High-opacity white or light flame-retardant polypropylene composition and preparation method thereof

A technology of flame-retardant polypropylene and composition, which is applied in the field of high light-shielding white or light-color flame-retardant polypropylene composition and its preparation, and can solve the problem of high-light-shielding white or light-color flame-retardant polypropylene, which has no patent report, Phosphorus nitrogen bromine compound flame retardant failure and other problems, to achieve the effect of low material cost, little impact on material physical properties, and less flame retardant addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-2

[0022] Preparation of high light-shielding white or light-colored flame-retardant polypropylene composition of embodiment 1-5 and comparative example 1-2

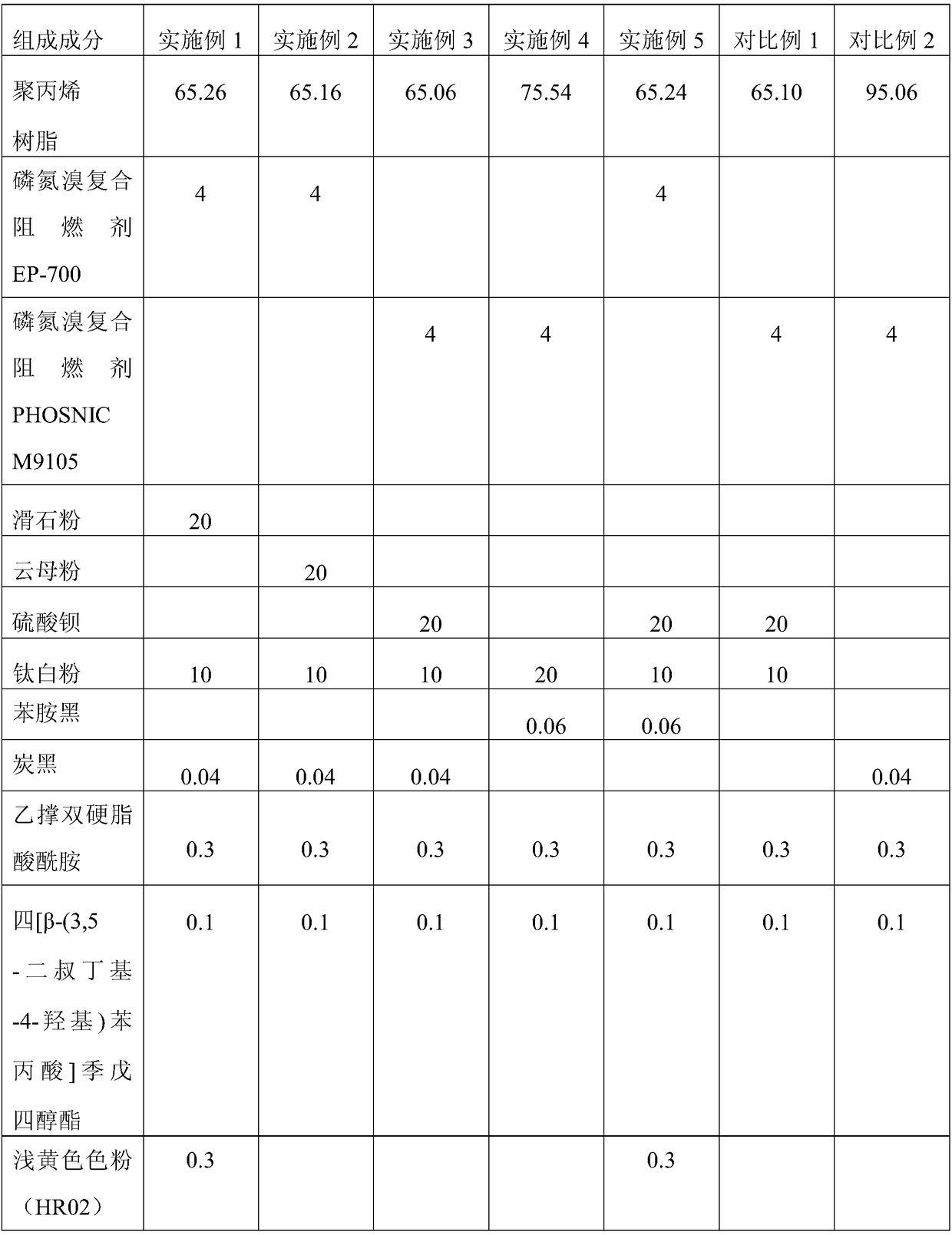

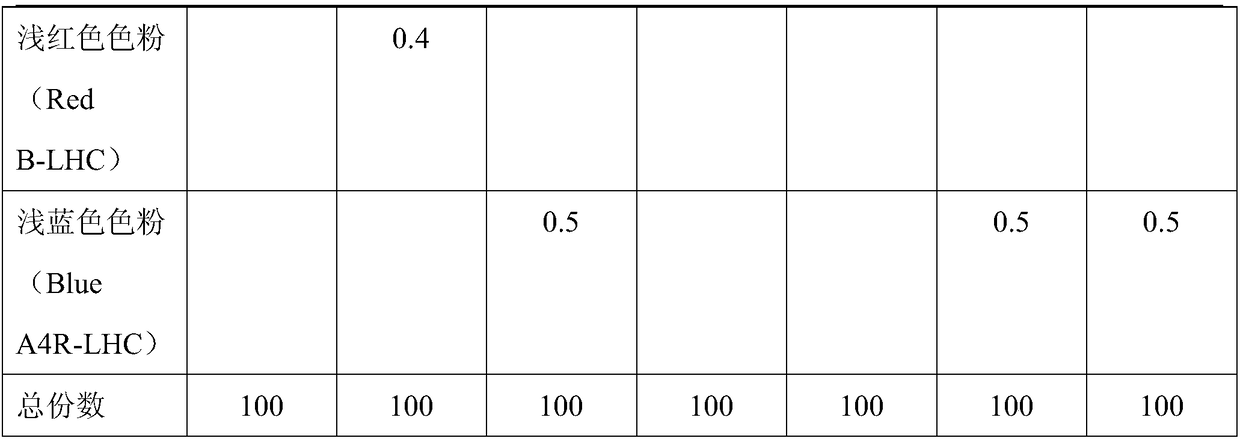

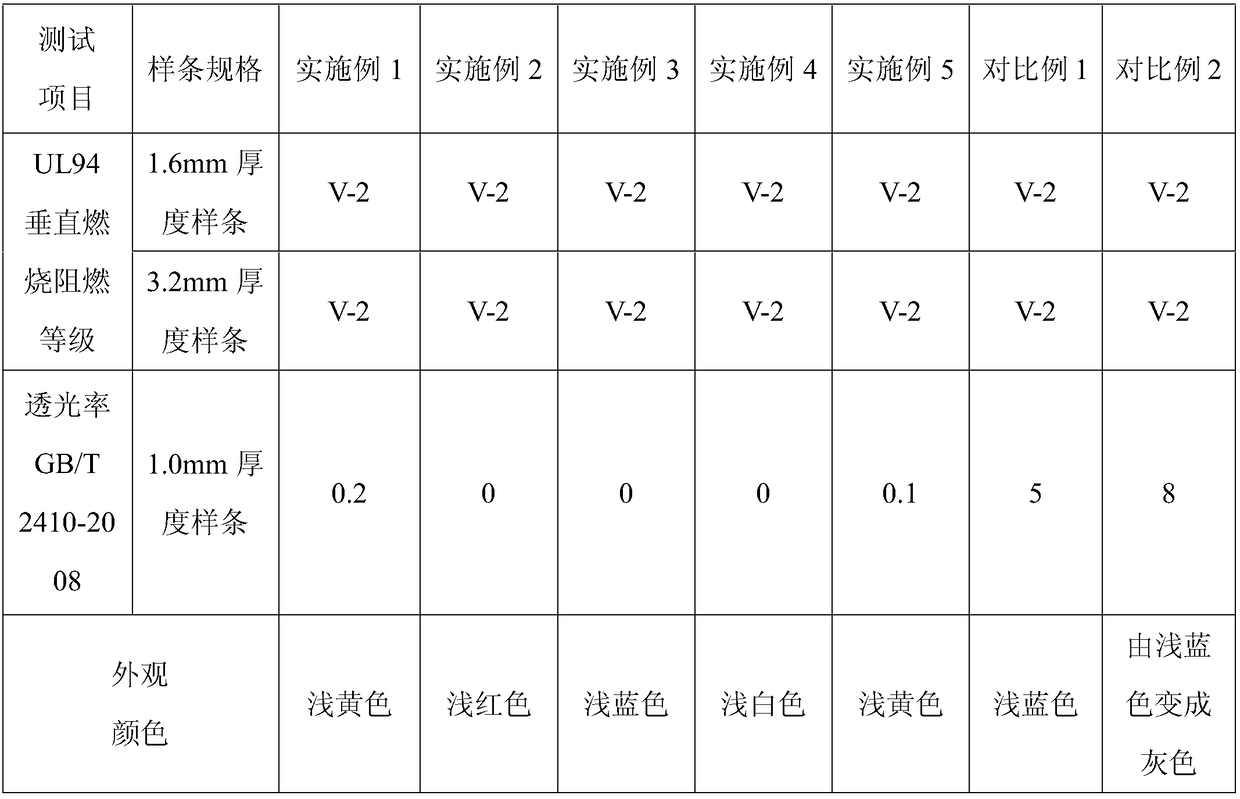

[0023] The formula composition of the high light-shielding white or light-colored flame-retardant polypropylene compositions of Examples 1-5 and Comparative Examples 1-2 is shown in Table 1:

[0024] Each embodiment of table 1 and the raw material formula composition of comparative example

[0025]

[0026]

[0027] In the above formulation, the difference between Comparative Example 1 and Example 3 is that it does not contain sunscreen agent B, specifically, does not contain carbon black, and the amount of polypropylene resin is increased accordingly. The difference between Comparative Example 2 and Example 3 is that it does not contain opacifying agent A, specifically, does not contain barium sulfate and titanium dioxide, and the amount of polypropylene resin is increased accordingly.

Embodiment 1

[0028] Embodiment 1 The preparation steps of high light-shielding white or light-colored flame-retardant polypropylene composition are:

[0029] (1) Weigh polypropylene resin, phosphorus nitrogen bromine composite flame retardant EP-700, talcum powder, titanium dioxide, carbon black, ethylene bis stearic acid amide, tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyl) phenylpropionic acid] pentaerythritol ester and light yellow toner, then all raw materials are added in the high mixer and mixed for 5min;

[0030] (2) Add the mixed raw materials from the feed port into the twin-screw extruder to extrude and granulate. The processing temperature of each zone of the twin-screw extruder is 200°C, and the rotating speed of the screw is 250r / min. 1. Cutting into pellets after blowing dry, and finally injecting the granular material into a standard spline in an injection molding machine to obtain a white or light-colored flame-retardant polypropylene composition with high shading.

Embodiment 2-5

[0031] Examples 2-5 and Comparative Examples 1-2 The preparation of the high light-shielding white or light-colored flame-retardant polypropylene composition refers to the steps of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical indicatrix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com