High-barrier anti-ultraviolet environment-friendly PET composite flexible packaging material and preparation method thereof

An anti-ultraviolet and high-barrier technology, applied in the field of packaging materials, can solve the problems of reduced adhesion between PET and PP composite materials and ink, poor adhesion of surface ink, and easy spoilage of food, so as to increase anti-ultraviolet performance and improve the barrier. Sexuality, the effect of slowing down spoilage and corruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

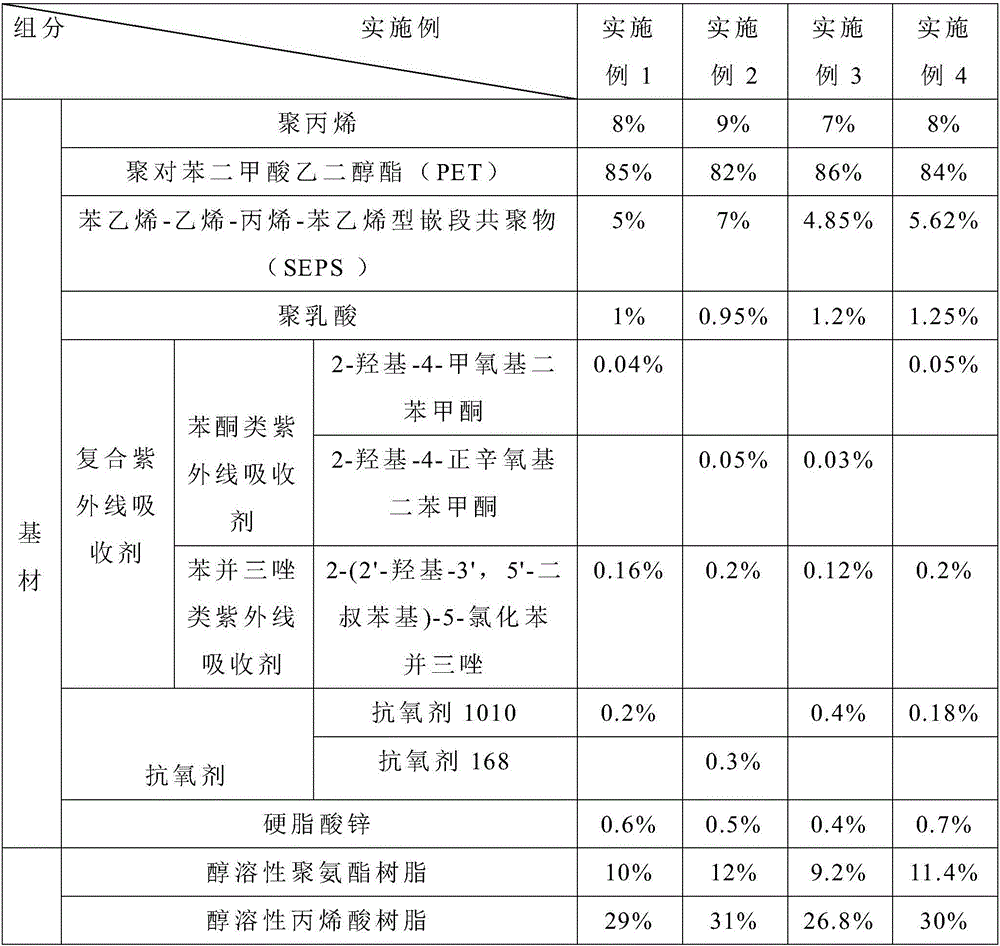

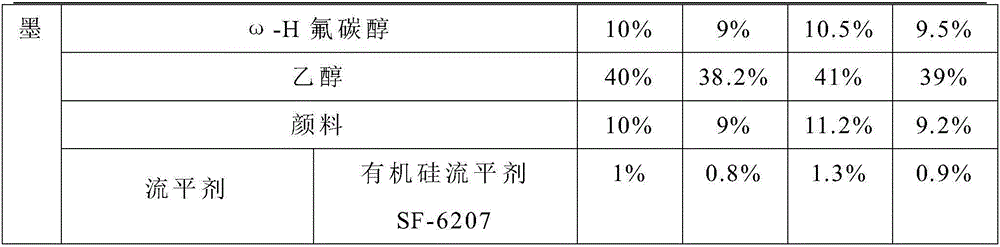

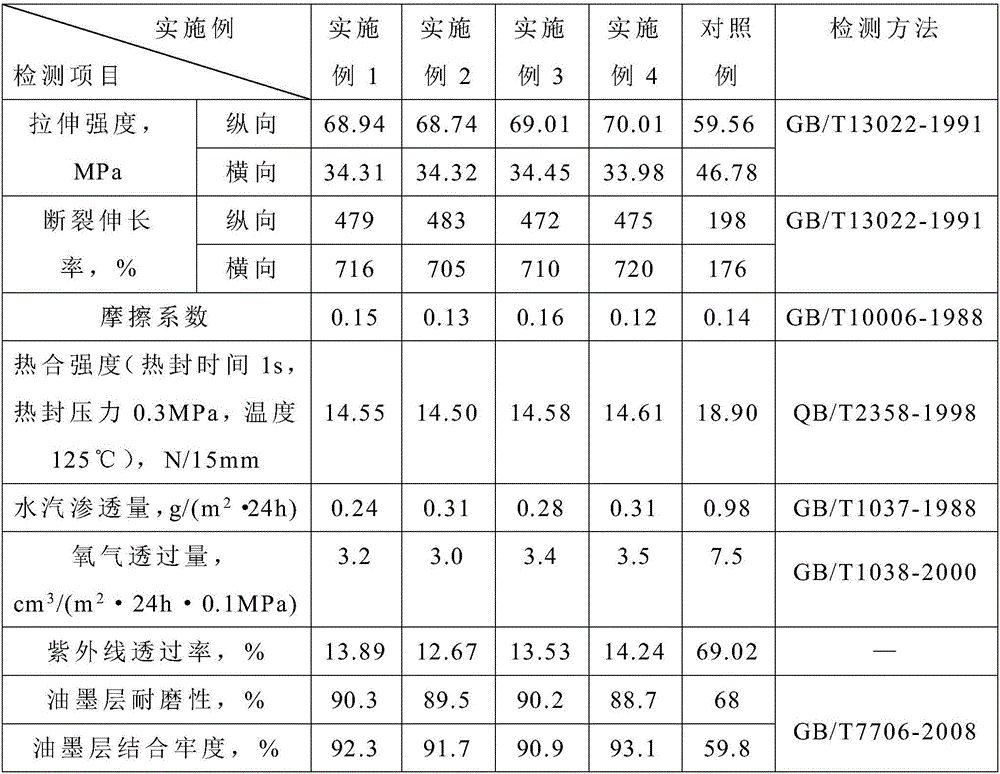

Embodiment 1 to Embodiment 4

[0025] Embodiment 1 to embodiment 4 prepare the preparation method of high barrier anti-ultraviolet environmental protection PET composite flexible packaging material as follows:

Embodiment 1

[0027] The preparation method of described high barrier ultraviolet ray-resistant environment-friendly PET composite flexible packaging material comprises the steps:

[0028] Step 1: According to the mass ratio, weigh the raw materials required for the substrate layer, and mix polypropylene, polyethylene terephthalate, styrene-ethylene-propylene-styrene block copolymer, Polylactic acid, composite ultraviolet absorber, antioxidant and zinc stearate are placed in a high mixer, mixed and stirred evenly, tape-cast at 210°C, cooled and trimmed to obtain the substrate layer, wherein the The speed during stirring is 1000r / min;

[0029] Step 2: According to the mass ratio, weigh the raw materials required for the ink layer, add alcohol-soluble polyurethane resin and alcohol-soluble acrylic resin to ethanol in turn, after stirring evenly, add leveling agent, ω-H fluorocarbon Alcohol, continue to stir, and add pigment while stirring, after stirring evenly, get printing ink, wherein the...

Embodiment 2

[0032] The present invention also provides a preparation method of the high-barrier, ultraviolet-resistant and environment-friendly PET composite flexible packaging material, comprising the following steps:

[0033] Step 1: According to the mass ratio, weigh the raw materials required for the substrate layer, and mix polypropylene, polyethylene terephthalate, styrene-ethylene-propylene-styrene block copolymer, Polylactic acid, composite ultraviolet absorber, antioxidant and zinc stearate are placed in a high mixer, mixed and stirred evenly, tape-cast at 205°C, cooled and trimmed to obtain the substrate layer, wherein the The speed during the stirring is 800r / min;

[0034] Step 2: According to the mass ratio, weigh the raw materials required for the ink layer, add alcohol-soluble polyurethane resin and alcohol-soluble acrylic resin to ethanol in turn, after stirring evenly, add leveling agent, ω-H fluorocarbon Alcohol, continue to stir, and add pigment while stirring, after st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com