lens, an optical disc, an optical fiber, a substrate for a plat panel display, a window material for an automobile, and the like. A silicone resin composition, which comprises a silicone resin comprising, as a primary component, a polyorganosilsesquioxane being represented by the formula: [RSiO3 / 2]n, wherein R represents an organic functional group having a (meth)acryloyl group, and n is 8, 10 or 12, and having a cage type structure in its structural unit, and an unsaturated compound having, in its molecule, at least one unsaturated group represented by —R3—CR4═CH2 or —CR4═CH2, wherein R3 represents an alkylene group, an alkylidene group or a —OCO— group and R4 represents a hydrogen atom or an alkyl group, and being capable of radically copolymerizing with the above silicone resin, in a weight proportion of 1:99 to 99:1.

Owner:NIPPON STEEL CHEMICAL CO LTD

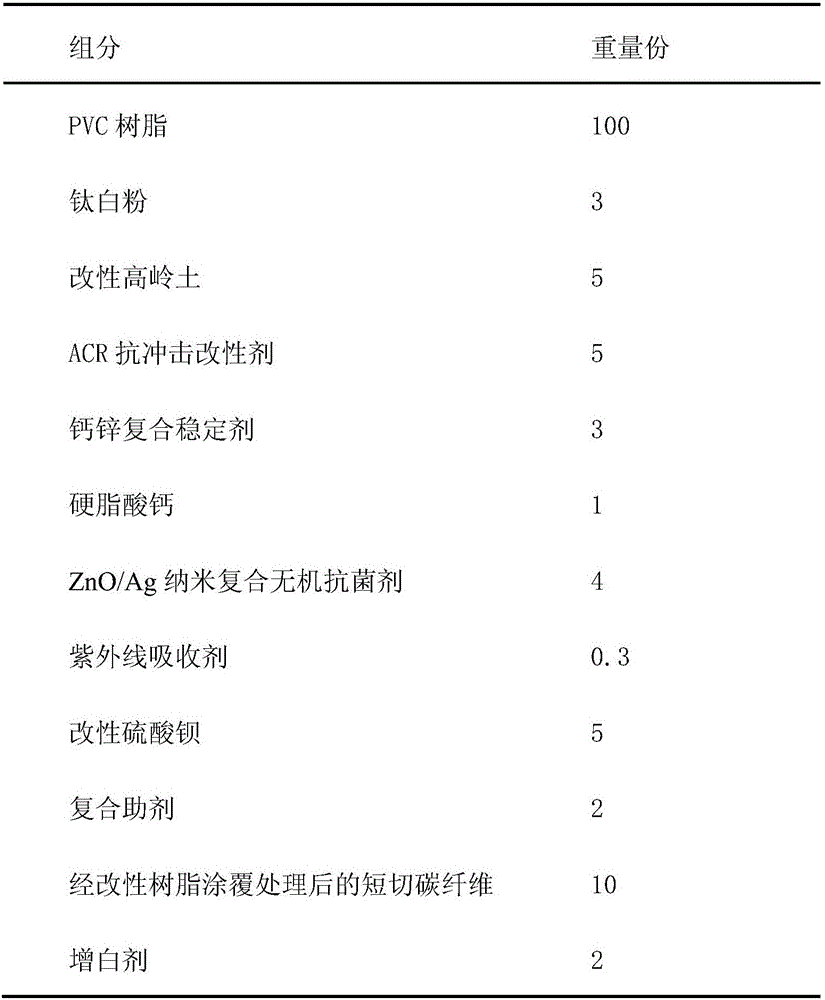

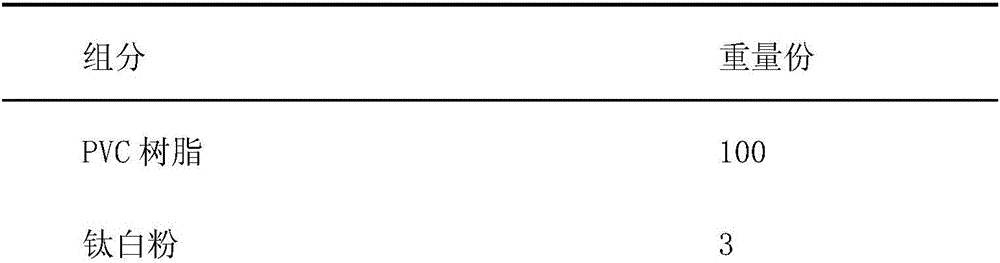

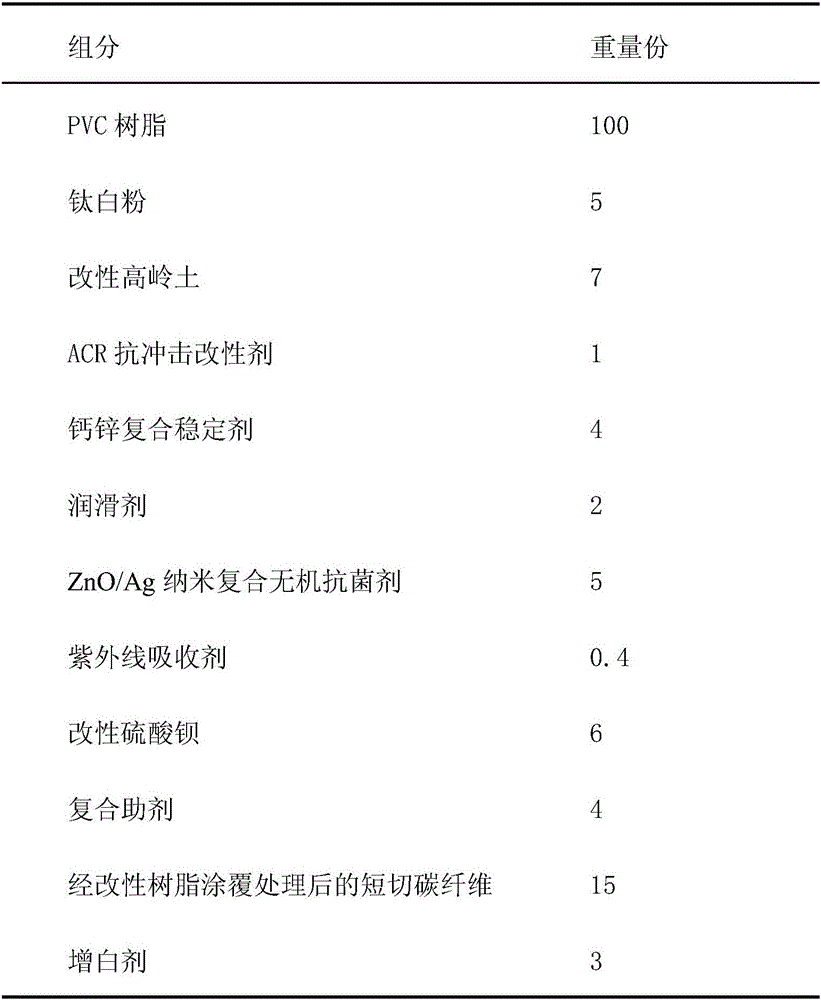

Green antibacterial carbon fiber reinforced PVC (polyvinyl chloride) material and preparation method thereof

The invention discloses a green antibacterial carbon fiber reinforced PVC (polyvinyl chloride) material and a preparation method thereof. The green antibacterial carbon fiber reinforced PVC material is prepared from the following raw materials in parts by weight: 98-100 parts of PVC resin, 3-6 parts of titanium dioxide, 5-10 parts of modified kaolin, 5-12 parts of ACR impact resistance modifier, 3-5 parts of environment-friendly stabilizer, 0.5-3 parts of lubricant, 4-8 parts of inorganic antibacterial agent, 0.3-0.5 part of ultraviolet absorbent UV-327, 5-10 parts of modified barium sulfate, 2-5 parts of compound additive, 1-20 parts of short-cut carbon fiber coated with modified resin, and 0-5 parts of fluorescent whitening agent CBS. The green antibacterial carbon fiber reinforced PVC material of the invention has the advantages of excellent anti-fatigue performance, high and low temperature resistances, and waterproofness, small expansion coefficient, light weight, as well as excellent antibacterial performance and environment friendliness.

Owner:ANHUI XINGXIN CHEM TECH

Rare earth coated calcium oxide based ceramic core

The invention discloses a rare earth coated calcium oxide based ceramic core, which is characterized by being composed of the following raw materials by weight: 6-12wt% a mineralization agent, 10-17wt% of a plasticizer, 1-1.4wt% of oleic acid, and the balance rare earth coated calcium oxide powder. The product has enough room temperature, high temperature strength, good chemical stability, low firing shrinkage and linear expansion rate, adopts rare earth coated calcium oxide as aggregate and has very good core removal ability, thus reducing the use cost.

Owner:WUHU ZHEXIN NEW ENERGY

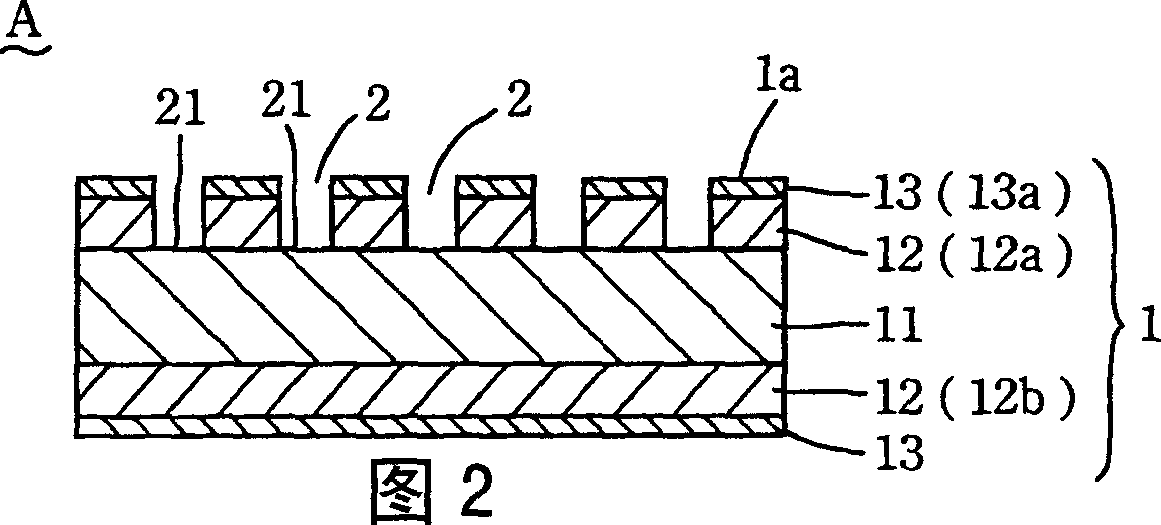

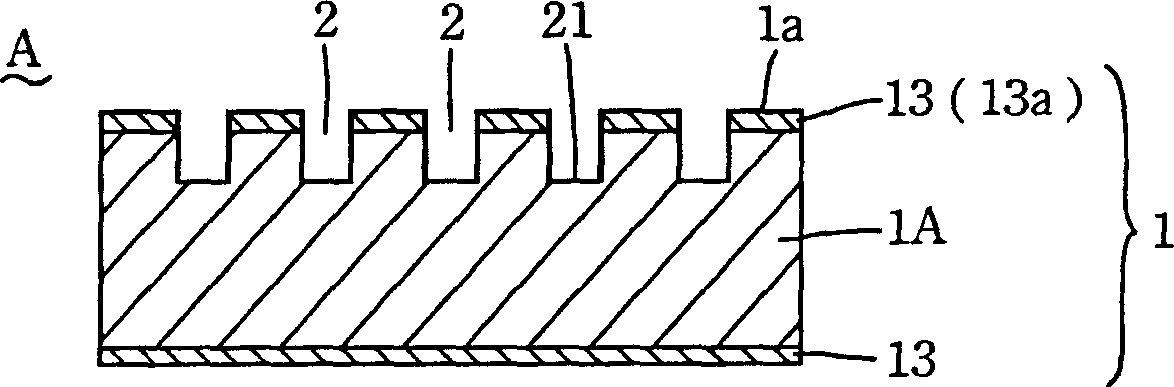

Sheet-shaped mold, production method therefor, and application therefor

ActiveUS20160009006A1High strengthSolve the high breakage rateConfectioneryPhotomechanical apparatusCellulosePolymer science

Provided is a sheet-shaped mold possessing a high strength and having a low breakage rate in demolding even in a case where the mold is thin and has a large-area. The sheet-shaped mold is prepared by combining a cured silicone rubber containing a polyorganosiloxane and a fiber for reinforcing the cured silicone rubber. The fiber may comprise a cellulose nanofiber. The sheet-shaped mold may have an uneven pattern on at least one surface (or side) thereof. The fiber may be surface-treated with a hydrophobizing agent. The fiber may forma nonwoven fabric, and the nonwoven fabric may be impregnated with the cured silicone rubber. The cured silicone rubber may comprise a two-component curable silicone rubber having a polydimethylsiloxane unit. The sheet-shaped mold may be a mold for nanoimprint lithography using a photo-curable resin.

Owner:DAICEL CHEM IND LTD

Green antibacterial carbon fiber reinforced PVC (polyvinyl chloride) material and preparation method thereof

The invention discloses a green antibacterial carbon fiber reinforced PVC (polyvinyl chloride) material and a preparation method of the material. The material comprises the following raw materials in parts by weight: 100 parts of PVC resin, 3-6 parts of titanium dioxide, 5-10 parts of modified kaoline, 5-12 parts of shock-resistant modifier, 3-5 parts of environment-friendly stabilizer, 0.5-3 parts of lubricant, 4-8 parts of inorganic antibacterial agent, 0.3-0.5 parts of ultraviolet absorber, 5-10 parts of modified barium sulfate, 2-5 parts of composite assistant, 1-20 parts of chopped carbon fiber treated by modified resin coating, and 0-5 parts of brightener. The green antibacterial carbon fiber reinforced PVC material is excellent in fatigue resistance, excellent in high and low temperature resistance, excellent in water resistance, small in expansion coefficient, light in weight, excellent in antibacterial property, and environment-friendly.

Owner:安庆市月岭塑业有限公司

Insulating adhesive film, prepreg, laminate, cured article, and composite article

InactiveUS20140234614A1Low linear expansionExcellent in via hole formabilityNon-macromolecular adhesive additivesSynthetic resin layered productsPolymer scienceAdhesive

An insulating adhesive by having a plateable layer which is comprised of a plateable layer-use resin composition which contains a polar group-containing alicyclic olefin polymer (A1) and a curing agent (A2) and an adhesive layer which is comprised of an adhesive layer-use resin composition which contains a polar group-containing alicyclic olefin polymer (B1), a curing agent (B2), and an inorganic filler (B3), wherein a ratio of content of the polar group-containing alicyclic olefin polymer (A1) to the solid content as a whole which is contained in the plateable layer is 50 to 90 wt %, and a ratio of content of the polar group-containing alicyclic olefin polymer (B1) to the solid content as a whole which is contained in the adhesive layer is 1 to 30 wt % and a ratio of content of the inorganic filler (B3) is 50 to 90 wt % is provided.

Owner:ZEON CORP

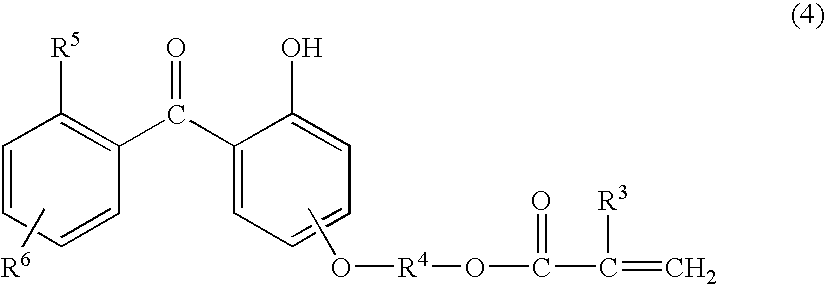

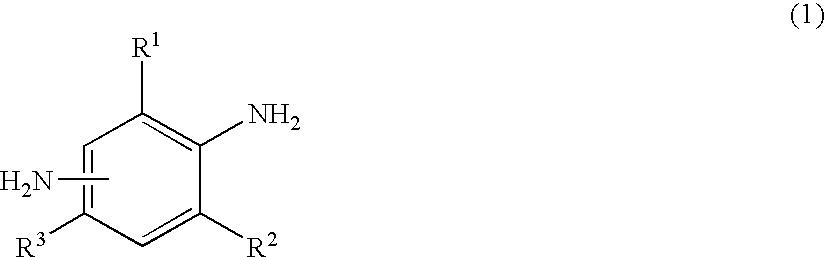

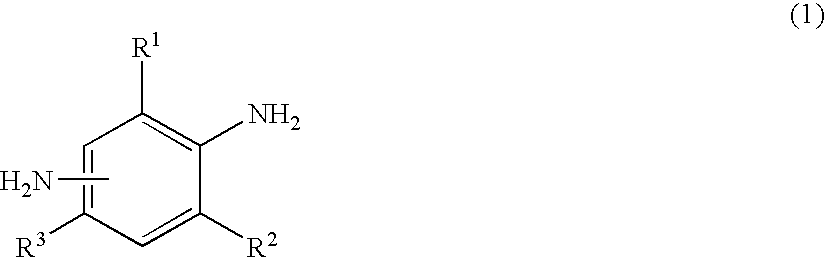

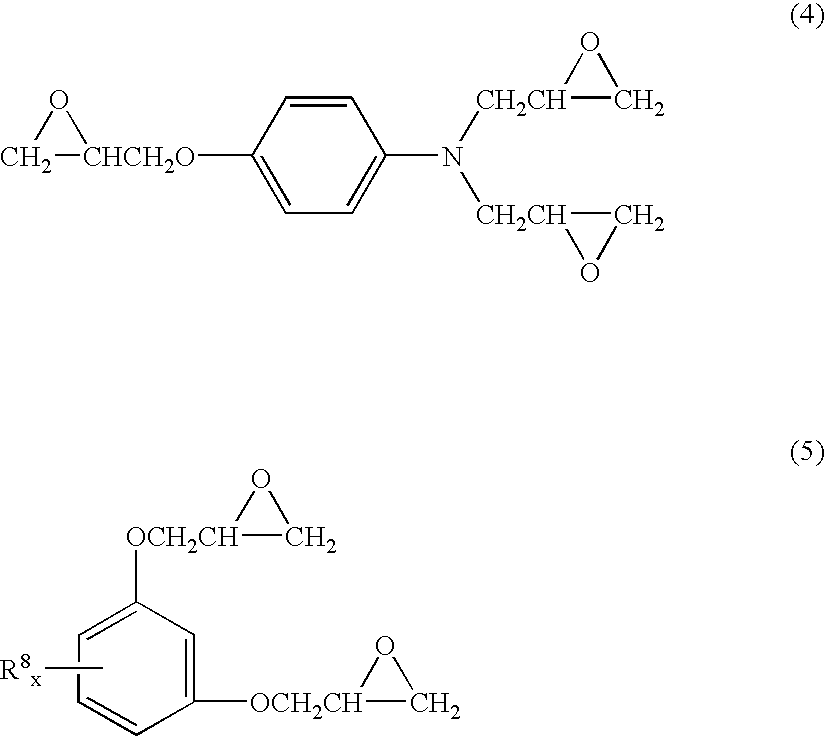

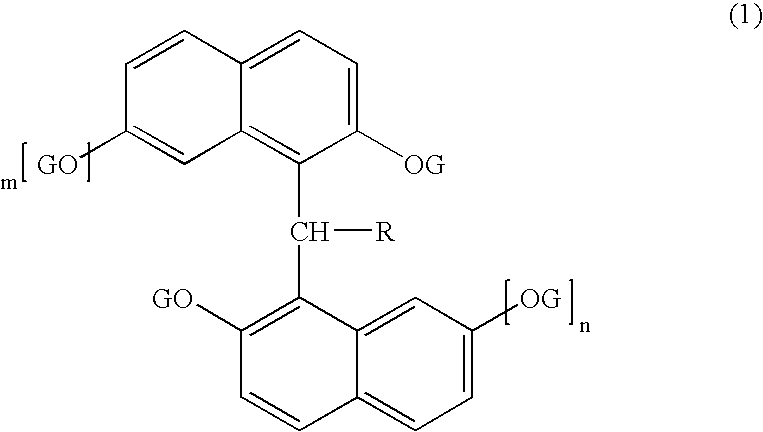

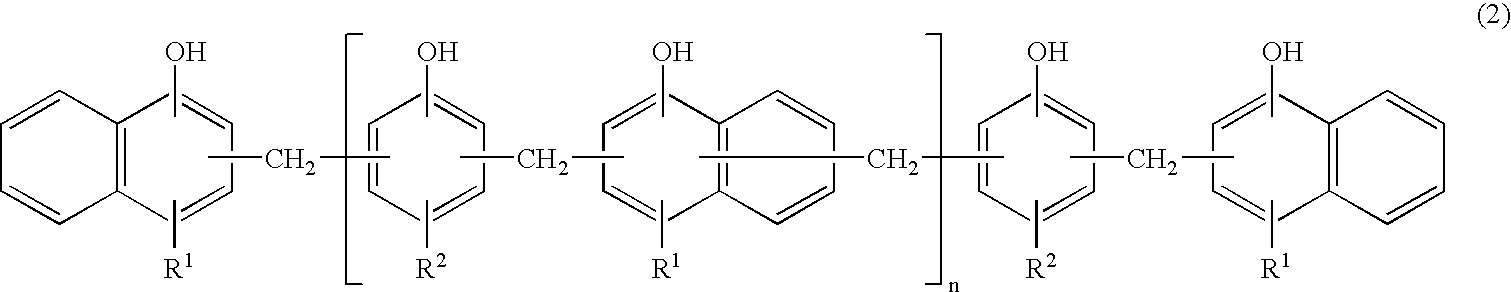

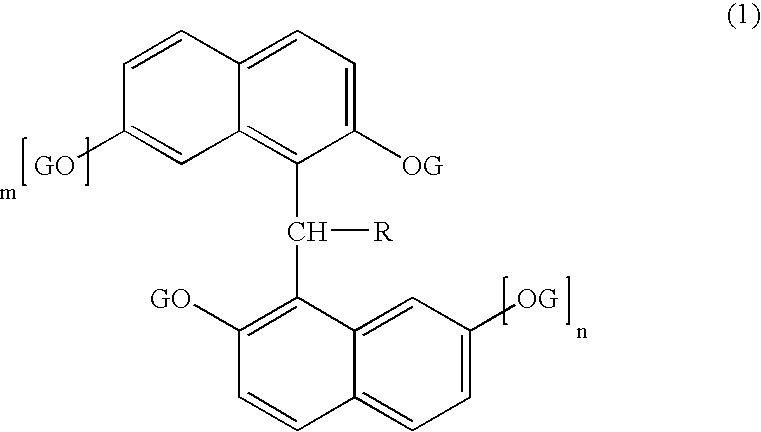

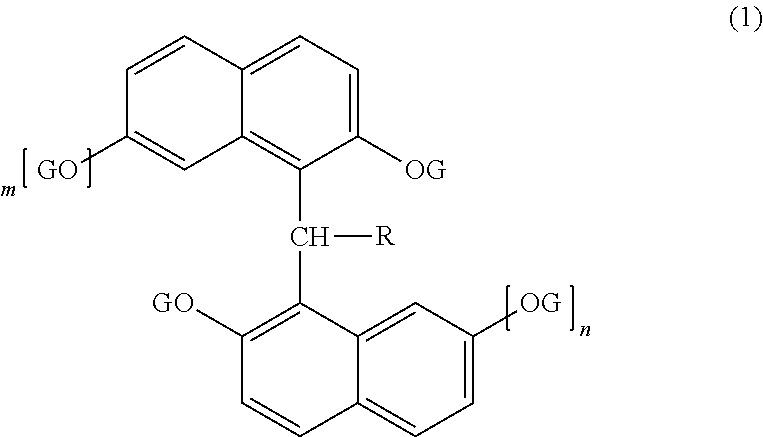

Soluble imide skeleton resin, soluble imide skeleton resin solution composition, curable resin composition, and cured product thereof

ActiveUS20120043508A1Improve solubilityReduction factorConductive materialSynthetic resin layered productsEpoxyImide

An imide skeleton resin represented by the following general formula (1) has a coefficient of linear expansion as low as that of polyimide resin and excellent processability like epoxy resin, and is useful as a resin composition for electrical laminates. Five percent by mole or more of the entirety of the A component is a linking group having an imide skeleton represented by the following general formula (4-1). B denotes a hydrogen atom or a group represented by the following structural formula (5). n denotes an integer in the range of 0 to 200. If both of the B's are hydrogen atoms, then n denotes an integer of 1 or more.

Owner:MITSUBISHI CHEM CORP

Semiconductor encapsulating epoxy resin composition and semiconductor device

InactiveUS20070207322A1Easy to moveHigh glass transition temperatureSemiconductor/solid-state device detailsSynthetic resin layered productsPolymer scienceDevice material

An epoxy resin composition comprising (A) a mixture of a naphthalene type epoxy resin and an anthracene type epoxy resin, (B) a curing agent in the form of a naphthalene type phenolic resin, and (C) an inorganic filler is best suited for semiconductor encapsulation.

Owner:SHIN ETSU CHEM IND CO LTD

Semiconductor encapsulating epoxy resin composition and semiconductor device

ActiveUS7943706B2Improve crack resistanceReduction factorSemiconductor/solid-state device detailsSynthetic resin layered productsEpoxyPolymer science

An epoxy resin composition comprising(A) at least one epoxy resin comprising (a) a naphthalene ring-containing epoxy resin having at least one substituted or unsubstituted naphthalene ring in a molecule and having an epoxy equivalent of 175 to 210,(B) a phenolic resin having at least one substituted or unsubstituted naphthalene ring in a molecule, and(C) an inorganic filler,the substituted or unsubstituted naphthalene ring of the epoxy resin (a) being contained in an amount of 45 to 60% by weight in the total amount of the epoxy resin (A) is best suited for semiconductor encapsulation because it has good flow, a low coefficient of linear expansion, a high Tg, minimal moisture absorption, and crack resistance upon lead-free soldering.

Owner:SHIN ETSU CHEM IND CO LTD

Iron-nickel alloy having a low coefficient of expansion

Iron / nickel alloy having a low coefficient of expansion, the chemical composition of which comprises iron, nickel, manganese, silicon, calcium, magnesium, less than 0.005% of aluminum, less than 0.001% of sulfur, less than 0.01% of oxygen, less than 0.005% of nitrogen, and less than 0.003% of phosphorus, the chemical composition furthermore satisfying the relationship:<paragraph lvl="0"><in-line-formula>S<=0.02xMn+0.8xCa+0.6xMg< / in-line-formula>

Owner:IMPHY SA FR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com