Method for preparing metallic nickel nano-wire

A technology of metal nickel and nanowires, which is applied in the field of preparation of metal nickel, can solve the problems of low yield and high production cost, and achieve the effects of high yield, low cost and good crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

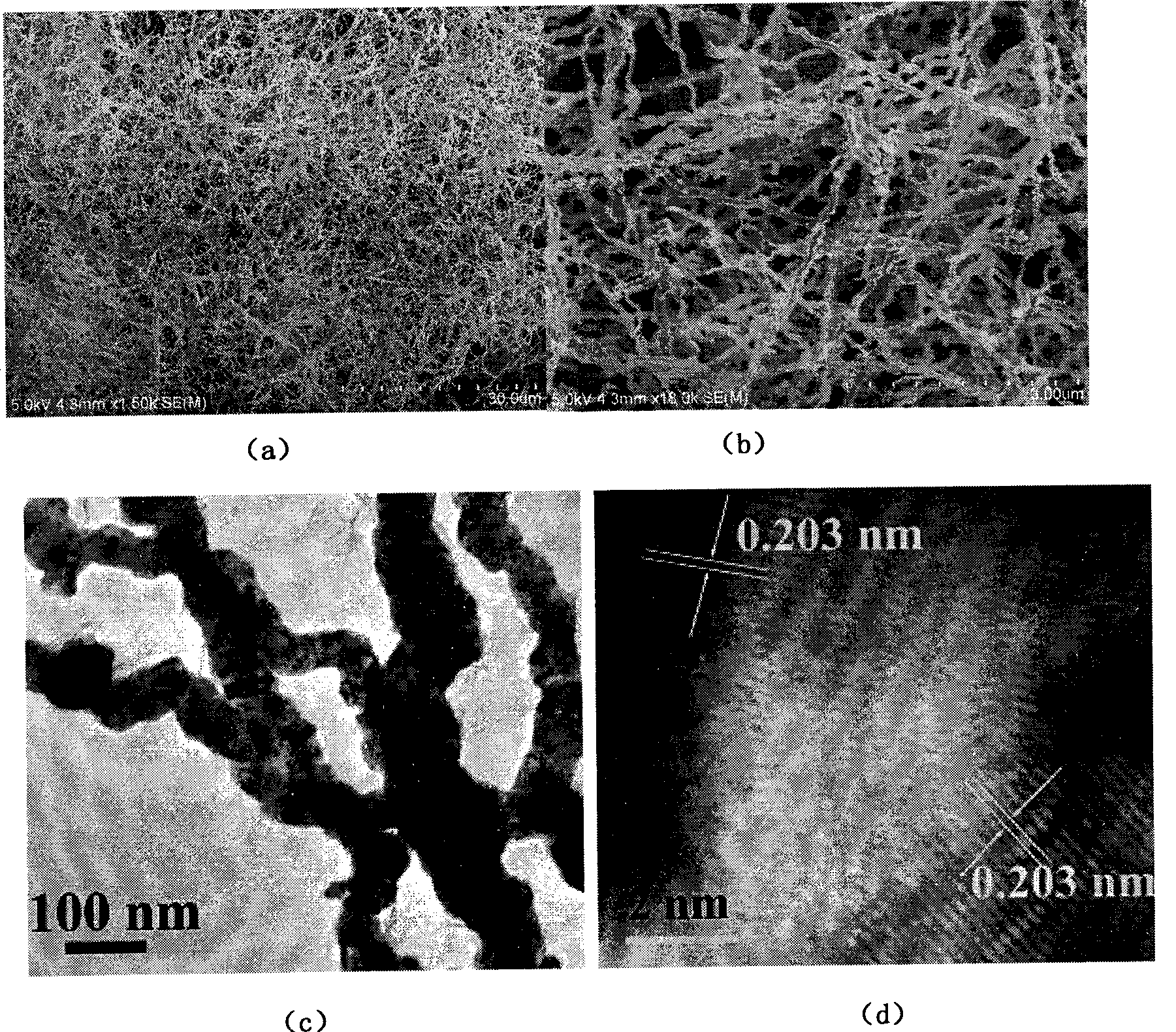

[0015] First 0.27g NiCl 2 ·6H 2 O and 1g of polyvinylpyrrolidone PVP (molecular weight MW30,000) were dissolved in 75ml of ethylene glycol (EG), and then molar ratio of hydrazine hydrate: NiCl 2 ·6H 2 The ratio of O=0.3:1, add 50% Vol.A.R. of hydrazine hydrate and 5ml ethanol to the above solution, then heat to boiling point and reflux for 4 hours, the solution turns from initial blue to yellow-green and finally black matter produced. The precipitate was washed 6 times with absolute ethanol and then dried at 80°C to obtain loose black powdery metal nickel nanowires, metal nickel nanowires, such as figure 1 , 2 As shown, the diameter is about 80nm, and the average length is 10-100 microns. Such as image 3 As shown, it has magnetic anisotropy as well as high squareness ratio and coercive force.

Embodiment 2

[0017] First 0.27g NiCl 2 ·6H 2 O and 1g of PVP (MW40,000) were dissolved in 75ml of ethylene glycol (EG) under vigorous stirring, then molar ratio of hydrazine hydrate:NiCl 2 ·6H 2 O=1.9:1 ratio, add 50% Vol.A.R. hydrazine hydrate and 5ml ethanol to the above solution, then heat to boiling point and reflux for 48 hours, a large number of black nano-nickel wires are produced at the bottom of the bottle.

Embodiment 3

[0019] First, dissolve 0.5g of nickel sulfate and 2g of polyvinylpyrrolidone PVP (molecular weight MW30,000) in 75ml of ethylene glycol (EG) at a mass ratio of 1:4, and then use a molar ratio of hydrazine hydrate: nickel sulfate = 0.8:1 In the above solution, add 50% Vol.A.R. of hydrazine hydrate and 15ml of ethanol, then control the temperature at 180°C, react for 6 hours, the solution turns from the initial blue to yellow-green and finally black nanowires are produced . The precipitate was washed 6 times with absolute ethanol and then dried at 80°C to obtain loose black metallic nickel nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com