Preparation method of nano iron oxide yellow or nano iron oxide red

The technology of iron oxide yellow and iron oxide red is applied in the field of preparation of nanomaterials, which can solve problems such as heating and heat preservation, and achieve the effects of short production cycle, good crystal shape and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

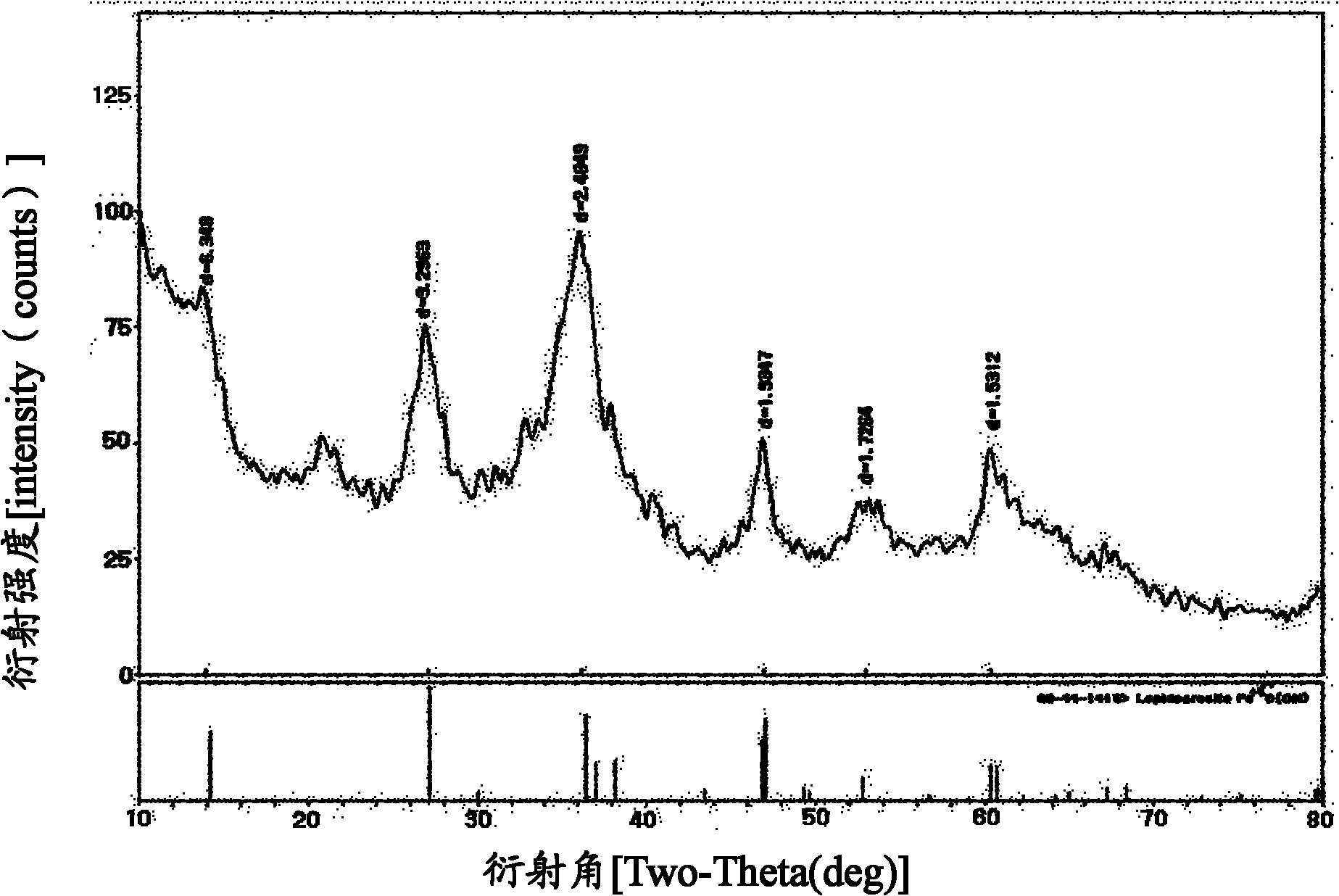

Embodiment 1

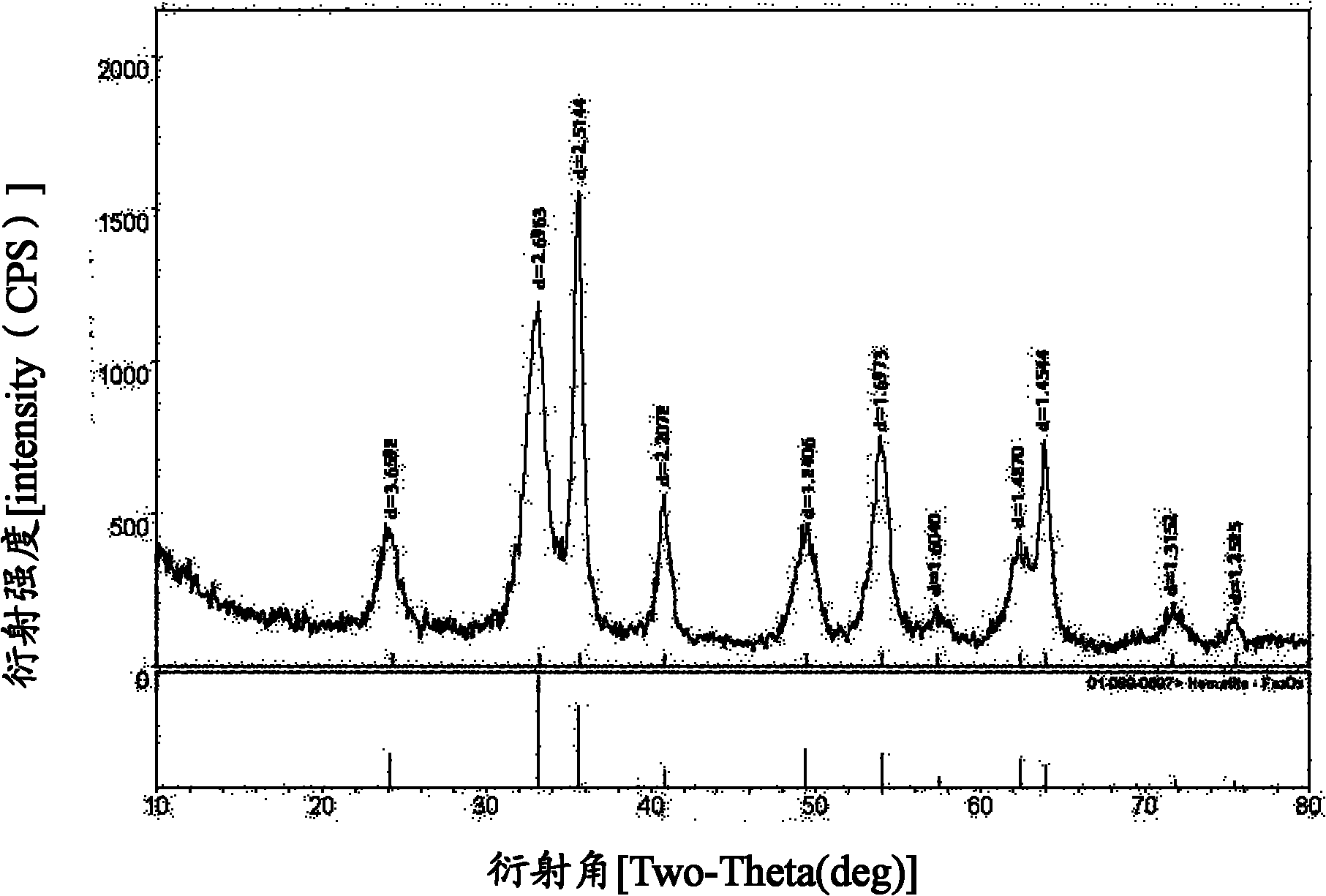

[0032] Weigh FeSO4·7H 2 O analytical pure 14g (0.05mol), make 1L aqueous solution, add 3.8g tartaric acid to mix well, add 6mol / L ammonia solution dropwise while stirring, until the pH value of the reaction system is 4.8, continue to add 20% peroxide dropwise while stirring 8mL of hydrogen solution, after the addition, continue to react for 90 minutes at about 35°C. After the precipitate is suction filtered and washed, it is dried in an oven at 100°C to obtain a solid, which is taken out and ground to obtain about 4.6 g of nanometer iron oxide yellow. The particle size of nano-iron oxide yellow is about 30nm measured by X-diffraction method and scanning electron microscope method.

[0033] The obtained solid is calcined in a muffle furnace at 900° C. for 1.5 h, taken out, and ground after cooling to obtain 4.0 g of nanometer iron oxide red. The particle size of nano iron oxide red is about 75nm measured by X-diffraction method and scanning electron microscope method.

Embodiment 2

[0035] Weigh FeSO 4 ·7H 2 O analytical pure 140g (0.5mol), make 1L aqueous solution, add 48g citric acid, mix well, add 10% mass fraction of sodium hydroxide aqueous solution while stirring, until the pH of the system is 3.8, continue to add dropwise while stirring 250ml sodium hypochlorite aqueous solution with a mass fraction of 20%, after the addition, the reaction was continued for 2h at room temperature (25°C). After the precipitate is suction filtered and washed, it is placed at 30°C for vacuum drying for 1 hour to obtain a solid, which is taken out and ground to obtain about 48 g of nanometer iron oxide yellow. The particle size of nano-iron oxide yellow is about 35nm measured by X-diffraction method and scanning electron microscope method.

[0036] The solid obtained above is calcined in a muffle furnace at 800° C. for 1 h, taken out, and ground after cooling to obtain about 42 g of nano iron oxide red. The particle size of nano iron oxide red is about 85nm measured by X...

Embodiment 3

[0038] Weigh FeSO 4 ·7H 2 O analytical pure 140g (0.5mol) is mixed into 1L aqueous solution, add 13mL ethylene glycol and mix well, add 10% sodium hydroxide solution dropwise while stirring, until the pH value of the reaction system is 4.3, continue adding dropwise while stirring 300 mL of a sodium persulfate solution with a mass fraction of 30%, after the addition, continue to react at about 30°C for about 100 minutes to form a precipitate. After the precipitate is suction filtered and washed, it is placed at 35° C. and vacuum-dried for 1 hour to obtain a solid, which is taken out and ground to obtain about 44 g of nanometer iron oxide yellow. The particle size of nano-iron oxide yellow is about 40nm measured by X-diffraction method and scanning electron microscope method.

[0039] The obtained solid is calcined in a muffle furnace at 700° C. for 2 hours, taken out, cooled, and ground to obtain 40 g of nano iron oxide red. The particle size of nano iron oxide red is about 90nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com