A heat insulation board, a production method of a heat insulation board, and a cold storage box

A production method and heat insulation board technology, applied in the field of heat insulation boards, can solve problems such as direct replacement of expanded polystyrene, achieve stable and controllable quality, reduce thermal conductivity, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A thermal insulation panel, comprising: a vacuum insulation panel and a foam material completely covering the vacuum insulation panel.

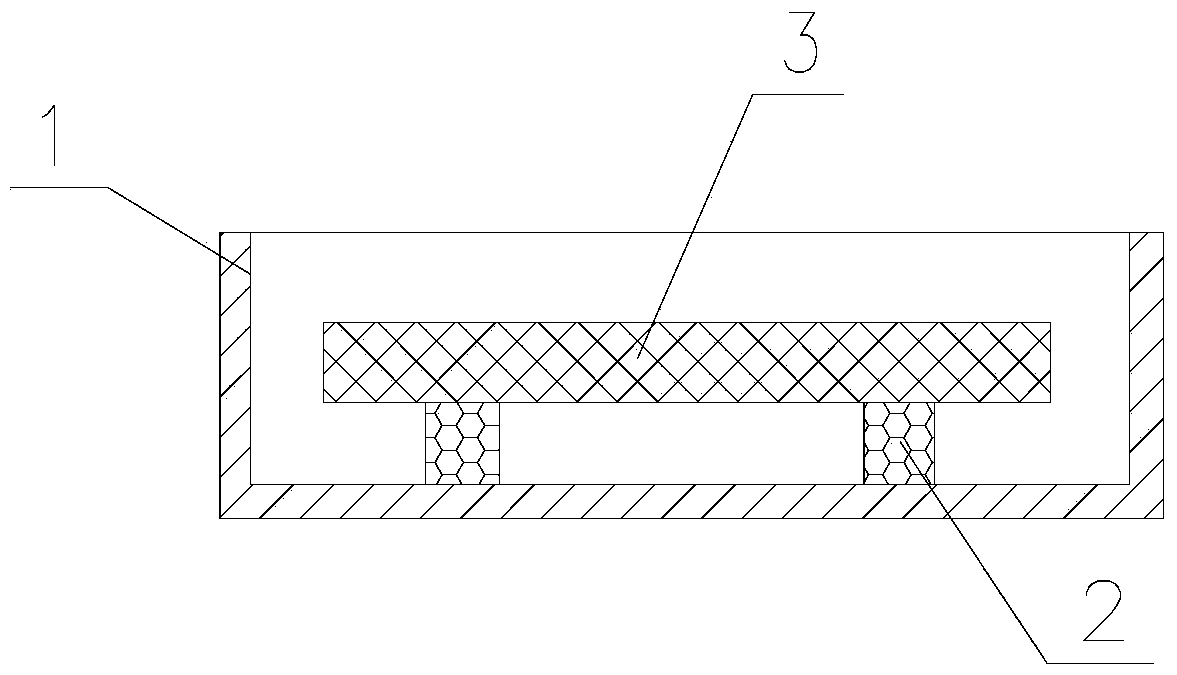

[0067] like figure 1 , the production method of the above-mentioned thermal insulation panel, which includes: horizontally arranging the vacuum insulation panel 3 in the first cavity 1, and setting the small blocks 2 prefabricated with foaming materials on the bottom of the surroundings of the vacuum insulation panel 3, and making the vacuum insulation The bottom and surroundings of the plate 3 have gaps with respect to each inner wall of the first cavity; then pour light polymer and foaming agent into the first cavity 1, and seal the opening of the first cavity Cover the top cover so that the generated foam material completely covers the vacuum insulation panel; open the top cover after molding, and take out the heat insulation panel.

Embodiment 2

[0069] On the basis of Embodiment 1, there are the following modifications in this embodiment:

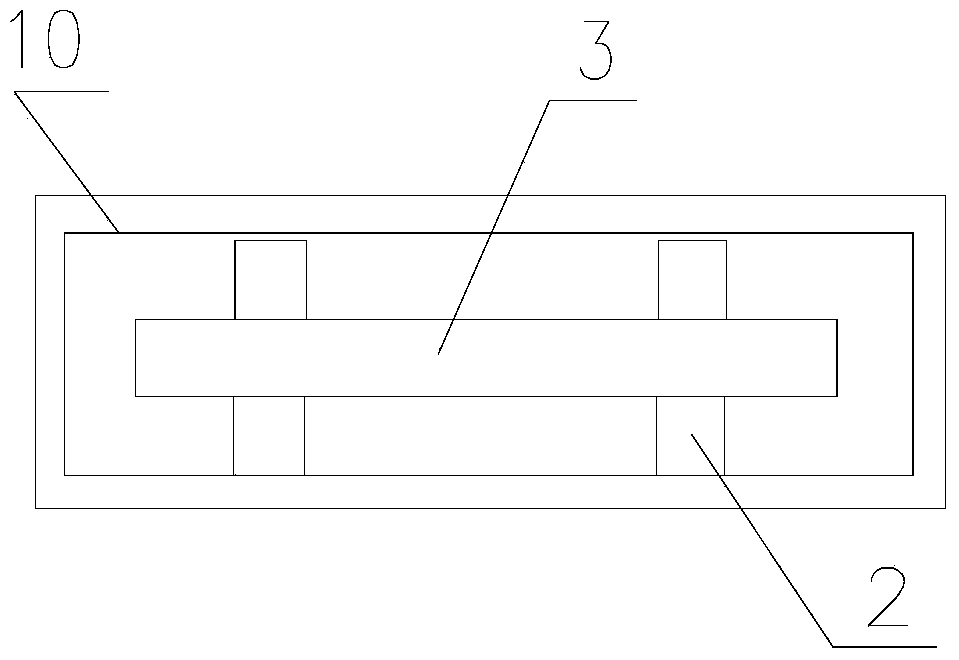

[0070] like figure 2 , the production method of the heat insulation board, which includes: vertically setting the vacuum heat insulation board 3 in the second cavity 10, and setting the small block 2 prefabricated with foaming material (generally adopting bonding and fixing, for example, using double-sided Tape paper or glue) on the bottom and surrounding side walls of the vacuum insulation panel, so that there are gaps at the bottom and surrounding of the vacuum insulation panel 3; then pour light polymer and foam into the second cavity 10 agent, and cover the top opening of the second cavity 10 so that the generated foam material completely covers the vacuum insulation panel; after molding, open the top cover and take out the insulation panel.

Embodiment 3

[0072] On the basis of Embodiment 1, there are the following modifications in this embodiment:

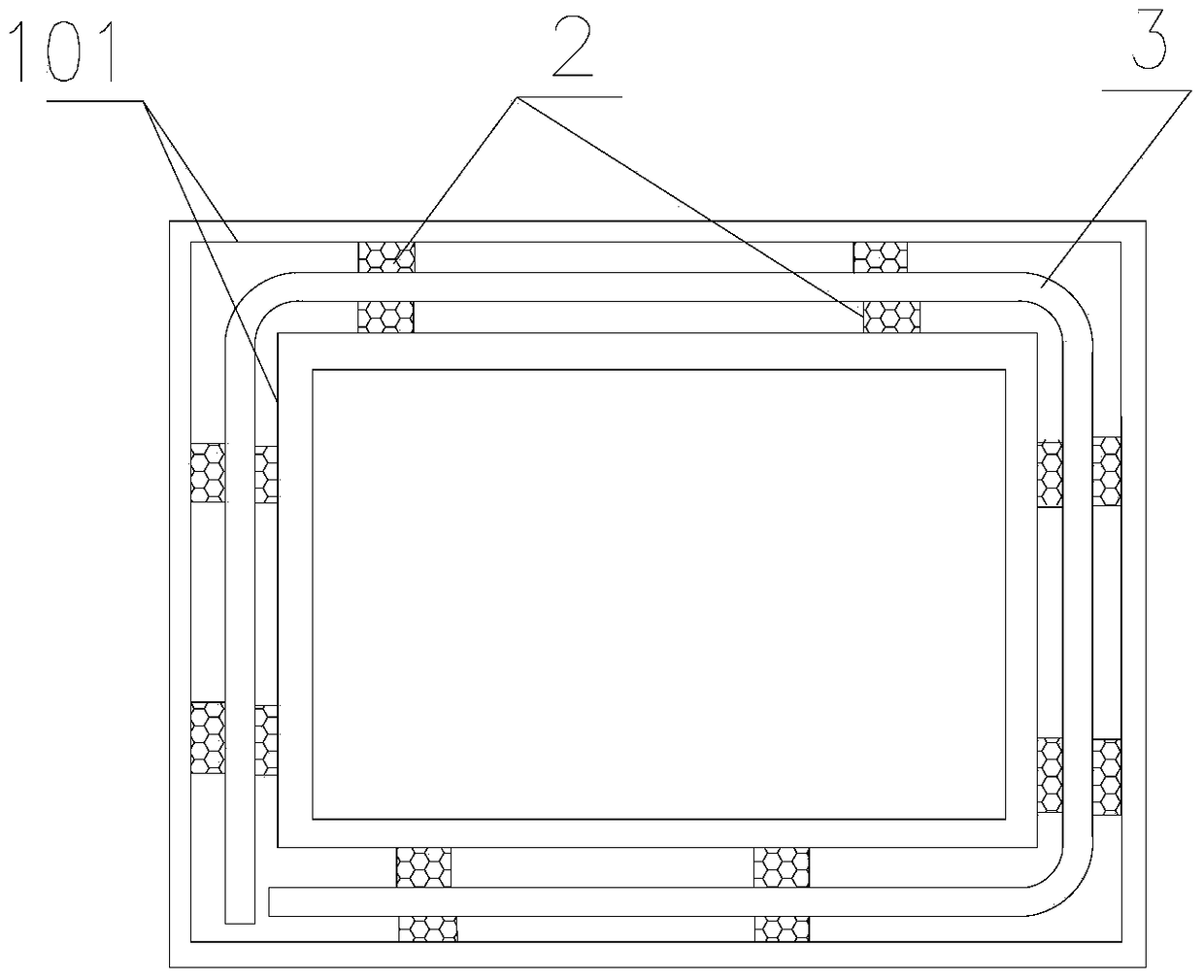

[0073] like image 3 , the production method of the thermal insulation board, it comprises: adopt bendable vacuum heat insulation board 3 to fold into the hollow cylinder that the cross section is the shape of a square; In the third cavity 101 of the vacuum insulation panel 3, the small blocks 2 prefabricated with foaming materials are arranged on the inner, outer sides and bottom of the vacuum insulation panel 3, so that the inner, outer sides and bottom of the vacuum insulation panel 3 are in contact with the third cavity 101 There are gaps in the inner walls of the third cavity; then pour light polymer and foaming agent into the third cavity, and cover the opening of the third cavity with a top cover, so that the generated foam material can completely cover the cavity. Cover the vacuum insulation board; open the top cover after forming, and take out the integrated heat insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com