Layer-stranded strip-shaped optical cable

A ribbon optical cable and layer-stranded technology, applied in the field of layer-stranded ribbon optical cable, can solve the problems of optical cable burning in case of fire, secondary environmental pollution, difficulty in personnel escaping, etc., and achieve bending resistance and tensile resistance. Improved performance, high reliability, increased tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

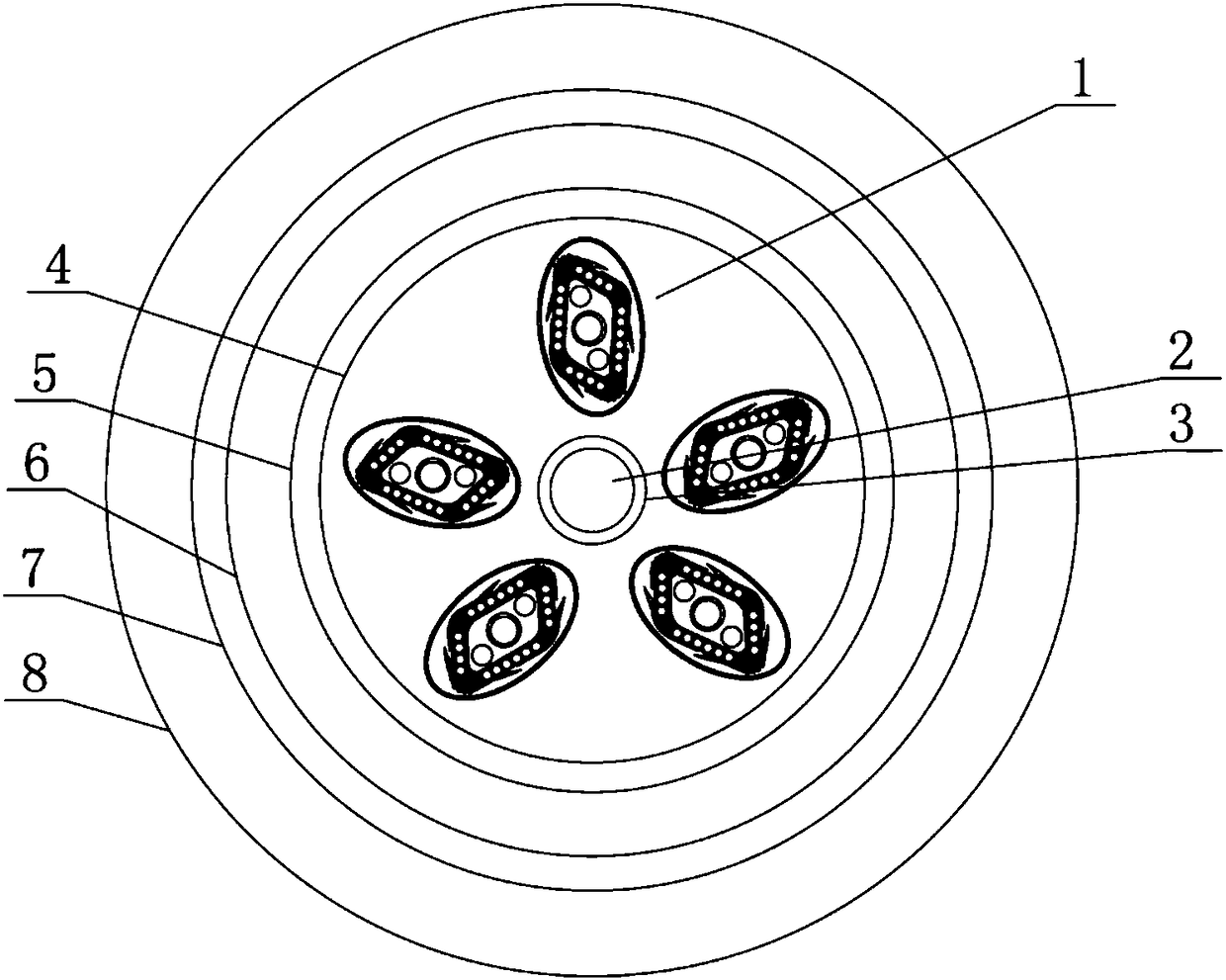

[0037] like figure 1 As shown, the present invention provides a layer-stranded ribbon optical cable, which includes an optical fiber part 1 and a metal strengthening core 2. There are five optical fiber parts 1, and the five optical fiber parts 1 are evenly distributed in the insulating layer 4. The metal reinforcing core 2 is set in the middle of the insulating layer 4, the insulating layer 4 is provided with a water blocking layer 5, the water blocking layer 5 is provided with an inner sheath 6, the inner sheath 6 is provided with a reinforcing layer 7, and the reinforcing layer 7 is provided with an outer sheath 8. The reinforcing layer 7 is made of aramid yarn.

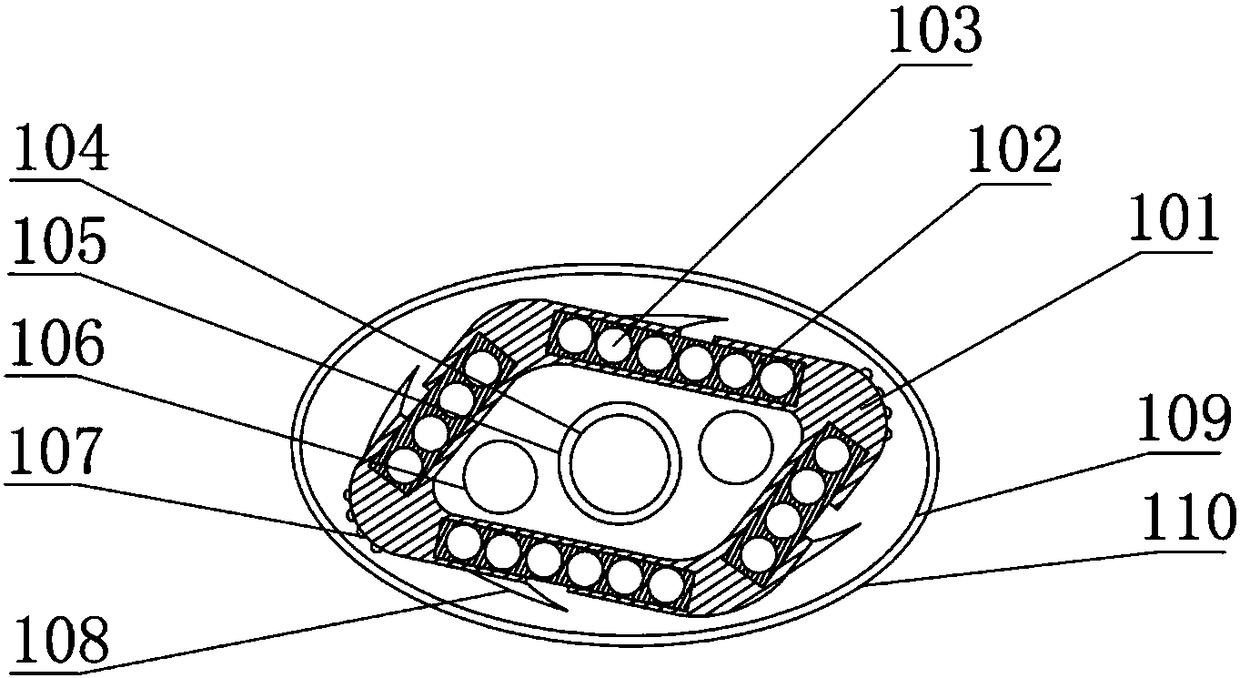

[0038] like image 3As shown, the optical fiber portion 1 includes an accommodating portion 101 and an optical fiber ribbon 103 . The accommodating portion 101 is a rhombus-shaped frame body. The inner cavity of the rhombus-shaped frame is provided with a metal reinforcing core 104 and a filling rope 106 , and a ...

Embodiment 2

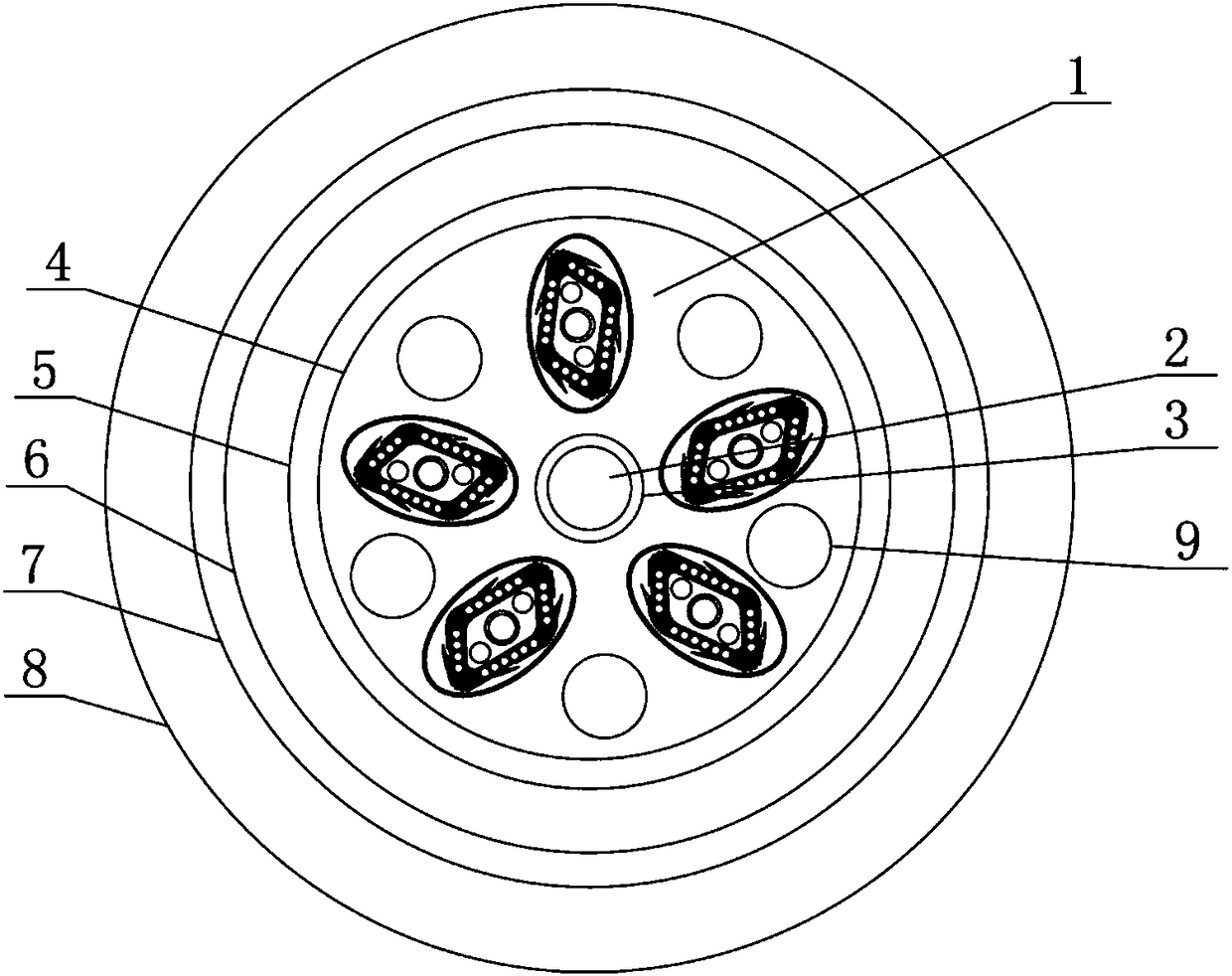

[0044] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a filling rope 9 is arranged between each optical fiber part 1 to reduce the gap between each optical fiber part 1, and the filling rope 9 also plays a protective role at the same time. Steel wire reinforcing cores can also be arranged between each optical fiber portion 1 to improve the structural strength of the entire optical fiber cable.

Embodiment 3

[0046] A flame retardant ointment, comprising the components by mass: 78 parts of base oil, 9 parts of composite thickener, 0.8 part of flame retardant, and 0.5 part of antioxidant.

[0047] Described base oil is hydrogenated paraffin base oil / hydrogenated naphthenic oil mixed oil, and mass ratio is 2:3; Described composite thickener is polyacrylamide / fatty alcohol polyoxyethylene ether, and mass ratio is 5: 7; the flame retardant is triallyl isocyanurate and nano-tin powder, and the mass ratio is 90:0.15, wherein triallyl isocyanurate is a thermal crosslinking agent, and nano-tin powder is a catalyst ; Antioxidant is tert-butyl hydroquinone.

[0048] Example 1 Flame retardant performance table of flame retardant ointment:

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com