Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Little impact on physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

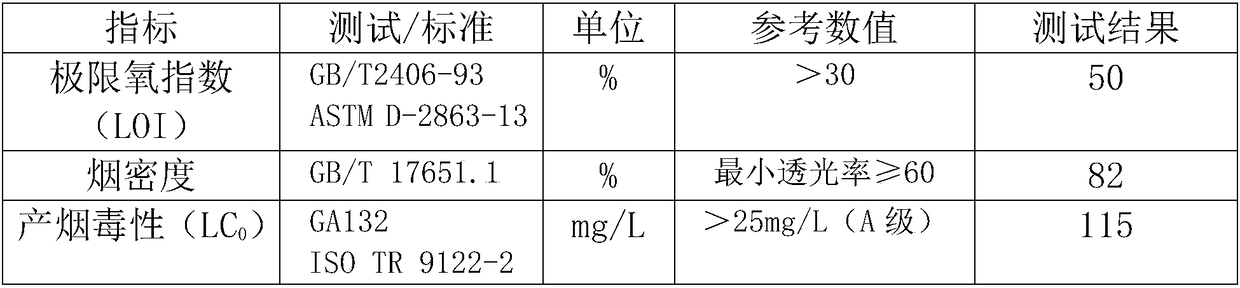

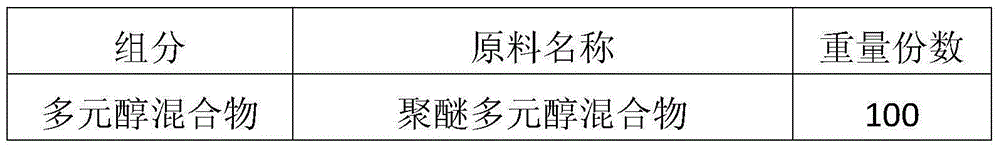

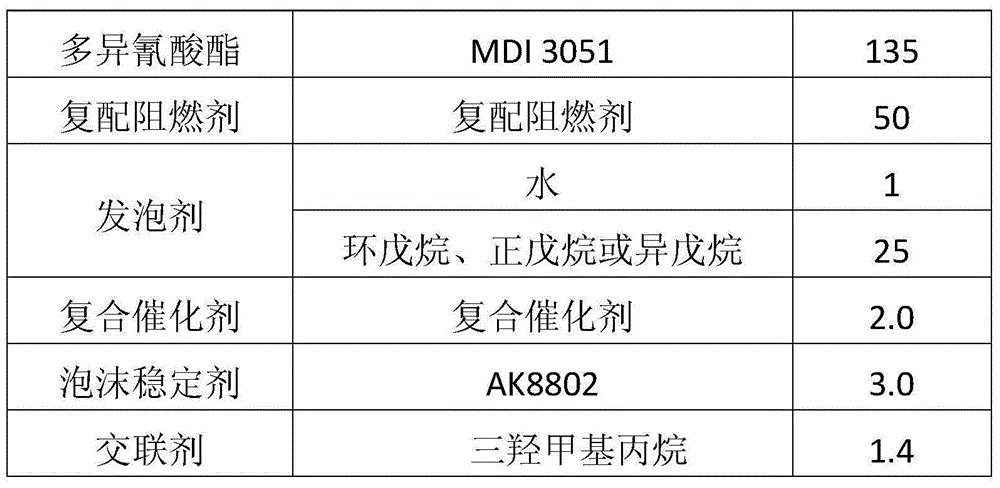

Halogen-free flame-retardant rigid polyurethane foamed plastic and preparation method for same

ActiveCN103694438ALittle impact on physical propertiesGood physical propertiesHydrogen halideToxic gas

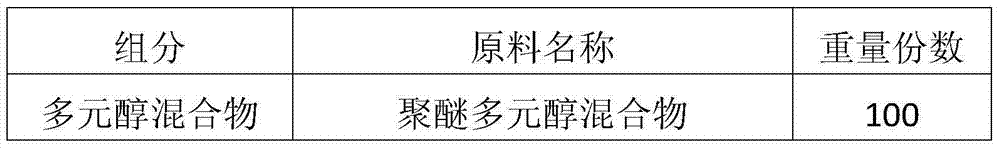

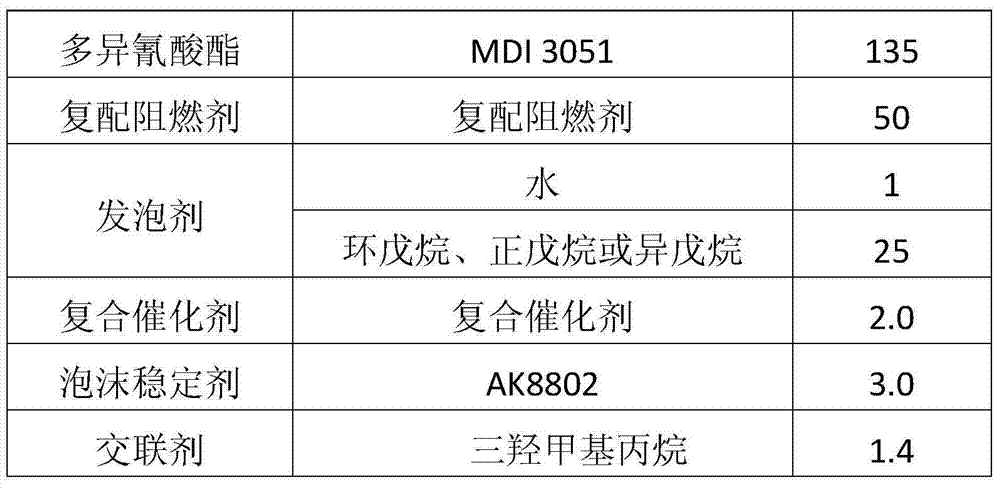

The invention discloses halogen-free flame-retardant rigid polyurethane foamed plastic and a preparation method for the same. The polyurethane foamed plastic consists of the following raw materials in parts by weight: 100 parts of polyalcohol mixture, 105 to 180 parts of polyisocyanate, 20 to 80 parts of compound halogen-free flame retardant, 1 to 50 parts of foaming agent, 1 to 3 parts of composite catalyst, 2 to 4 parts of foam stabilizer and 1 to 2 parts of cross-linking agent. An obtained product is high in flame retardance and environment-friendly, the raw materials are free of halogen, and the production of toxic gas such as hydrogen halide during combustion is avoided; the raw materials are readily available and low in cost, so that the preparation cost of the polyurethane foamed plastic is greatly lowered; the polyurethane foamed plastic also has the characteristic of wide application range, and is applied to cold storage and heat-preservation industries of external wall heat-preservation of buildings, heat-preservation of pipelines, refrigerators, freezers and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

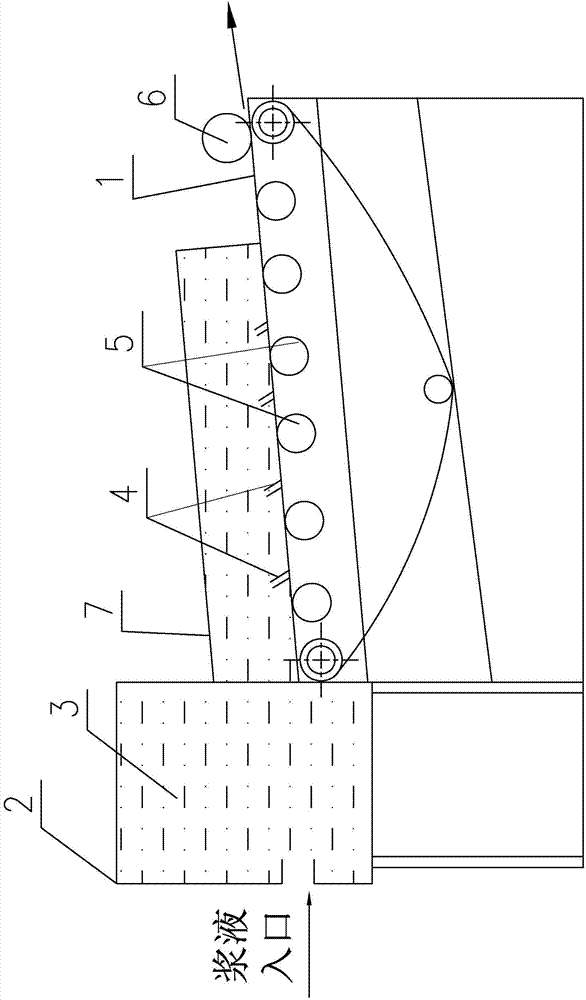

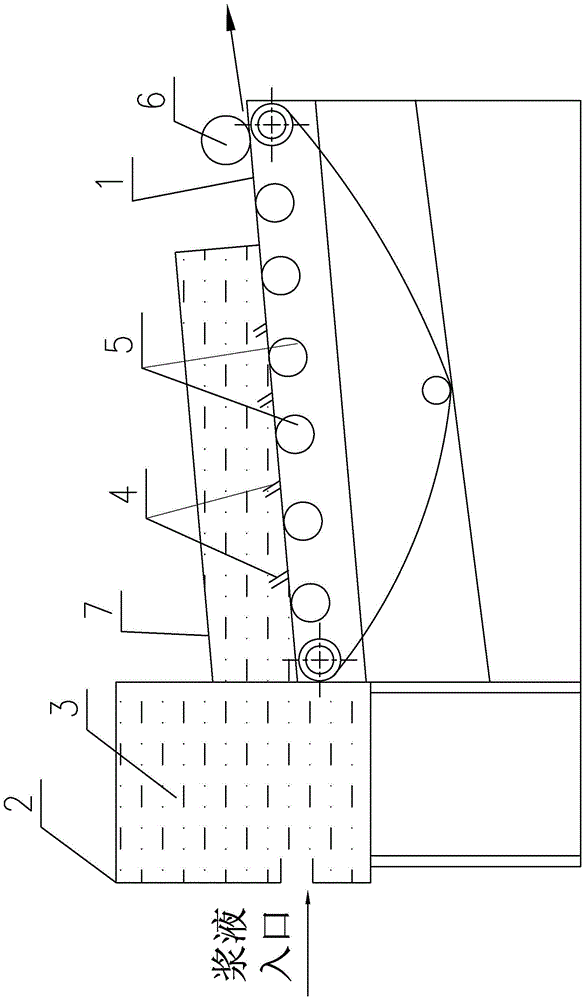

Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

InactiveCN101168940AImprove retentionLittle impact on physical propertiesWater-repelling agents additionComplex typeParaffin wax

The invention relates to a preparation method of paraffin wax / AKD complex type neutral paper-making sizing agent. The step is as follows: firstly, AKD and paraffin wax powder are melted in AKD solution; secondly, compound emulsifying agent after being heated is added in melted AKD solution and mixed with a quick shearing mixing machine; thirdly, a rotating speed of the quick shearing blending machine is improved and preheating water is added to lead the formed AKD solution to performing emulsification nearby a W / O to O / W inversion point; quick mixing is performed and the preheating water is added and the mixing is continuously performed; fourthly, the water solution of flocculating agent PAC is added, and the mixing is continuously performed; fifthly, the mixing is stopped and the cold water is used for quickly performing cooling and cool down, and then the finished product of the paraffin wax / AKD complex-typed neutral paper-making sizing agent emulsion is produced. The complex-typed neutral sizing agent produced by the invention has the advantages that the holding rate is high, the effect on the physical property of the paper is small, and the emulsion is stable.

Owner:TIANJIN UNIV OF SCI & TECH

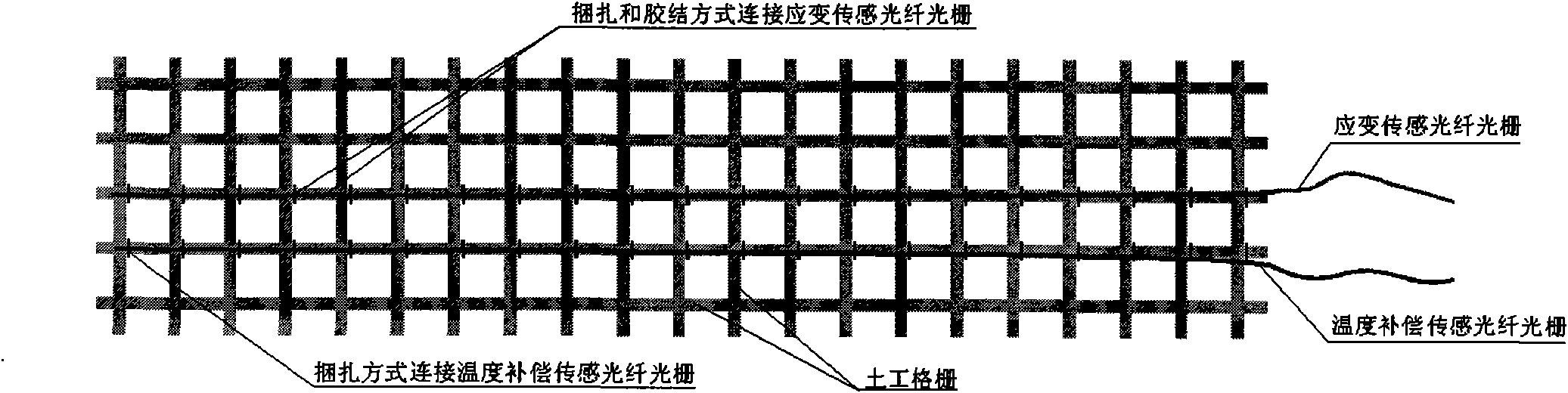

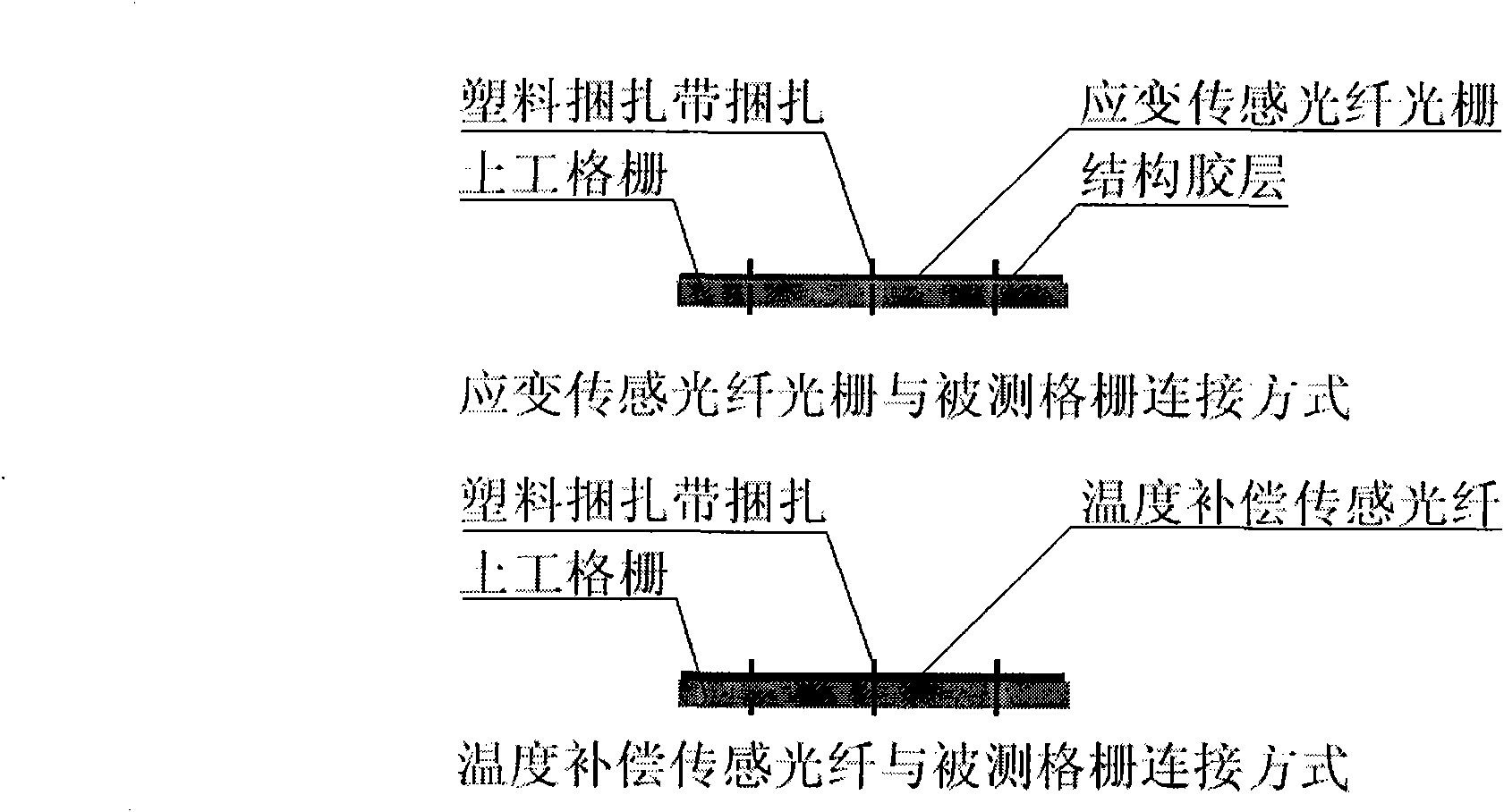

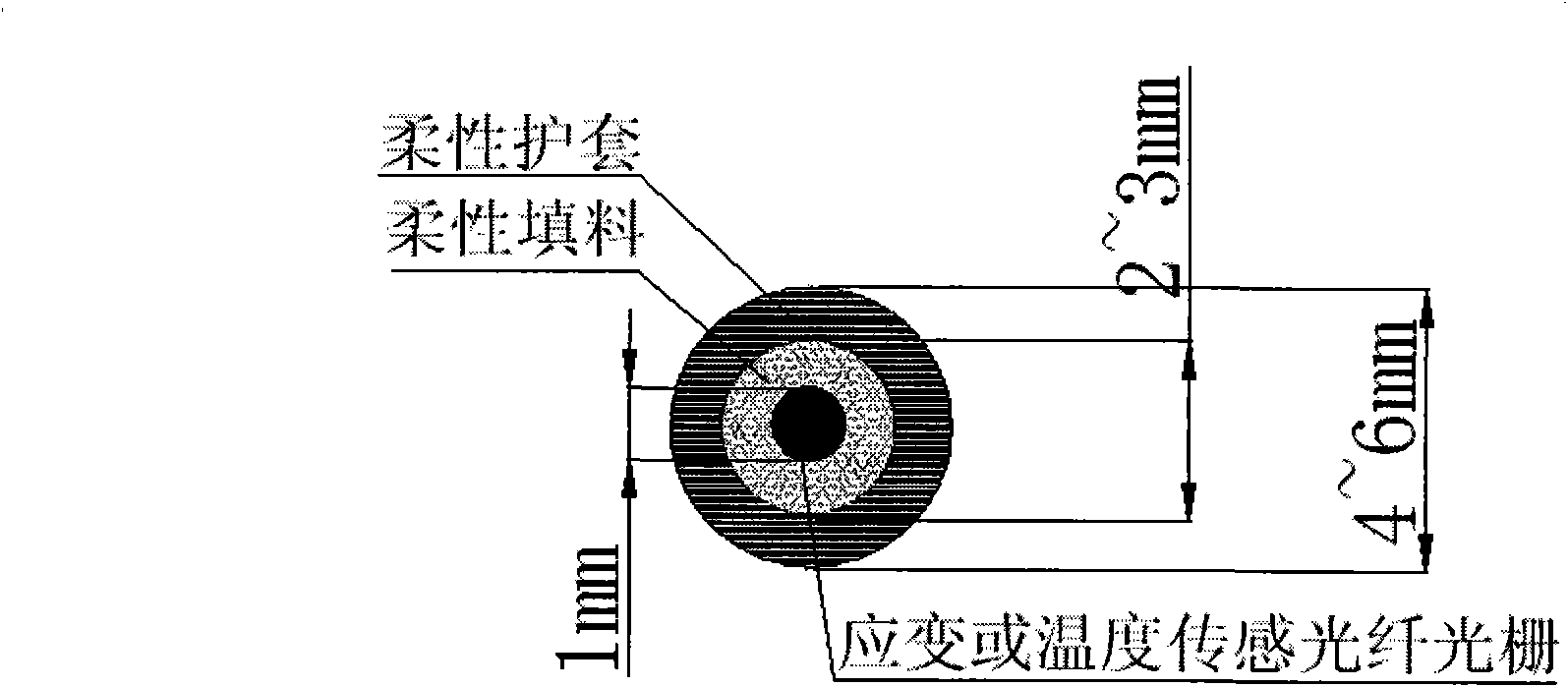

Method for measuring geogrid deformation and stress by utilizing fiber bragg grating

InactiveCN101915552ALow costAccurate measurementForce measurement by measuring optical property variationUsing optical meansAdhesiveAccuracy and precision

The invention discloses a method for measuring geogrid deformation and stress by utilizing a fiber bragg grating, comprising the following steps: connecting a strain fiber and a sensing fiber with longitude gate or latitude gate of the measured geogrid by adopting a structural adhesive and a banding manner; laying a temperature compensation sensing fiber on the adjacent longitude gates or latitude gates of the measured geogrid; manufacturing a sensing fiber armoring structure; packing geogrid longitude gate or latitude gate laid with sensing fibers by adopting adhesive tapes after the laying of sensing fibers on the measured geogrid is finished; laying and installing the geogrid which is laid with sensing fibers and finishes protection structure in place; one end of sensing fiber bragg grating leads out and is connected with a fiber optic jumper joint to enter into a distributed fiber measuring system. The method of the invention is simple and easily operated, has low cost and can accurately measure the deformation and stress of the geogrid, and the measuring precision can satisfy project actual measuring demands.

Owner:NANJING HYDRAULIC RES INST

Environment-friendly polypropylene composite material with high efficiency flame retardance

InactiveCN101693835ALittle impact on physical propertiesImprove thermal stabilityFireproof paintsPolypropylene compositesPentaerythritol

The invention relates to a nitrogen-phosphorus expanded halogen-free flame retardant and a polypropylene composite material containing the flame retardant, wherein the flame retardant comprises the following components in percentage by weight: 30-40 percent of melamine cyanurate, 20-30 percent of melamine phosphate amine, 20-25 percent of pentaerythritol and 10-30 percent of hydroxide, wherein the hydroxide is aluminium hydroxide or magnesium hydroxide or the mixture of the aluminium hydroxide and the magnesium hydroxide. Compared with the traditional halogen-free flame retardant polypropylene composite material, the polypropylene composite material prepared from the flame retardant has high flame retardant efficiency, small influence on the physical performance of the finally prepared composite material due to the addition of only a smaller quantity of flame retardant, easier processing process and better thermal stability of the composite material.

Owner:太仓市华鼎塑料有限公司

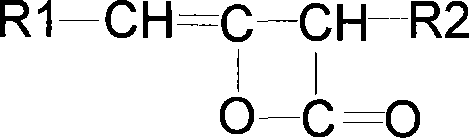

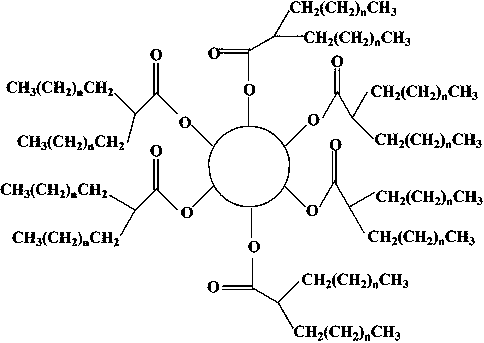

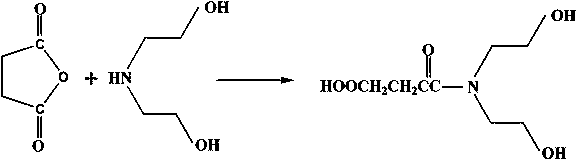

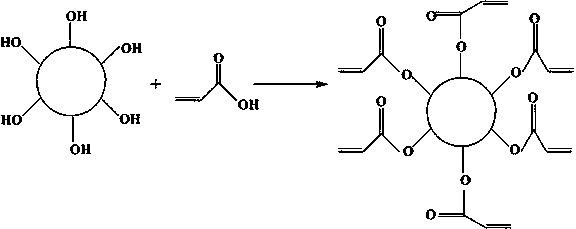

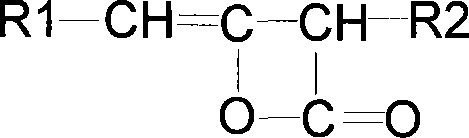

Preparation method of hyperbranched paraffin and application of hyperbranched paraffin in artificial boards

ActiveCN109134839AThe synthesis process is simpleEase of industrial productionFlat articlesDomestic articlesParaffin waxEnd-group

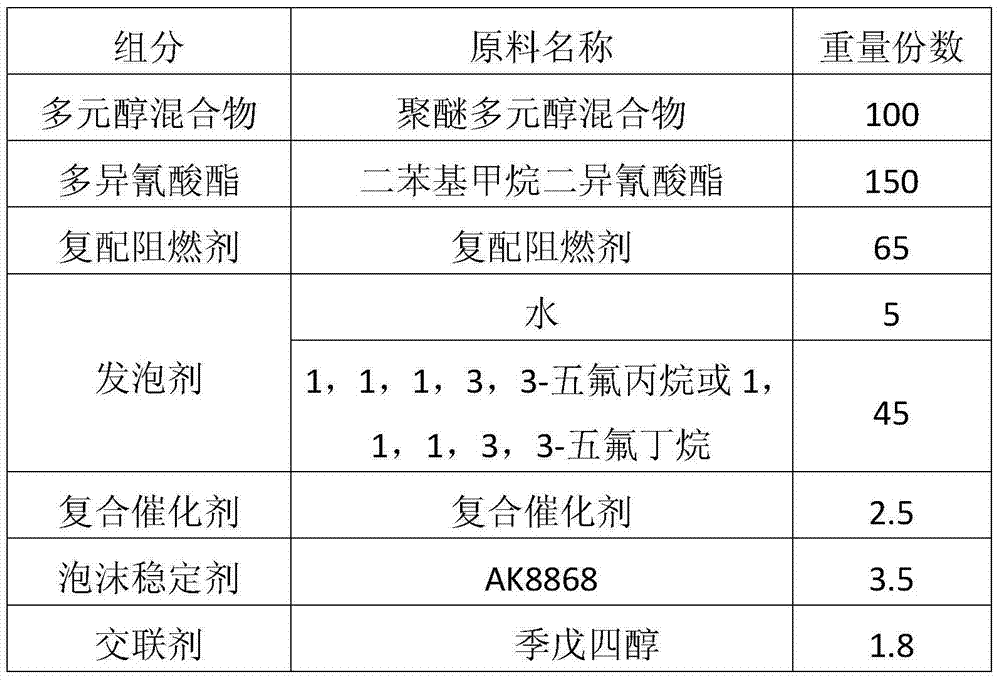

The invention relates to the field of artificial boards, in particular to a preparation method of hyperbranched paraffin and application of the hyperbranched paraffin in artificial boards. The preparation method includes: synthesizing hydroxyl terminated hyperbranched polymer; using acrylic acid modification to introduce double bonds to the terminal of the polymer to synthesize double-bond hyperbranched polymer; polymerizing the double-bond-terminated hyperbranched polymer with paraffin under the effect of an initiator to obtain the hyperbranched paraffin. The hyperbranched paraffin which is an artificial-board waterproof agent excellent in performance is good in waterproof effect, good in stability and lasting in effect. The synthesizing process of the hyperbranched paraffin is simple andeasy to achieve industrialization.

Owner:UNIV OF JINAN

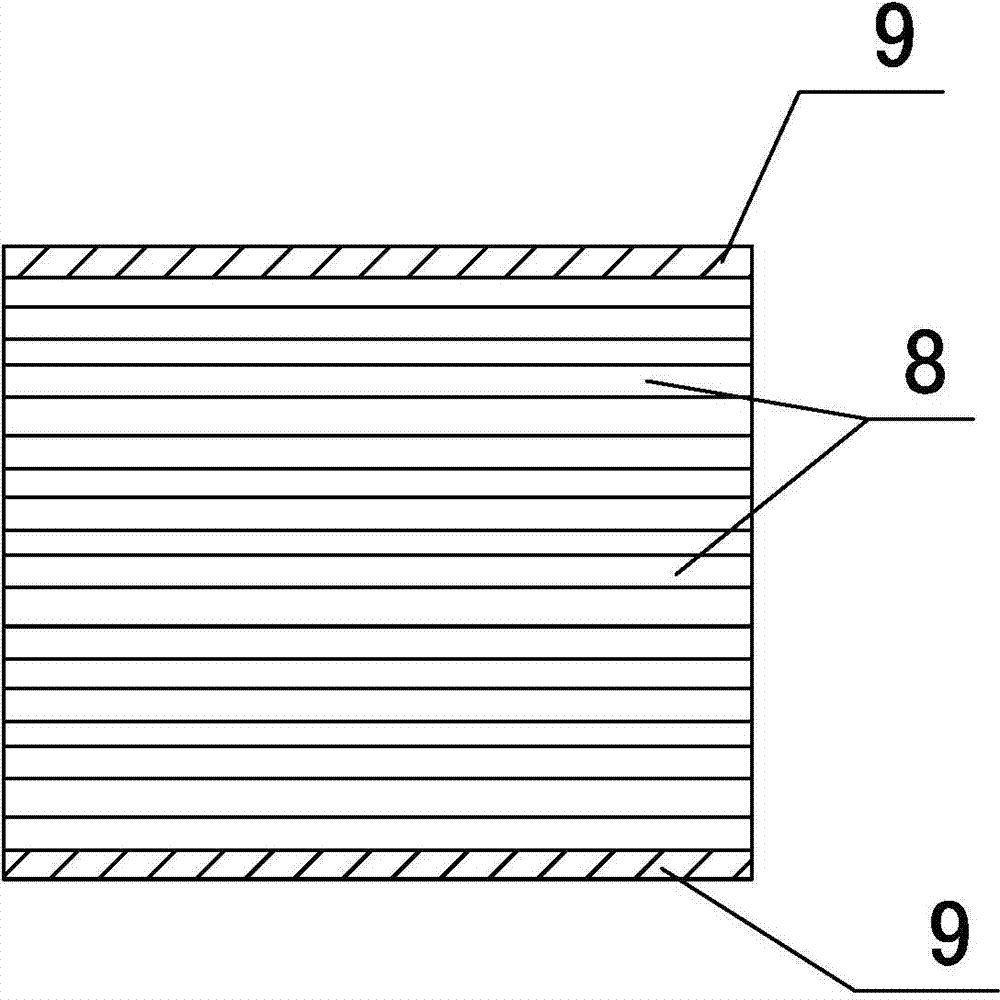

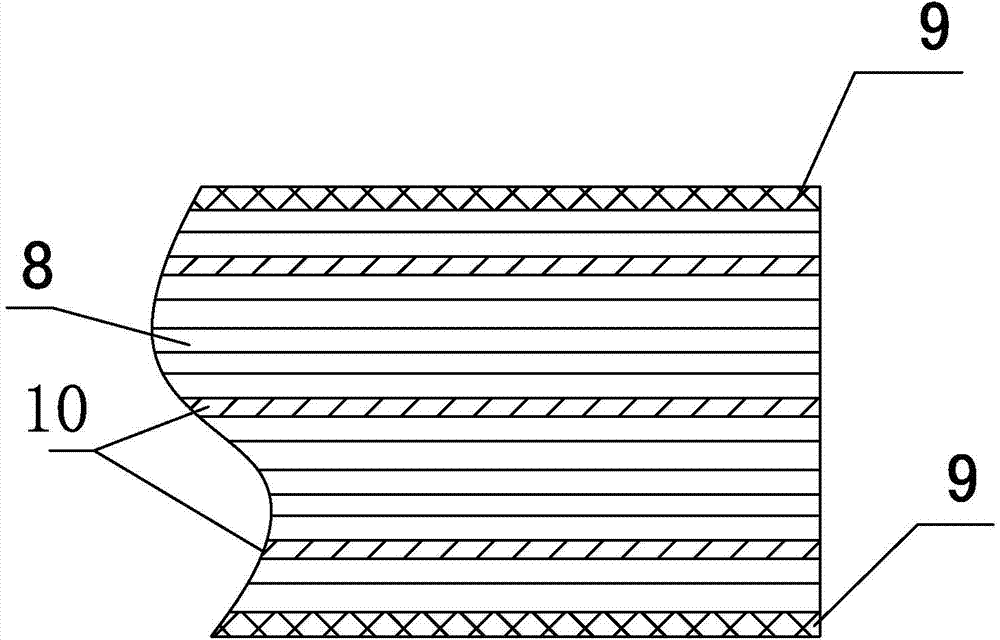

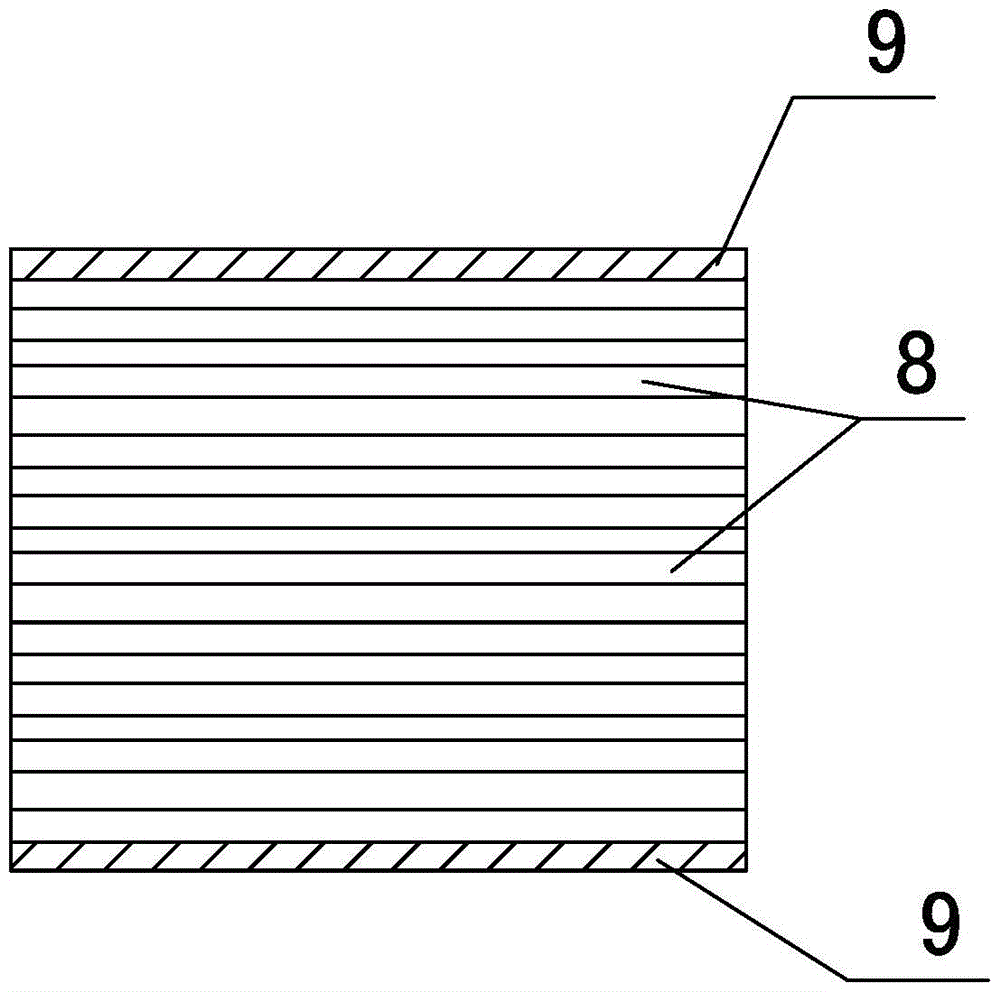

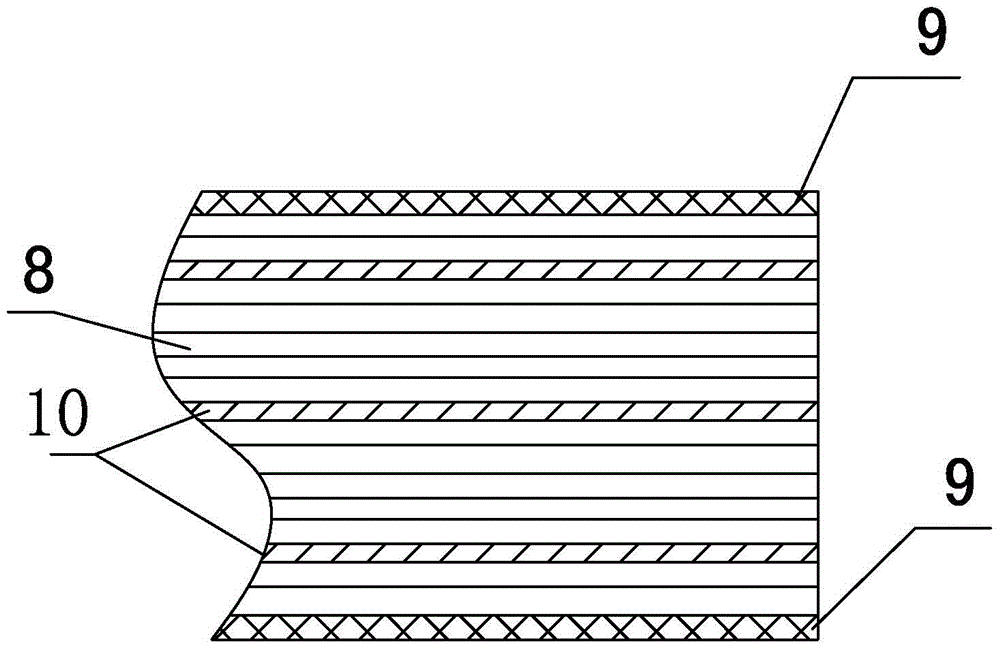

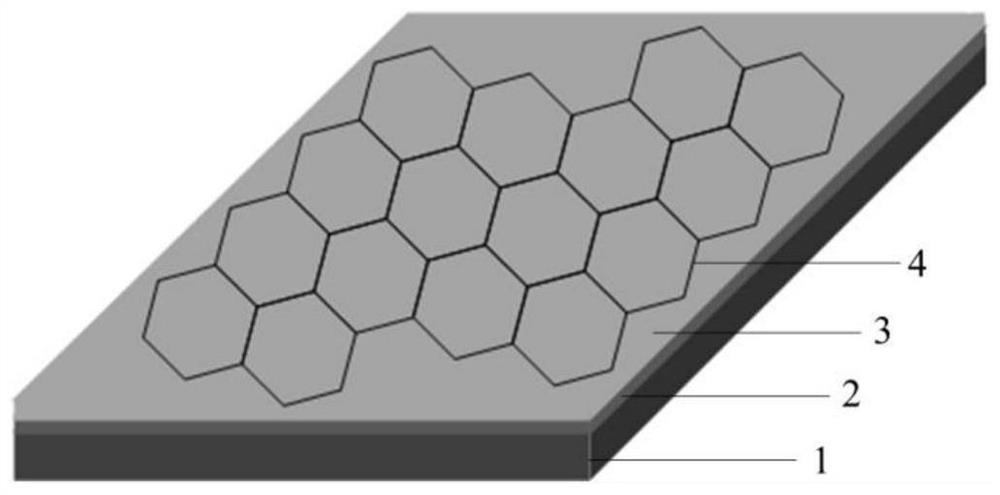

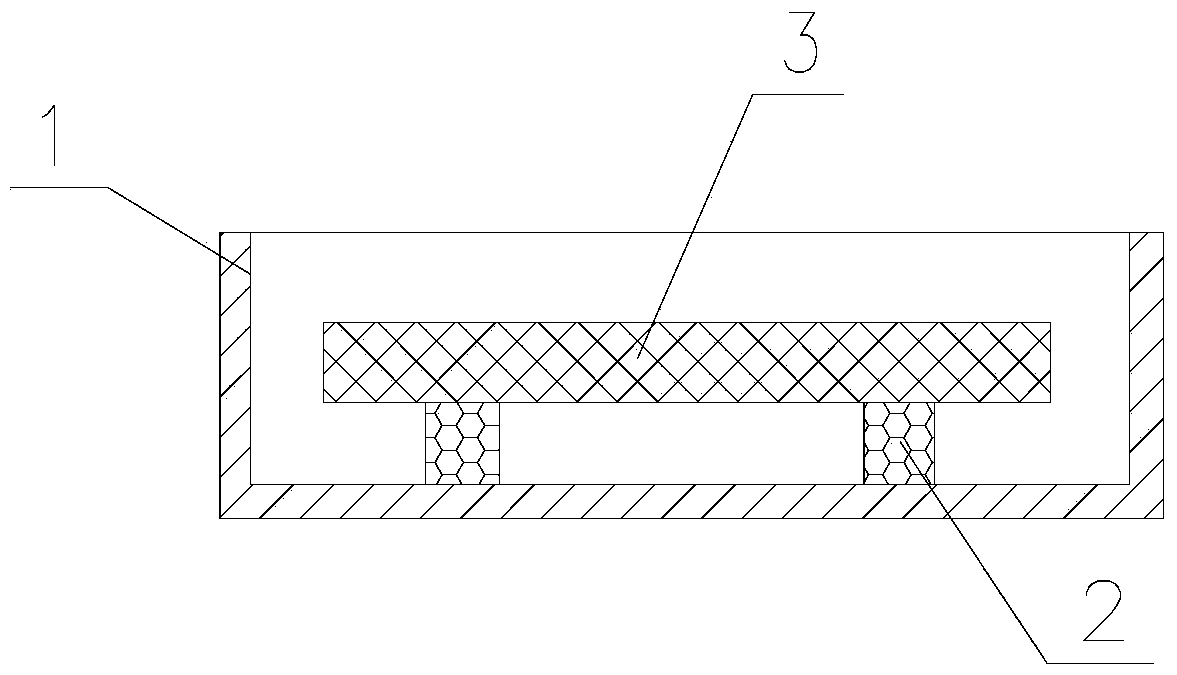

Packaging membrane used for vacuum insulation board and vacuum insulation board thereof

ActiveCN104742445ALow thermal conductivityLow costGlass/slag layered productsEngineeringProtection layer

The invention relates to a packaging membrane with large heatproof scope and flame retardation used for a vacuum insulation board and the vacuum insulation board by using the packaging membrane, and more specifically relates to the packaging membrane of a hot melt adhesive layer formed by employing ETFE. The packaging membrane comprises a protection layer, an air partition layer and the hot melt adhesive layer, the hot melt adhesive layer is an ETFE material layer, wherein the thickness is 15-95mum. The ETFE has little physical attribute influence to most chemical substances, has low permeability to common gas and steam, is in favor of increasing the isolation gas moisture performance of a membrane material, and is in favor of increasing comprehensive quality of VIP and prolonging its life span; ETFE flame retardation effect is better, and the flame resistance performance of the produced composite membrane is better.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

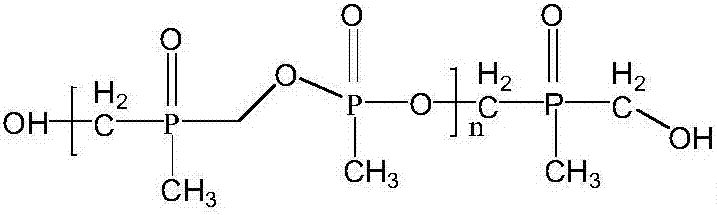

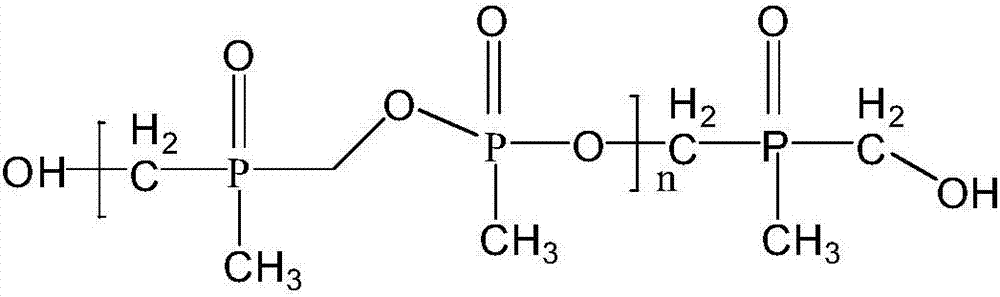

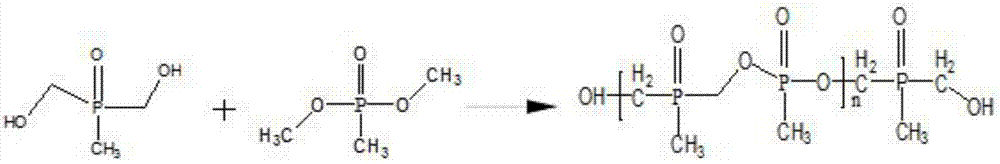

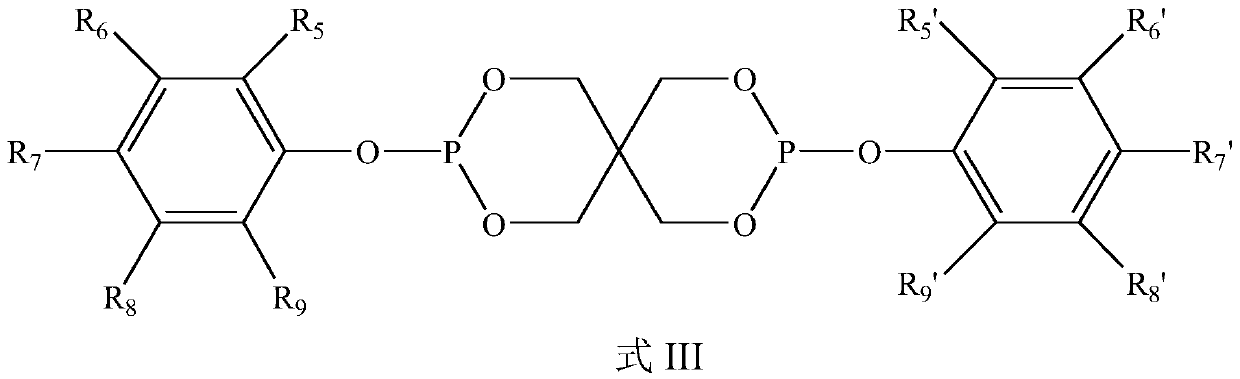

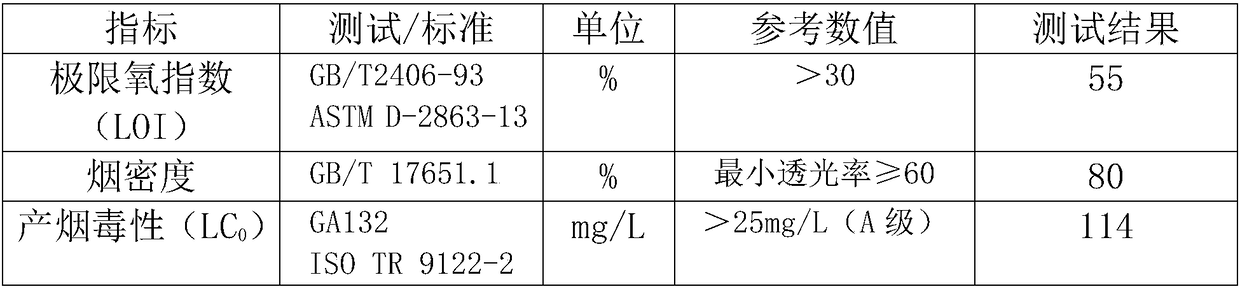

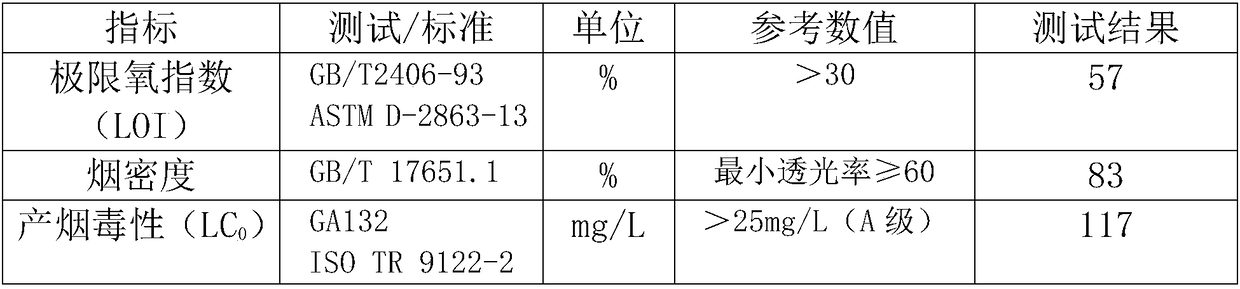

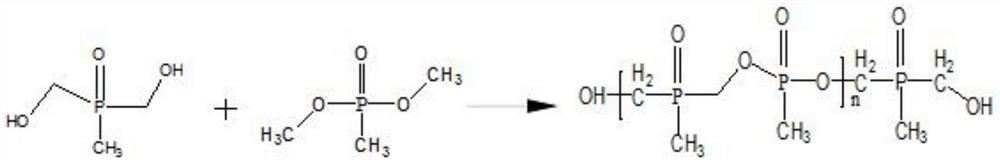

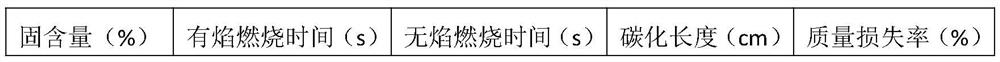

Oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant and preparation method thereof

ActiveCN107955039AHigh molecular weightHigh decomposition temperatureGroup 5/15 element organic compoundsLeather impregnationEpoxyPolyolefin

The invention relates to an oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant and a preparation method thereof. The preparation method includes: allowing a certain mole proportion of dihydroxymethyl methyl phosphine oxide and dimethyl methylphosphonate to have reaction for 4-7 hours under nitrogen protection, the effect of a catalyst and the temperature of 90-120DEG C, and performing pressure-reducing reaction for 0.5-2 hours under 120-150 DEG C to obtain the oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant. The oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant has the advantages that high-phosphorous-content polyphosphonate is oligomer, active hydroxyl functional groups in the structurecan well compatible with polymer materials, and migration cannot occur easily; the active hydroxyl functional groups can be combined with the polymer materials to form the flame-retardant material, and product stability and high decomposing temperature are achieved; the flame retardant is wide in application range and suitable for being used as the flame retardant of polyolefin, polyurethane, epoxy resin, unsaturated resin and leather. The preparation method is simple in process, low in equipment investment and easy to achieve industrial production.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

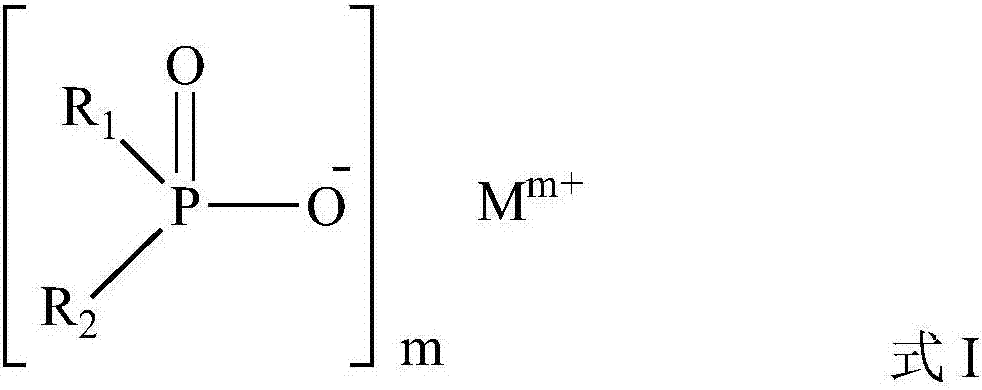

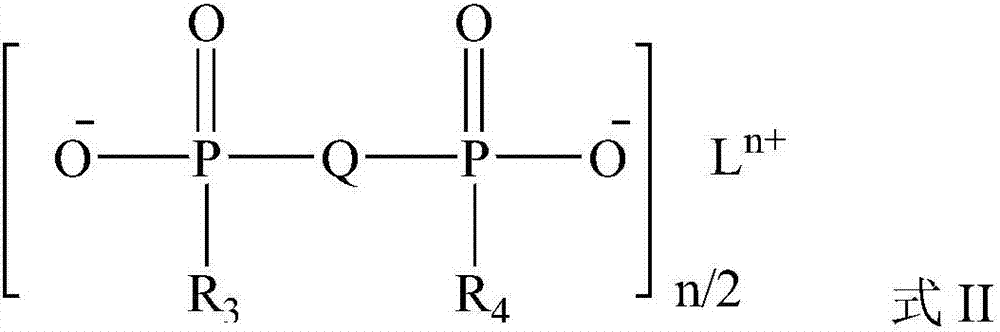

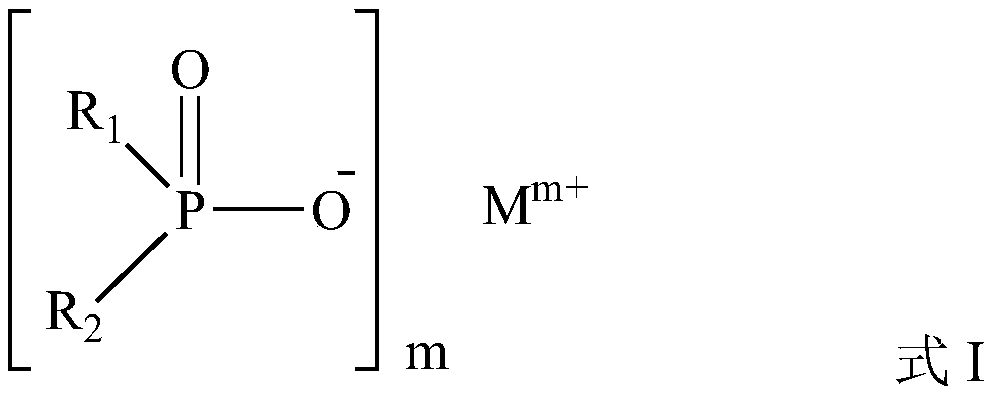

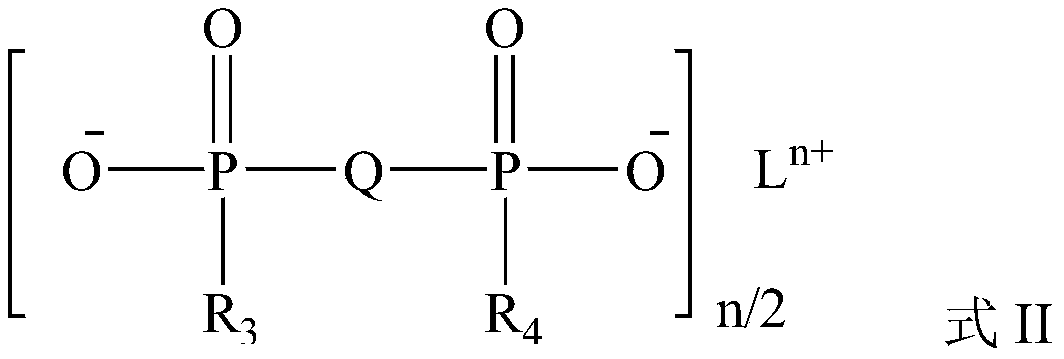

Halogen-free flame retardant and high-polymer material with same

ActiveCN107057300AImprove thermal stabilityHigh flame retardant efficiencyPentaerythritolCarboxylic salt

The invention discloses a halogen-free flame retardant. The halogen-free flame retardant is characterized by comprising components A and components B; the components A selectively comprise at least one type of compounds in chemical formulas shown as a formula I and compounds in chemical formulas shown as a formula II; the components B selectively comprise at least one type of phosphite of pentaerythritol, organophosphate of pentaerythritol and carboxylate ester of pentaerythritol. The halogen-free flame retardant has the advantages that the shortcoming of low flame retardant efficiency of dialkyl phosphinates for engineering plastics can be overcome by the aid of the halogen-free flame retardant, and the problems of low heat stability, poor flame retardant efficiency, narrow application range and possible defects in the aspects of processing and physical properties of dialkyl phosphinates synergists in the prior art can be solved by the aid of the halogen-free flame retardant.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

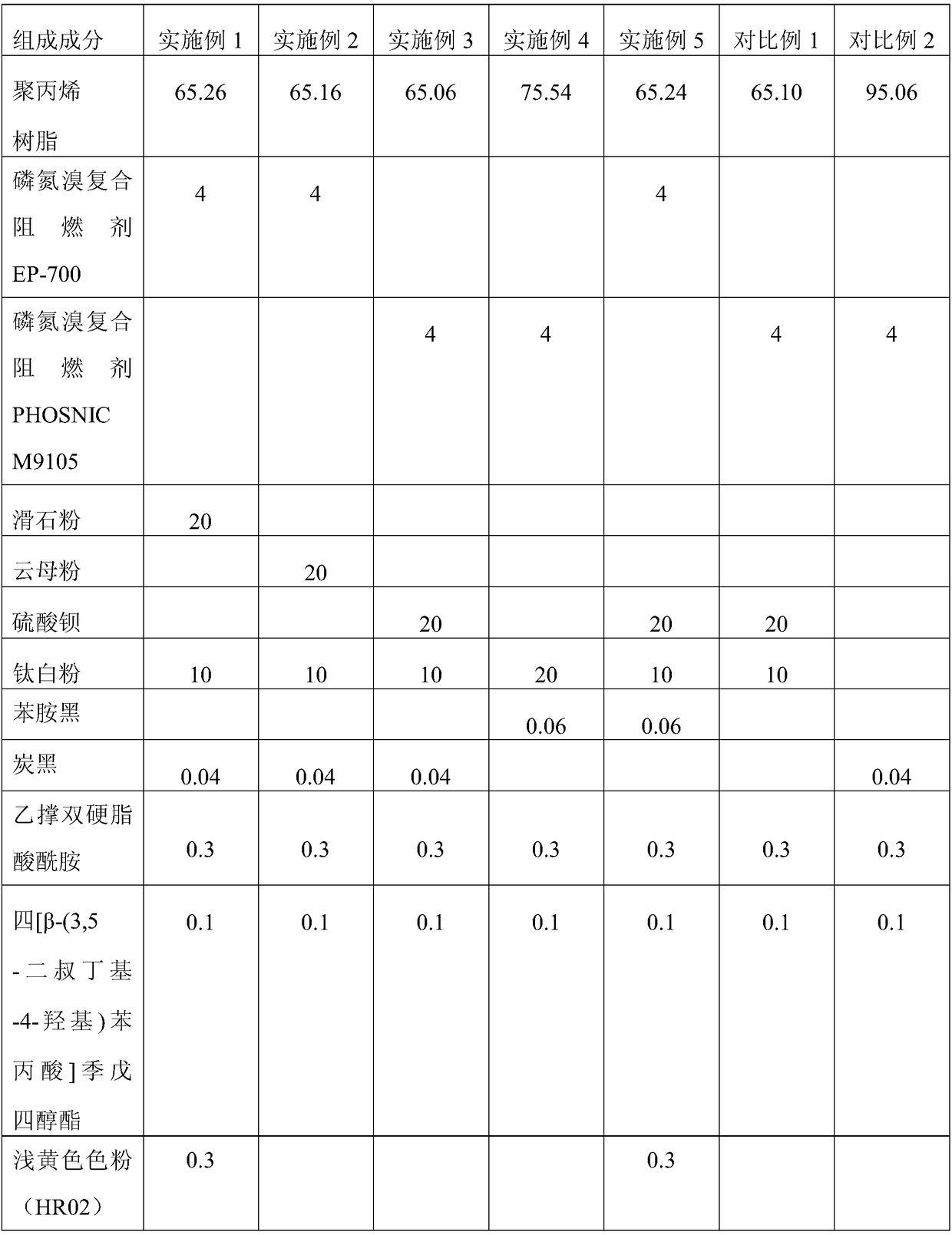

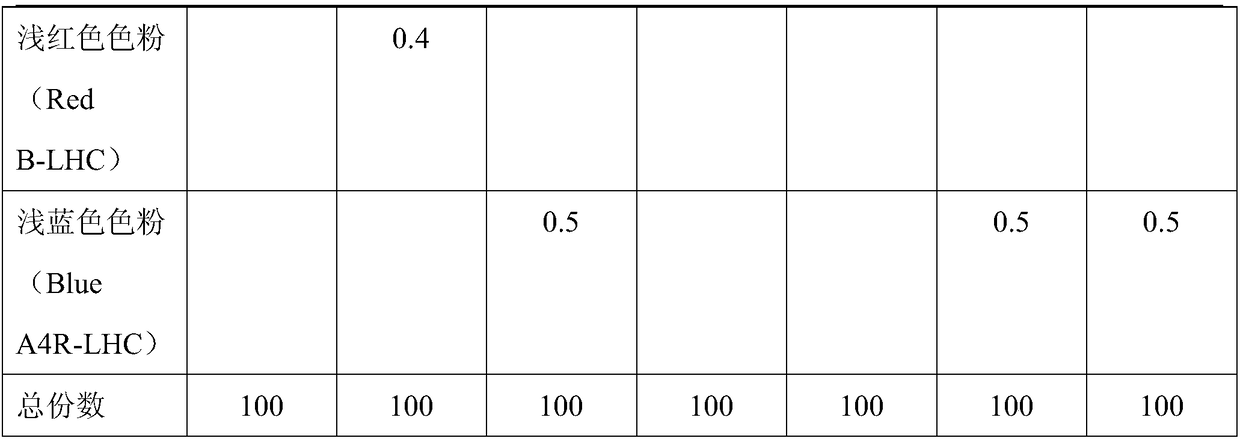

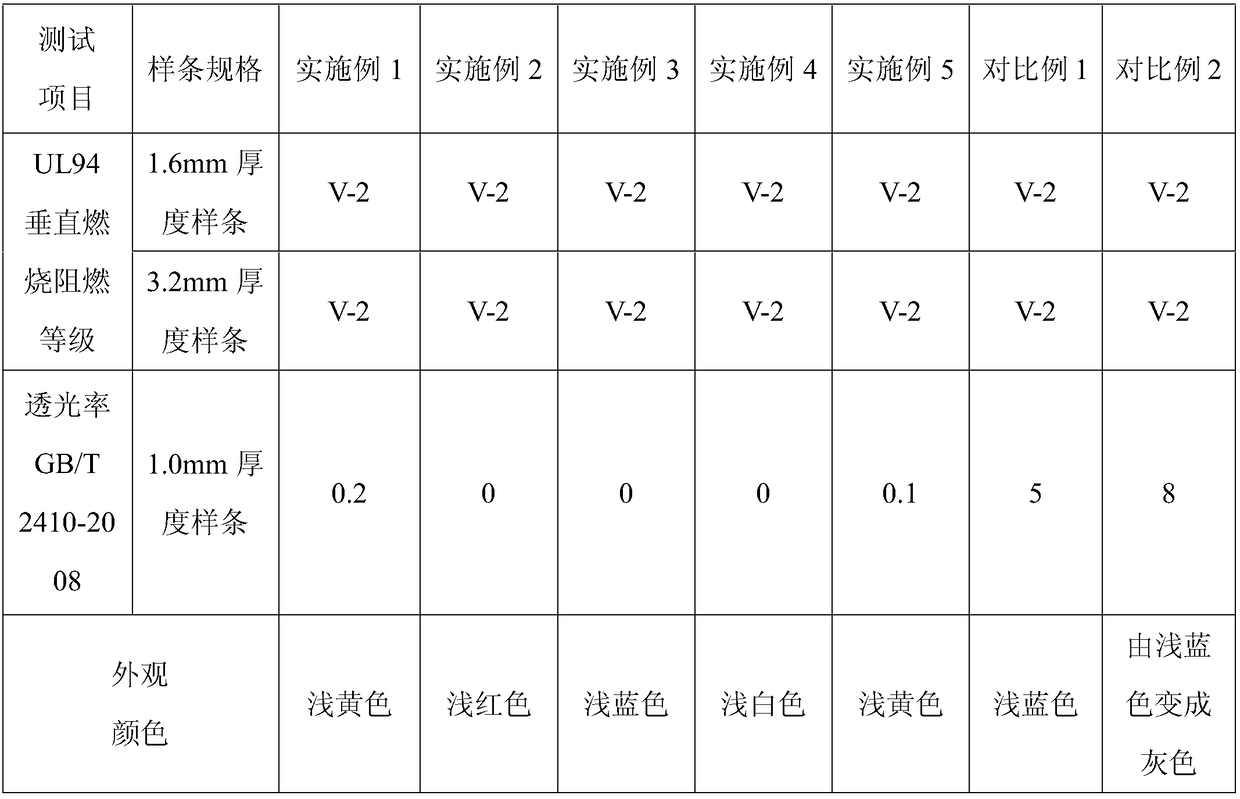

High-opacity white or light flame-retardant polypropylene composition and preparation method thereof

The invention discloses a high-opacity white or light flame-retardant polypropylene composition and a preparation method thereof. The high-opacity white or light flame-retardant polypropylene composition comprises, by weight, 35-75 parts of polypropylene resin, 3-5 parts of environment-friendly phosphorus, nitrogen and bromide composite flame retardant, 15-40 parts of opacifying agent A, 0.01-0.1part of opacifying agent B, 0.2-1 part of antioxygen, 0.3-1 part of lubricant and 0.1-1 part of white or light toner. By the aid of the efficient environment-friendly phosphorus, nitrogen and bromidecomposite flame retardant, the composition meets requirements for vertical combustion V2 grade of a UL94 flammability standard, by matching of the opacifying agent A and the opacifying agent B, extremely low transmission of light of the composition is realized, and the composition can be prepared into high white or various light colors. By utilizing the environment-friendly flame retardant, low toxicity and low smoke effects can be realized during combustion, mechanical property of the composition can be kept well, and the composition is applicable to preparation of various white or light products requiring flame retardant and lightproof effects.

Owner:中山市华邦塑料有限公司

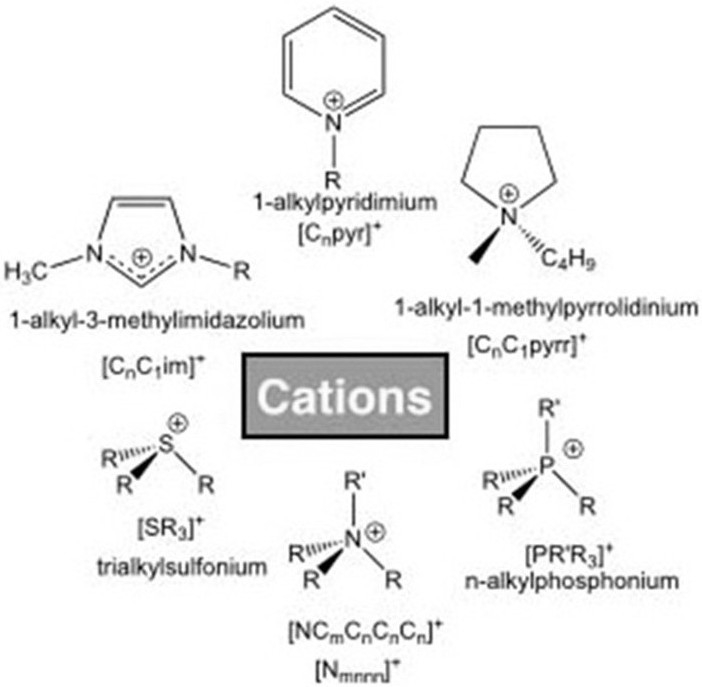

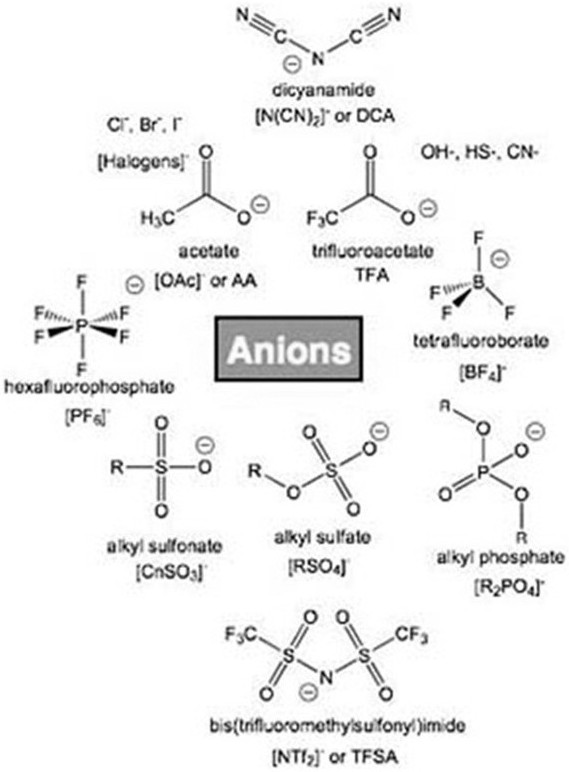

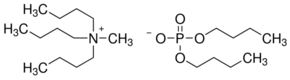

Flame-retardant thermoplastic polyurethane plastic, flame retardant and application

The invention discloses a novel flame-retardant thermoplastic polyurethane plastic (flame-retardant TPU), and components, preparation and application thereof. Specifically, the flame-retardant TPU disclosed by the invention comprises polyether type TPU and polyester type TPU, the TPU flame retardant disclosed by the invention comprises an ionic liquid component, and the ionic liquid can be a single ionic liquid component, can be shared by several ionic liquids, and can also be a mixture of the ionic liquid and a traditional flame retardant. The flame-retardant TPU plastic plate disclosed by the invention can be applied to the fields of automobiles, buildings, national defense, aviation and the like.

Owner:南通诺为新材料科技有限公司

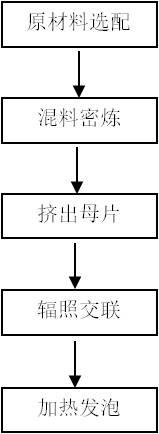

Flame-retardant irradiation cross-linked polyethylene foam material and preparation method thereof

InactiveCN113402803AImprove qualityEasy to processLinear low-density polyethyleneLow-density polyethylene

The invention discloses a flame-retardant irradiation cross-linked polyethylene foam material, which comprises the following components: 35-45 parts of low-density polyethylene, 5-15 parts of linear low-density polyethylene, 5-15 parts of high-density polyethylene, 10-15 parts of a polyolefin elastomer, 2-10 parts of a foaming agent, 2-10 parts of a foaming aid, 0.5-5 parts of a cross-linking agent, 5-20 parts of decabromodiphenyl ethane, 1-10 parts of antimony trioxide, 4-8 parts of magnesium hydroxide, 1-10 parts of talcum powder and 1-5 parts of a compatibilizer, wherein under the condition of 190 DEG C*2.16 kg, the melt index of the low-density polyethylene is 1-3 g / 10 min, the melt index of the linear low-density polyethylene is 2-6 g / 10 min, and the melt index of the high-density polyethylene is 7-22 g / 10 min. According to the invention, the flame-retardant irradiation cross-linked polyethylene foam material is simple in preparation process, and the obtained product is good in size stability, cell compactness and uniformity, non-toxic, free of peculiar smell and excellent in flame retardance.

Owner:中广核高新核材科技(苏州)有限公司 +1

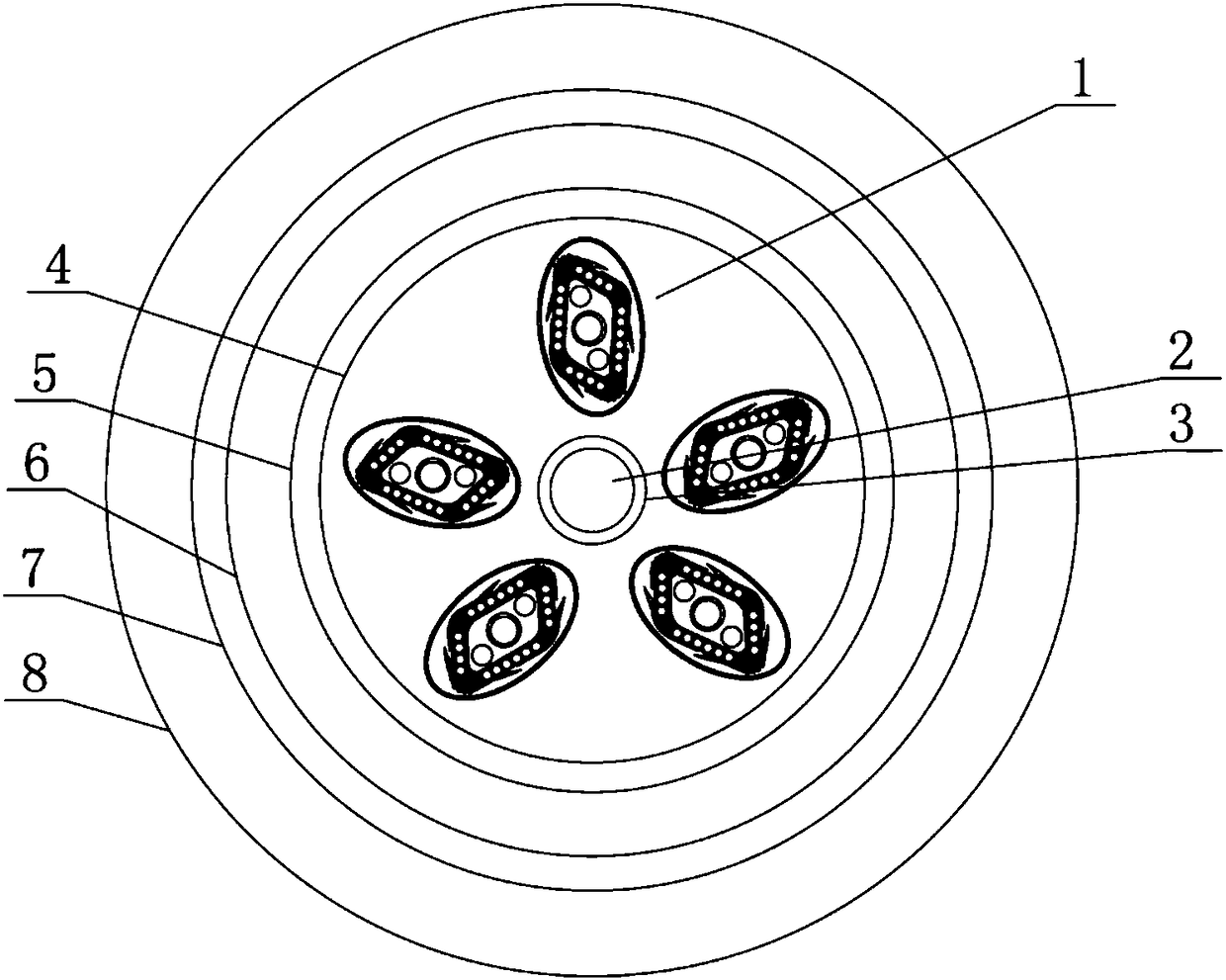

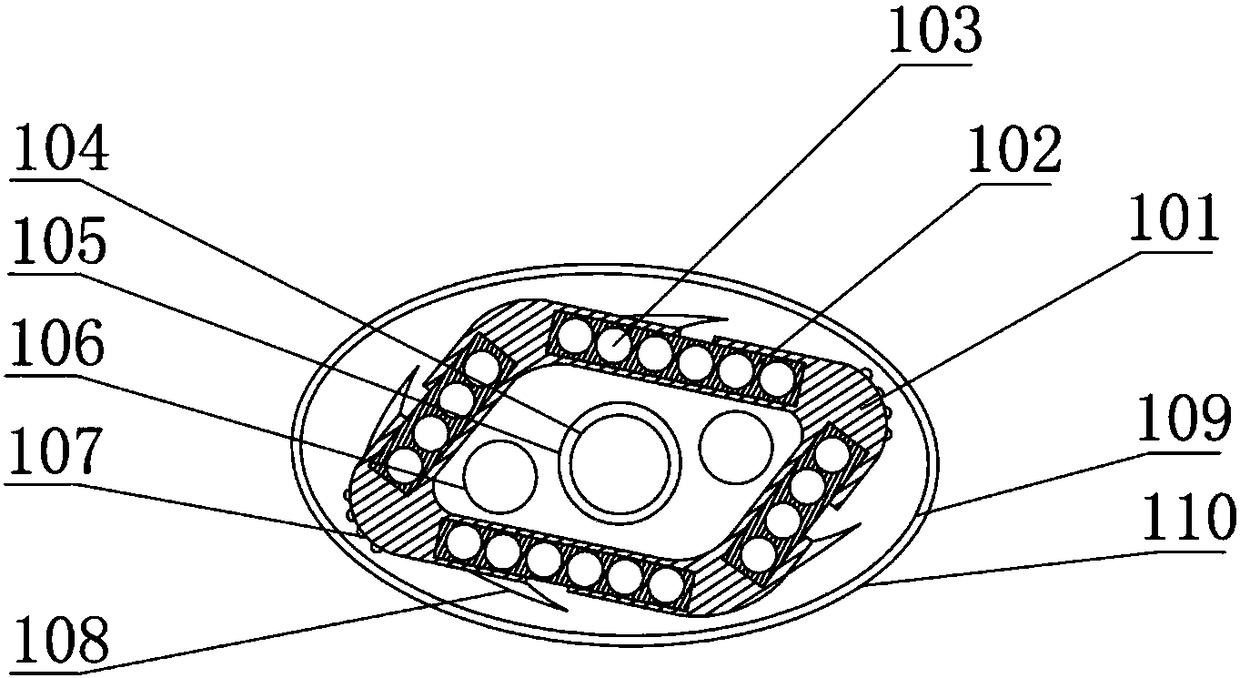

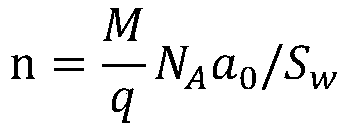

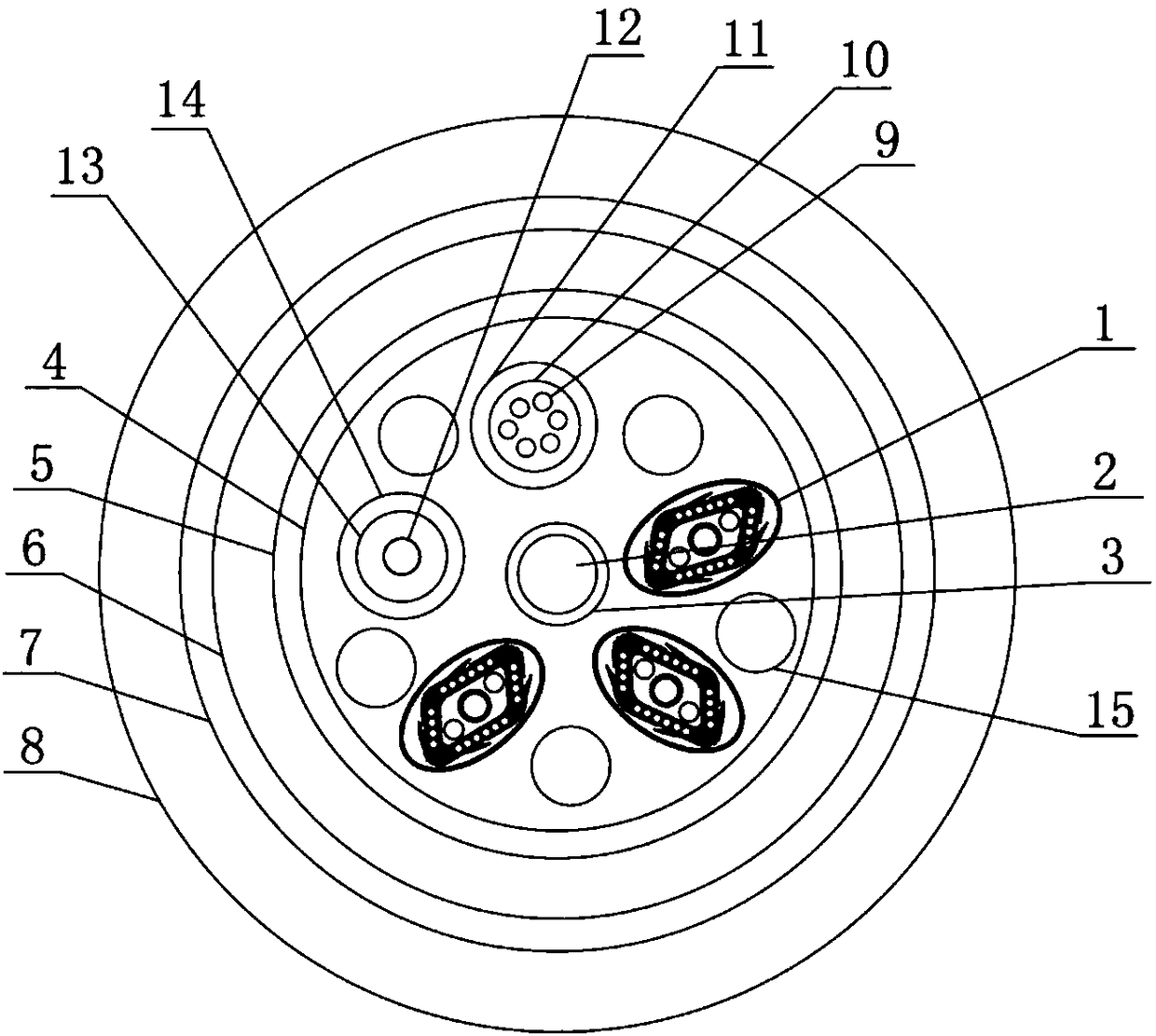

Layer-stranded strip-shaped optical cable

PendingCN108387987AImproved flexural and tensile propertiesStable performanceFibre mechanical structuresEngineeringFire retardant

The invention discloses a layer-stranded strip-shaped optical cable. The layer-stranded strip-shaped optical cable comprises five optical fiber parts and a first metal reinforcing core, the optical fiber parts are uniformly distributed in an insulating layer, and the first metal reinforcing core is arranged in the middle of the insulating layer; a water stopping layer is arranged outside the insulating layer, an inner sheath is arranged outside the water stopping layer, a reinforcing layer is arranged outside the inner sheath, and an outer sheath is arranged outside the reinforcing layer; eachoptical fiber part comprises an accommodating part and an optical fiber belt, an insulating inner layer covers the periphery of each optical fiber belt, the optical belts are arranged in rectangulargrooves, filling layers are arranged among the rectangular grooves and the optical fiber belts, shielding layers are arranged outside the rectangular grooves, and reinforcing cores are arranged amongthe rectangular grooves and the shielding layers. The layer-stranded strip-shaped optical cable has good stretch resistance, water resistance, a good fire retardant effect, a large transmission capacity, a high speed, and good interference resistance, and is suitable for an occasion in which a large-scale network is built.

Owner:SHAANXI SCI TECH UNIV

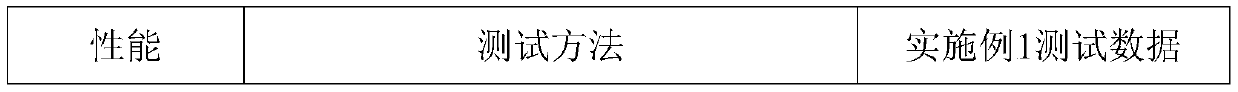

Ultrafine modified magnesium hydroxide flame retardant and preparation method thereof

PendingCN111073666AHigh flame retardant efficiencyLittle impact on physical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsMagnesium saltActive agent

The invention relates to the technical field of inorganic flame retardant materials, in particular to an ultrafine modified magnesium hydroxide flame retardant and a preparation method thereof. The superfine modified magnesium hydroxide flame retardant is prepared from the following preparation raw materials in parts by weight: 30-50 parts of an alkaline precipitator, 20-30 parts of magnesium salt, 6-8 parts of an activating agent, 8-12 parts of a surfactant and 1-3 parts of a dispersing agent. The superfine modified magnesium hydroxide flame retardant prepared by the invention has the advantages of higher flame-retardant efficiency, favorable compatibility with materials, higher cost performance, environment friendliness and no toxicity.

Owner:HEFEI ZHONGKE FLAME RETARDANT NEW MATERIAL

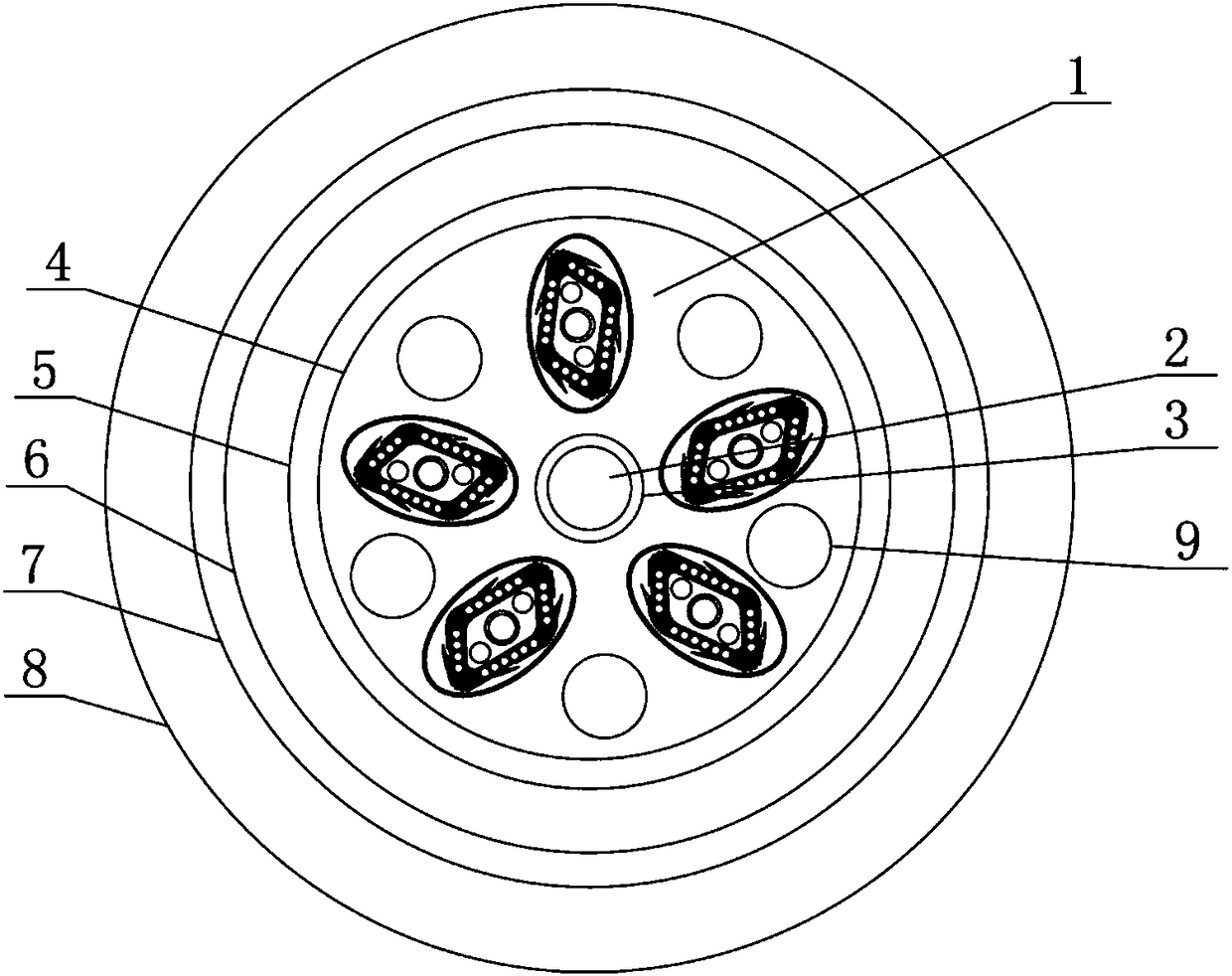

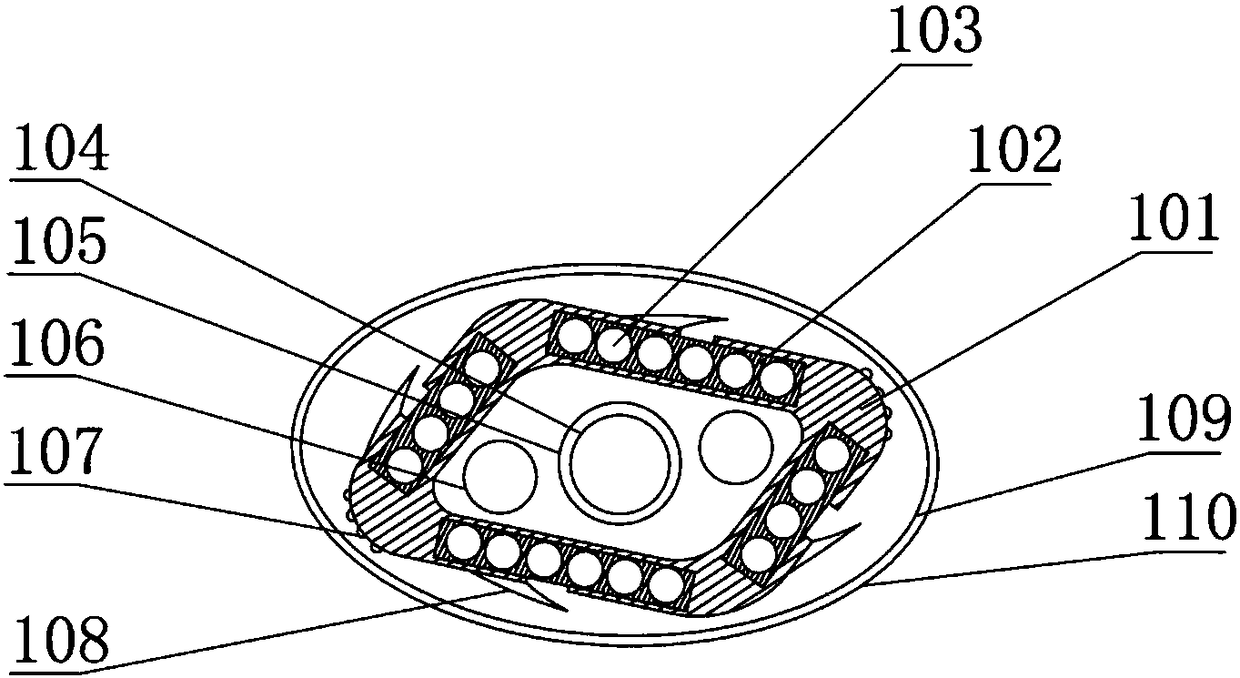

Composite ribbon optical cable

PendingCN108398758AImprove bending resistanceImprove tensile propertiesFibre mechanical structuresBand shapeEngineering

The invention discloses a composite ribbon optical cable. The optical fiber comprises a first optical fiber part, a second optical fiber part, a third optical fiber part and a first metal reinforcingcore; the first optical fiber part, the second optical fiber part and the third optical fiber part are uniformly distributed in an insulating layer; a first water blocking layer is arranged outside the insulating layer, a first shielding layer is arranged outside the first water blocking layer, a reinforcing layer is arranged outside the first shielding layer, and an outer sheath is arranged outside the reinforcing layer; the first optical fiber part comprises a containing part and an optical fiber ribbon, the containing part is a rhombic frame body, a second metal reinforcing core is arrangedin an inner cavity of the rhombic frame body, and a PE cushion layer is arranged outside the second metal reinforcing core; the rhombic frame body comprises a first side edge, a second side edge, a third side edge and a fourth side edge, and the first side edge, the second side edge, the third side edge and the fourth side edge are each provided with a rectangular groove; the optical fiber ribbonis arranged in the rectangular grooves. The tensile property and water resistance of the optical fiber are good, and meanwhile, the optical fiber is good in flame-retardant effect, high in transmission capacity, high in speed, good in anti-interference performance and suitable for being applied to occasions with large-scale networks.

Owner:SHAANXI SCI TECH UNIV

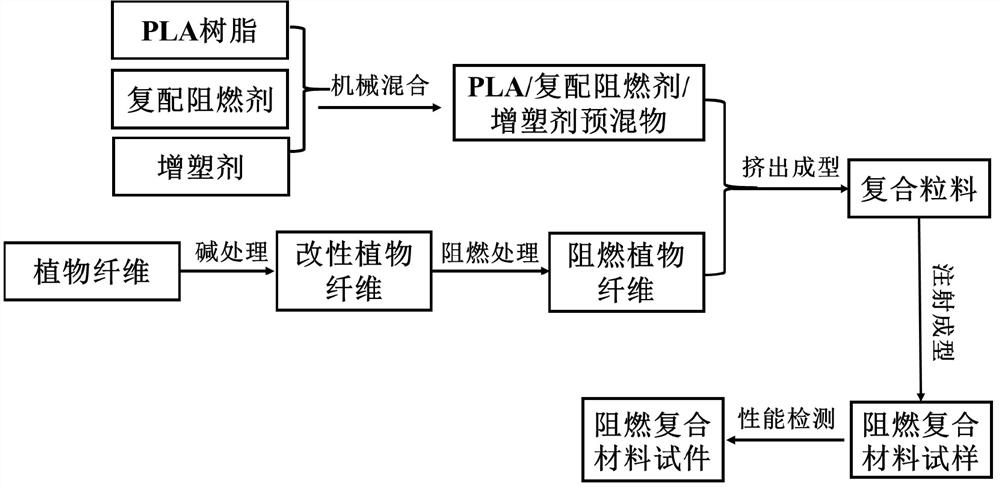

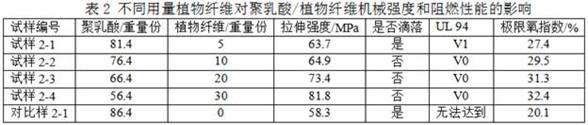

Compound halogen-free flame-retardant plant fiber reinforced polylactic acid material and preparation method thereof

ActiveCN111793338AEfficient flame retardantLittle impact on physical propertiesPolymer scienceAntioxidant

The invention belongs to the technical field of modification of biodegradable polymer materials, and particularly relates to a compound halogen-free flame-retardant plant fiber reinforced polylactic acid material and a preparation method thereof. The preparation method comprises the following steps: (1) putting plant fibers into 1-8 wt% of an alkaline solution, carrying out surface modification, putting the modified plant fibers into 0.5-5 wt% of an ammonium polyphosphate solution, and carrying out flame-retardant treatment to obtain flame-retardant plant fibers; and (2) uniformly mixing polylactic acid, a compound flame retardant, a flexibilizer and an antioxidant, carrying out melt blending on the obtained mixture and the flame-retardant plant fiber obtained in the step (1), and carryingout cooling granulation to obtain a polylactic acid / plant fiber composite material with flame retardancy, namely the compound halogen-free flame-retardant plant fiber reinforced polylactic acid material. According to the invention, the plant fibers are subjected to flame retardant pretreatment, so that the flame retardant property and mechanical strength of the plant fiber / polylactic acid composite material are significantly improved.

Owner:ZHENGZHOU UNIV

A kind of halogen-free flame retardant and polymer material using the halogen-free flame retardant

ActiveCN107057300BImprove thermal stabilityHigh flame retardant efficiencyPentaerythritolEngineering plastic

The invention discloses a halogen-free flame retardant. The halogen-free flame retardant is characterized by comprising components A and components B; the components A selectively comprise at least one type of compounds in chemical formulas shown as a formula I and compounds in chemical formulas shown as a formula II; the components B selectively comprise at least one type of phosphite of pentaerythritol, organophosphate of pentaerythritol and carboxylate ester of pentaerythritol. The halogen-free flame retardant has the advantages that the shortcoming of low flame retardant efficiency of dialkyl phosphinates for engineering plastics can be overcome by the aid of the halogen-free flame retardant, and the problems of low heat stability, poor flame retardant efficiency, narrow application range and possible defects in the aspects of processing and physical properties of dialkyl phosphinates synergists in the prior art can be solved by the aid of the halogen-free flame retardant.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

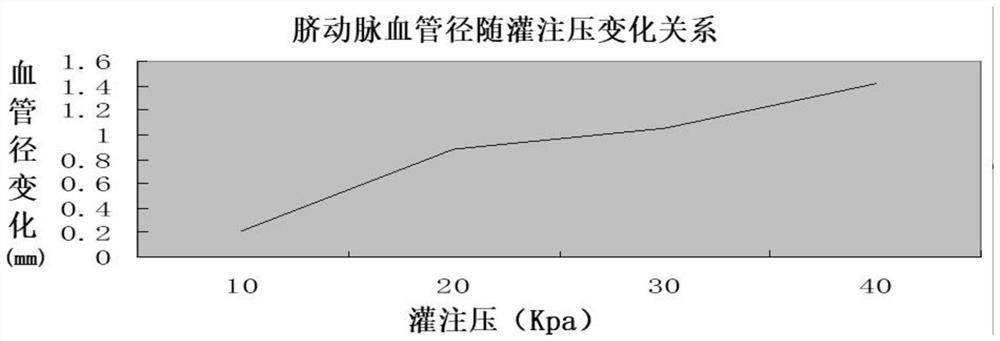

Application of umbilical artery in preparation of graft blood vessel material for coronary artery bypass grafting and method for preparing graft blood vessel material for coronary artery bypass grafting

InactiveCN114504682ALarge caliberLittle impact on physical propertiesTissue regenerationProsthesisCoronary arteriesCoronary Artery Bypasses

The invention relates to the field of biomedicine, in particular to application of an umbilical artery in preparation of a vascular graft material for coronary artery bypass grafting and a method for preparing the vascular graft material for coronary artery bypass grafting. The feasibility of applying the umbilical artery to coronary artery bypass grafting is discussed from the aspects of the physiological anatomical structure of the umbilical artery, the antigenic removal and anti-calcification treatment effect, animal experiments and the like, and a new vascular transplantation material source is found for coronary artery vascular reconstruction. Test results show that the umbilical artery can meet the requirements of being used as a blood vessel transplantation material for coronary artery bypass grafting in the aspects of physiological anatomical structure and physical performance; the diameter of the umbilical artery can be increased through hydraulic expansion, spasm is prevented, and obvious damage to the vascular structure is not caused. After the umbilical artery is treated by adopting a liquid nitrogen profound hypothermia and glutaraldehyde (GA) method, the antigenic and anti-calcification effects are good, the influence on the physical properties of blood vessels is relatively small, and the method is easy to implement and can be stored for a relatively long time.

Owner:李平

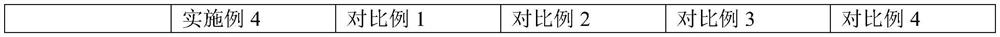

Alkaline finishing method of low-gram-weight polyester colored gauze

PendingCN114808435AAvoid tearingAvoid the phenomenon of slippingLight resistant fibresLiquid repellent fibresPolyesterYarn

The invention relates to the technical field of polyester colored gauze finishing, and discloses an alkaline finishing method for low-gram-weight polyester colored gauze, which comprises the following steps: immersing the low-gram-weight polyester colored gauze into an alkaline finishing agent, heating to 100-110 DEG C, preserving heat for 10-30 minutes, cooling, taking out and drying; the gram weight of the low-gram-weight polyester colored gauze is 85-125g / m < 2 >; the alkaline finishing agent comprises hydrogen peroxide and liquid caustic soda, and the pH is 8-10. The alkaline finishing agent hydrolyzes fiber ester bonds, and fibers on the surface of the low-gram-weight polyester color gauze generate an alkaline etching effect, so that the surface of the color gauze becomes smooth, the phenomena of yarn cracking and stitch slipping are avoided, and the product quality is improved; the mechanical property of the finished low-gram-weight polyester colored gauze is still good, and particularly, the tensile strength and the wear resistance of gray fabric are optimal; the finishing time can be shortened, and the purposes of saving energy, reducing consumption and reducing cost are achieved.

Owner:圣山集团有限公司

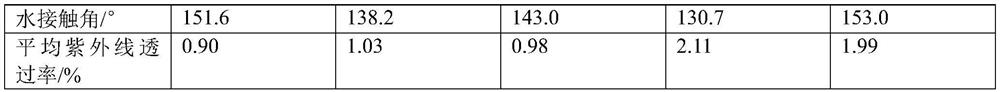

Gas blocking agent and preparing method and application thereof

The invention discloses a gas blocking agent and a preparing method and application thereof. The main component of the gas blocking agent is modified calcium carbonate. The gas blocking agent is a novel material formed in the manner that the surface of the superfine calcium carbonate is processed by a coupling agent and a dispersing auxiliary. The gas blocking agent has a slabbed structure and is high-quality fine-layer sheet structure powder. The preparing method is simple, raw materials are easy to obtain, and cost is low. The gas blocking agent is applied to tire air impervious liner sizing materials. The physical performance of the sizing materials is hardly affected after 10-40 parts of gas blocking agent is added to the air impervious liner sizing materials, bubbles are obviously reduced during attachment, cord fabric and the air impervious liner sizing materials can be bonded very well, the lamination processing performance is improved, and due to the fact that the gas blocking agent is added to the air impervious liner, the air impermeability of a finished inner tube can be improved, and the sizing material cost can be reduced.

Owner:SHANDONG FENGYUAN TIRE MFG +1

Packaging film for vacuum insulation panel and vacuum insulation panel

ActiveCN104742445BWide temperature rangeHigh tensile strengthGlass/slag layered productsHot meltProtection layer

The invention relates to a packaging membrane with large heatproof scope and flame retardation used for a vacuum insulation board and the vacuum insulation board by using the packaging membrane, and more specifically relates to the packaging membrane of a hot melt adhesive layer formed by employing ETFE. The packaging membrane comprises a protection layer, an air partition layer and the hot melt adhesive layer, the hot melt adhesive layer is an ETFE material layer, wherein the thickness is 15-95mum. The ETFE has little physical attribute influence to most chemical substances, has low permeability to common gas and steam, is in favor of increasing the isolation gas moisture performance of a membrane material, and is in favor of increasing comprehensive quality of VIP and prolonging its life span; ETFE flame retardation effect is better, and the flame resistance performance of the produced composite membrane is better.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

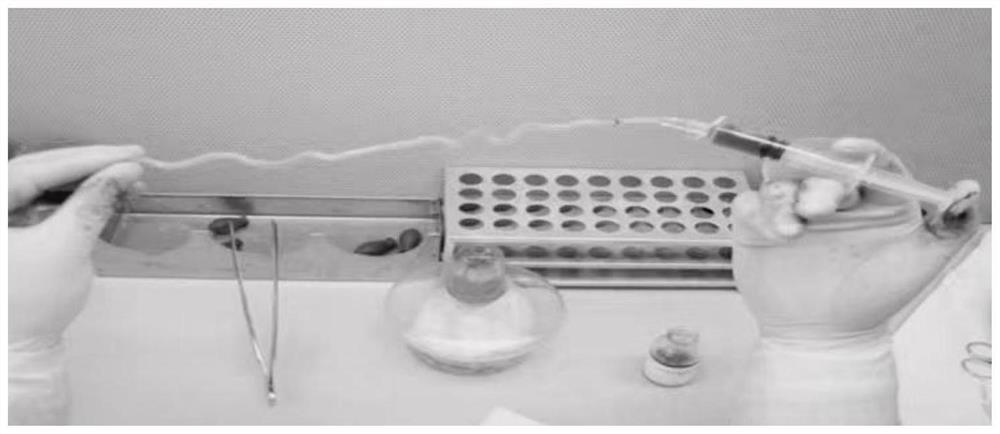

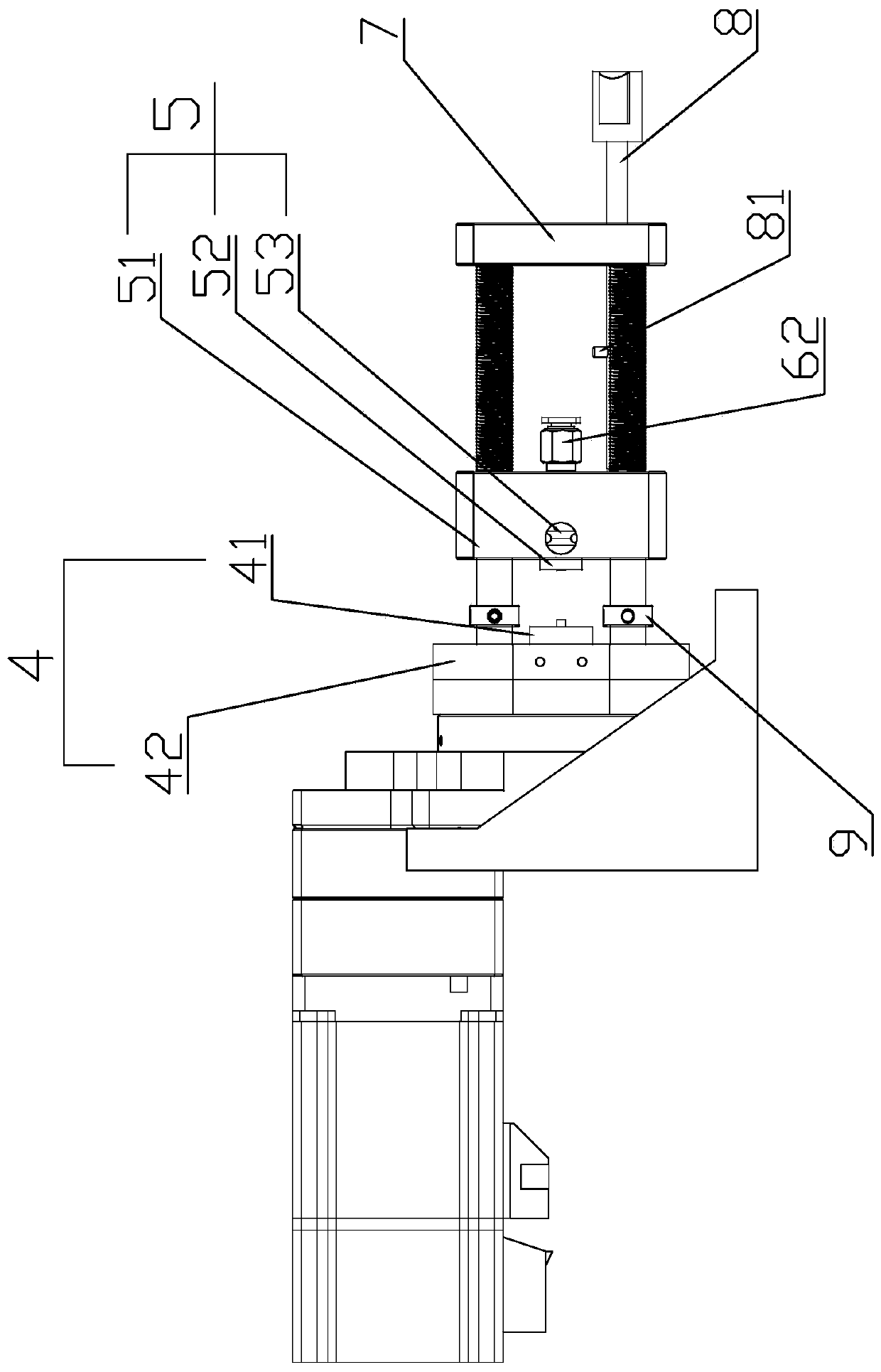

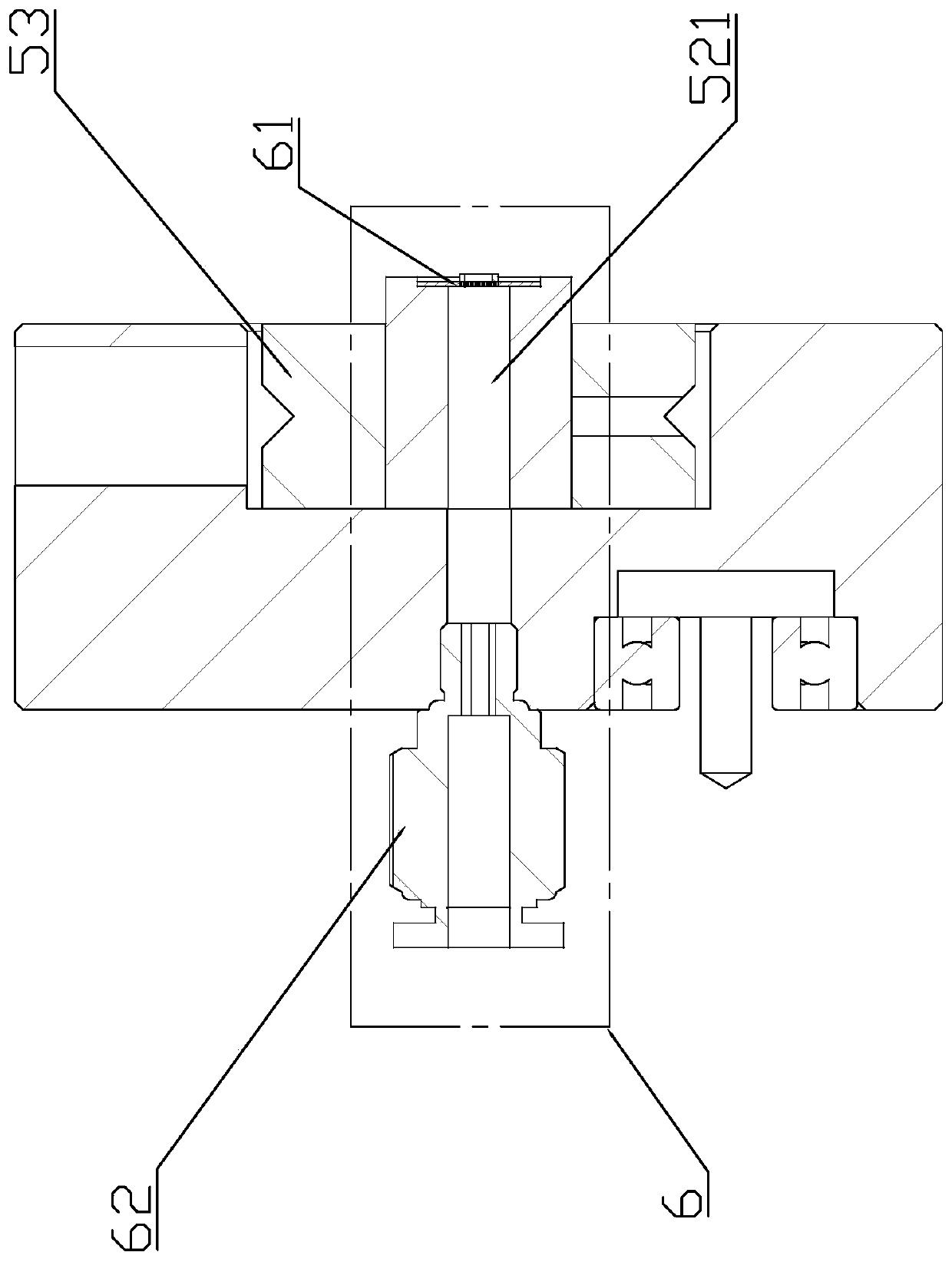

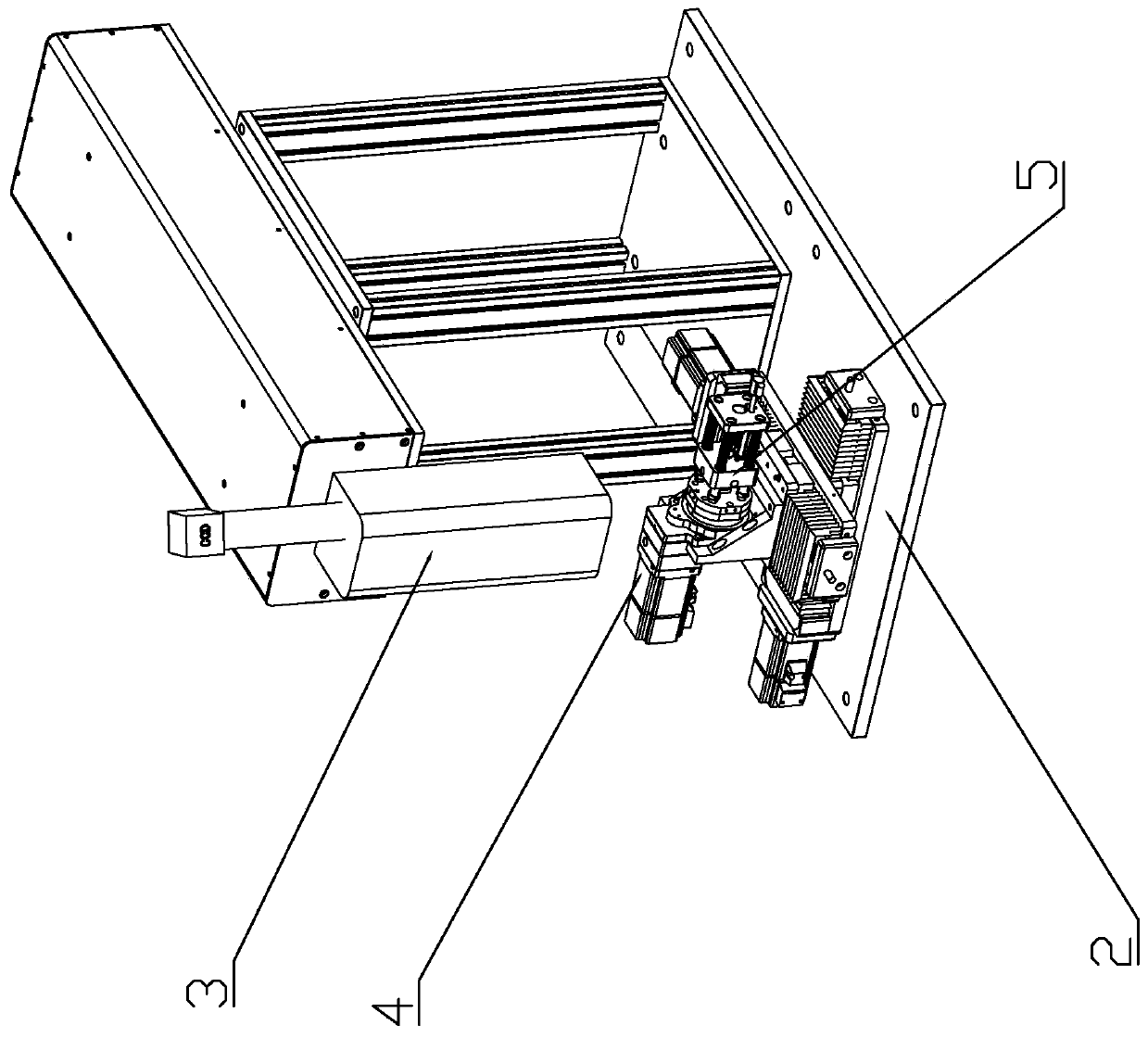

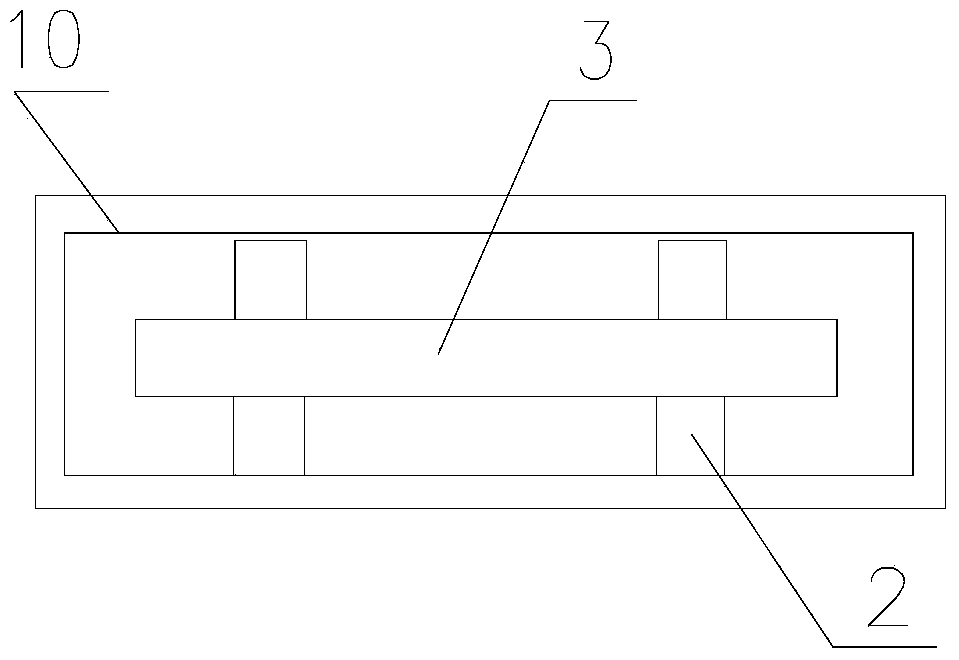

A crystal welding equipment

ActiveCN108788458BEffect of light transmissionLittle impact on physical propertiesWelding/soldering/cutting articlesMetal working apparatusElectric machineEngineering

The invention discloses a crystal welding device, and relates to the field of crystals.. The crystal welding device comprises a rack, a laser generator and a crystal clamping mechanism; the crystal clamping mechanism comprises a rotating motor, a crystal positioning block and a membrane clamping mechanism, the membrane clamping mechanism comprises a sliding table and a membrane positioning block,the sliding table can slide in the left and right direction, the membrane positioning block is arranged on the left side of the sliding table, an electric control system is further included and is electrically connected with the laser generator and the rotating motor, two parts are tightly pressed, through the laser heating melting welding manner, the two parts can be evenly and compactly connected, and the welding quality is higher; in addition, through a fixing table, a pull rod and a spring, the membrane clamping mechanism and the crystal clamping mechanism can be conveniently kept in tightpressing or separation, and through an absorbing device, the membrane is prevented from falling off when the sliding table moves.

Owner:佛山市富兰激光科技有限公司

Anticorrosive coating for nano metal and preparation method of anticorrosive coating

PendingCN112108346AConducive to long-term stabilityLittle impact on physical propertiesPretreated surfacesAnti-corrosive paintsPoly ethyleneBoron nitride

The invention discloses an anticorrosive coating for nano metal and a preparation method of the anticorrosive coating. The anticorrosive coating comprises a polymer coating and a two-dimensional material coating, the polymer coating is arranged on the surface of an easily oxidized precious metal nano structure, and the polymer and two-dimensional material nano coating is formed on the surface of the metal nano structure after a two-dimensional material is transferred. The polymer coating is any one of a polyvinylpyrrolidone (PVP) layer, a polymethyl methacrylate (PMMA) layer and a polydimethylsiloxane (PDMS) layer, and the two-dimensional material is graphene or hexagonal boron nitride (hBN). The polymer and two-dimensional material mixed coating prepared by the invention can protect an easily oxidized metal nano material, and is beneficial to the long-term stable use of the nano structure.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Low-smoke-amount flame-retardant optical cable factice

ActiveCN108456430AReduced compatibilityHigh content of saturated hydrocarbonsFibre mechanical structuresParaffin waxAntioxidant

The invention discloses low-smoke-amount flame-retardant optical cable factice. The factice comprises, by mass, 78-85 parts of base oil, 9-12 parts of composite thickener, 0.8-1.5 parts of flame retardant and 0.5-0.8 part of antioxidant. The base oil is hydrogenated paraffin base oil and hydrogenated naphthene base oil mixed oil, and the mass ratio of hydrogenated paraffin base oil to hydrogenatednaphthene base oil is (2-2.5):(3-4.2); the composite thickener comprises polyacrylamide and fatty alcohol-polyoxyethylene ether, and the mass ratio of polyacrylamide to fatty alcohol-polyoxyethyleneether is (5-6):(7-8); the flame retardant comprises triallyl isocyanurate and nano tin powder, and the mass ratio of triallyl isocyanurate to the nano tin powder is (90-100):(0.15-0.2). The factice solves the technical problems that optical fibers are easy to combust and release a large amount of toxic smoke and toxic gas in combustion. The low-smoke-amount flame-retardant optical cable factice isprovided, the high-molecular reaction type flame retardant is added, the factice does not contain halogen-free flame retardant, the smoke amount is low, and the performance of the factice is not influenced.

Owner:SHAANXI SCI TECH UNIV

Oligomer type high phosphorus content polyphosphonate halogen-free flame retardant and preparation method thereof

ActiveCN107955039BHigh molecular weightHigh decomposition temperatureGroup 5/15 element organic compoundsLeather impregnationEpoxyPolymer science

The invention relates to an oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant and a preparation method thereof. The preparation method includes: allowing a certain mole proportion of dihydroxymethyl methyl phosphine oxide and dimethyl methylphosphonate to have reaction for 4-7 hours under nitrogen protection, the effect of a catalyst and the temperature of 90-120DEG C, and performing pressure-reducing reaction for 0.5-2 hours under 120-150 DEG C to obtain the oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant. The oligomer type high-phosphorous-content polyphosphonate halogen-free flame retardant has the advantages that high-phosphorous-content polyphosphonate is oligomer, active hydroxyl functional groups in the structurecan well compatible with polymer materials, and migration cannot occur easily; the active hydroxyl functional groups can be combined with the polymer materials to form the flame-retardant material, and product stability and high decomposing temperature are achieved; the flame retardant is wide in application range and suitable for being used as the flame retardant of polyolefin, polyurethane, epoxy resin, unsaturated resin and leather. The preparation method is simple in process, low in equipment investment and easy to achieve industrial production.

Owner:TIANJIN UNIV OF SCI & TECH

A low-smoke flame-retardant optical cable ointment

ActiveCN108456430BReduced compatibilityHigh content of saturated hydrocarbonsFibre mechanical structuresParaffin waxAntioxidant

The invention discloses low-smoke-amount flame-retardant optical cable factice. The factice comprises, by mass, 78-85 parts of base oil, 9-12 parts of composite thickener, 0.8-1.5 parts of flame retardant and 0.5-0.8 part of antioxidant. The base oil is hydrogenated paraffin base oil and hydrogenated naphthene base oil mixed oil, and the mass ratio of hydrogenated paraffin base oil to hydrogenatednaphthene base oil is (2-2.5):(3-4.2); the composite thickener comprises polyacrylamide and fatty alcohol-polyoxyethylene ether, and the mass ratio of polyacrylamide to fatty alcohol-polyoxyethyleneether is (5-6):(7-8); the flame retardant comprises triallyl isocyanurate and nano tin powder, and the mass ratio of triallyl isocyanurate to the nano tin powder is (90-100):(0.15-0.2). The factice solves the technical problems that optical fibers are easy to combust and release a large amount of toxic smoke and toxic gas in combustion. The low-smoke-amount flame-retardant optical cable factice isprovided, the high-molecular reaction type flame retardant is added, the factice does not contain halogen-free flame retardant, the smoke amount is low, and the performance of the factice is not influenced.

Owner:SHAANXI SCI TECH UNIV

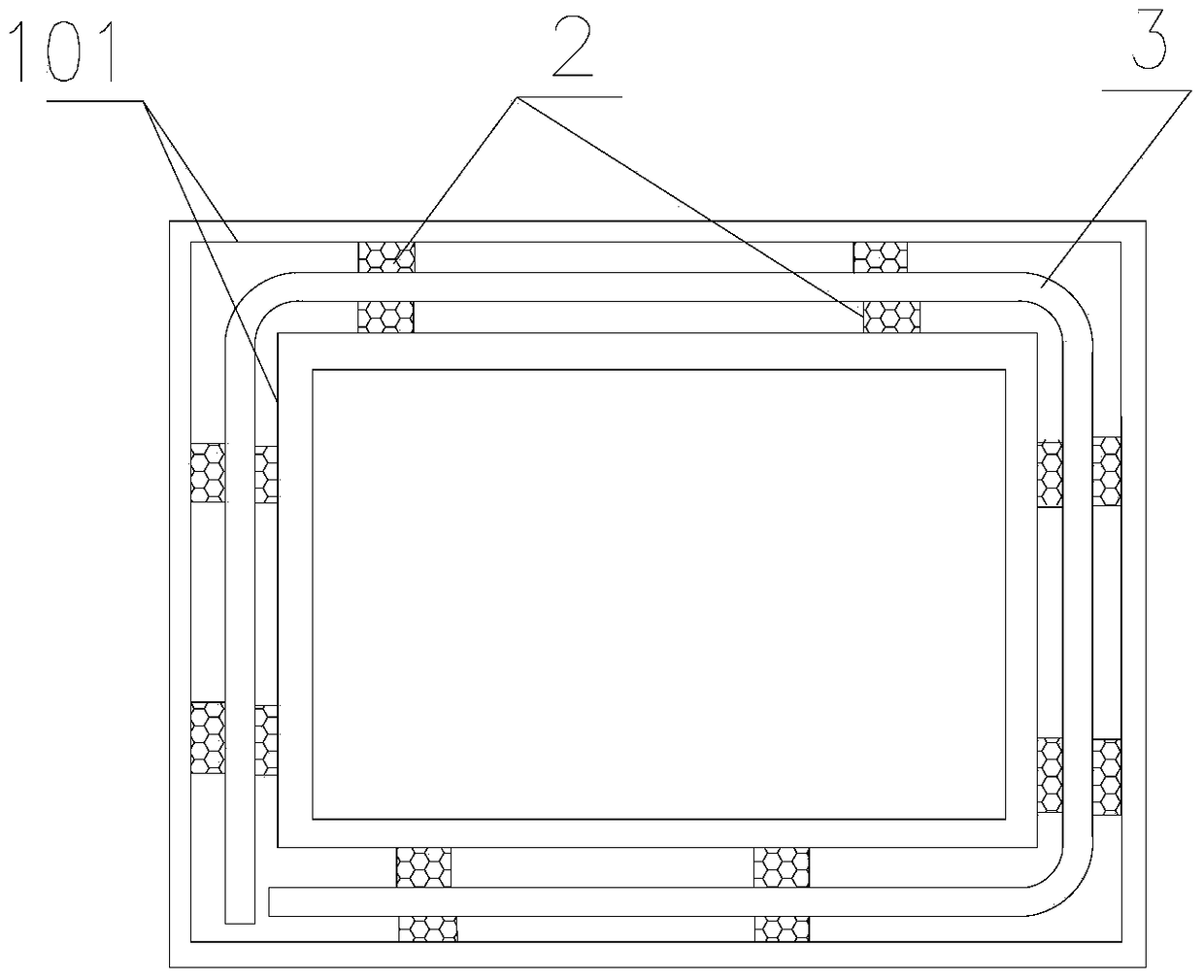

A heat insulation board, a production method of a heat insulation board, and a cold storage box

ActiveCN104859964BSimple production processLow costDomestic cooling apparatusLighting and heating apparatusInsulation layerCooling effect

The invention provides a heat insulation board, a production method of a heat insulation board, a cold storage box, and a heat insulation board, which are characterized in that they include: a vacuum heat insulation board and a foam material completely covering the vacuum heat insulation board. The cold storage box includes a box cover and a box body, and the box cover and the box body include the heat insulation layer; in the present invention, the foam material and the vacuum insulation board are formed into one body, and respectively constitute the insulation of the box cover and the box body. thermal layer. Furthermore, the vacuum insulation panel is completely covered by the foam material, so the wear resistance and impact resistance of the VIP can be greatly improved, and the VIP is not easily damaged. Furthermore, on the cold storage box, the thermal insulation advantage of VIP can be fully utilized to greatly improve the cold storage effect.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

InactiveCN101168940BImprove retentionLittle impact on physical propertiesWater-repelling agents additionParaffin waxBLENDER/MIXER

The invention relates to a preparation method of paraffin wax / AKD complex type neutral paper-making sizing agent. The step is as follows: firstly, AKD and paraffin wax powder are melted in AKD solution; secondly, compound emulsifying agent after being heated is added in melted AKD solution and mixed with a quick shearing mixing machine; thirdly, a rotating speed of the quick shearing blending machine is improved and preheating water is added to lead the formed AKD solution to performing emulsification nearby a W / O to O / W inversion point; quick mixing is performed and the preheating water isadded and the mixing is continuously performed; fourthly, the water solution of flocculating agent PAC is added, and the mixing is continuously performed; fifthly, the mixing is stopped and the cold water is used for quickly performing cooling and cool down, and then the finished product of the paraffin wax / AKD complex-typed neutral paper-making sizing agent emulsion is produced. The complex-typed neutral sizing agent produced by the invention has the advantages that the holding rate is high, the effect on the physical property of the paper is small, and the emulsion is stable.

Owner:TIANJIN UNIV OF SCI & TECH

Halogen-free environment-friendly composite flame-retardant viscose fiber spinning solution and preparation method thereof

ActiveCN102392314BNo flocculationNo condensationFlame-proof filament manufactureArtificial filaments from viscoseFlocculationPolymer science

The invention relates to halogen-free environment-friendly composite flame-retardant viscose fiber spinning solution and a preparation method thereof and belongs to the field of viscose fibers. The invention aims at solving the problems in the prior art that a flame-retardant agent has large grain size and wide grain size distribution; flame-retardant agent dispersion has bad stability to cause that the flame-retardant viscose fiber spinning solution is nonuniform to disperse, generates the flocculation phenomenon and has single effective flame-retardant component; and the flame-retardant agent has larger additive mount to affect the spinning performance and generate larger effect on the physical property of the spun flame retardant flame-retardant viscose fiber. The halogen-free environment-friendly composite flame-retardant emulsion composed of a water glass and phosphorus-nitrogen flame-retardant agent and a surface active agent has the advantages of no flocculation and stable performance. After being mixed with viscose, the halogen-free environment-friendly composite flame-retardant viscose fiber spinning solution is free from flocculation, has stable performance, is uniform to disperse and has multiple effective flame-retardant components.

Owner:CHENGDU GRACE FIBER +2

A kind of halogen-free flame-retardant rigid polyurethane foam and its preparation method

ActiveCN103694438BLittle impact on physical propertiesGood physical propertiesToxic gasHydrogen halide

The invention discloses halogen-free flame-retardant rigid polyurethane foamed plastic and a preparation method for the same. The polyurethane foamed plastic consists of the following raw materials in parts by weight: 100 parts of polyalcohol mixture, 105 to 180 parts of polyisocyanate, 20 to 80 parts of compound halogen-free flame retardant, 1 to 50 parts of foaming agent, 1 to 3 parts of composite catalyst, 2 to 4 parts of foam stabilizer and 1 to 2 parts of cross-linking agent. An obtained product is high in flame retardance and environment-friendly, the raw materials are free of halogen, and the production of toxic gas such as hydrogen halide during combustion is avoided; the raw materials are readily available and low in cost, so that the preparation cost of the polyurethane foamed plastic is greatly lowered; the polyurethane foamed plastic also has the characteristic of wide application range, and is applied to cold storage and heat-preservation industries of external wall heat-preservation of buildings, heat-preservation of pipelines, refrigerators, freezers and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of low-burnout rate flake silver powder

The invention provides a preparation method of low-burnout rate flake silver powder. In the method, spherical silver powder is utilized as a raw material. The method comprises the following steps: mixing the spherical silver powder, ball milling assistant and dispersant according to a weight ratio of 50-400:1-20:0.05-10, and adding de-ionized water to regulate the solution until the concentrationof the ball milling assistant is 10-200 g / L and the concentration of the dispersant is 0.5-100 g / L; carrying out ball milling on the mixed solution at a rotation speed of 100-400 r / min for 5-80 h, respectively washing with anhydrous alcohol and de-ionized water for 1-3 times, then filtering in vacuum, and drying at 30-120 DEG C for 4-20 h to obtain the low-burnout rate flake silver powder. The prepared powder has the advantages of large radius-thickness ratio, low loose density, good conductibility, low burnout rate, high flaking degree and good dispersibility, the particle size of the powderis 3.91-17.05 mu m, the specific area is 0.404-1.762 m<2> / g, the loose density is 0.871 m<3> / g, the tap density is 1.127 m<3> / g, and the burnout rate is 0.01-0.20%. Thus, the flake silver powder is well applicable to electronic paste appliances in the later period.

Owner:KUNMING UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com