Green antibacterial carbon fiber reinforced PVC (polyvinyl chloride) material and preparation method thereof

A PVC material, fiber reinforced technology, applied in the direction of carbon fiber, can solve the problems of material cracking, non-standard production process operation, low processing level, etc., to achieve excellent thermal shock resistance, high environmental protection performance, comprehensive cost-effective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

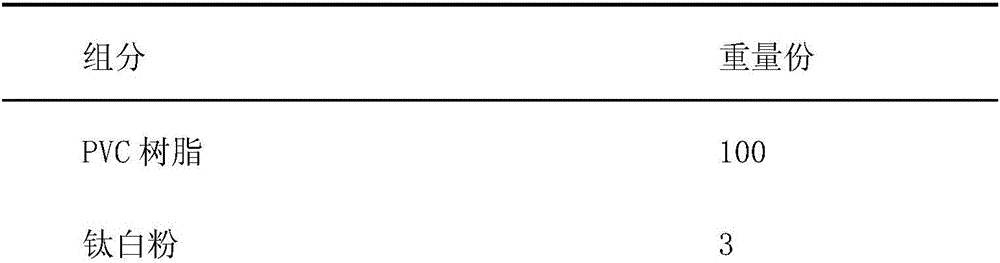

[0032] A green antibacterial carbon fiber reinforced PVC material, the ratio of each raw material is as follows:

[0033]

[0034]

[0035] The modified kaolin is prepared by the following method: calcining the kaolin at 400°C for 2 hours, cooling to room temperature, soaking in a sulfuric acid solution with a mass concentration of 10% for 3 hours, filtering, washing until neutral, drying, and pulverizing , through a 300-mesh sieve; the sieved powder is stirred with water to make a suspension with a concentration of 40%, and then 1% of the weight of the suspension is added with sodium tripolyphosphate, 2% of water-soluble nano-scale silica sol, and 2% of molybdenum Sodium phosphate, 2000rpm high-speed shear dispersion for 15 minutes, spray drying.

[0036] The modified barium sulfate is composed of the following components: 50 parts of barium sulfate, 0.5 part of coupling agent and 0.6 part of stearic acid.

[0037] The composite auxiliary agent is prepared by the follo...

Embodiment 2

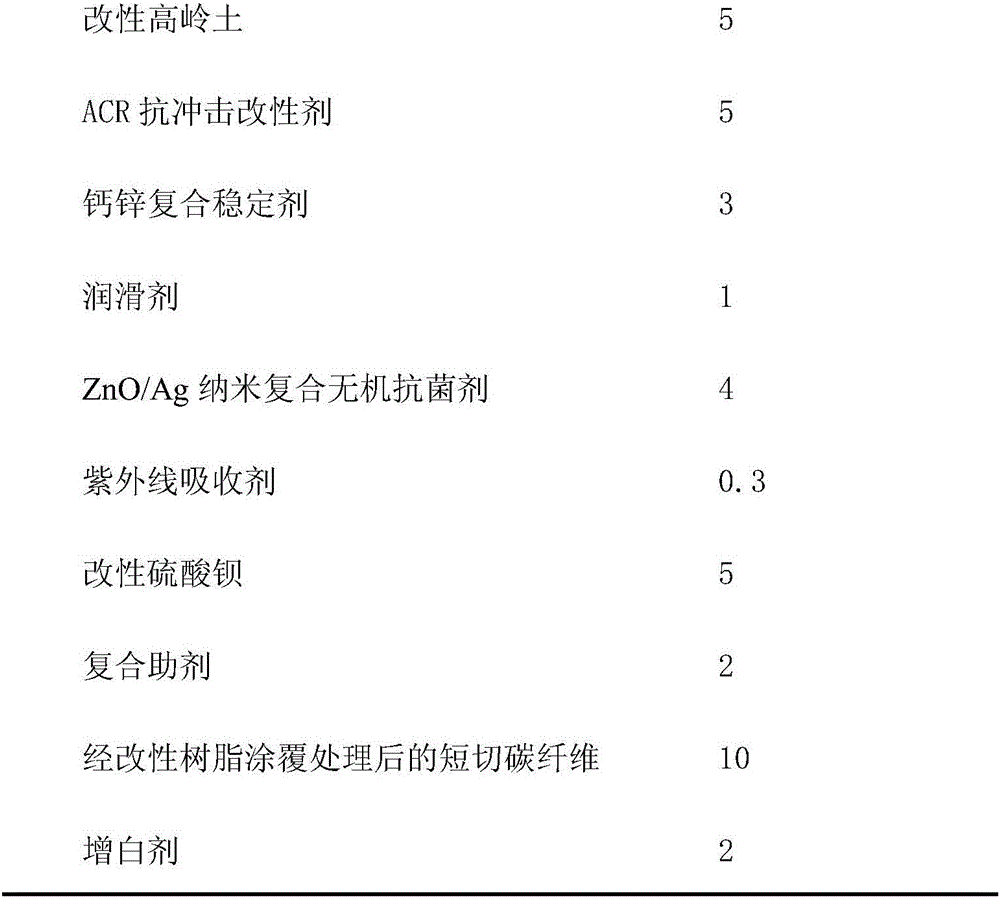

[0051] A green antibacterial carbon fiber reinforced PVC material, the ratio of each raw material is as follows:

[0052]

[0053] The modified kaolin is prepared by the following method: calcining kaolin at 450°C for 2 hours, cooling to room temperature, soaking in sulfuric acid solution with a mass concentration of 12% for 2 hours, filtering, washing until neutral, drying, and pulverizing , through a 400-mesh sieve; the sieved powder is stirred with water to make a suspension with a concentration of 45%, and then 2% of the weight of the suspension is added with sodium tripolyphosphate, 2% of water-soluble nano-scale silica sol, and 3% of molybdenum Sodium bicarbonate, 3000rpm high-speed shear dispersion for 10 minutes, spray drying.

[0054] The modified barium sulfate is composed of the following components: 60 parts of barium sulfate, 2.0 parts of coupling agent and 0.5 parts of stearic acid.

[0055] The composite auxiliary agent is prepared by the following method: 6...

Embodiment 3

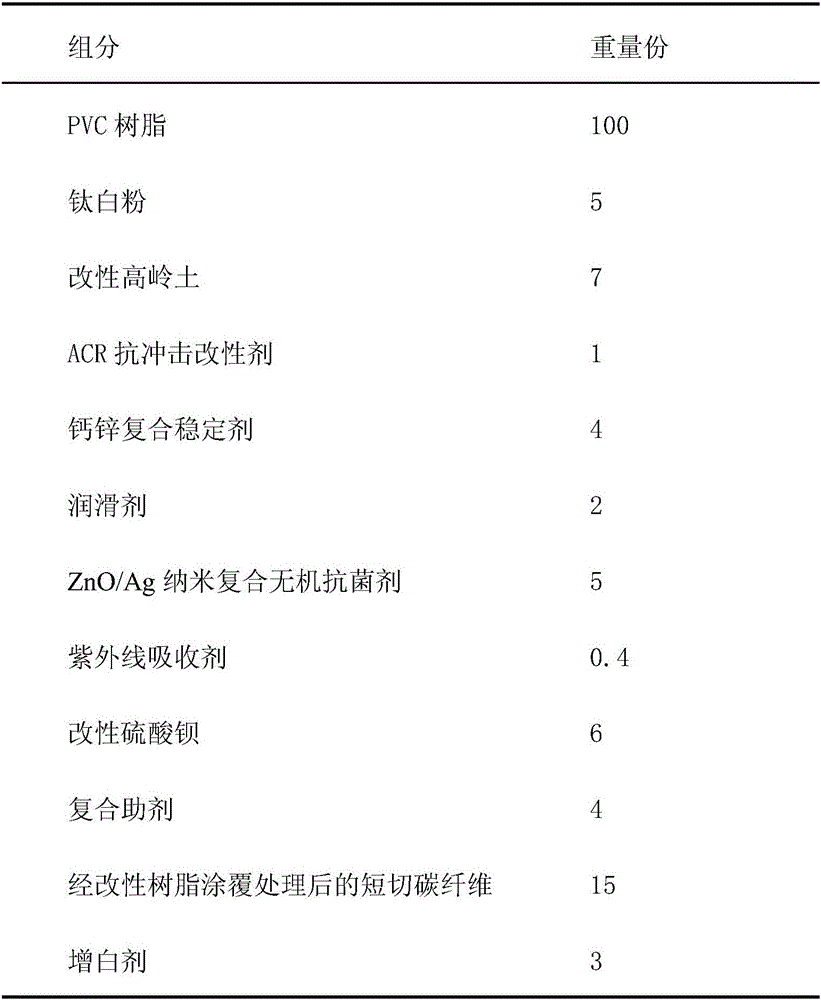

[0069] A green antibacterial carbon fiber reinforced PVC material, the ratio of each raw material is as follows:

[0070]

[0071] The modified kaolin is prepared by the following method: calcining kaolin at 500°C for 1 hour, cooling to room temperature, soaking in sulfuric acid solution with a mass concentration of 15% for 1 hour, filtering, washing until neutral, drying, and pulverizing , through a 400-mesh sieve; the sieved powder is stirred with water to make a suspension with a concentration of 50%, and then 2% of the weight of the suspension is added with sodium tripolyphosphate, 2% of water-soluble nano-scale silica sol, and 2% of molybdenum Sodium bicarbonate, 3000rpm high-speed shear dispersion for 15 minutes, spray drying.

[0072] The modified barium sulfate is composed of the following components: 70 parts of barium sulfate, 3.0 parts of coupling agent and 0.6 parts of stearic acid.

[0073] The composite auxiliary agent is prepared by the following method: 8 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com