Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Less dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

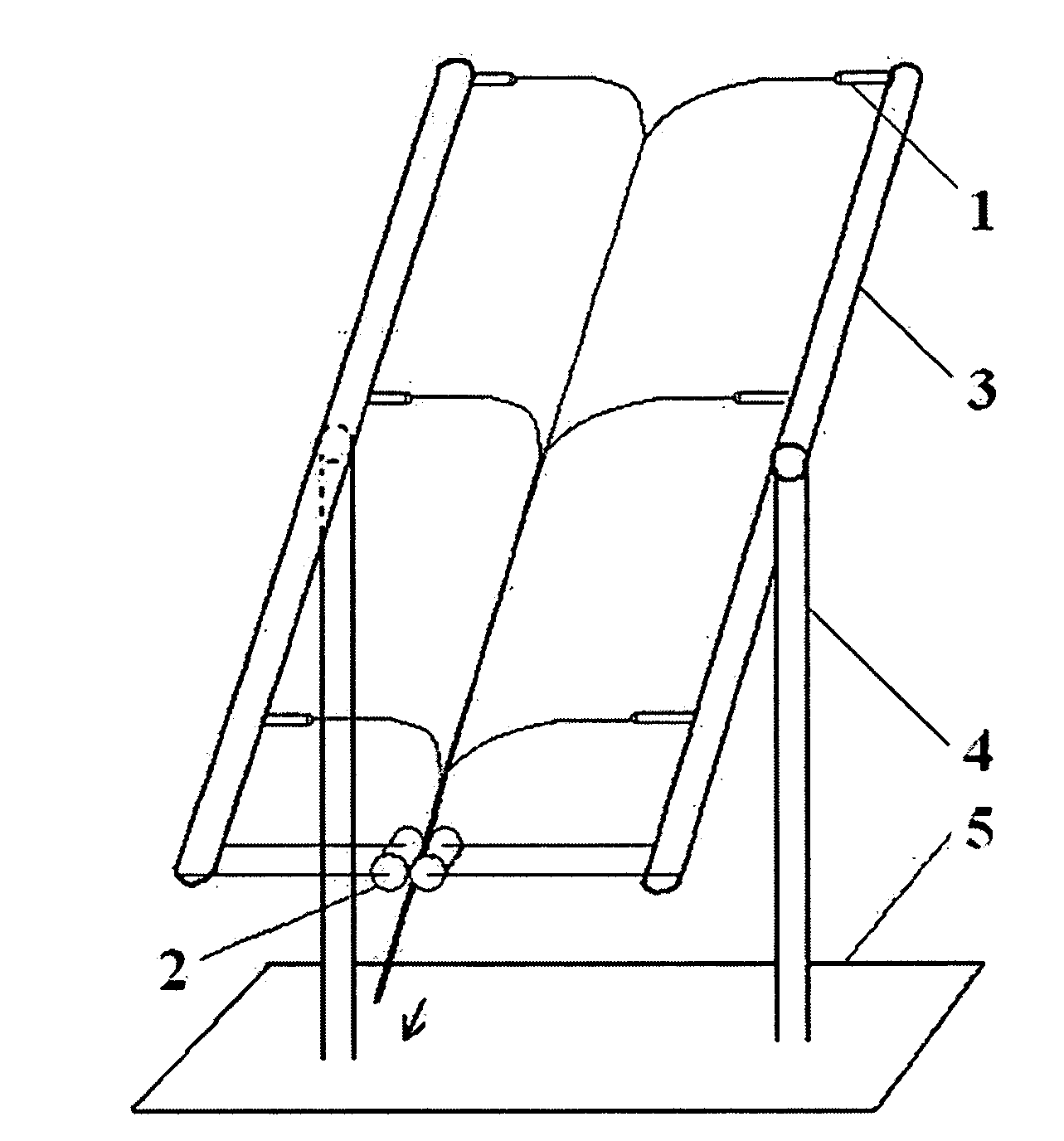

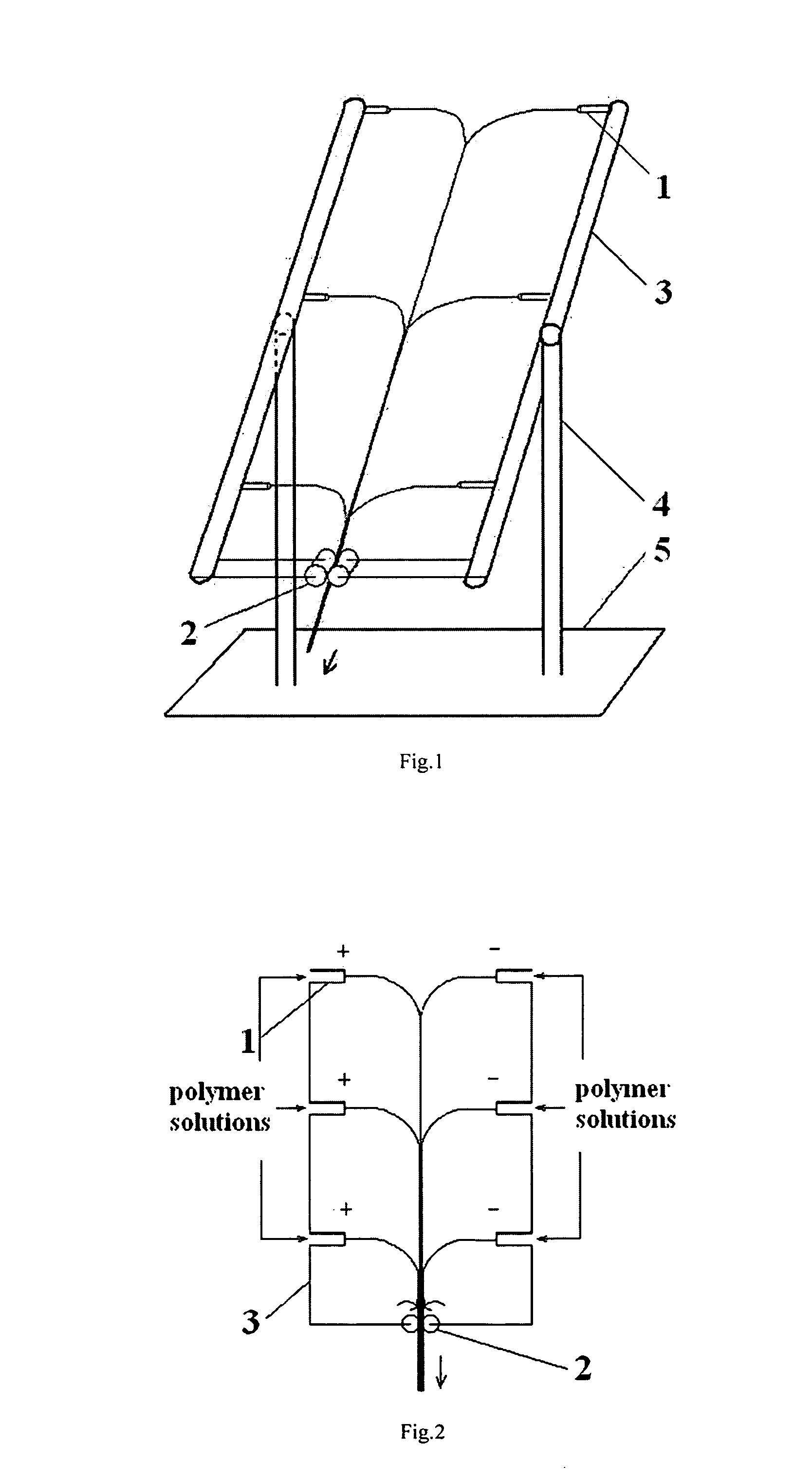

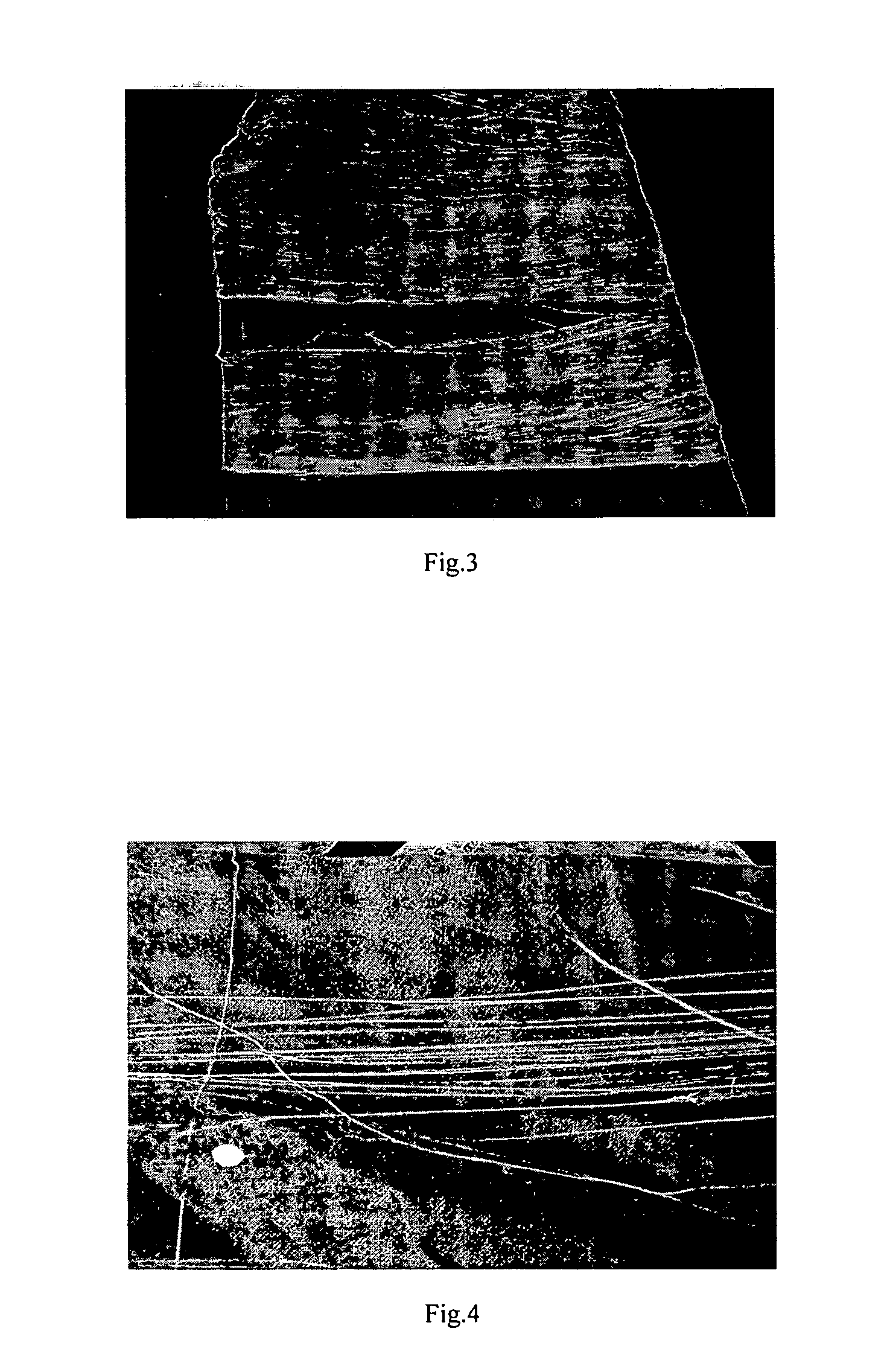

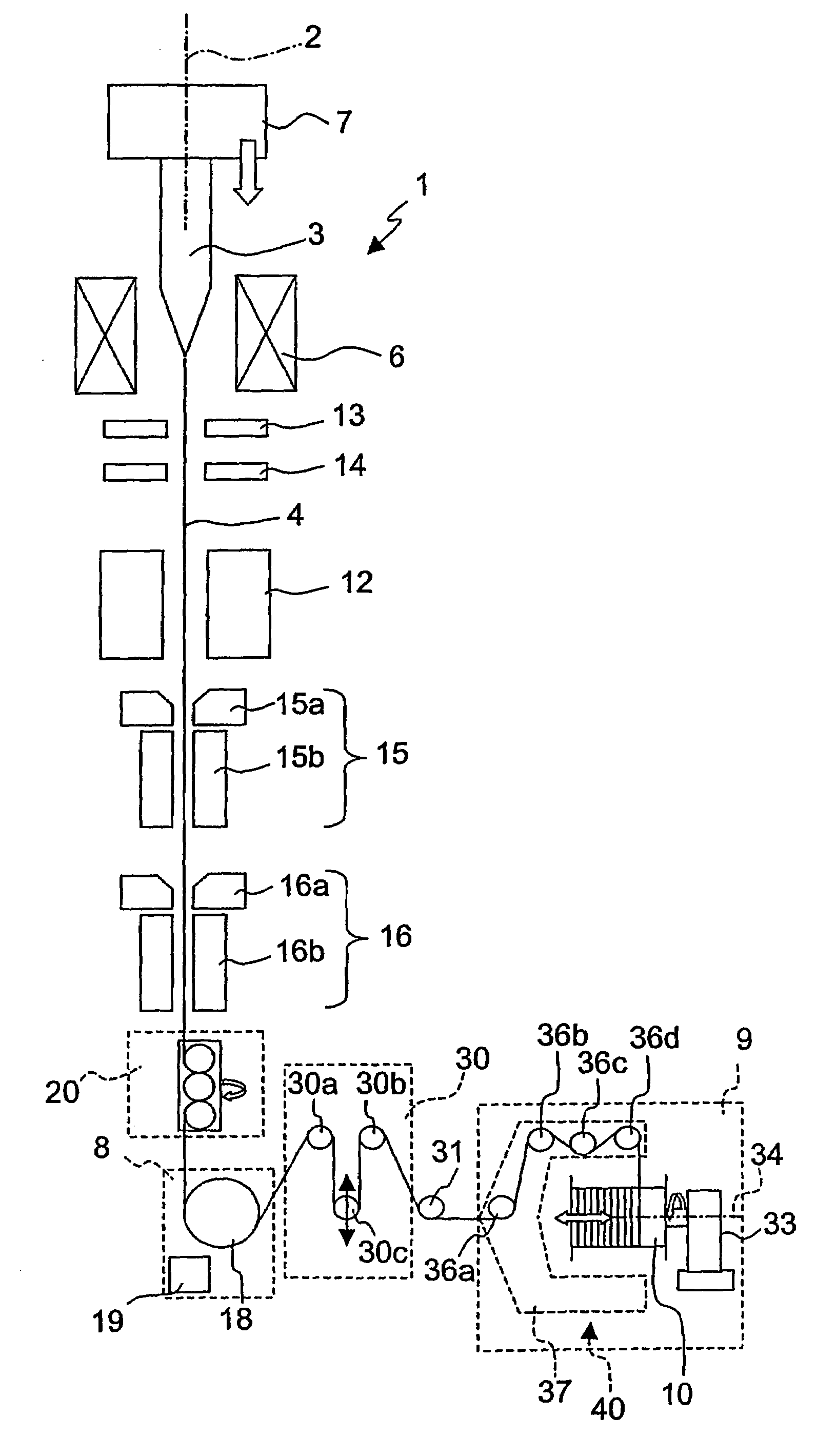

Device and Method for Preparing Filament Yarn of Composite Nanofibers

InactiveUS20080265469A1Less dispersionImprove mechanical propertiesFilament/thread formingConjugated artificial filamentsComposite nanofibersNanofiber

Device and method for preparing filament yarn of composite nanofibers. The device includes pairs of electrospinning nozzles on a frame and filament guiding roller pair under the frame. The spouts of each pair of nozzles are oppositely facing. The method includes feeding polymer solutions to the pairs of nozzles, applying high DC voltage with opposite polarity respectively to each one of the pairs of nozzles, forming composite nanofibers by attracting nanofibers with opposite charge from each nozzle and striking together of the charged nanofibers, pulling / stretching the composite nanofibers to form filament yarn of composite nanofibers, drawing down the filament yarn of composite nanofibers from the first pair of nozzles and using it as a carrier to receive the nanofibers with opposite charge electrospun from the second pair of nozzles and coated by the same so as to form multi-layer (e.g., two- or more-layer) filament yarn of composite nanofibers.

Owner:SOUTHEAST UNIV

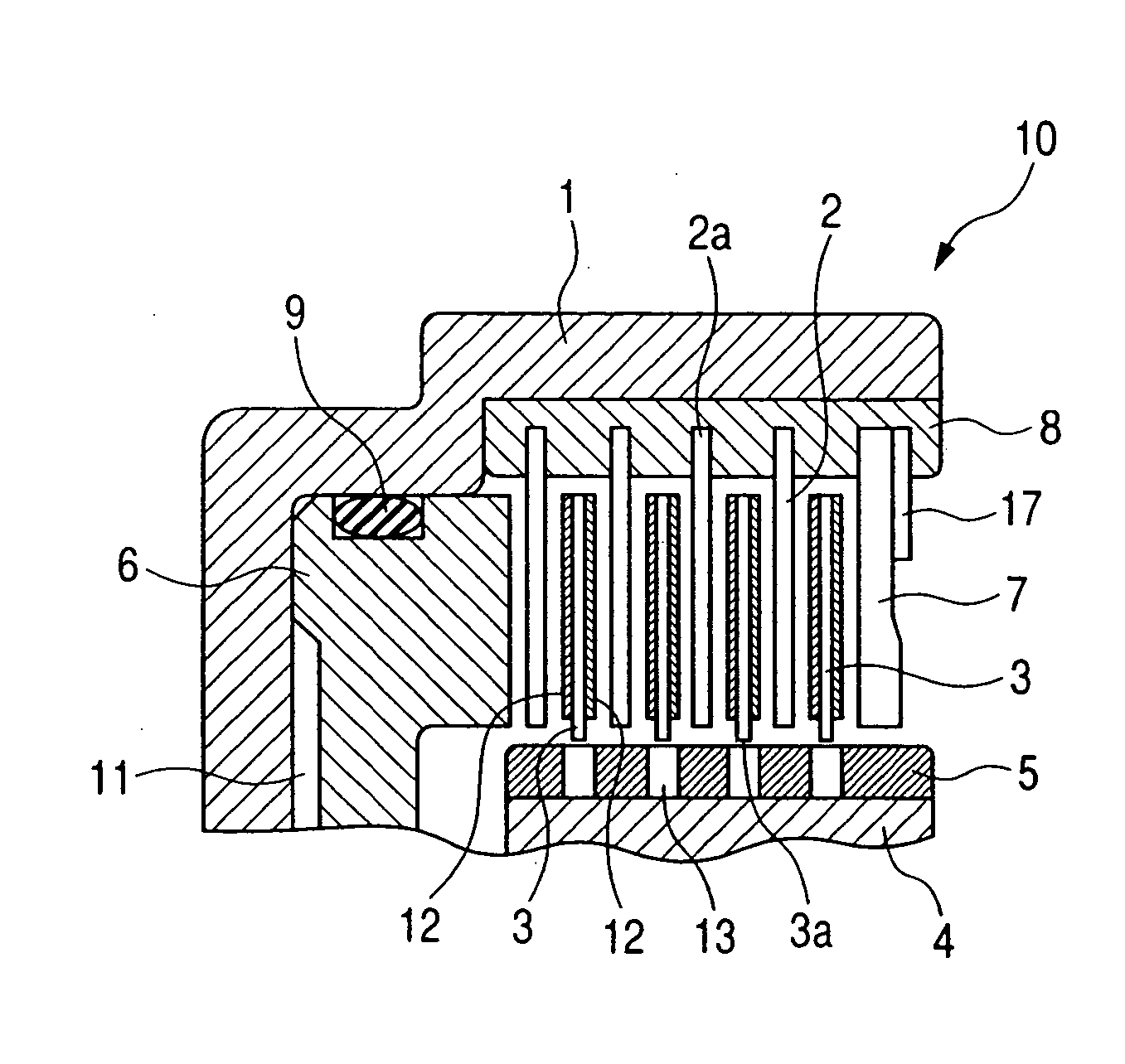

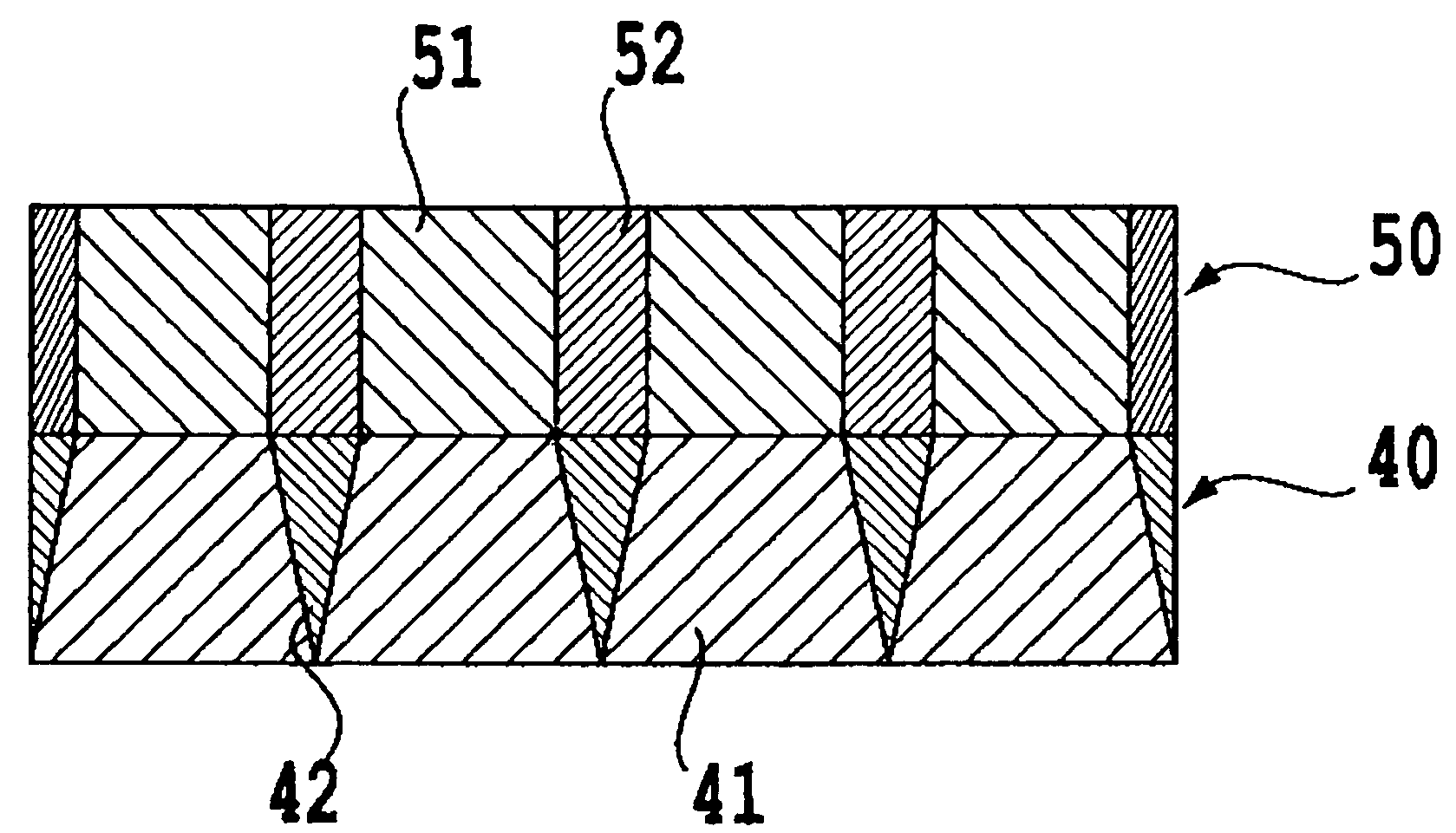

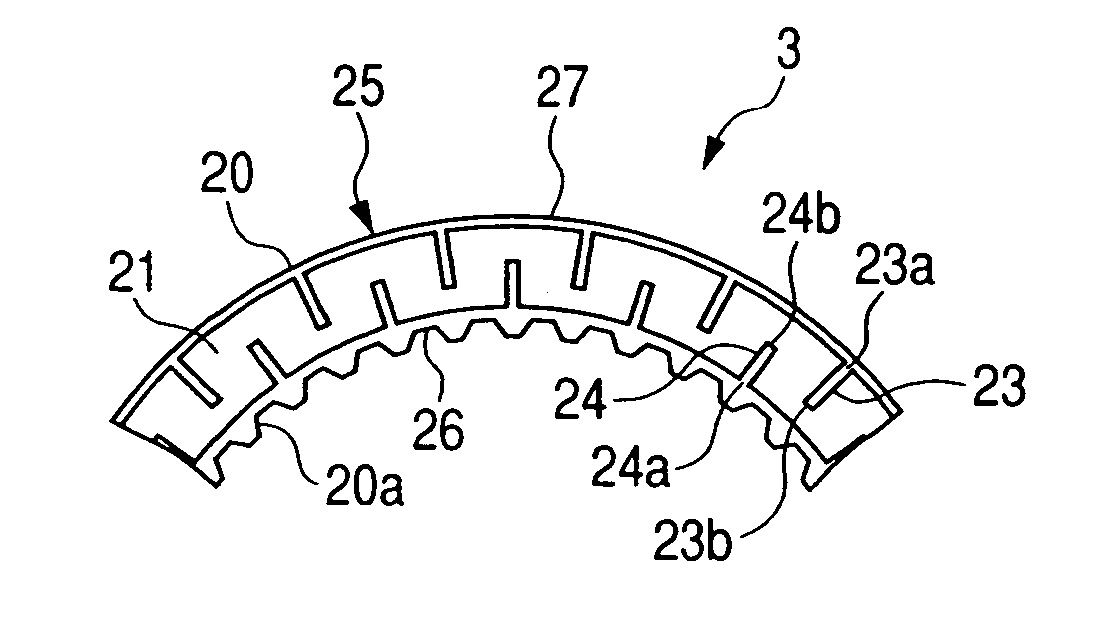

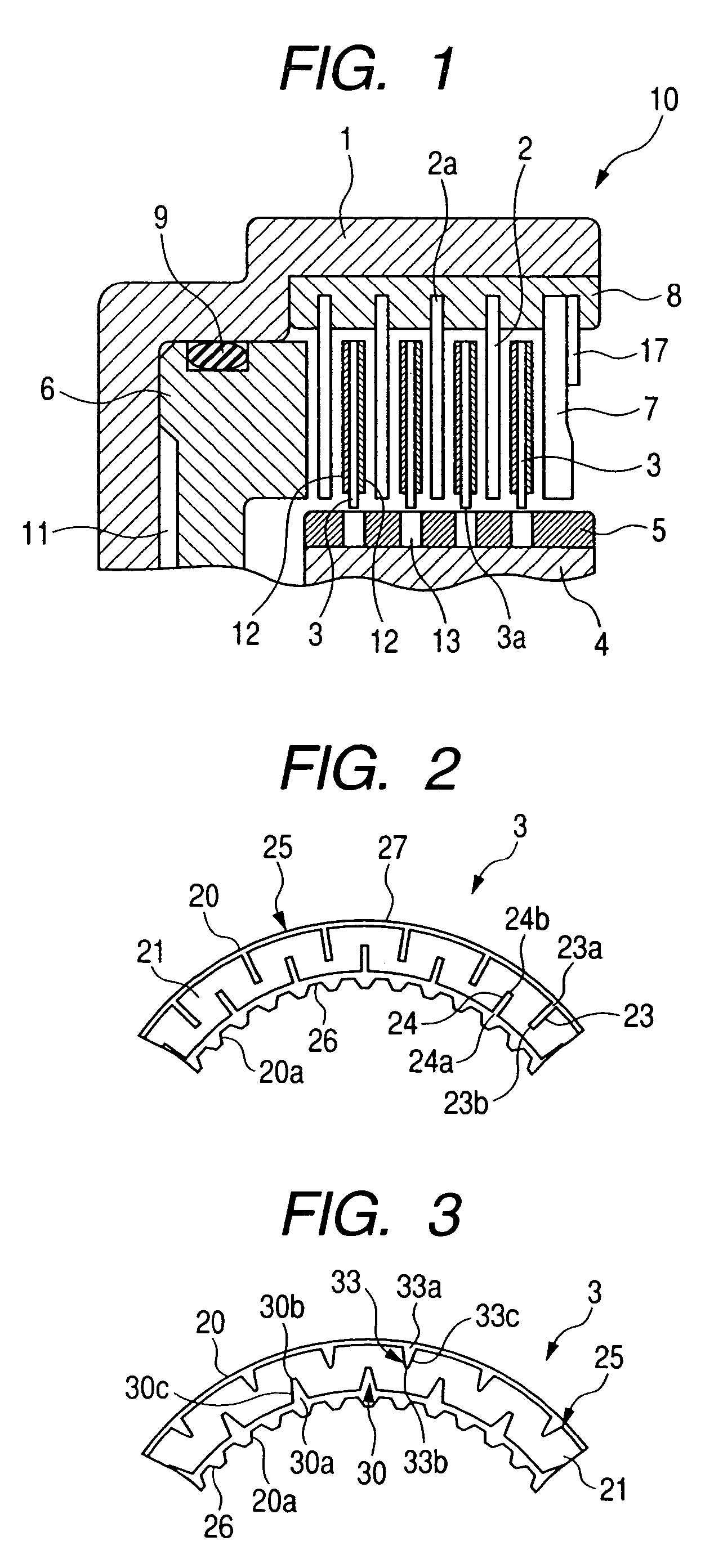

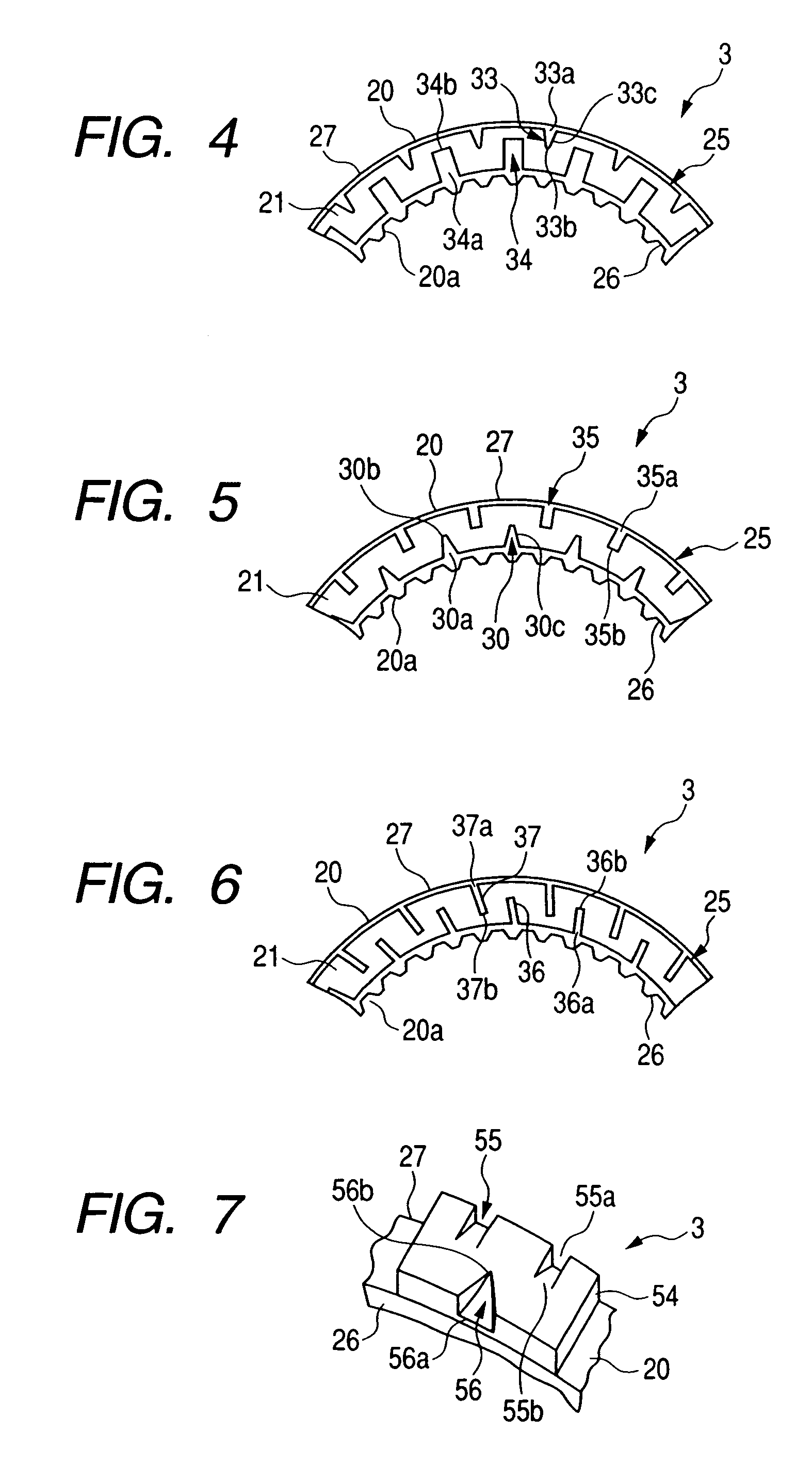

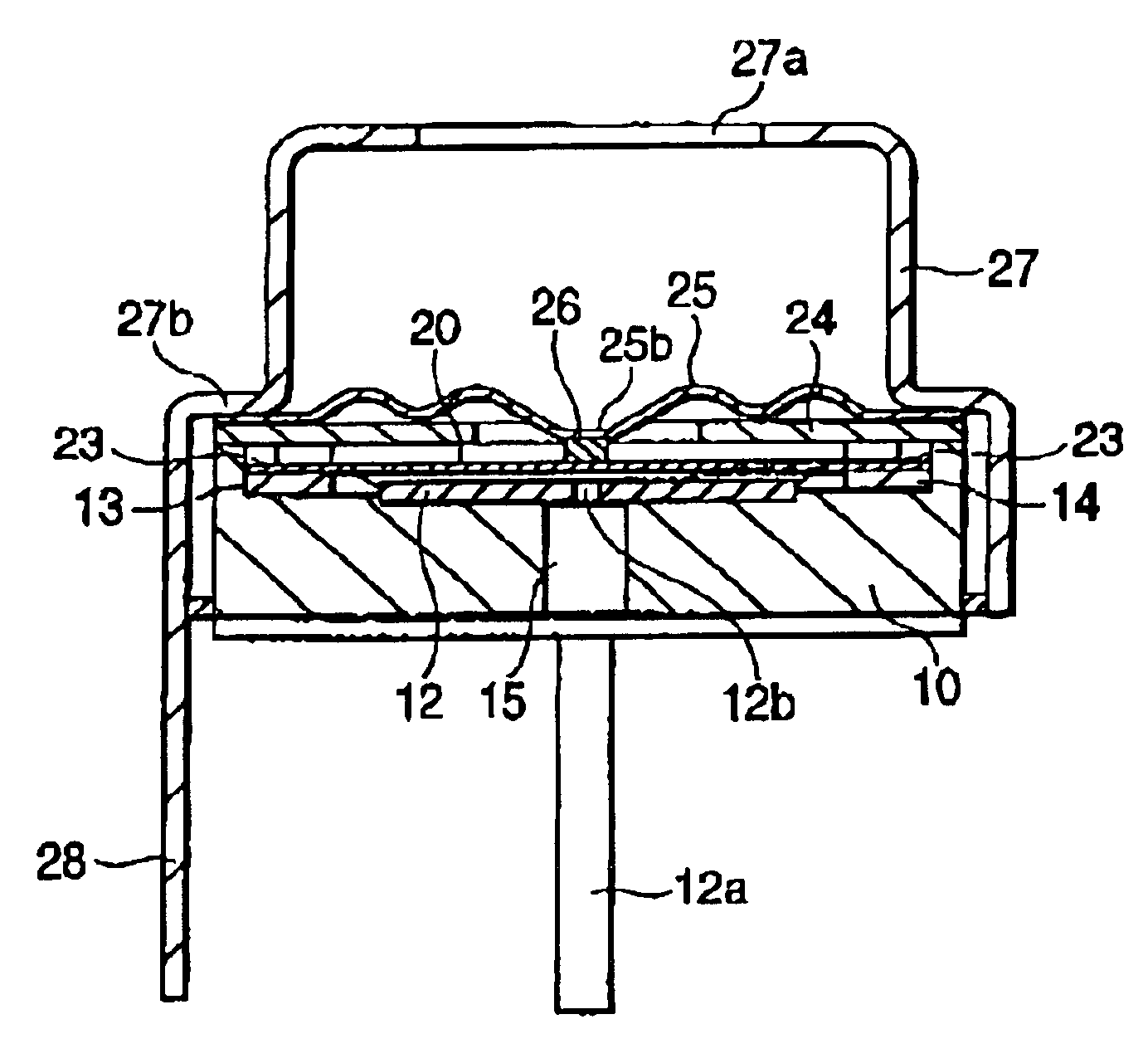

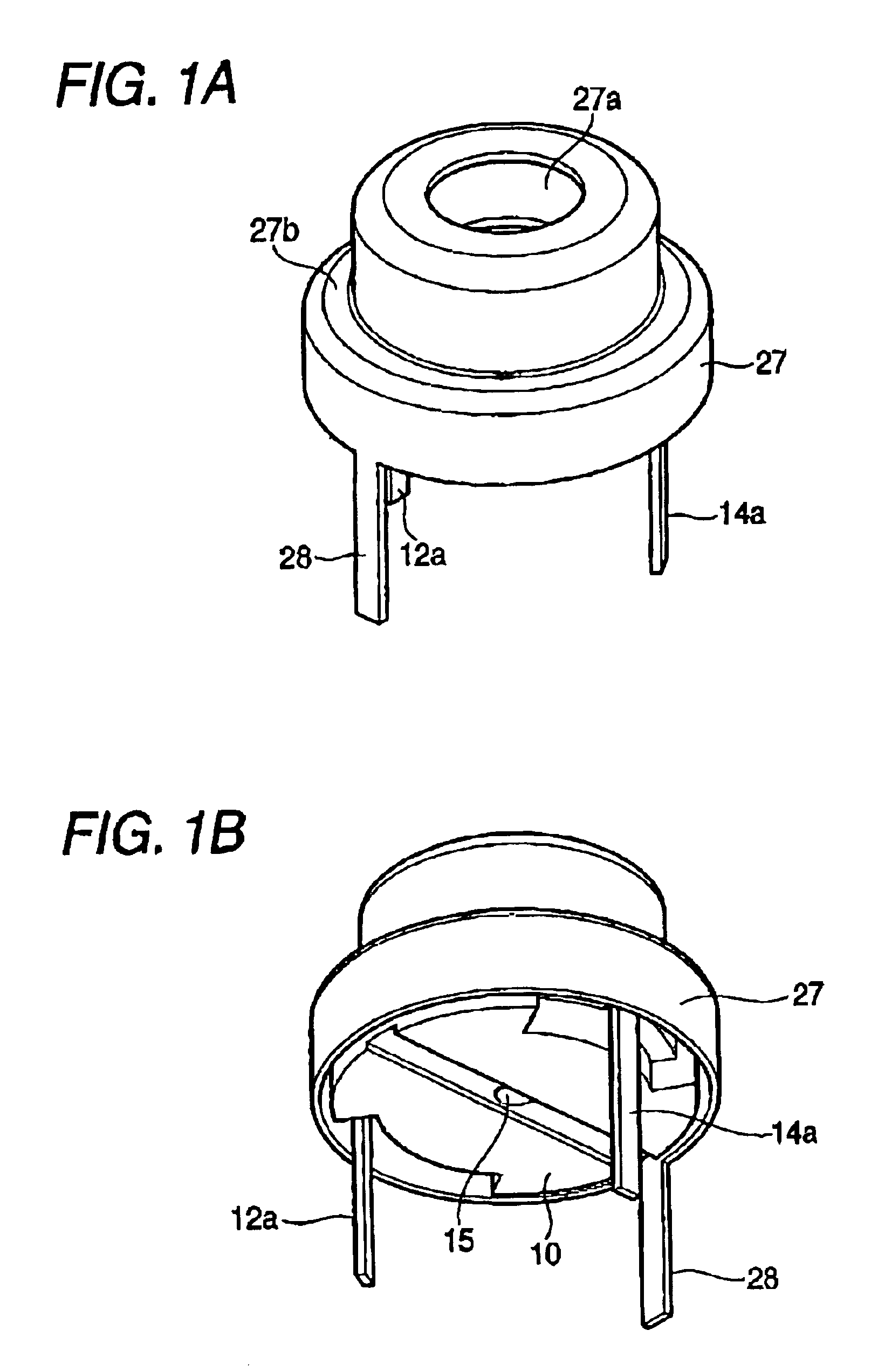

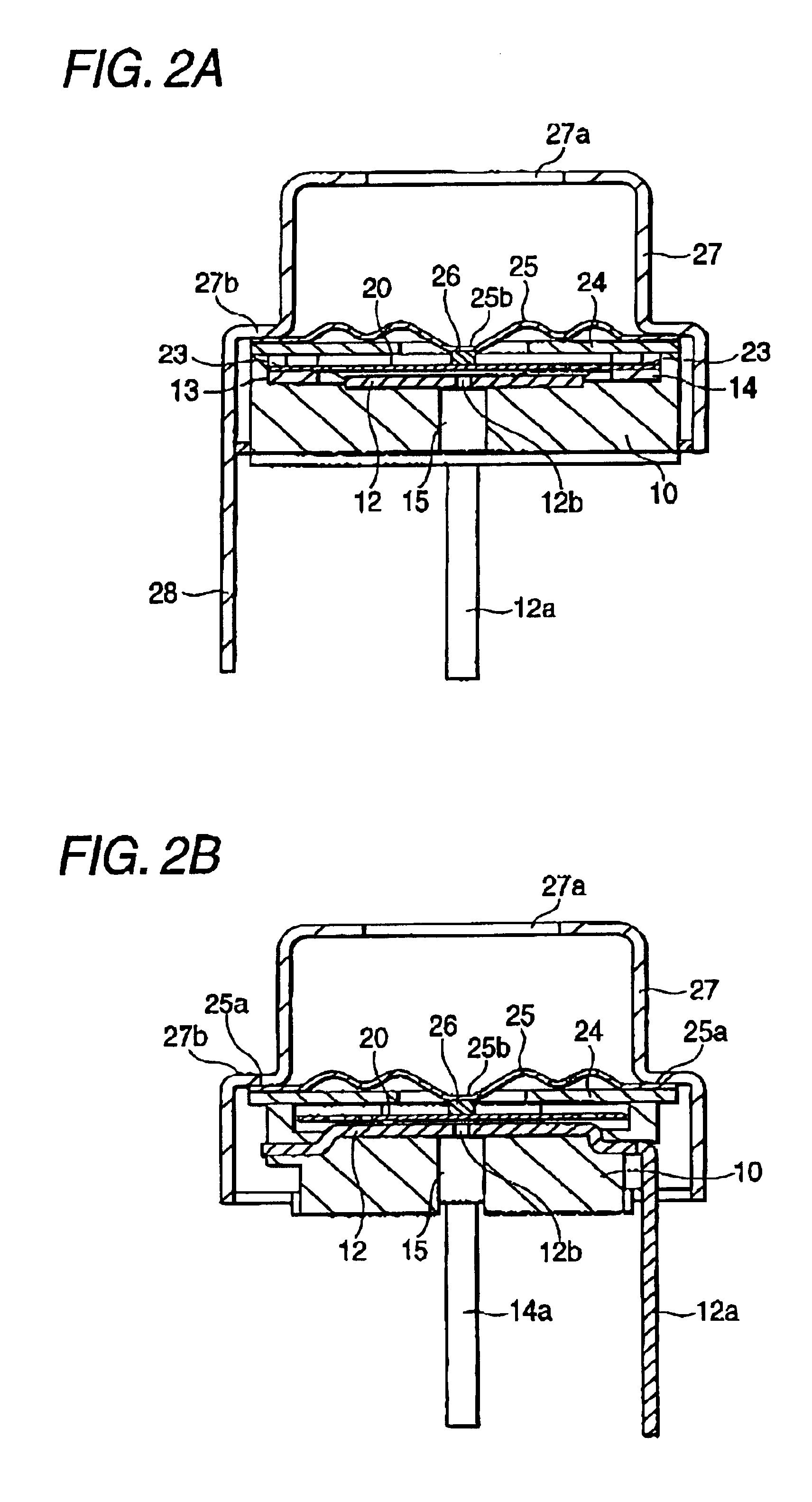

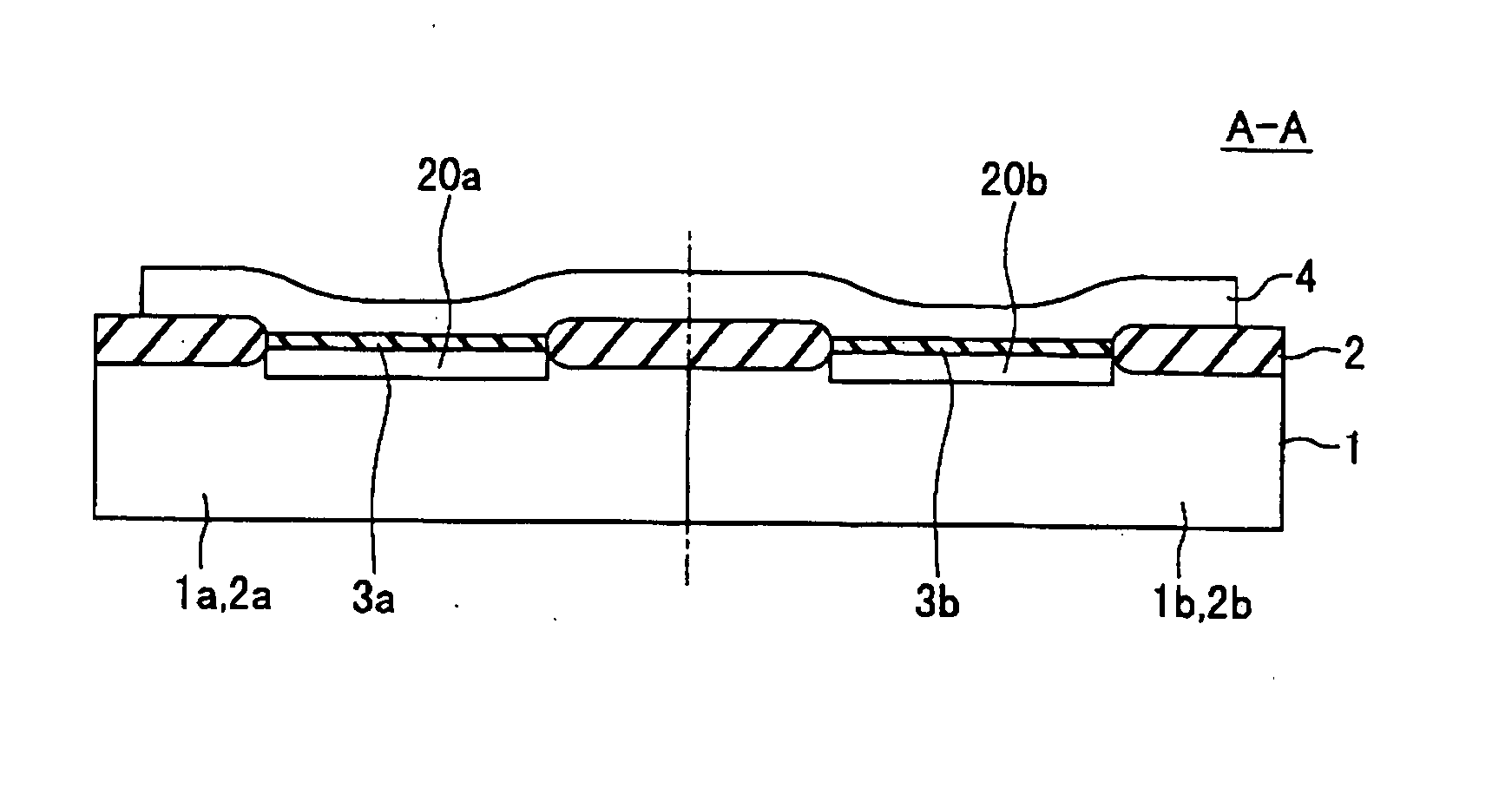

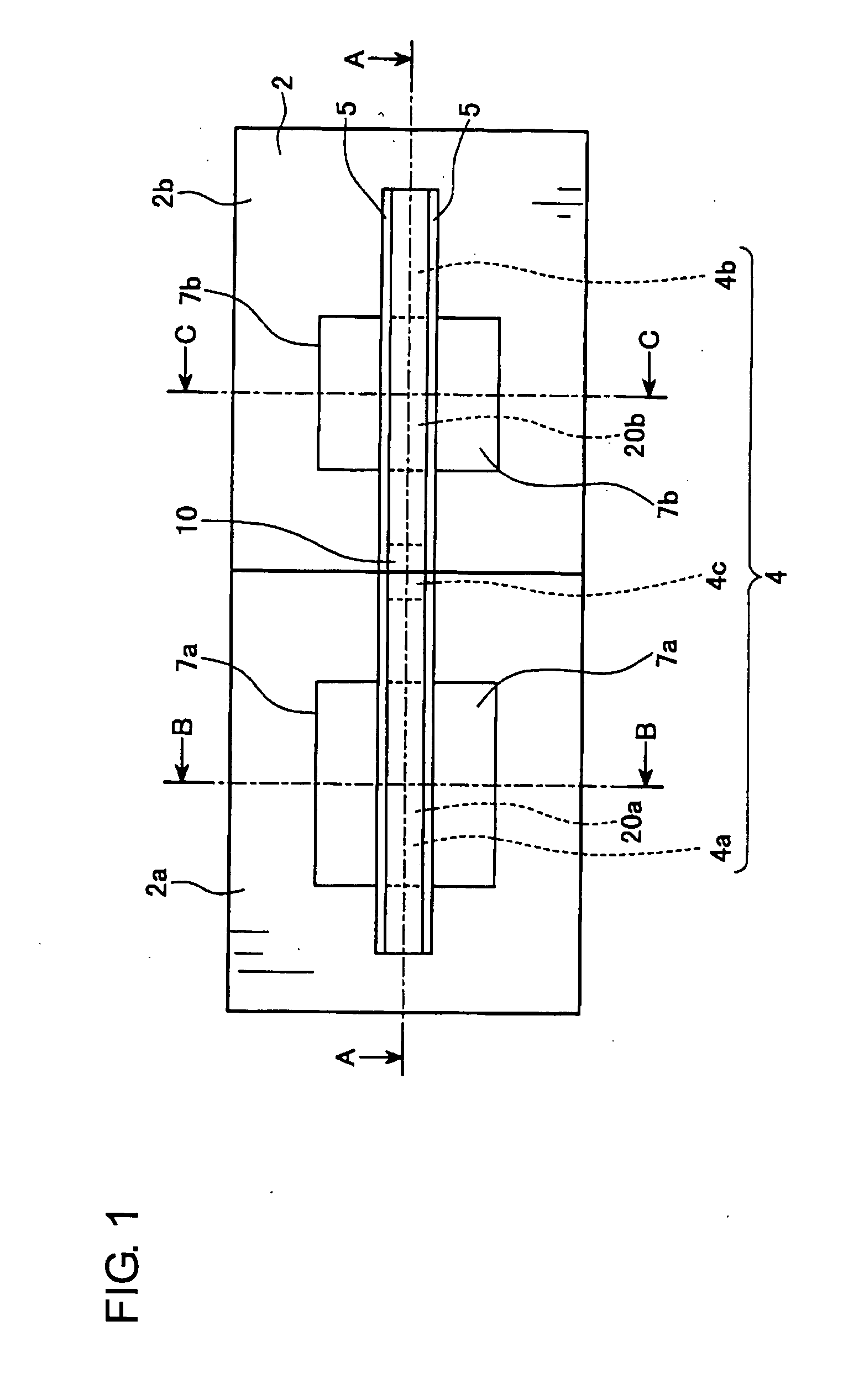

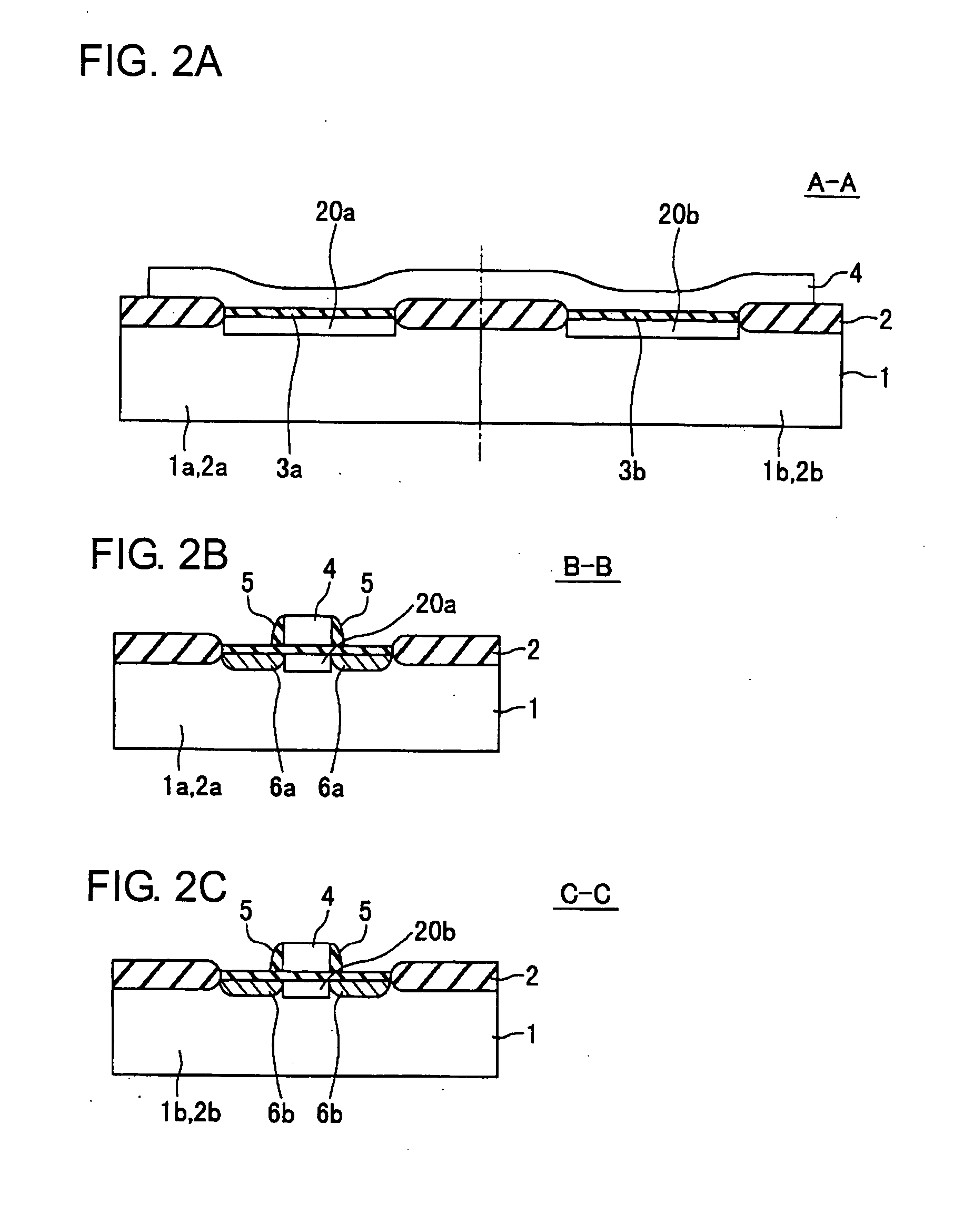

Friction plate and wet-type multi-plate clutch having such friction plate

InactiveUS20070199794A1Quality improvementImprove heat resistanceFluid actuated clutchesFriction clutchesEngineeringClutch

The present invention provides a friction plate having a friction surface formed by sticking an annular friction material to a substantially annular core plate and wherein the friction surface is provided with a first oil groove having an opening portion opened to an inner peripheral edge of the friction plate and an end terminating at a point between the inner peripheral edge and an outer peripheral edge, and a second oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end terminating at a point between the inner peripheral edge.

Owner:NSK WARNER

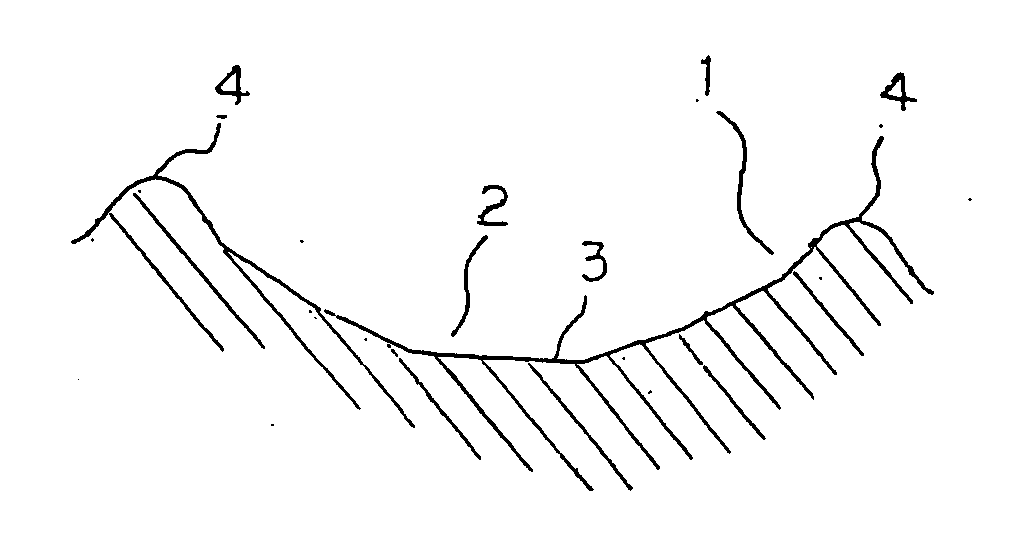

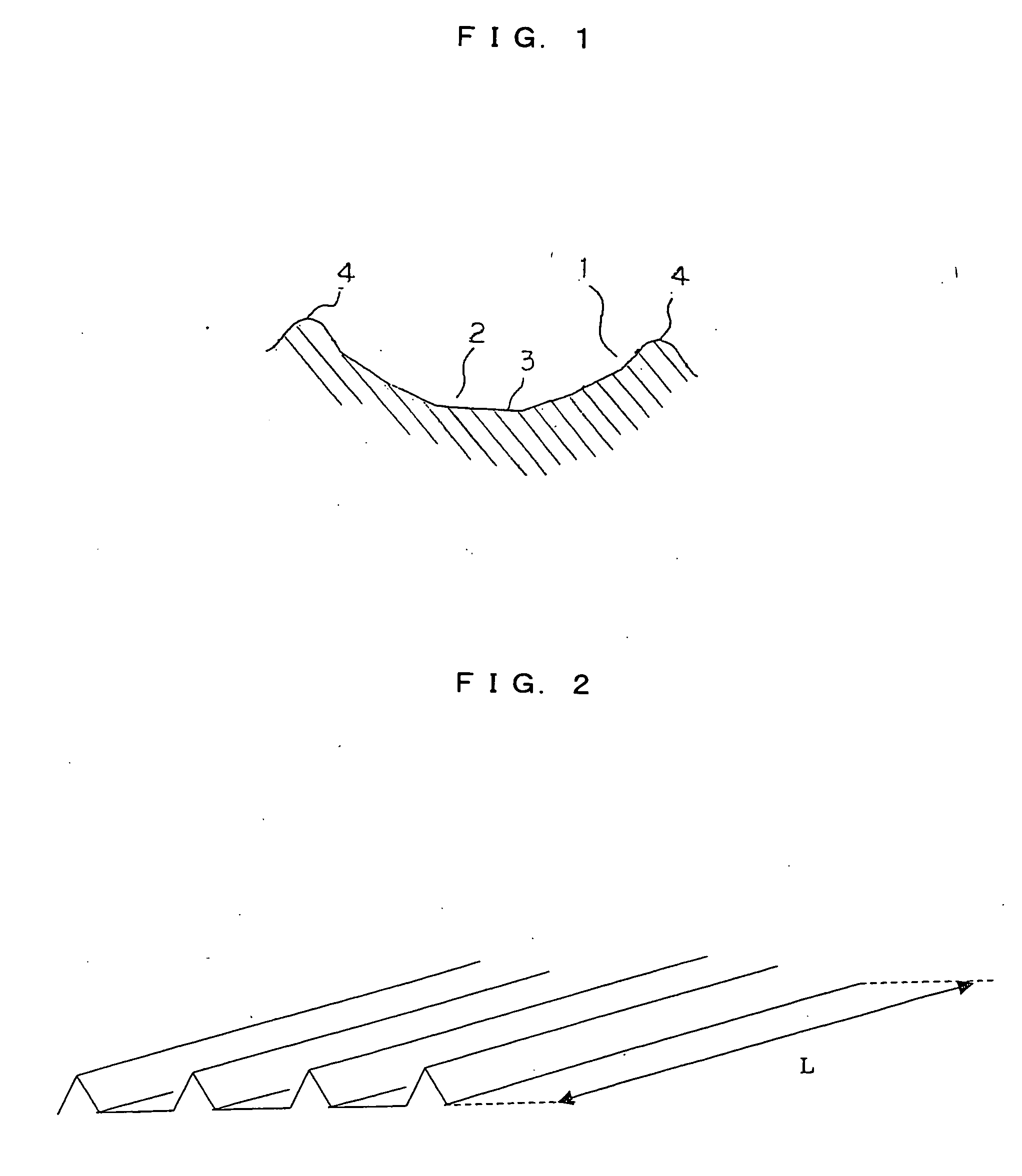

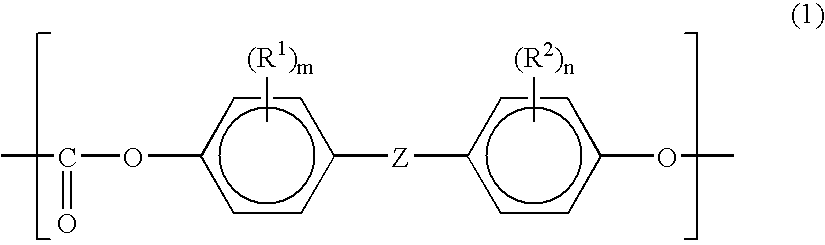

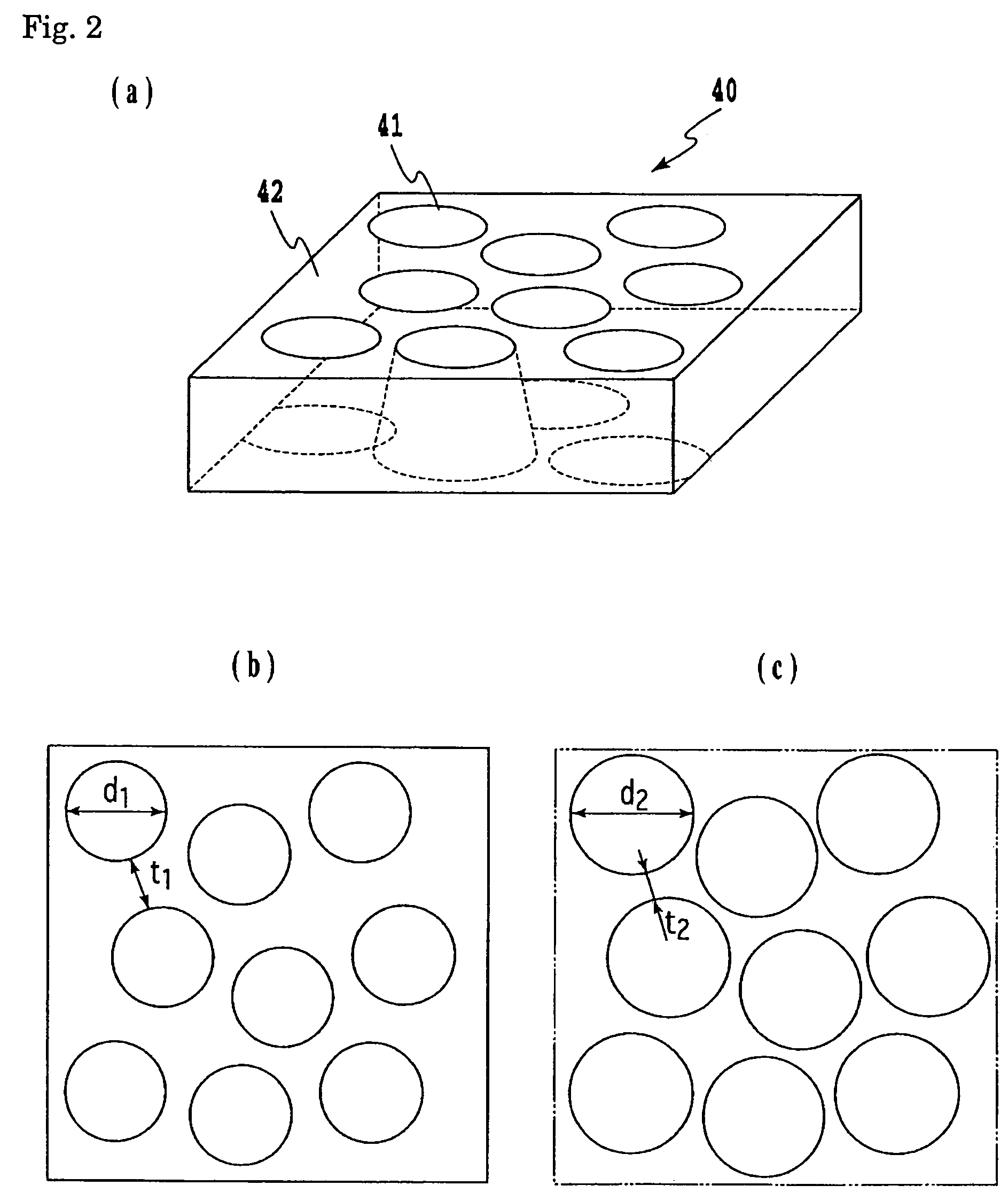

Light refection sheet, process for producing the same and molding thereof

InactiveUS20060159926A1Improve reflectivityHigh propertyDiffusing elementsSynthetic resin layered productsLight reflectionOptical transmittance

The light reflection sheet (I) of the present invention comprises a sheet having a thickness of 0.4 to 2 mm and comprising a polycarbonate resin composition containing (B) titanium oxide, and the sheet has a light reflectance of 98% or more and a light transmittance of less than 1%. It is excellent in a flame retardancy and a reflection characteristic. Also, the light reflection sheet (II) of the present invention is prepared by providing a light-fast layer which cuts or absorbs a UV ray in a thickness of 0.5 to 20 μm on at least one face of a base sheet having a thickness of 0.4 to 2 mm and comprising a PC resin composition containing a combination of 85 to 60 mass % of (A) a PC base polymer and 15 to 40 mass % of (B) titanium oxide. It is less yellowed and less reduced in a reflection characteristic even after used for a long period of time. Further, the light reflection sheet (III) of the present invention is prepared by providing a light diffusion layer which diffuses and reflects light in a thickness of 0.5 to 20 μm on at least one face of the same base sheet as in the light reflection sheet (II). It is improved in a light diffusing and reflecting property and can form a liquid crystal image plane having less luminance unevenness when it is used as a direct under type liquid crystal back light.

Owner:IDEMITSU KOSAN CO LTD

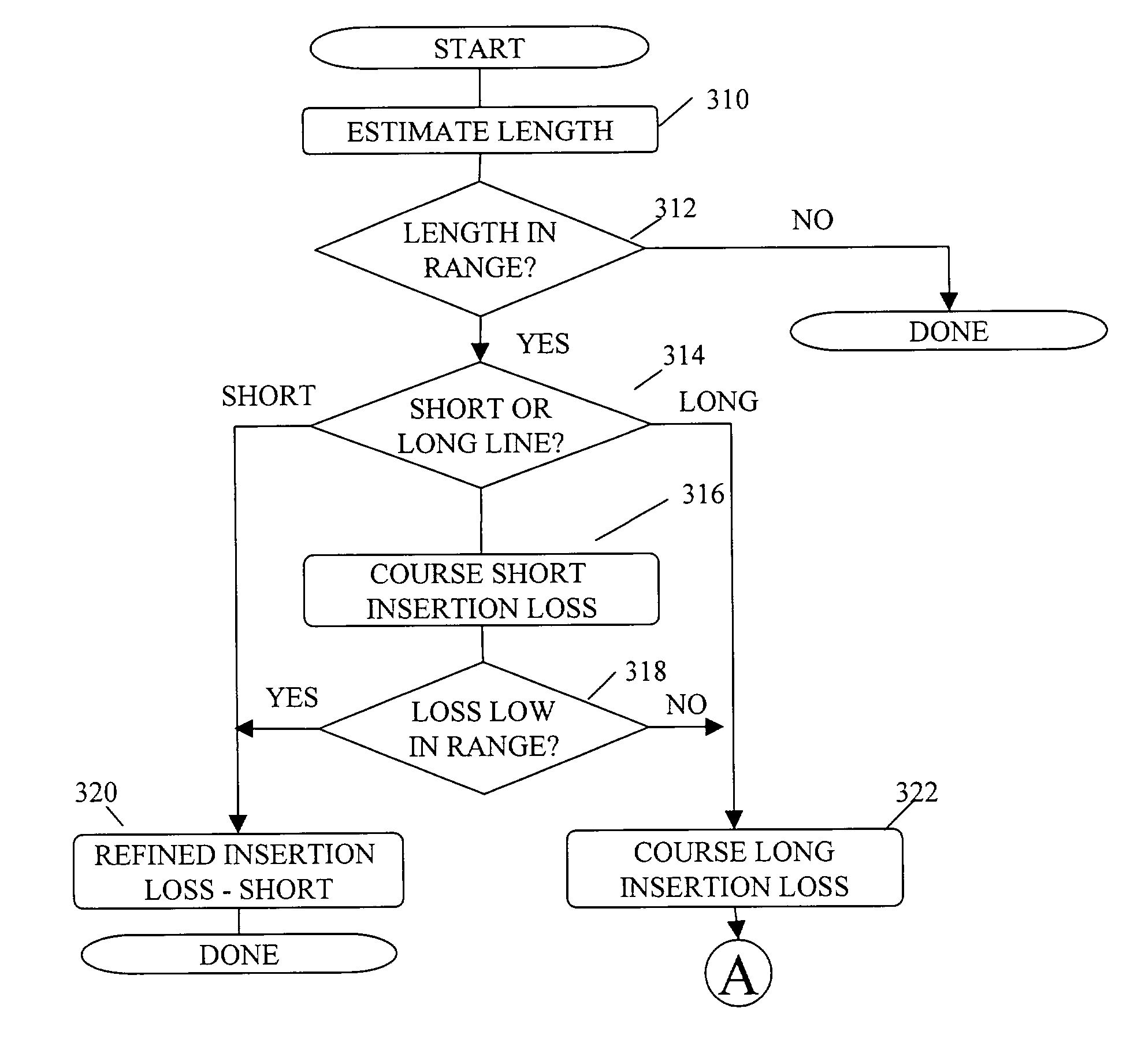

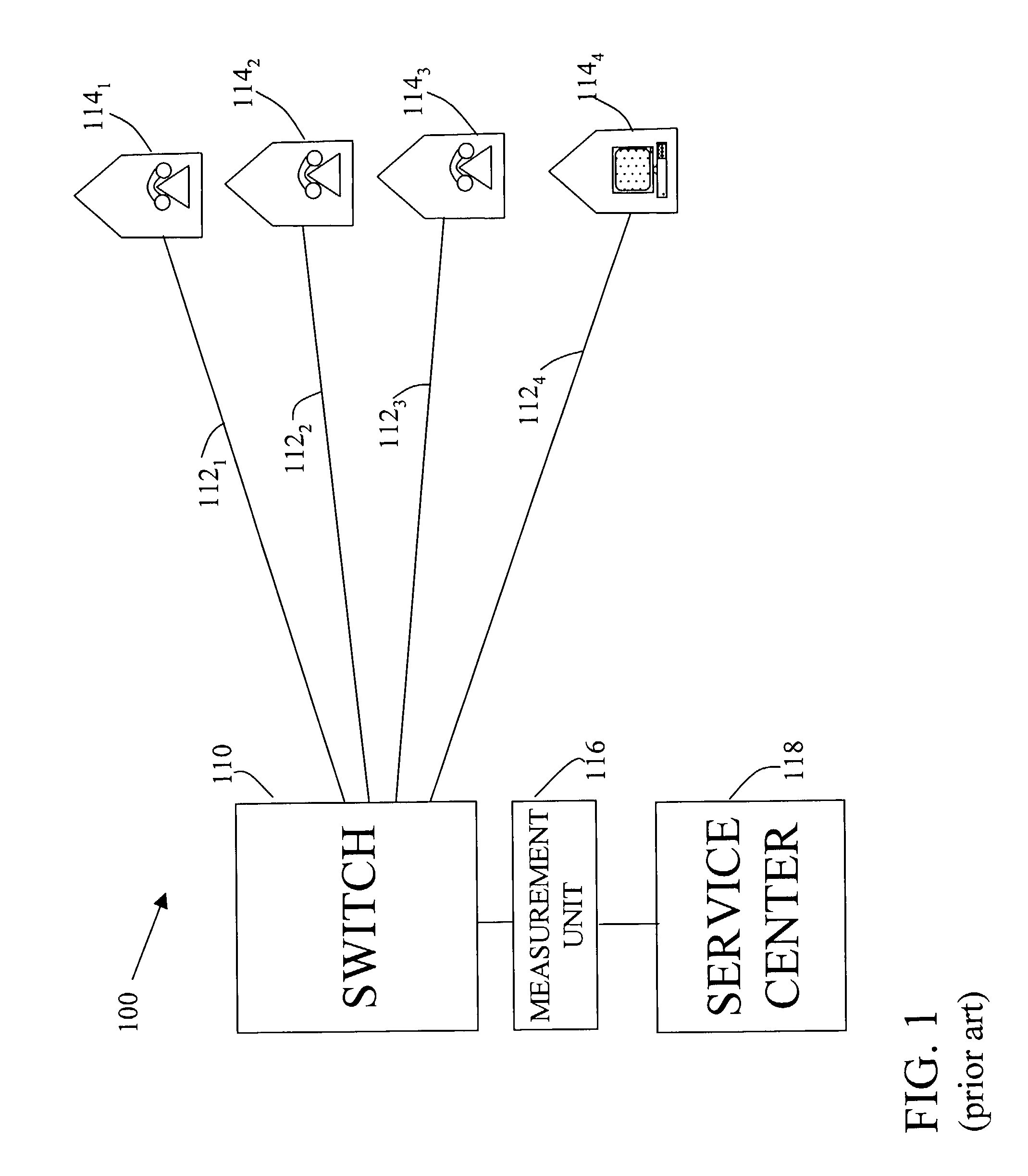

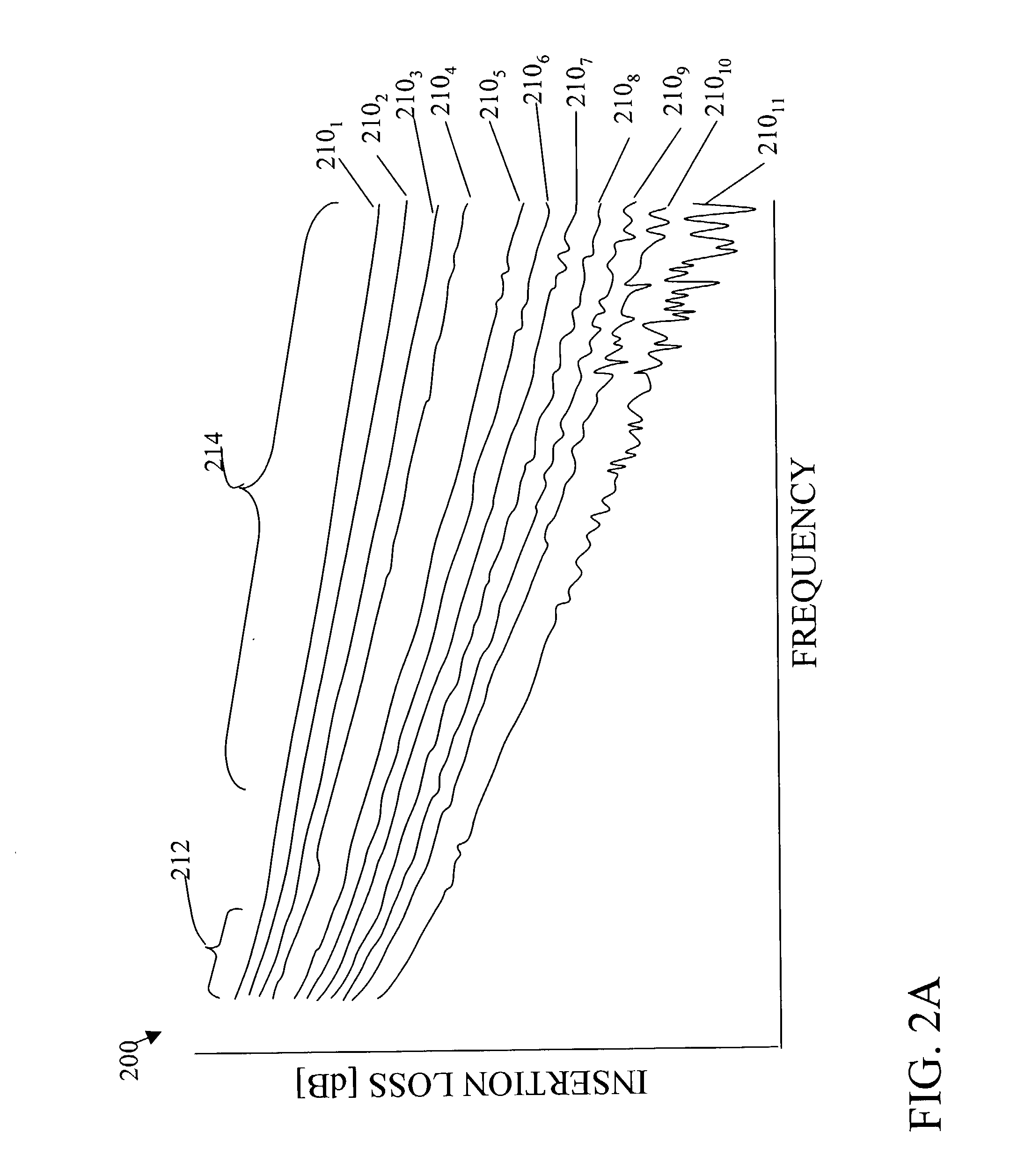

System and method for pre-qualification of telephone lines for DSL service using an average loop loss

InactiveUS20030235274A1Accurate representationRate of decrease is fasterSupervisory/monitoring/testing arrangementsSubstation equipmentTelephone networkComputer science

A system and method for testing lines in a network. The system and method are described in connection with a system for use with a telephone network to aid a network operator determine whether the any line can support high speed data services. According to the method, a mapping is created between low frequency measurements and average loop loss over a high frequency range. The average loop loss is sued to compute the equivalent working length of a line, which is an industry standard measure of the ability of a line to support high speed data services.

Owner:TOLLGRADE COMM INC

Heat-shrinkable polystyrene based resin film roll and method for production thereof, and heat-shrinkable label

InactiveUS20050019514A1Less dispersionReducing raw materialWrappers shrinkageLayered productsShrinkage ratePolystyrene

A film roll comprising a heat-shrinkable polystyrene based resin film wound into a roll, characterized in that, each of the samples taken out from the roll exhibits, in a heat shrinkage test under the condition of the immersion in a hot water at 85° C. for 10 sec, a heat shrinkage rate in the main shrinking direction of within ±5% relative to an average rate of the total samples; a heat-shrinkable polystyrene based resin film taken from the roll; a heat-shrinkable label comprising the film; a method for producing the heat-shrinkable polystyrene based resin film roll which comprises using raw material chips having a specific form, or using a hopper having a specific shape for feeding raw material chips to an extruder, or limiting the variation of the surface temperature of a film in a specific production step to a specific range.

Owner:TOYOBO CO LTD

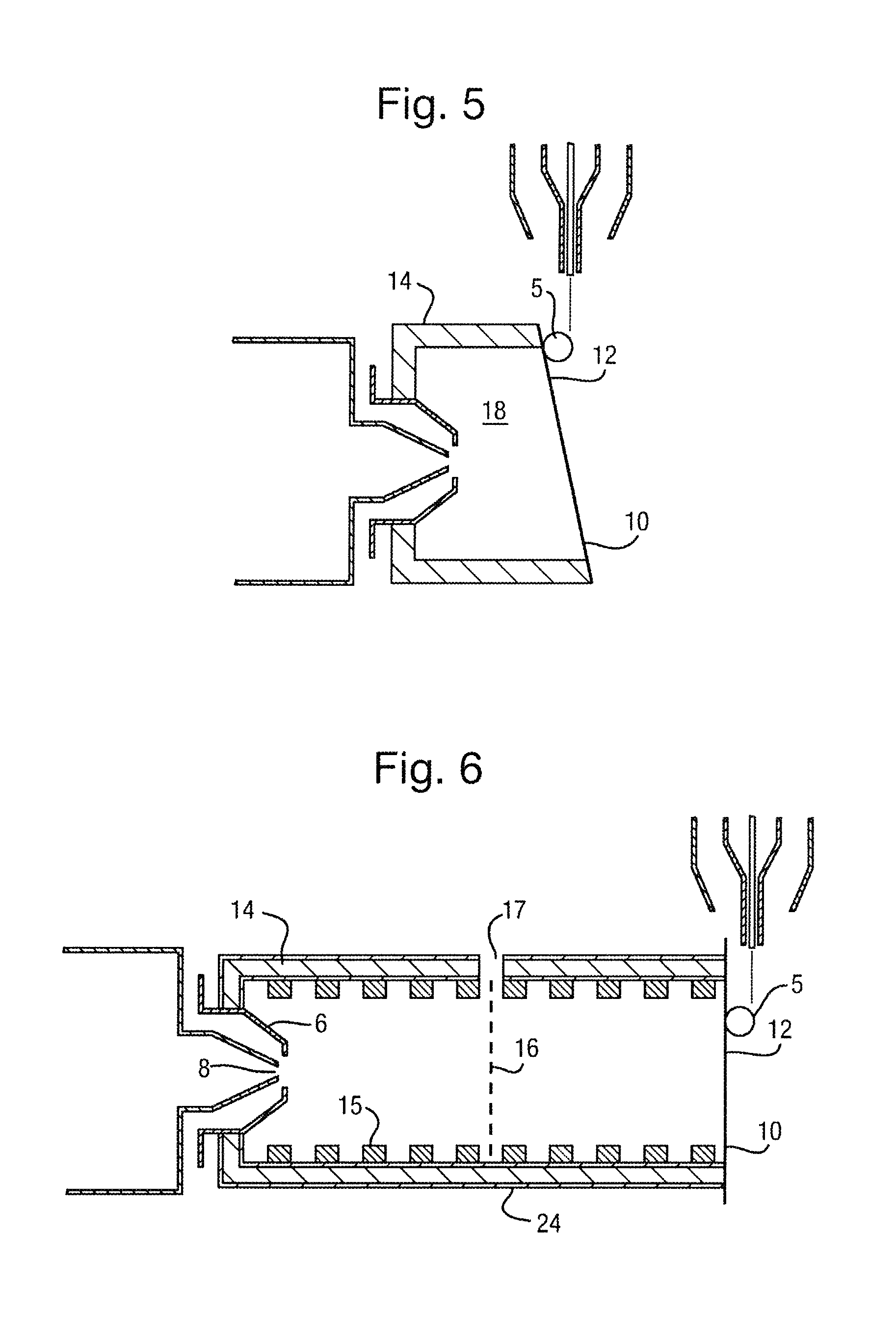

Hall effect thruster with cooling of the internal ceramic

ActiveUS20110062899A1Little and no instabilityImprove performanceTransit-time tubesMachines/enginesTemperature differenceCeramic

The invention relates to the field of Hall effect thrusters. The invention provides a Hall effect thruster having a discharge channel of annular shape extending along an axis, the discharge channel being defined by an outer wall of annular shape and an inner wall of annular shape situated inside the space defined by the outer wall, a cathode situated outside the discharge channel, and an injector system situated at the upstream end of the discharge channel and also forming an anode, the downstream end of the discharge channel being open, wherein the thruster includes a heat sink device comprising a heat sink in contact with the inner wall and of thermal conductivity that is greater than the thermal conductivity of the inner wall, the heat sink being a sleeve and the heat sink device being suitable for discharging heat from the inner wall to the outside of the thruster so as to reduce the temperature difference between the inner wall and the outer wall.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

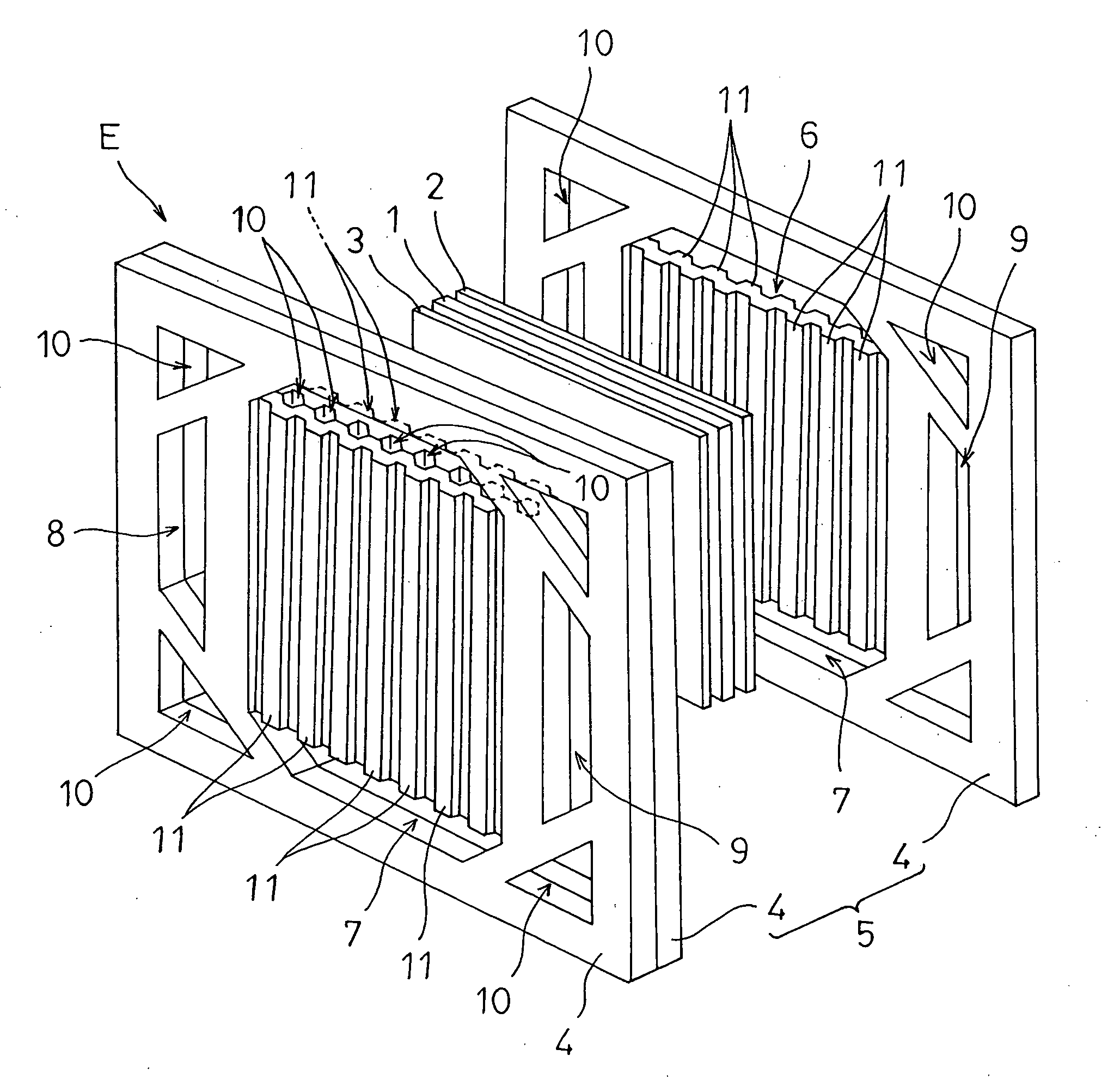

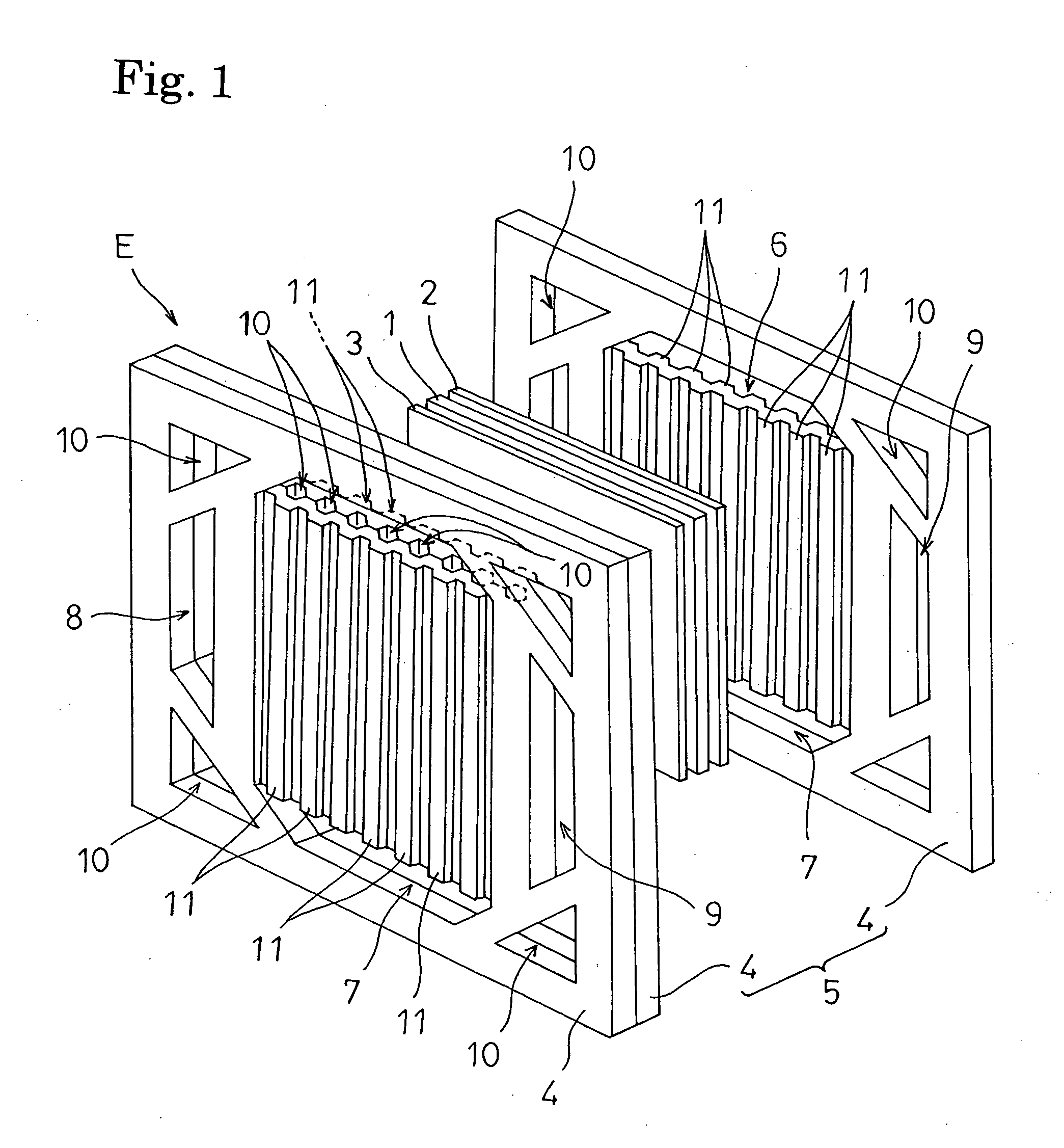

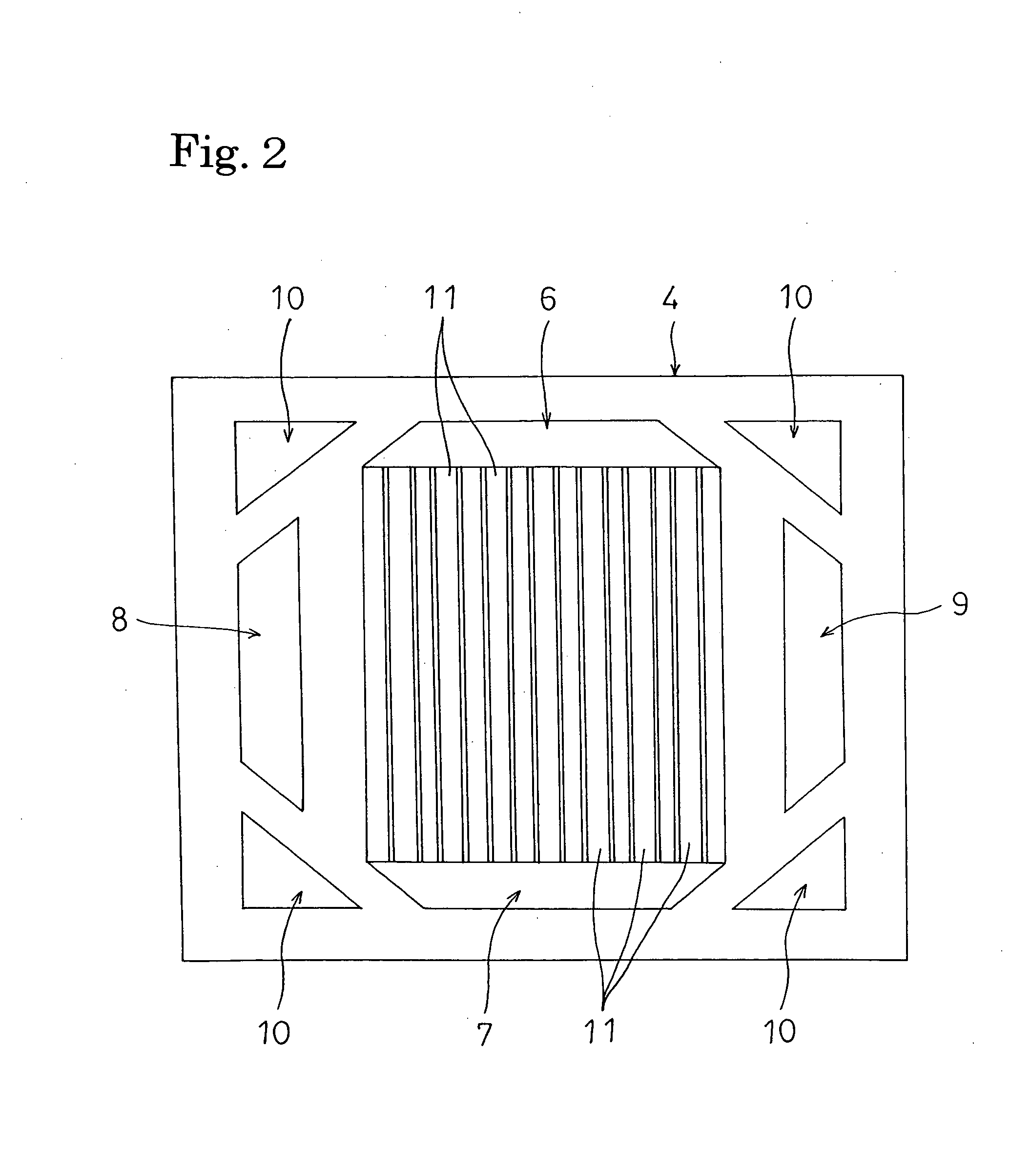

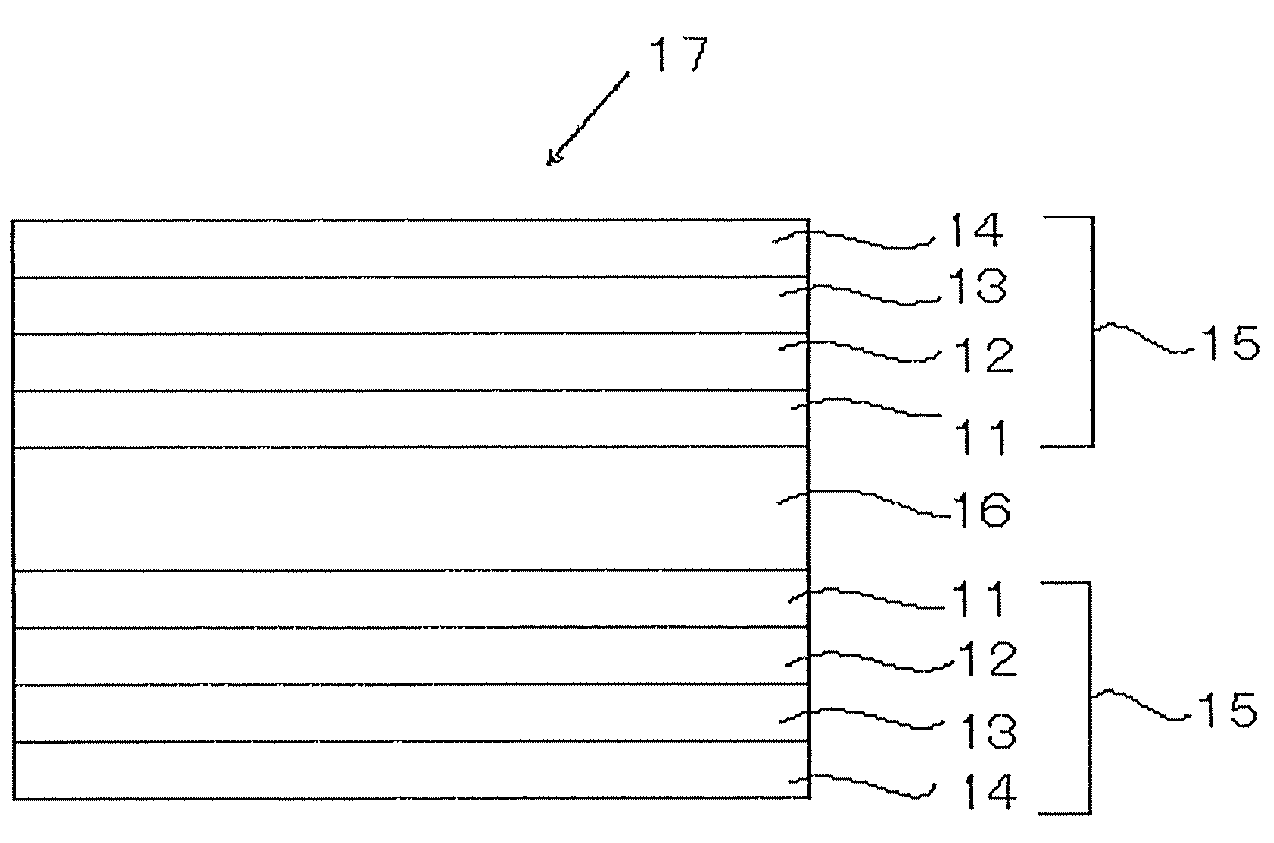

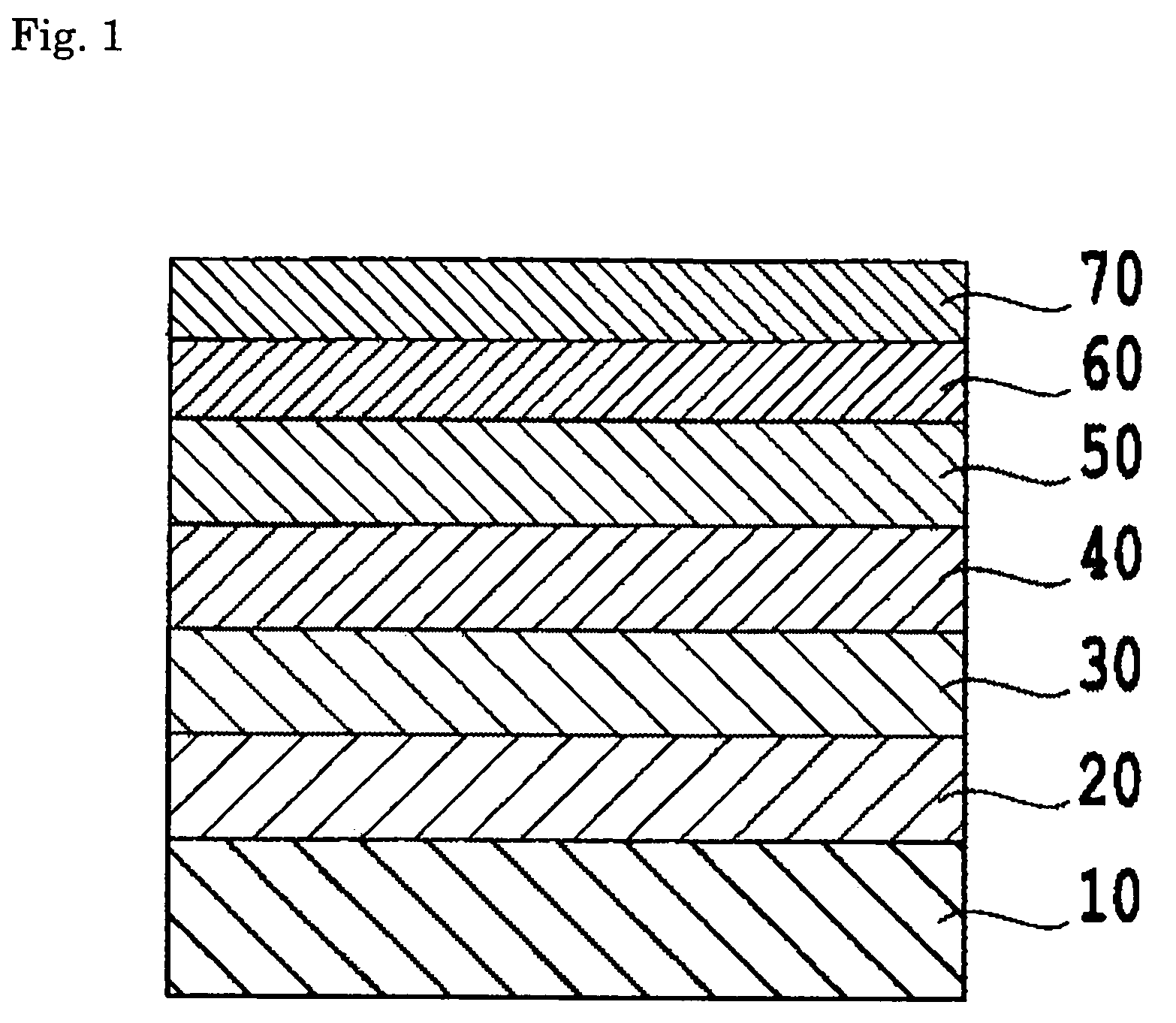

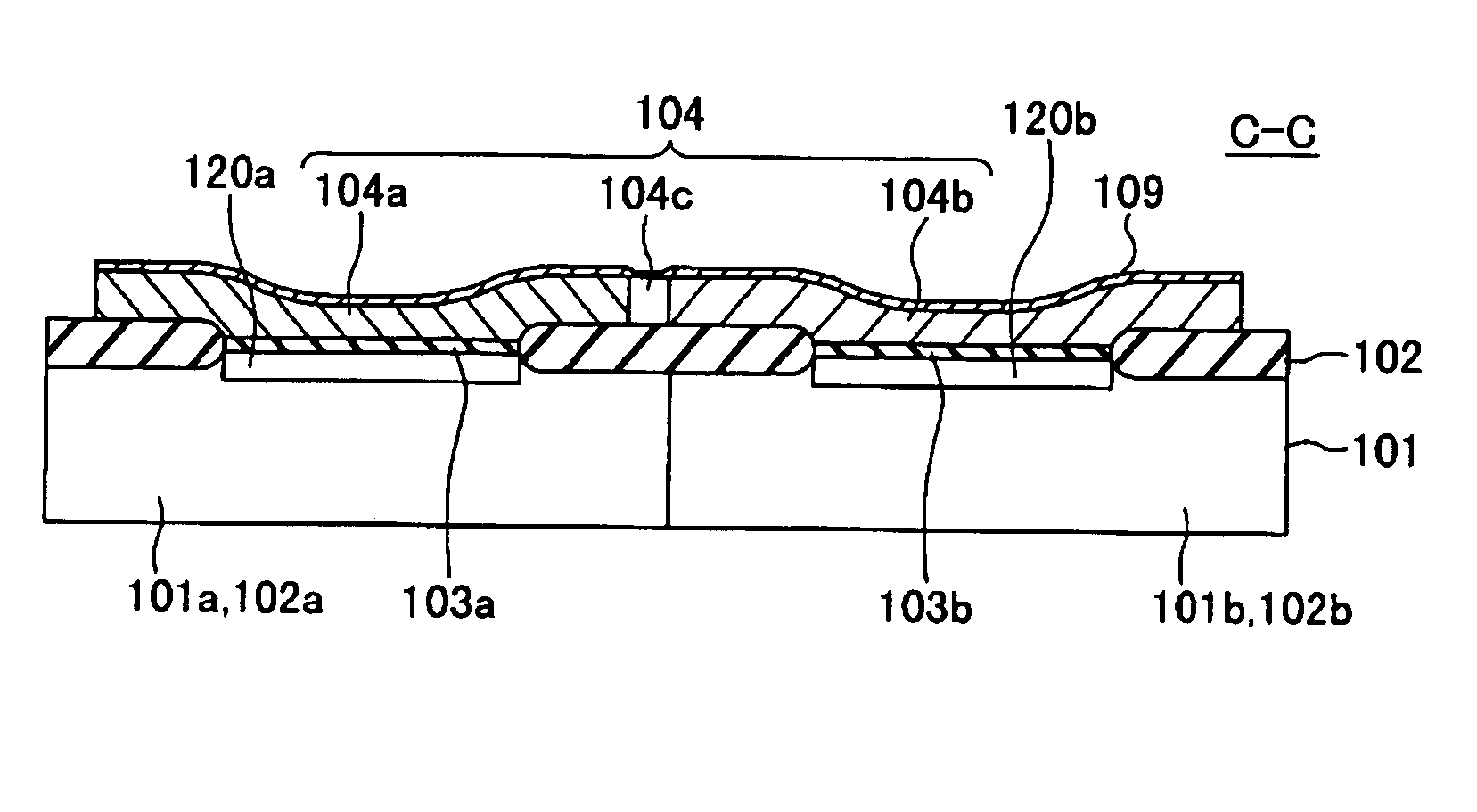

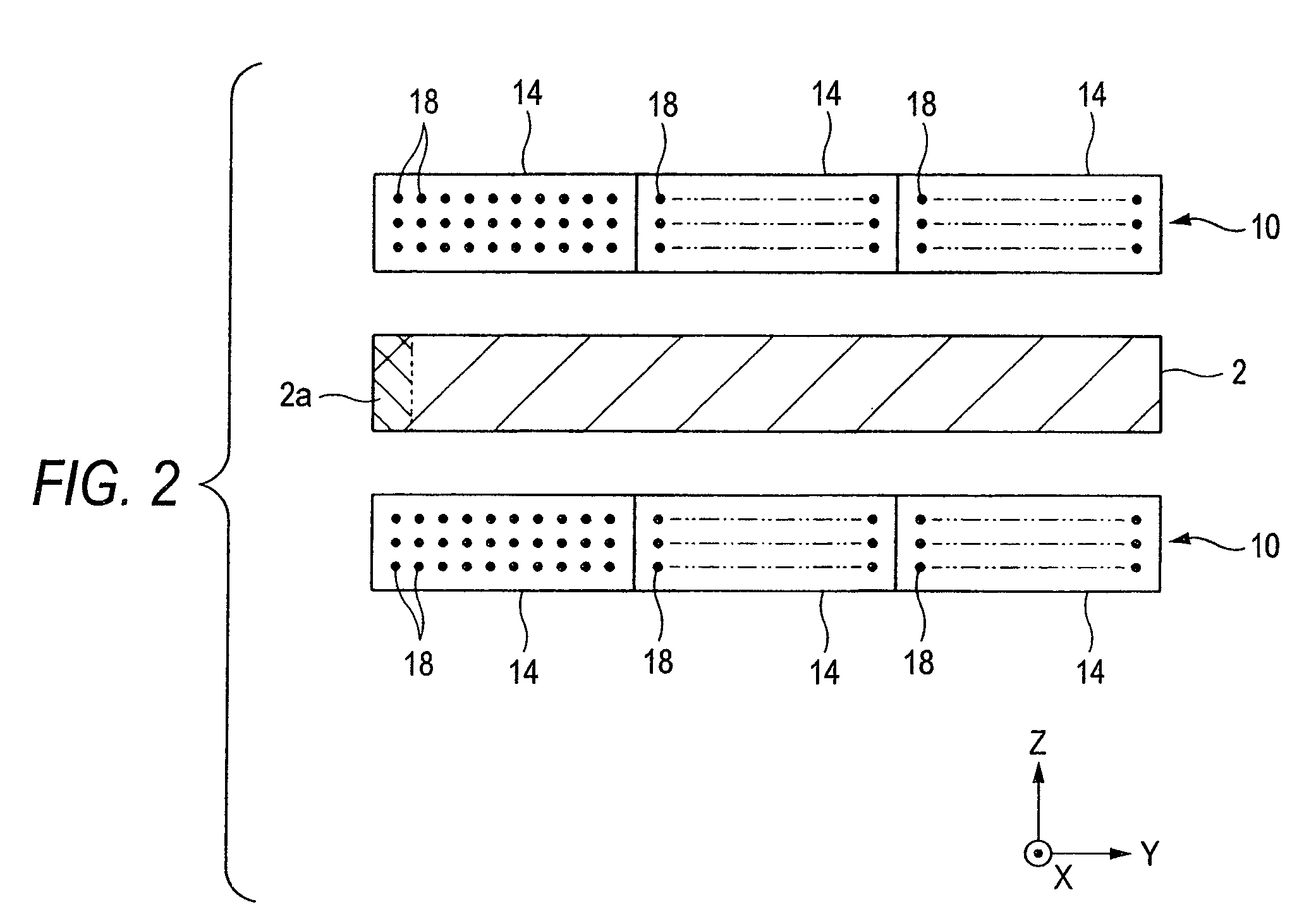

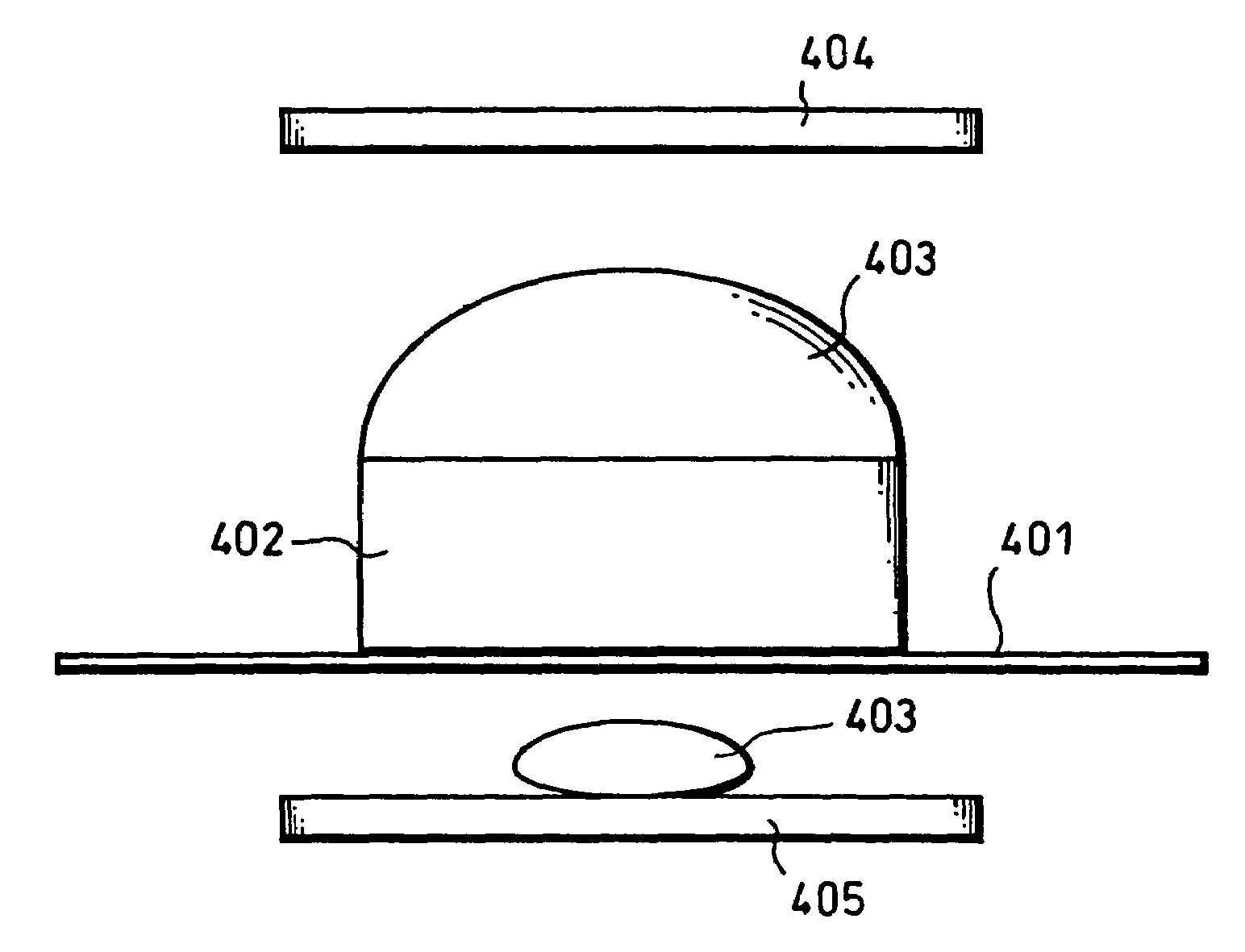

Separator for Fuel Cell and Process for Producing the Same

InactiveUS20100159357A1Good molding effectEasy to mass produceFinal product manufactureCell component detailsFiberFuel cells

In order to attain excellent electrical conductivity and molding processability, a fuel cell separator to be produced by performing press molding on a preform in which expanded graphite is used as the main raw material is improved so that the preform is produced by a papermaking method, whereby the characteristics of the mechanical strength, the flexibility, and the gas impermeability are improved, and a light and compact configuration that is preferred in the automobile use or the like can be realized. In a fuel cell separator which is to be produced by performing press molding on a preform 14 that is formed into a plate-like shape, with a molding die, therefore, the preform 14 is configured into a sandwich structure where a second sheet 14B in which a phenol resin is applied to graphite is interposed between a pair of first sheets 14A made by impregnating a sheet-like member with a phenol resin, the sheet-like member being obtained by a papermaking process using a raw material in which a fibrous filler is added to expanded graphite.

Owner:NIPPON PILLAR PACKING CO LTD

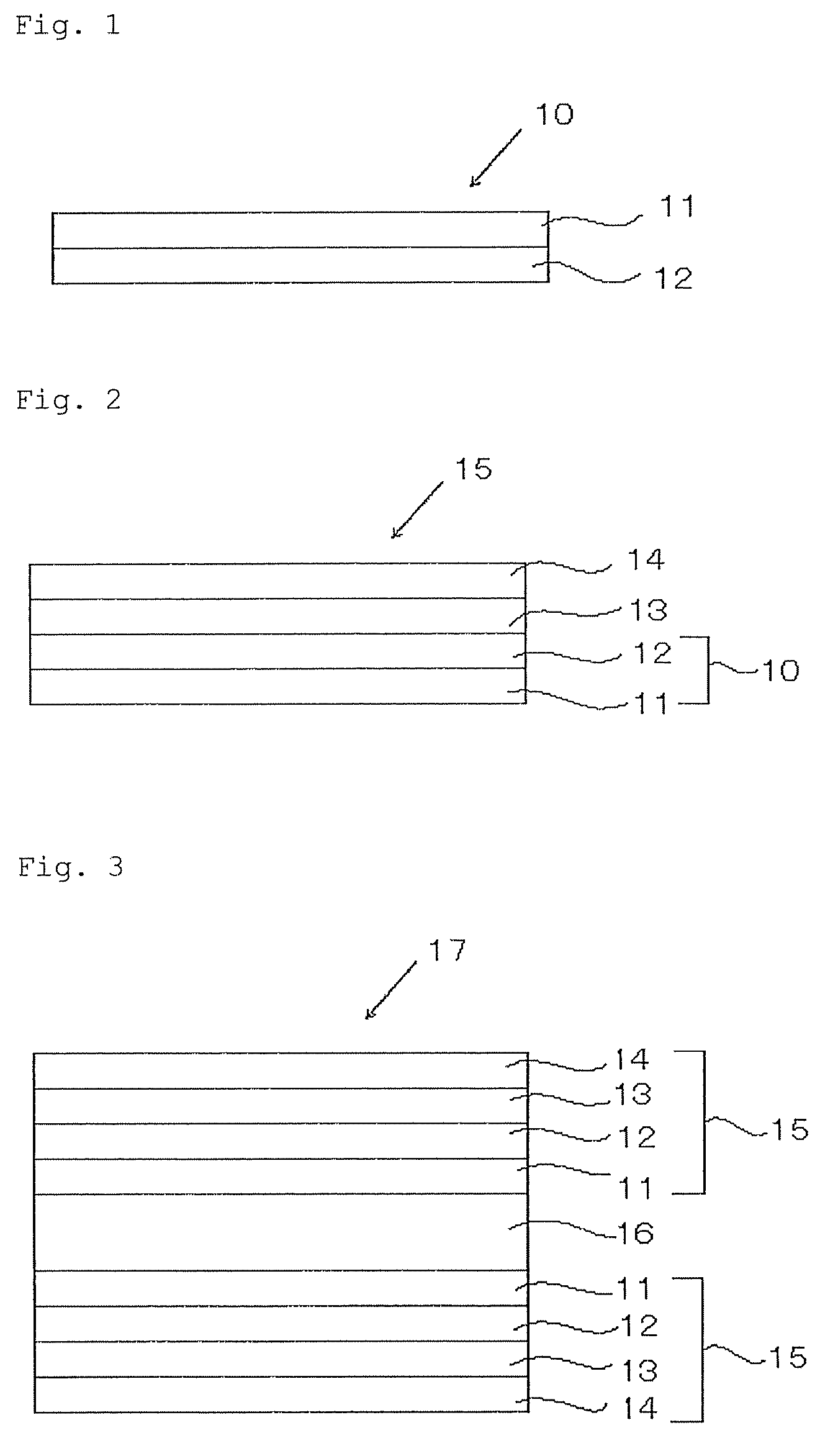

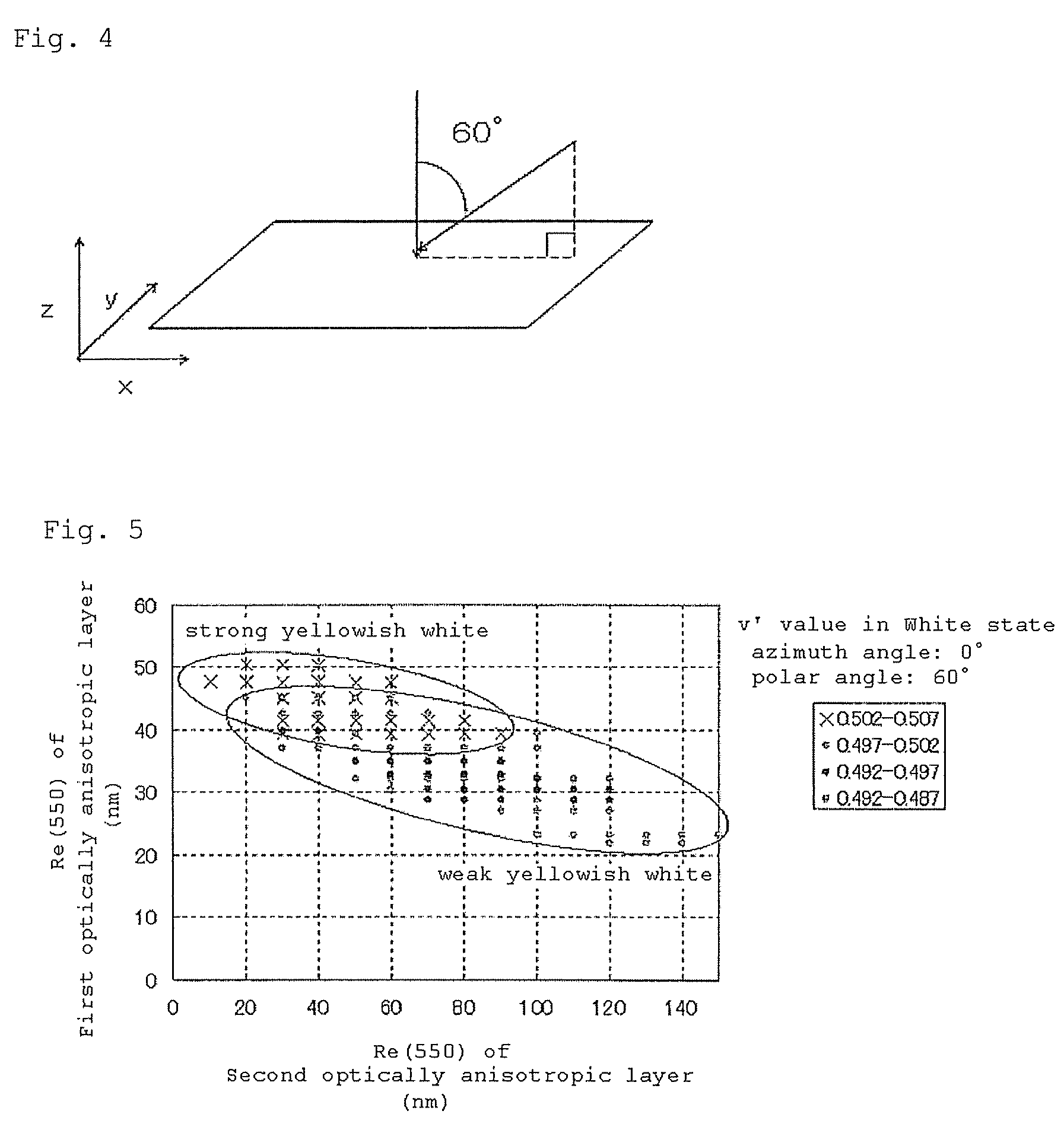

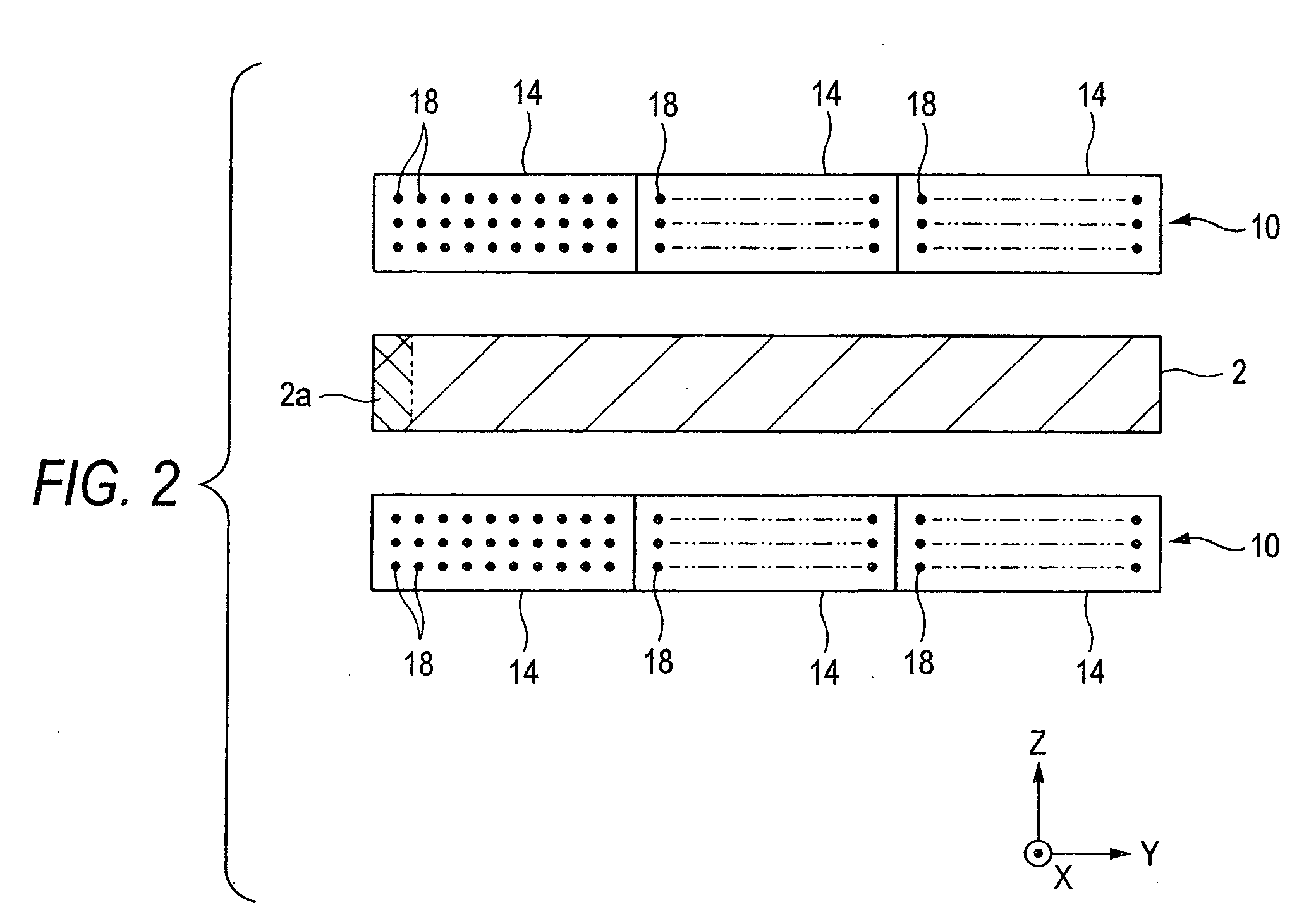

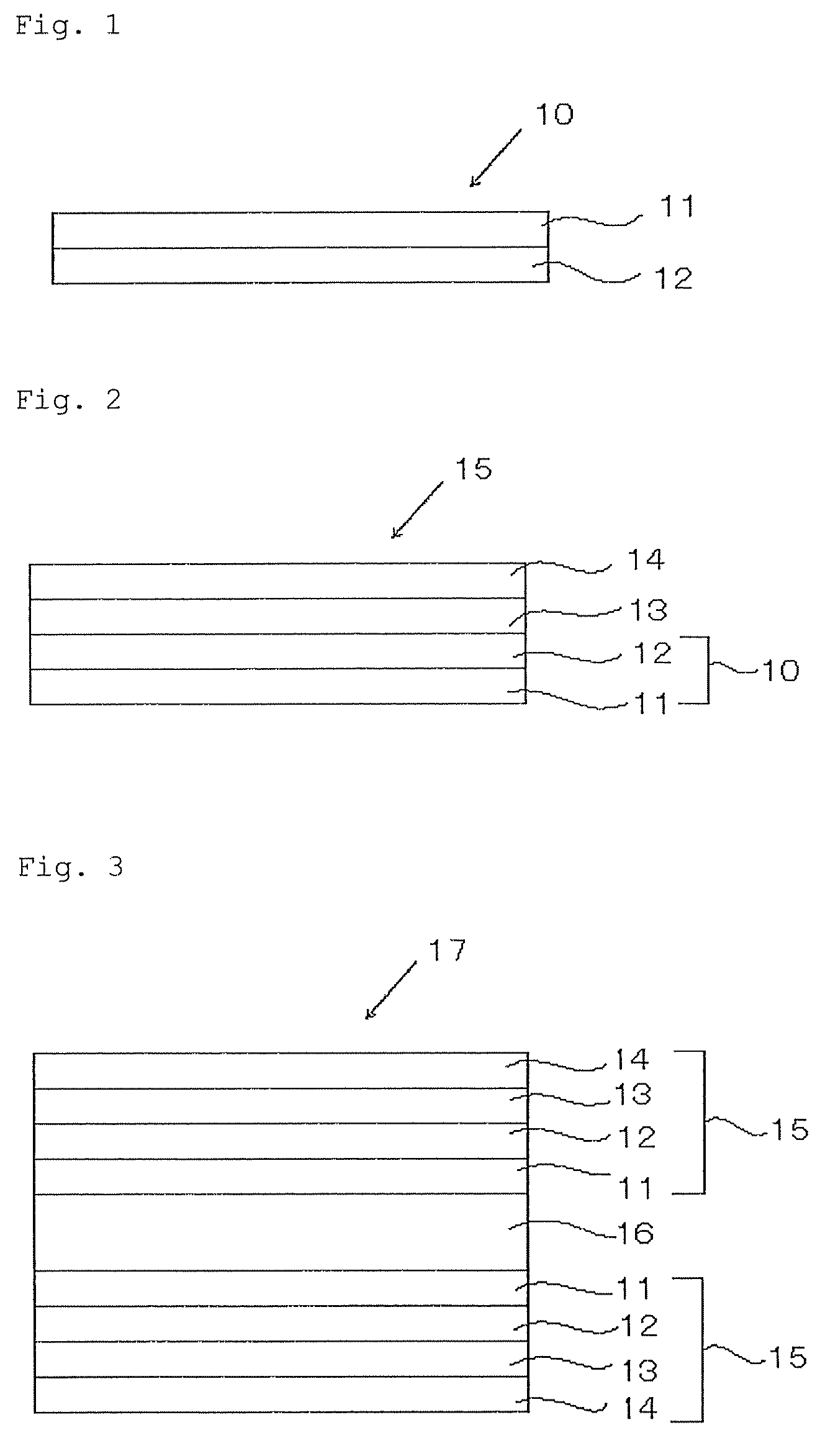

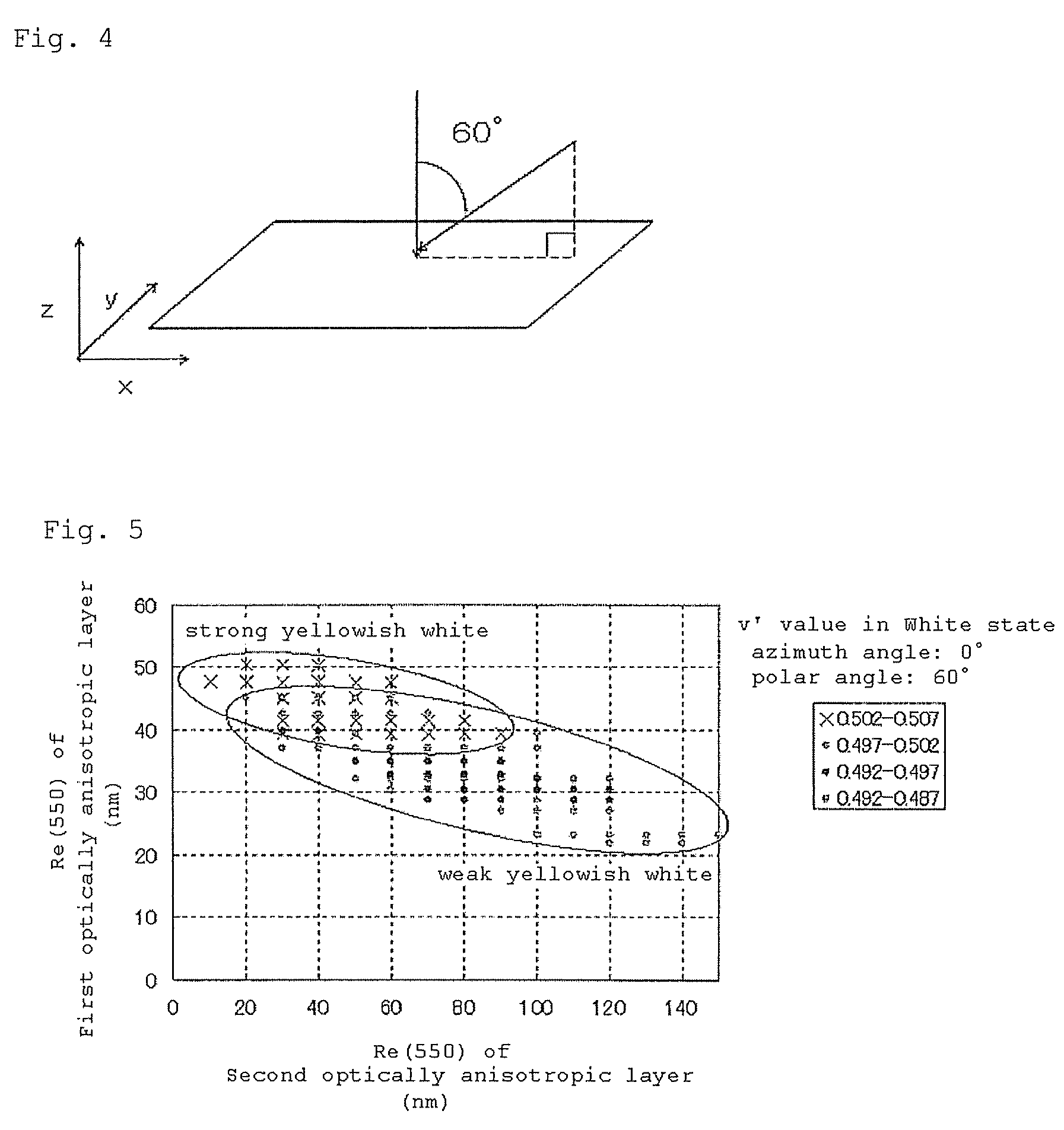

Optical compensation film, polarizing plate, and liquid-crystal display device

InactiveUS20090091691A1Improve viewing angle characteristicsReducing yellow color shiftPolarising elementsNon-linear opticsLiquid-crystal displayLength wave

Disclosed is an optical compensation film comprising first and second optically-anisotropic layers, wherein retardation in plane at a wavelength of 550 nm, Re(550), of the first optically-anisotropic layer is from 20 to 40 nm, the first optically-anisotropic layer does not have any direction in which its retardation at a wavelength of 550 nm is 0 nm, the direction in which the absolute value of retardation of the first optically-anisotropic layer is the smallest is neither in the normal line direction of the layer nor in the in-plane direction thereof, and Re(550) of the second optically-anisotropic layer is from 20 to 150 nm and retardation along thickness direction at a wavelength of 550 nm, Rth(550), thereof is from 40 to 110 nm.

Owner:FUJIFILM CORP

Perpendicular magnetic recording medium, method of manufacturing same, and magnetic recording device

ActiveUS7494726B2Small sizeLess dispersionRecord information storageMagnetic recordingRecording densityRecording layer

A perpendicular medium is disclosed in which an isolation structure of an underlayer is formed using a simple method as in a conventional manufacturing process for a medium of continuous films. The method suppresses dispersion of alignment and reduced magnetic cluster size in a magnetic recording layer. The perpendicular medium exhibits high recording density owing to thin film thickness of the underlayer. A perpendicular magnetic recording medium includes at least an underlayer and a magnetic recording layer sequentially laminated on a nonmagnetic substrate. The underlayer consists of crystal grains and an amorphous grain boundary, and the crystal grain has a shape holding a relation (an area of a bottom region at an initial stage of growth)>(an area of a top region).

Owner:FUJI ELECTRIC CO LTD

Electrically conductive polymer films

InactiveUS6932921B2Minimal tensile strengthLow viscosityConductive materialNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

A self-supporting conductive polymer film having distributed therein an electrically conductive polymer composition containing linearly conjugated π-electron systems and residues of sulfonated lignin or a sulfonated polyflavonoid. The conductive polymer film preferably has a surface resistivity of from about 102 ohms per square to about 1010 ohms per square and is preferably formed from a liquid dispersion of thermoplastic polymer having the electrically conductive polymer composition distributed therein. In a preferred embodiment, heat sealable conductive fluoropolymer films are prepared.

Owner:EI DU PONT DE NEMOURS & CO

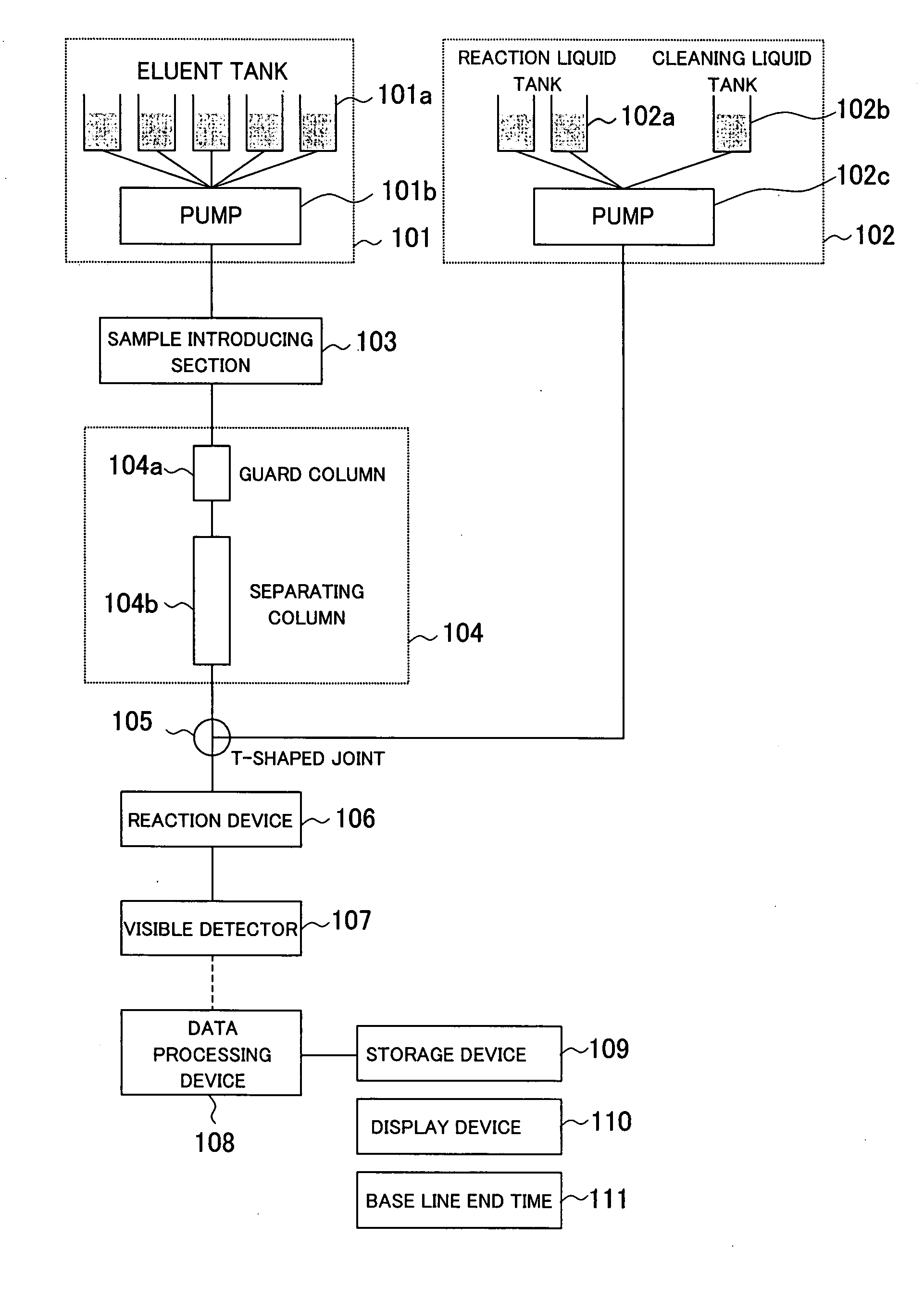

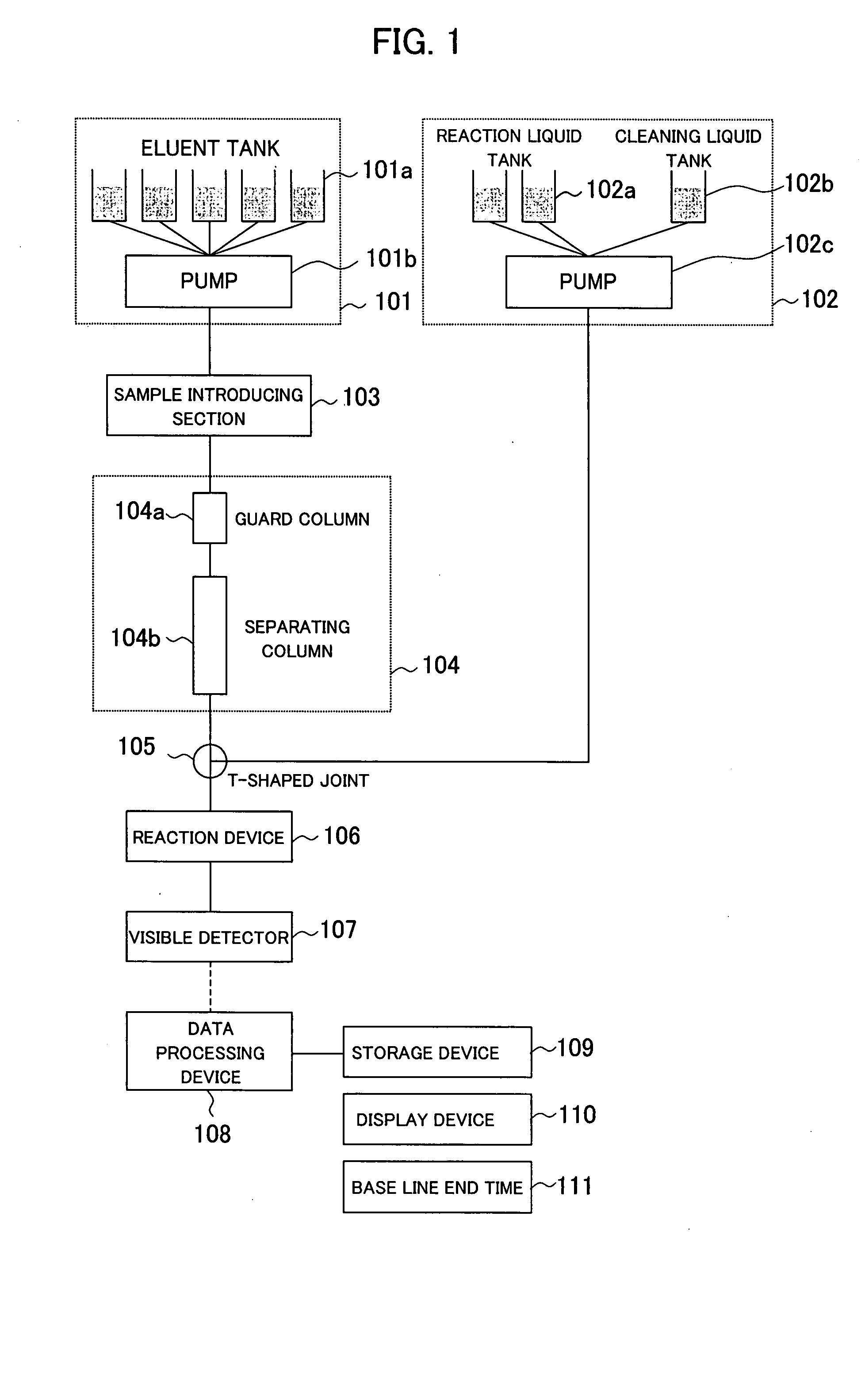

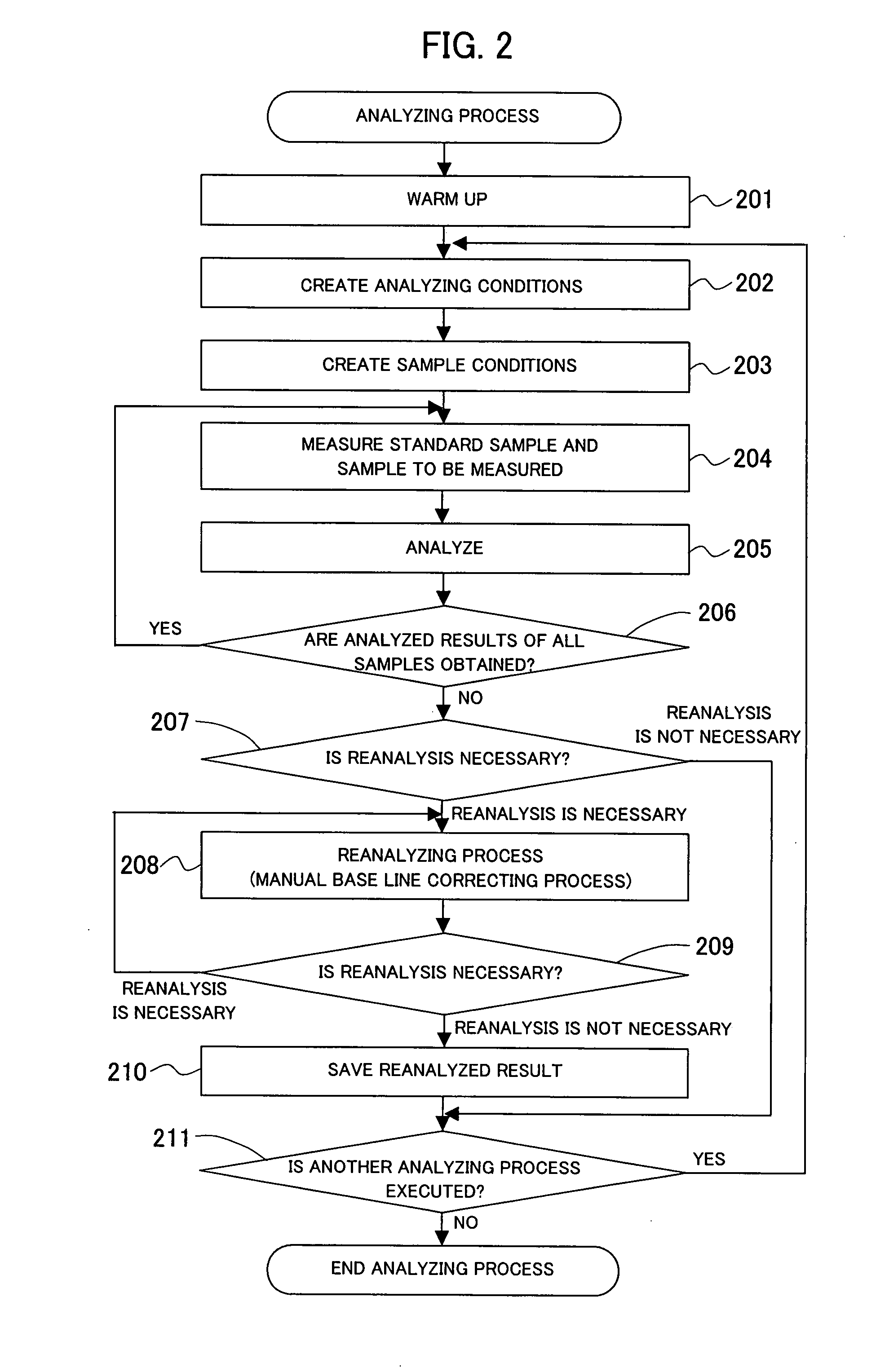

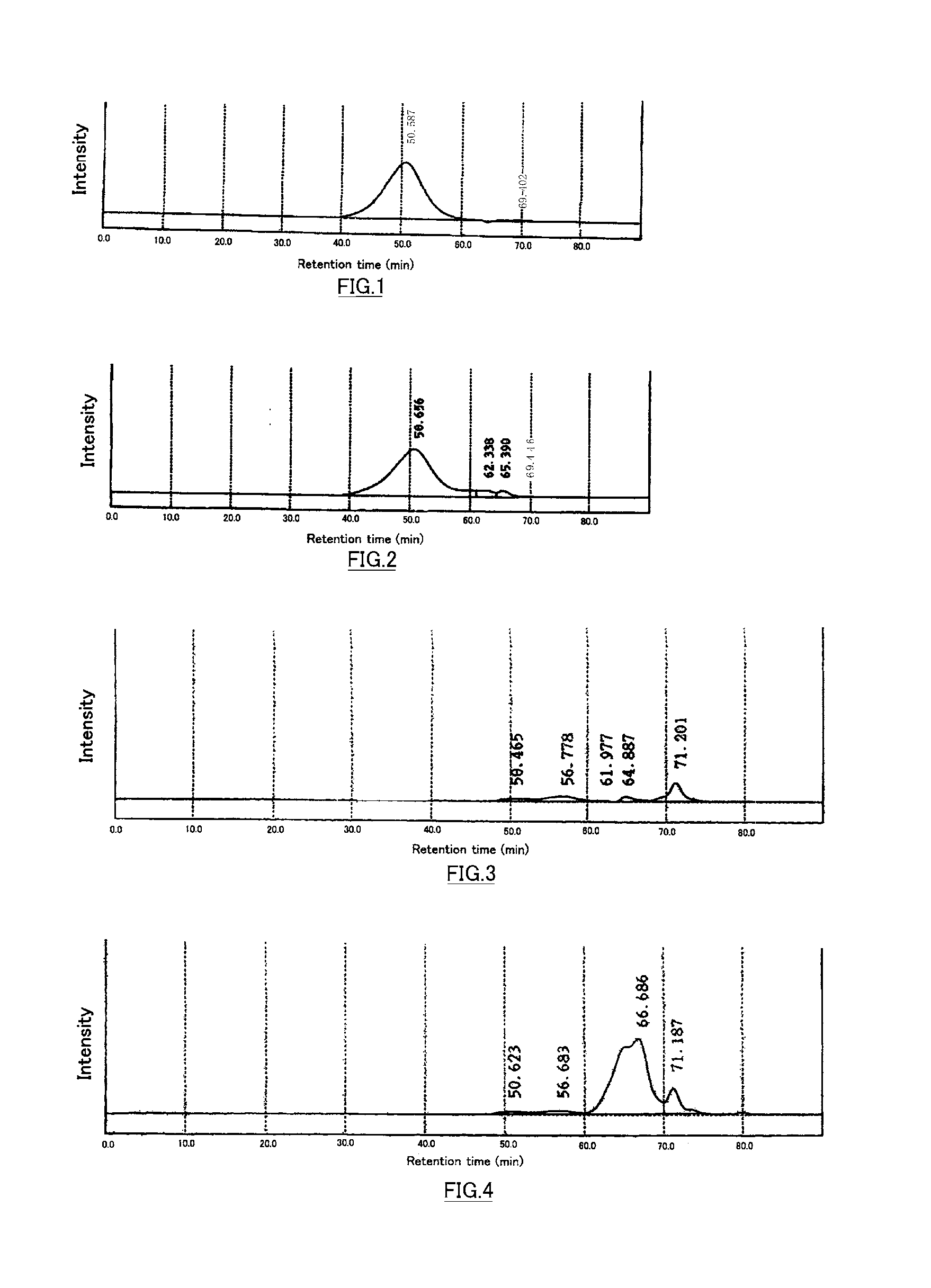

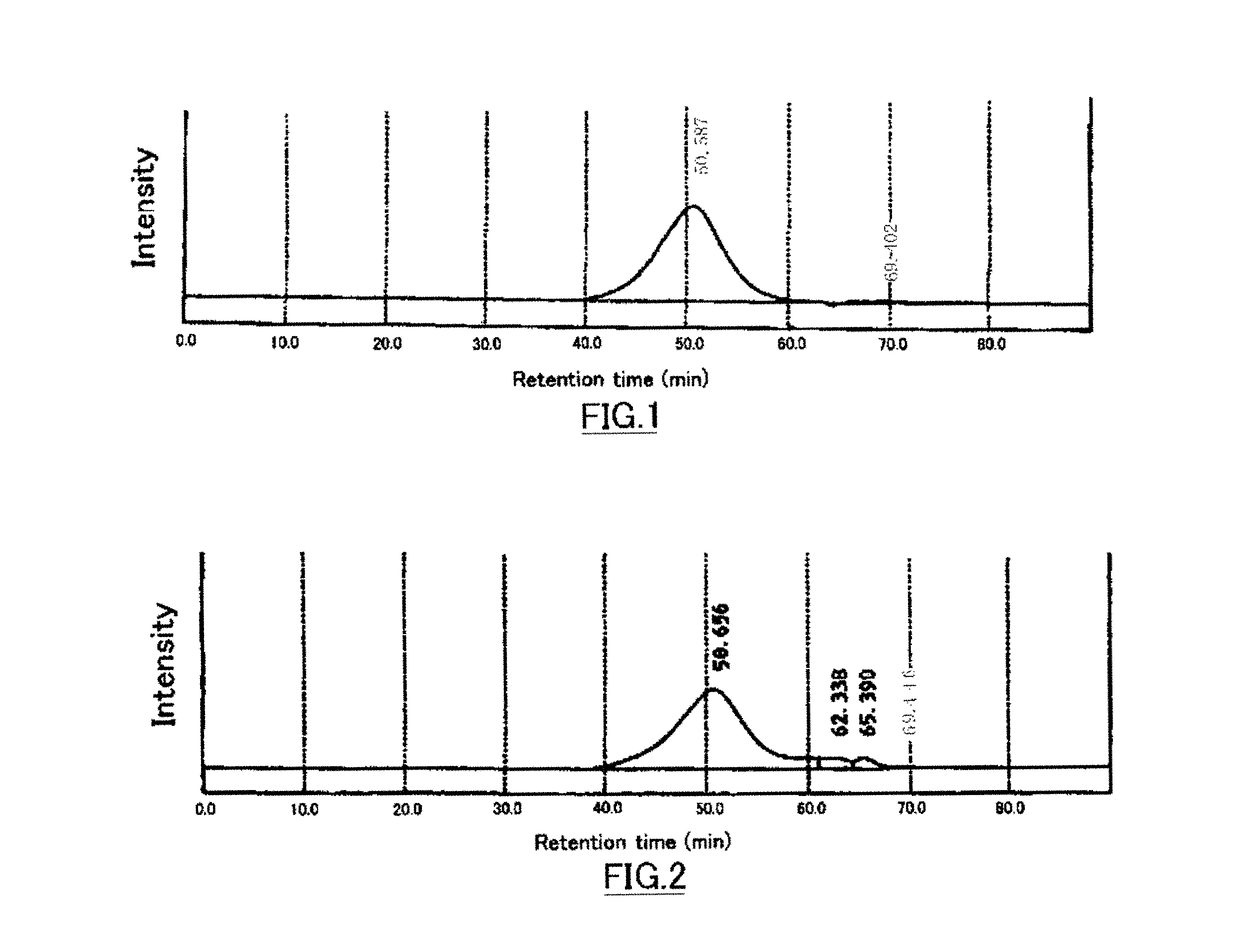

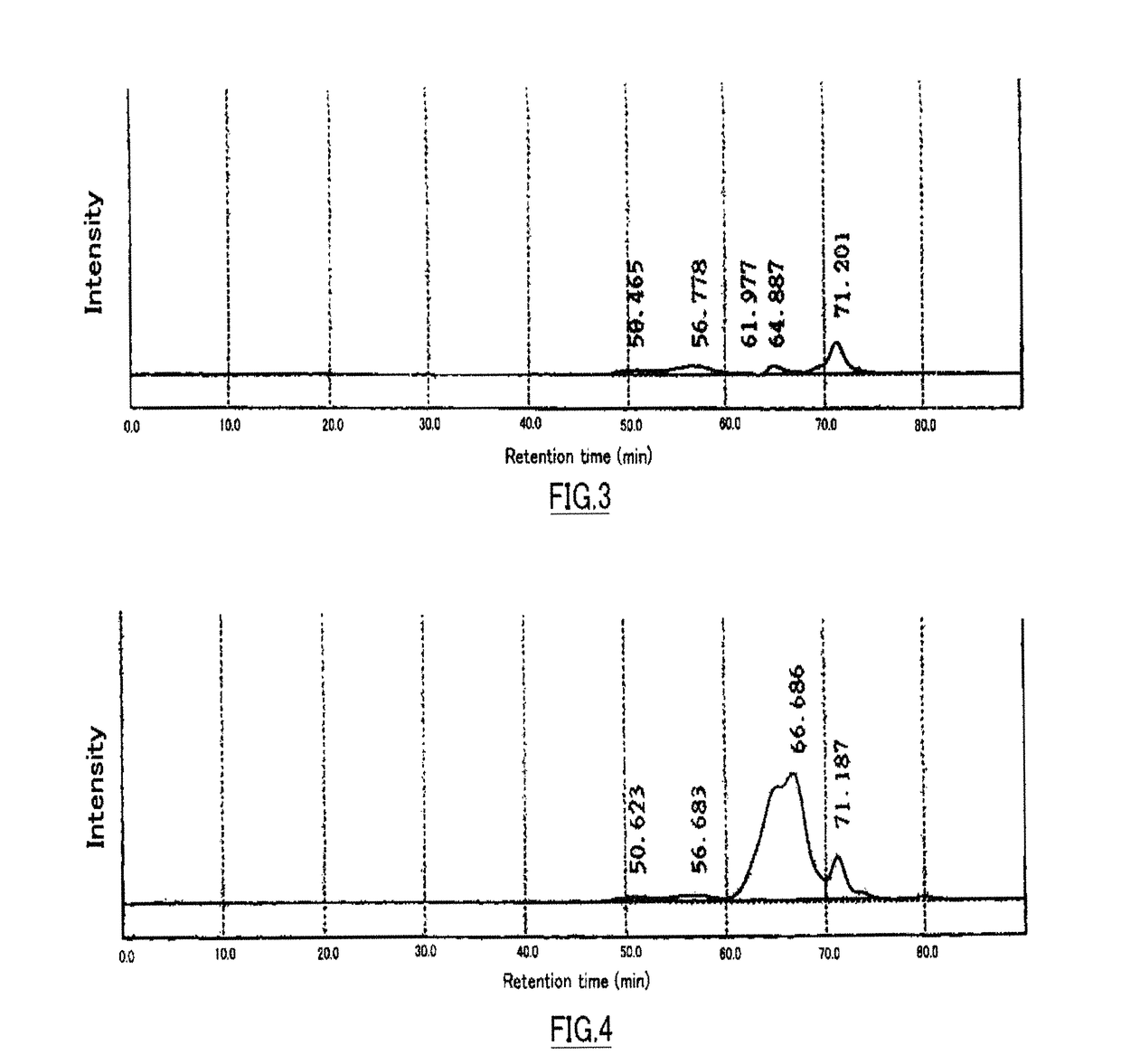

Chromatograph analyzing device

ActiveUS20080059079A1Less dispersionThe result is accurateComponent separationSpecial data processing applicationsComputational physicsEngineering

There is provided a chromatograph analyzing device, in which results of a quantitative calculation process on an unseparated peak have less dispersion. The chromatograph analyzing device according to the present invention automatically executes a base line setting process on the unseparated peak using base line setting conditions set in advance.

Owner:HITACHI HIGH-TECH CORP

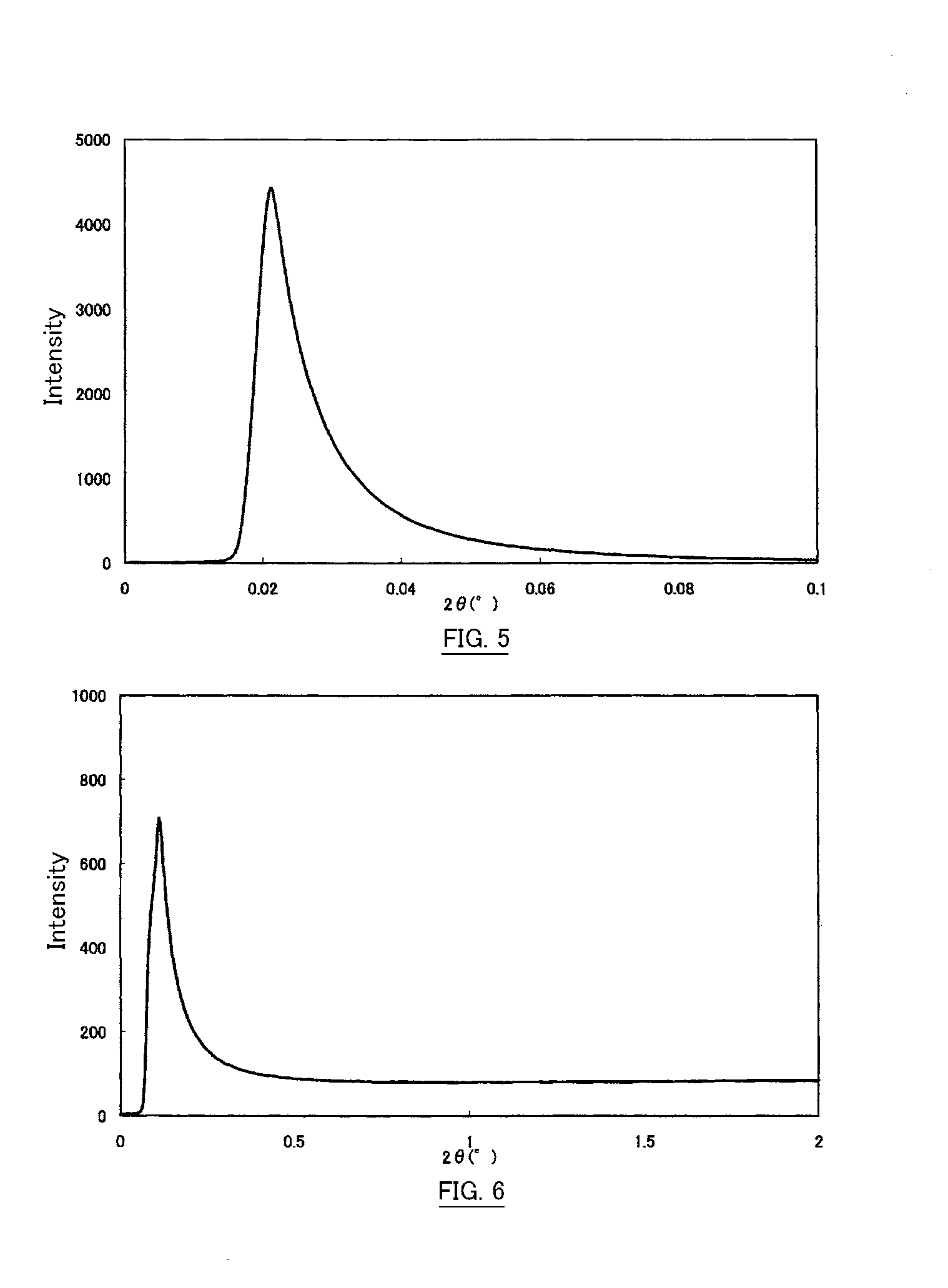

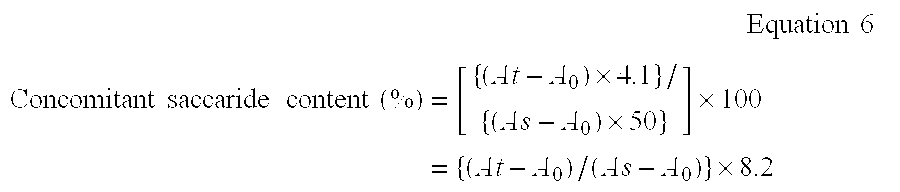

Pullulan-containing powder, method for producing the same and use thereof

InactiveUS20130195941A1Quality improvementHigh breaking strengthCosmetic preparationsBiocideParticulatesPullulan

The present invention aims to provide a particulate composition containing pullulan, which can be produced without employing any complicated purification step such as solvent precipitation and, when formed into a film, exhibits a higher rupture strength compared to conventional ones; a process for producing the same; and uses thereof. The present invention solves the above object by providing a particulate composition containing pullulan which is produced from a culture obtained by culturing a mutant of a microorganism of the species Aureobasidium pullulans in a culture medium containing glucose and maltose as carbon sources, without employing a step of removing concomitant saccharides; contains a pullulan fraction and a concomitant saccharide fraction that are respectively insoluble and soluble in 75% by volume of methanol in water; has a percentage of 3% by weight or lower of the content of concomitant saccharides contained in the concomitant saccharide fraction against the content of total saccharides contained in the whole particulate composition, when determined based on the anthrone sulfuric acid method; and contains mannitol; and by providing the process of the same and uses thereof.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

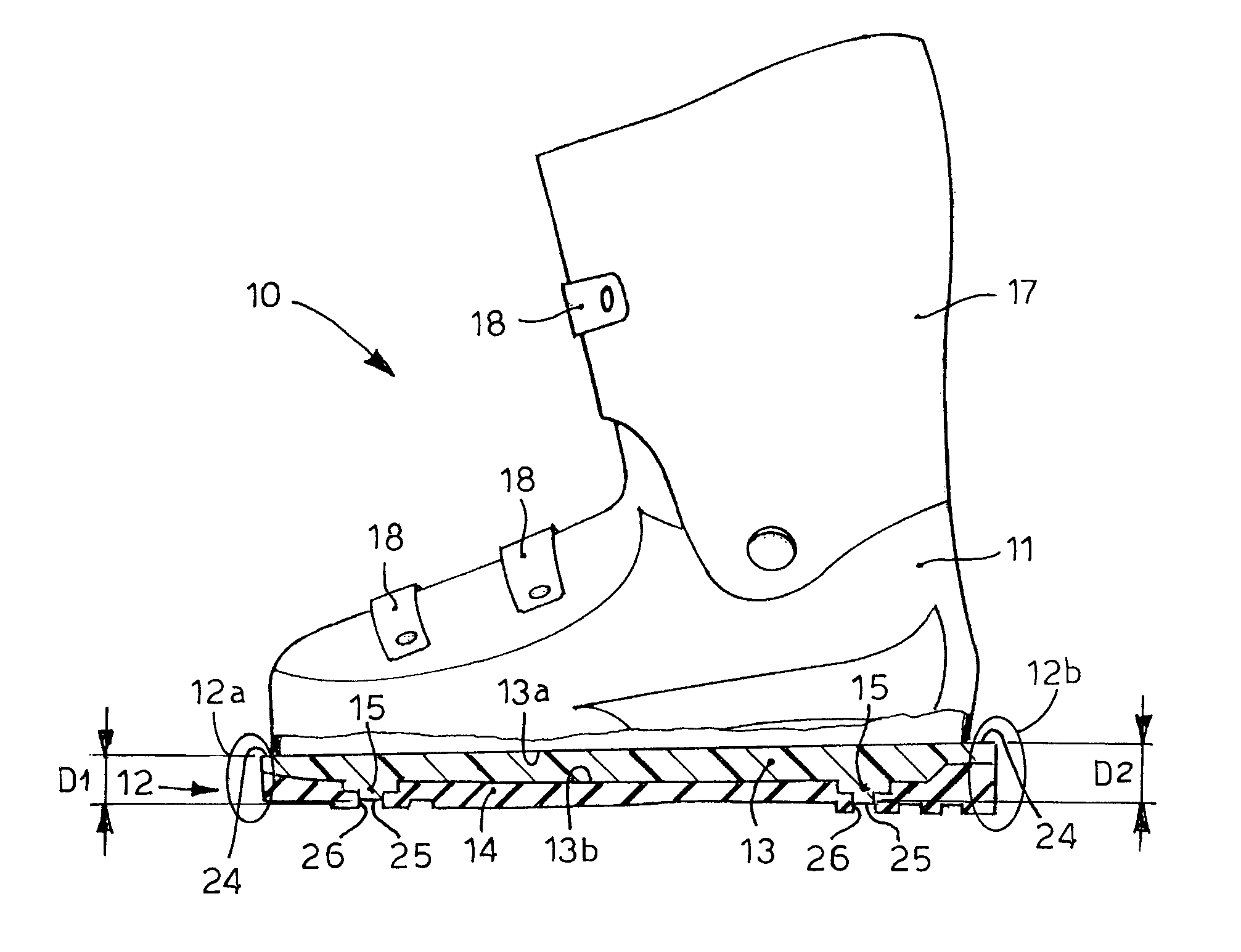

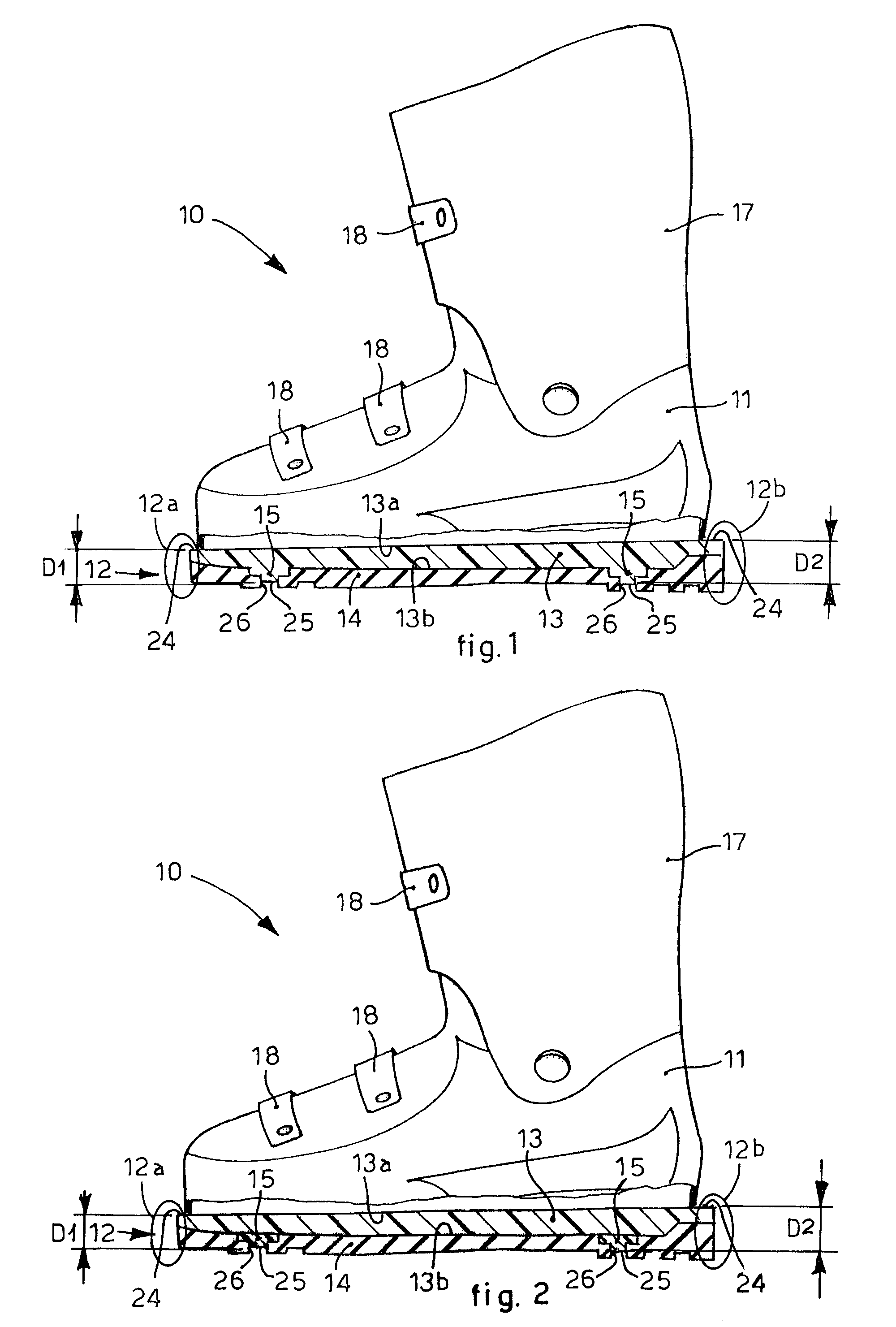

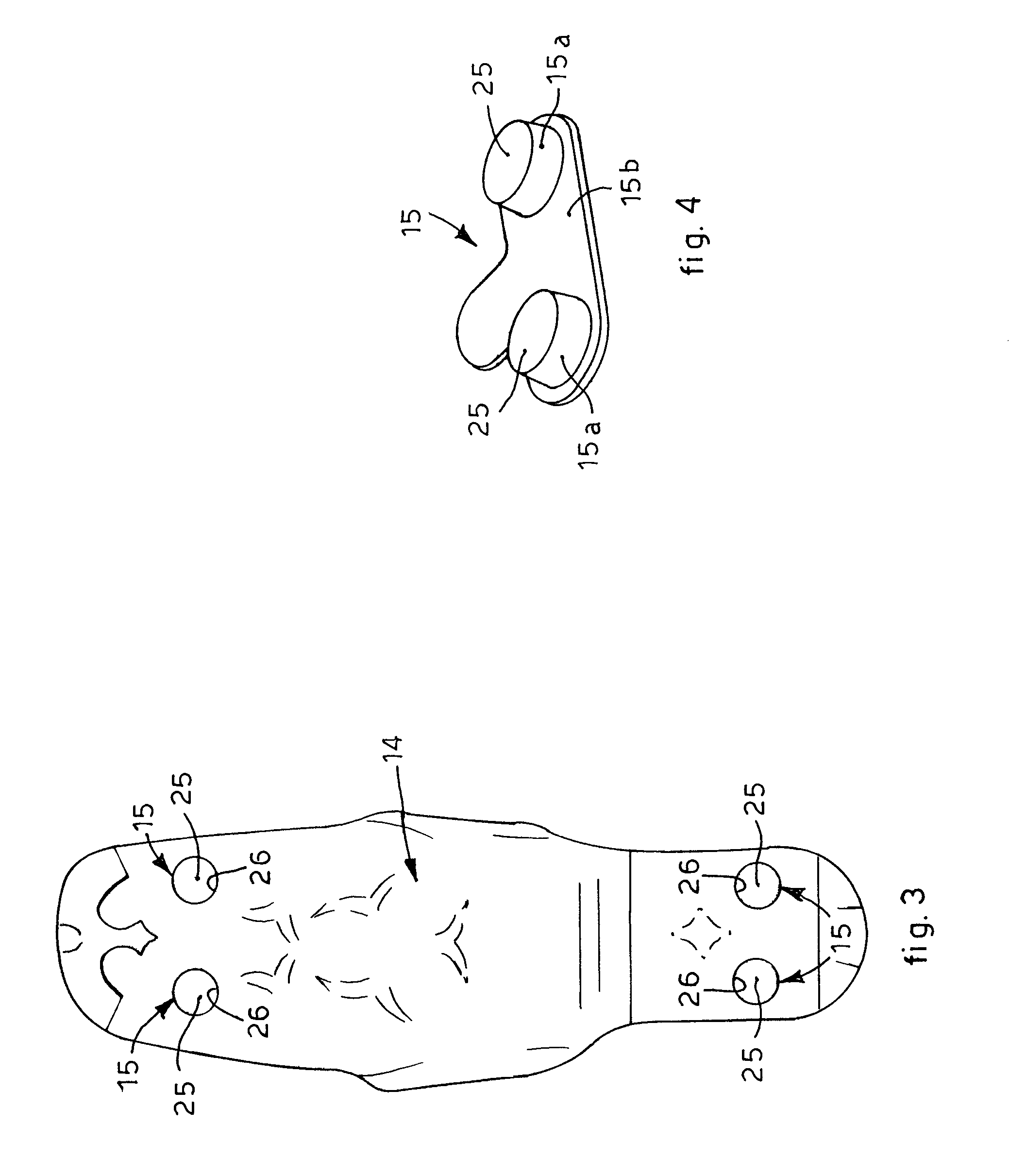

Sports footwear

Owner:CALZATURIFICIO DAL BELLO

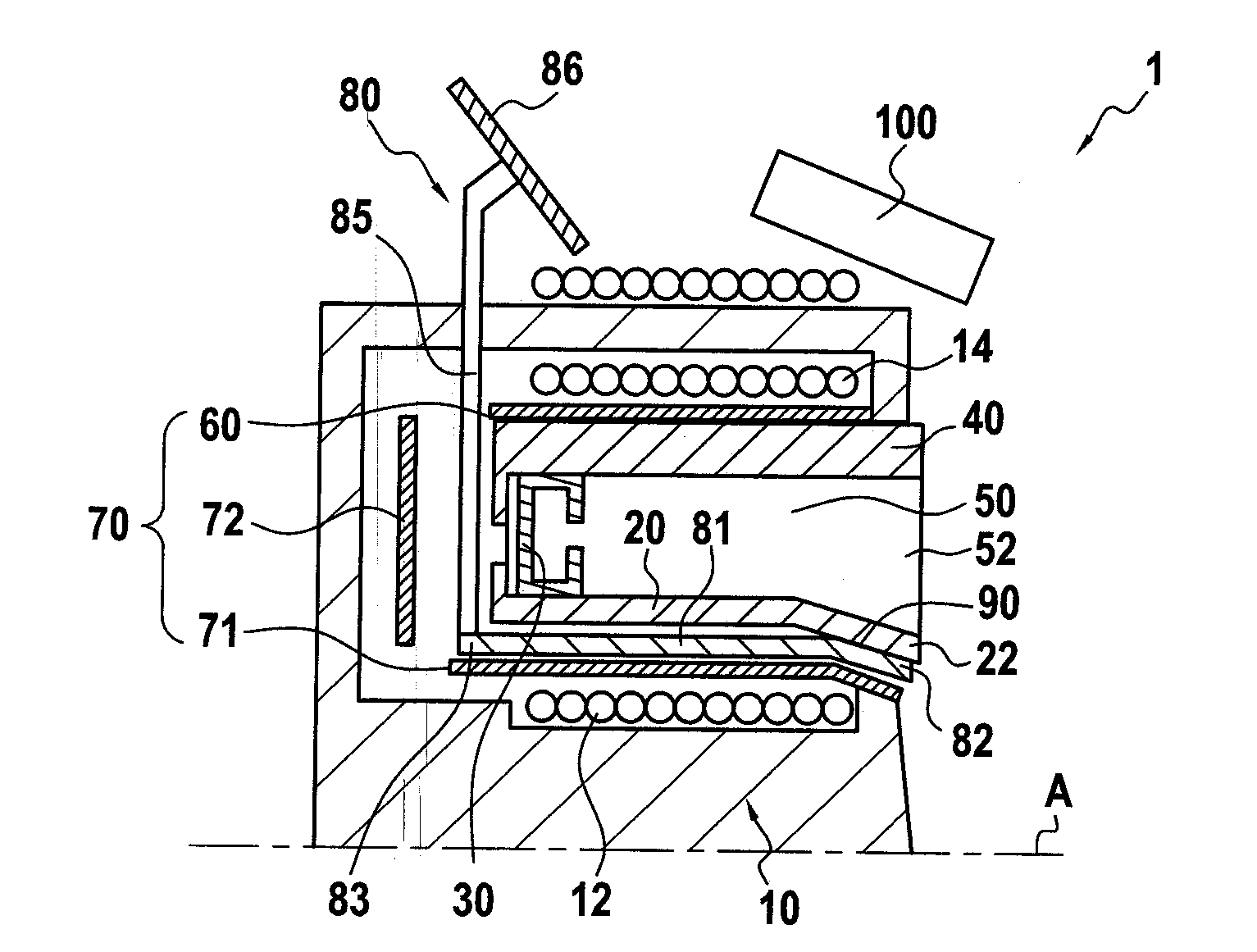

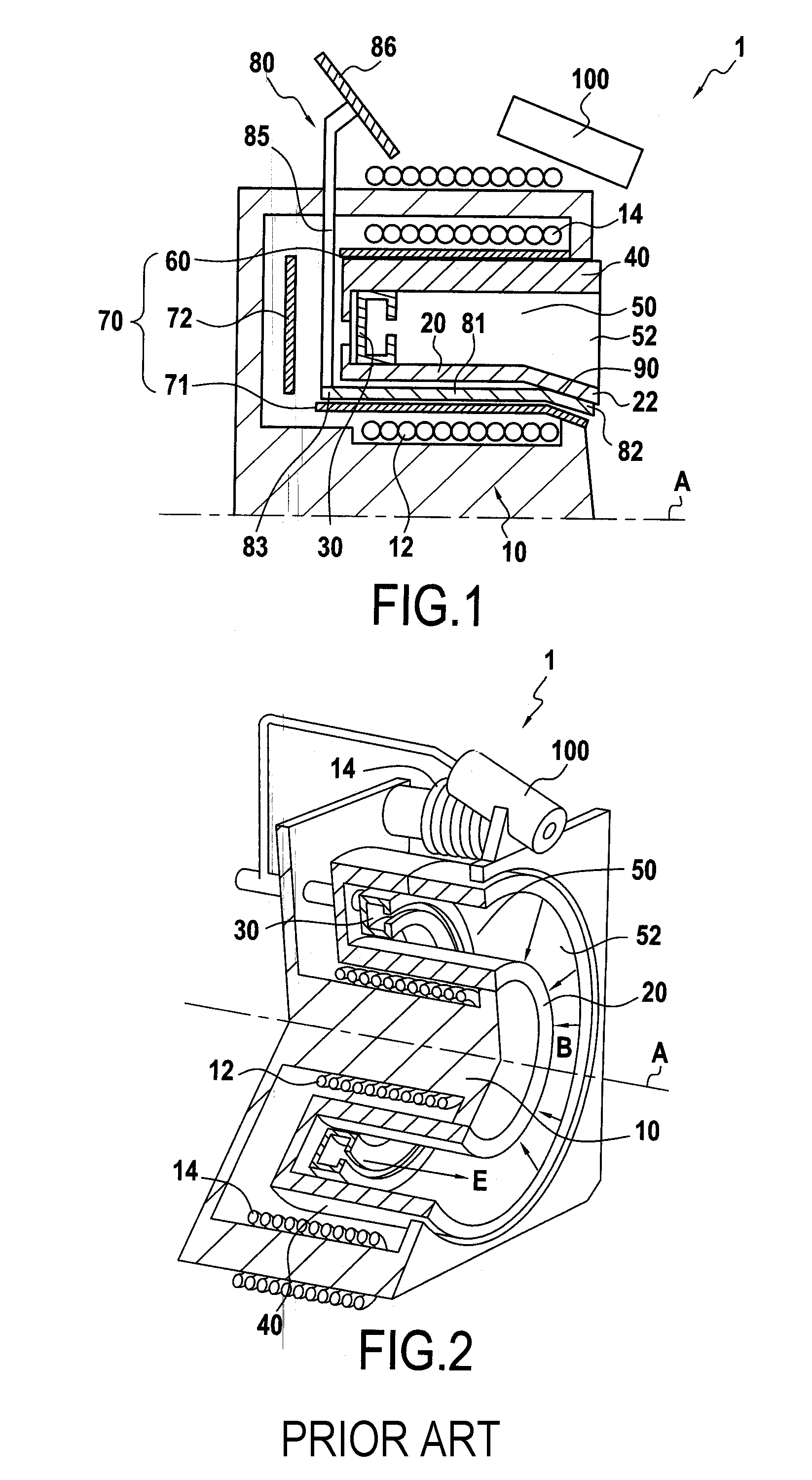

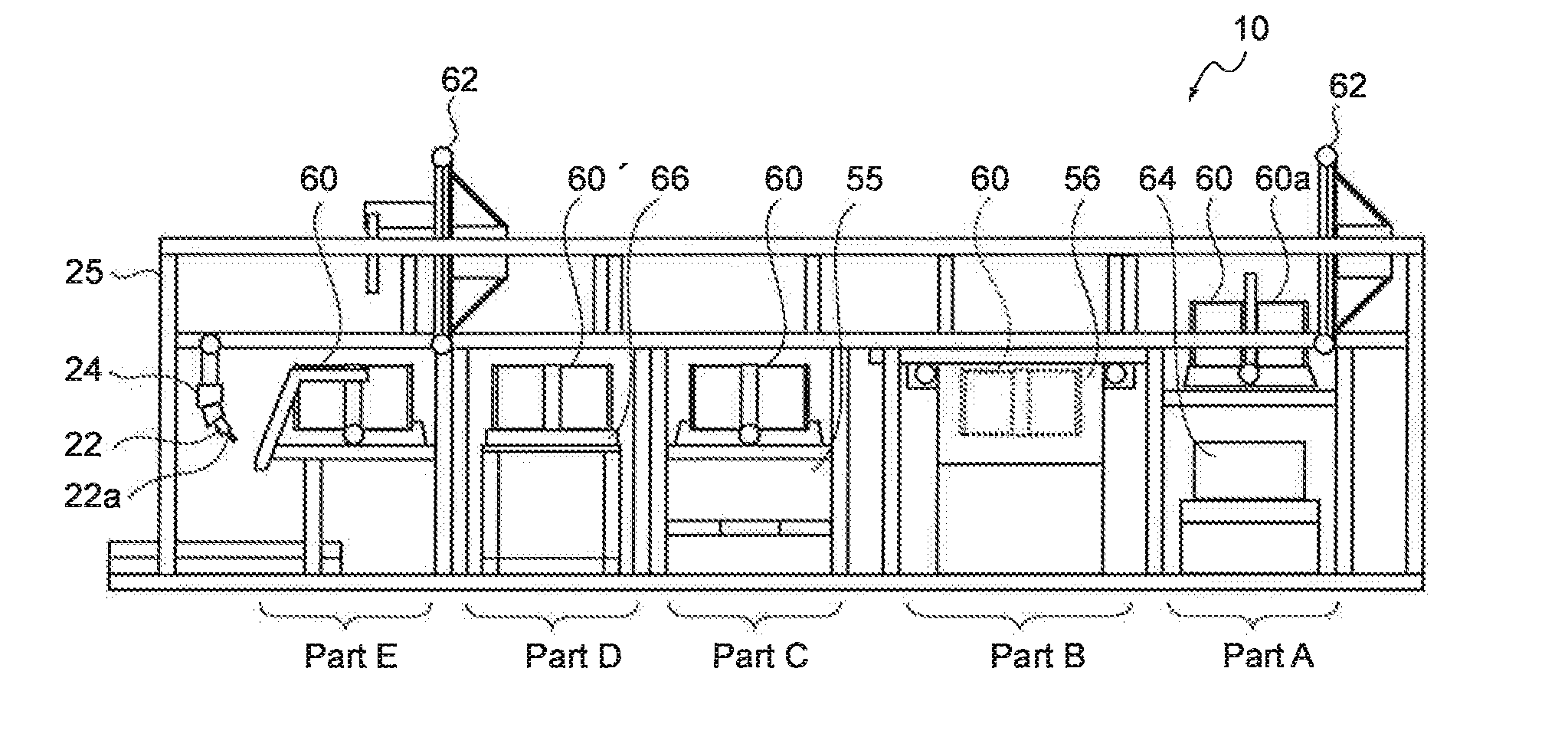

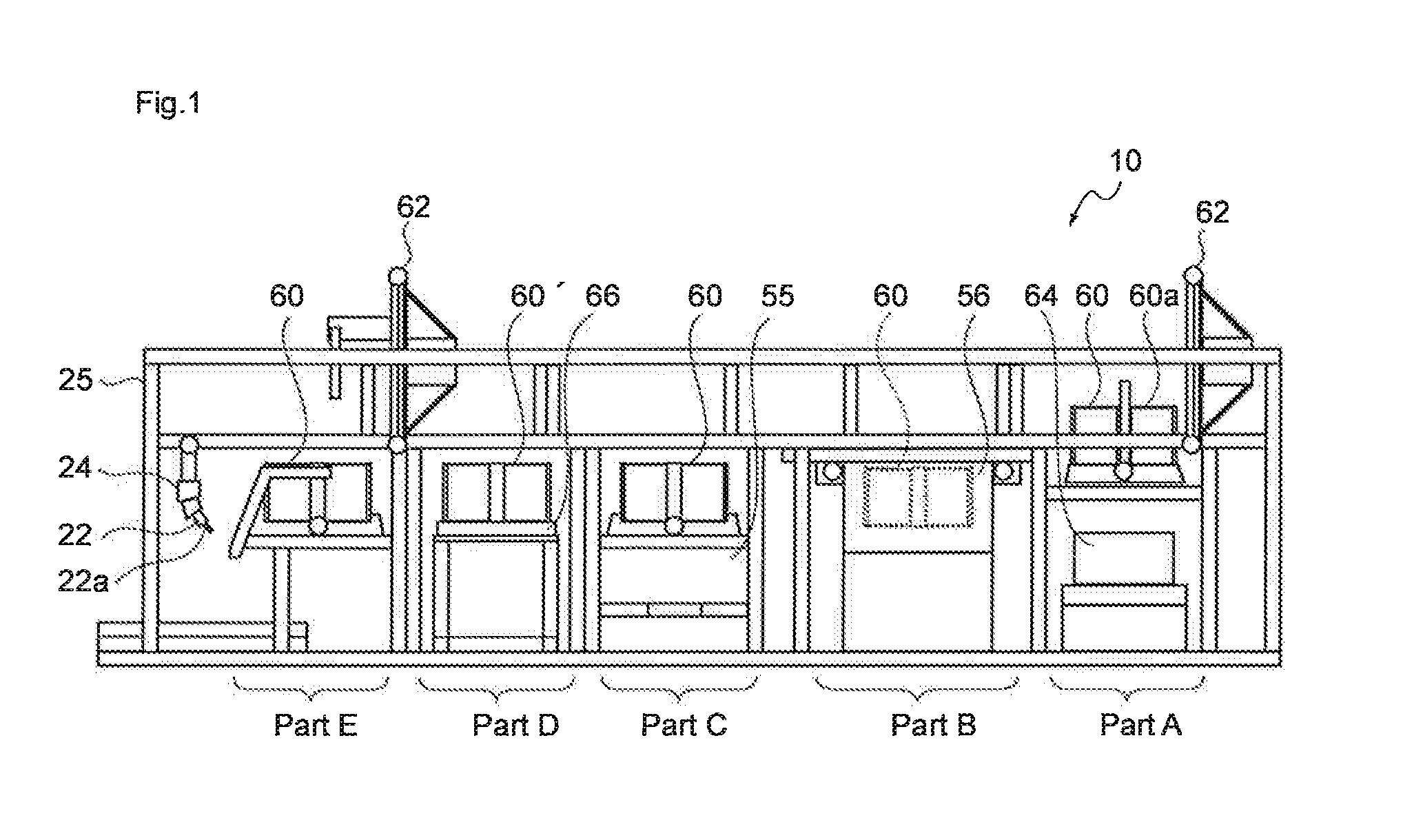

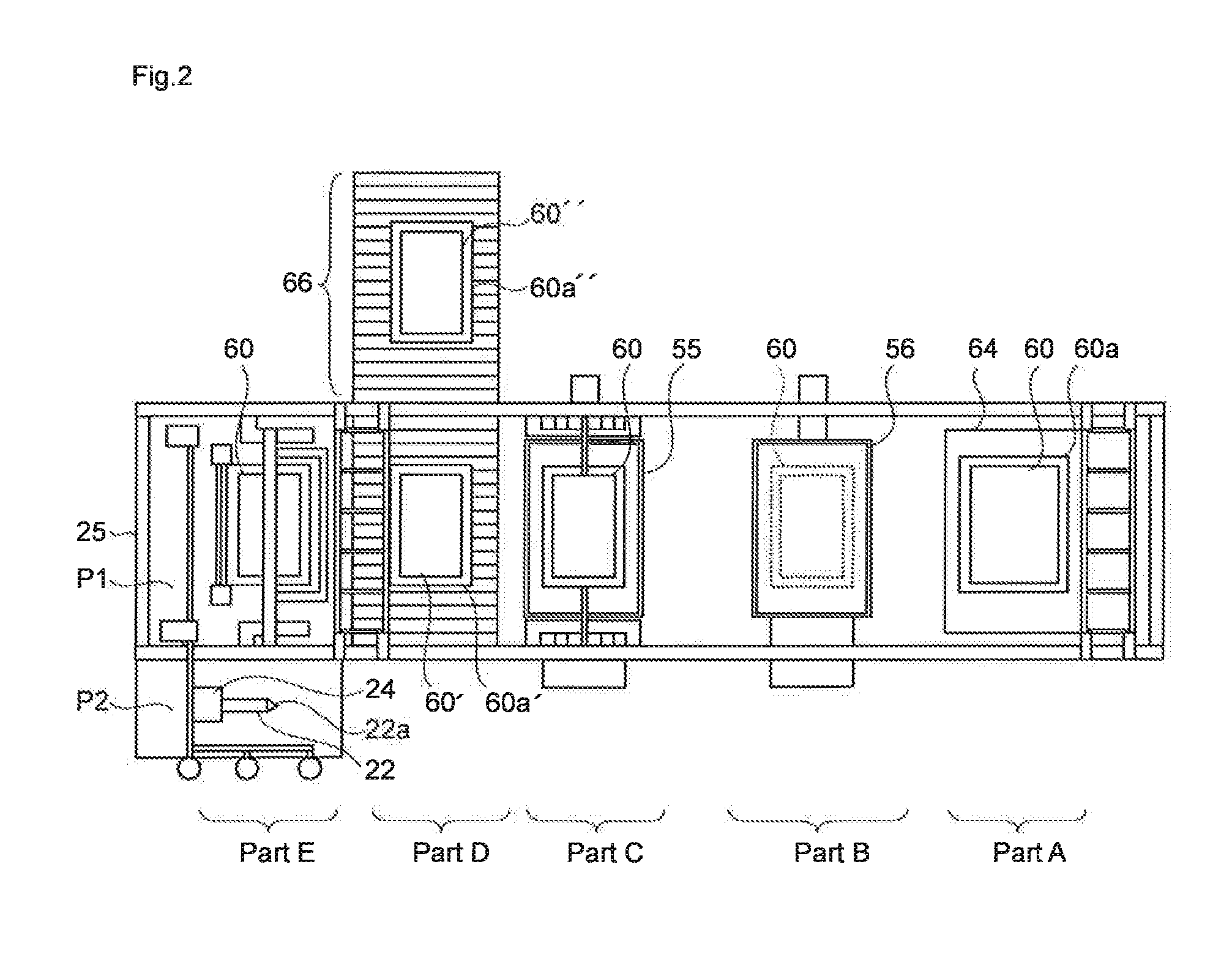

Powder Slush Molding Machine and Powder Slush Molding Method

InactiveUS20110316184A1Improve adhesionLess dispersionConfectioneryWood working apparatusMolding machineResin coating

To provide a powder slush molding apparatus and a powder slush molding method that could quickly and stably produce a 2-color molded sheet-like article with high-durability and the like.The present invention is directed to a powder slush molding apparatus provided with a powder slush part (Part A), a mold heating part (Part B), a mold cooling part (Part C), and a coating / demolding part (Part E) for manufacturing the 2-color molded sheet-like article and the powder slush molding method thereof. After a 1-200 μm thick coating layer consisting of a first resin is coated by a resin coating device in the coating / demolding part, a sheet-like article consisting of a second resin which is different from the first resin is molded on or adjacent to the coating layer consisting of the first resin in the powder slush part.

Owner:NAKATA COATING CO LTD +1

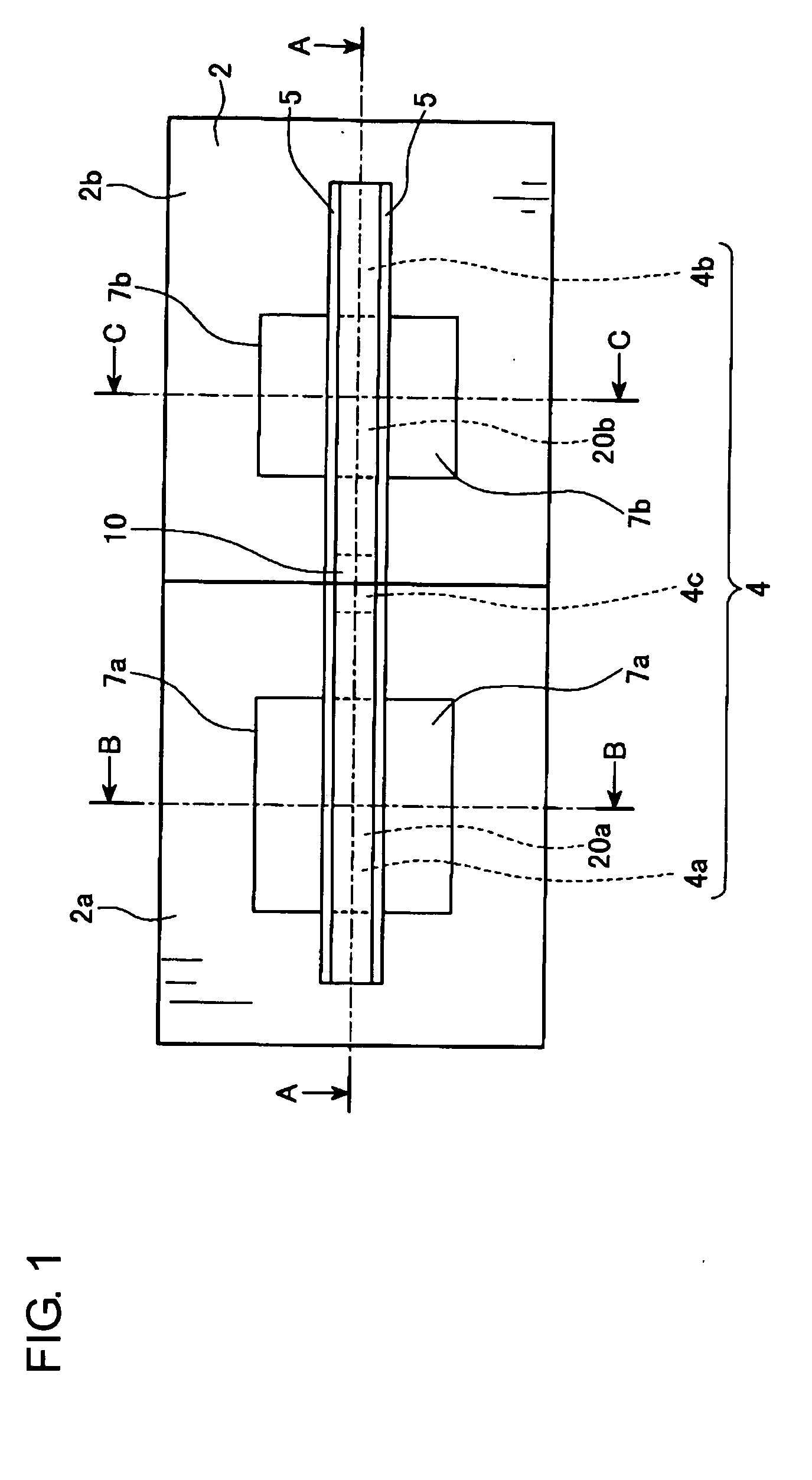

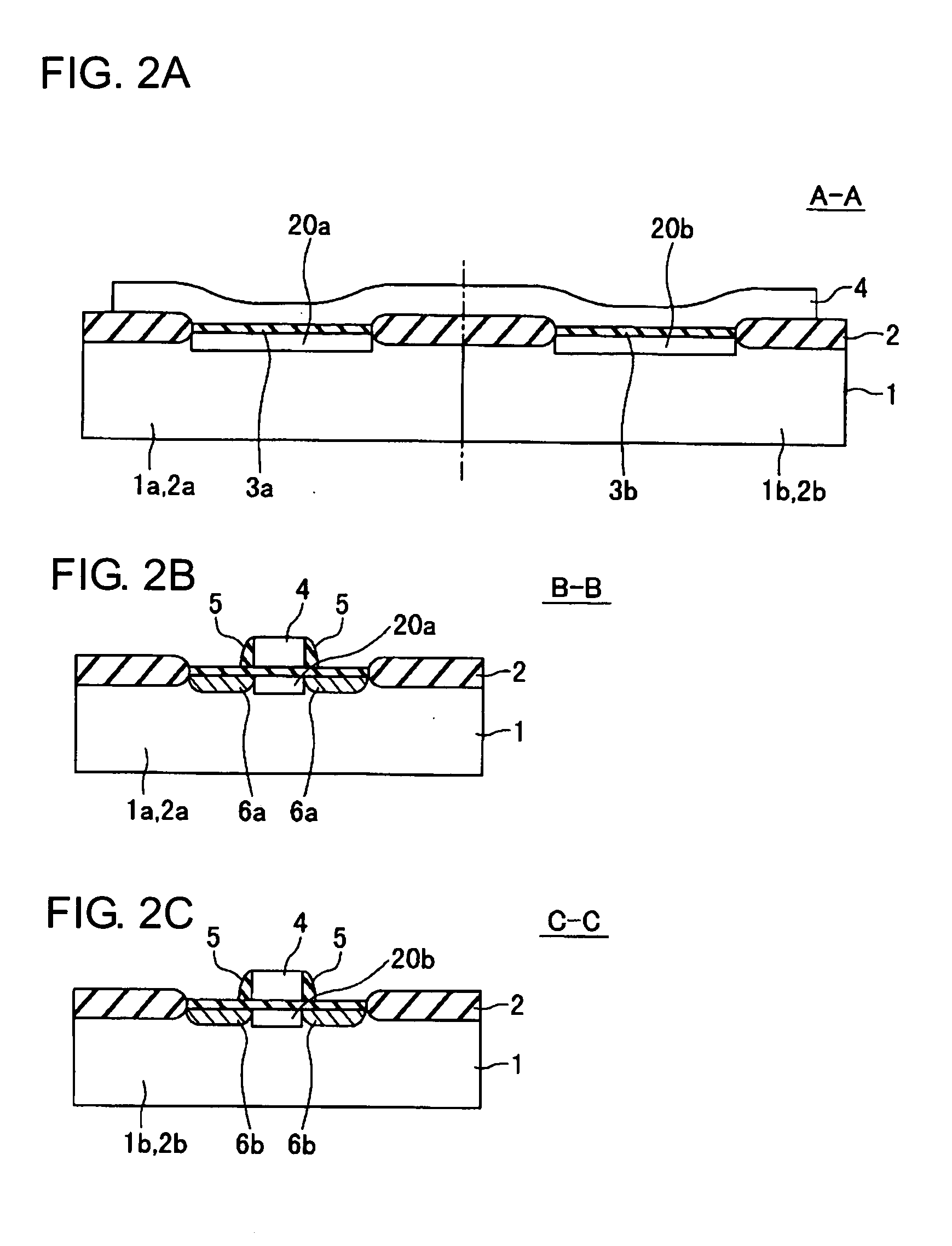

Friction plate and wet-type multi-plate clutch having such friction plate

InactiveUS8146725B2Improve heat resistanceQuality improvementFluid actuated clutchesFriction clutchesEngineeringMechanical engineering

The present invention provides a friction plate having a friction surface formed by sticking an annular friction material to a substantially annular core plate and wherein the friction surface is provided with a first oil groove having an opening portion opened to an inner peripheral edge of the friction plate and an end terminating at a point between the inner peripheral edge and an outer peripheral edge, and a second oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end terminating at a point between the inner peripheral edge.

Owner:NSK WARNER

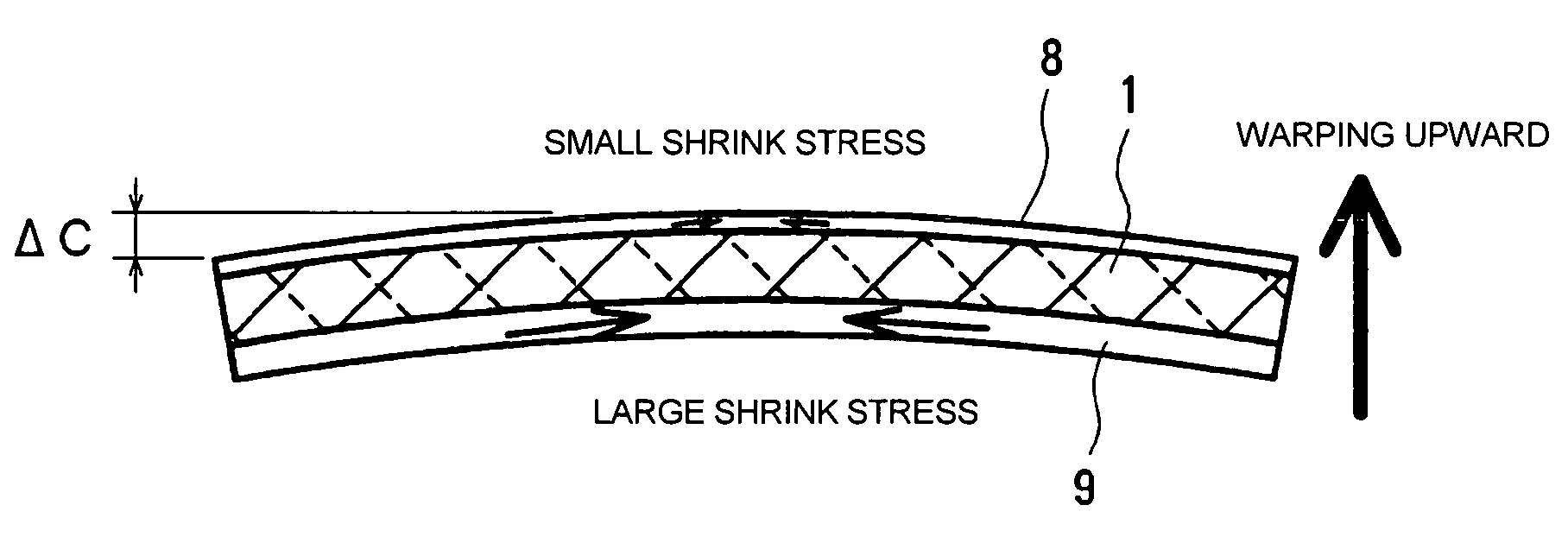

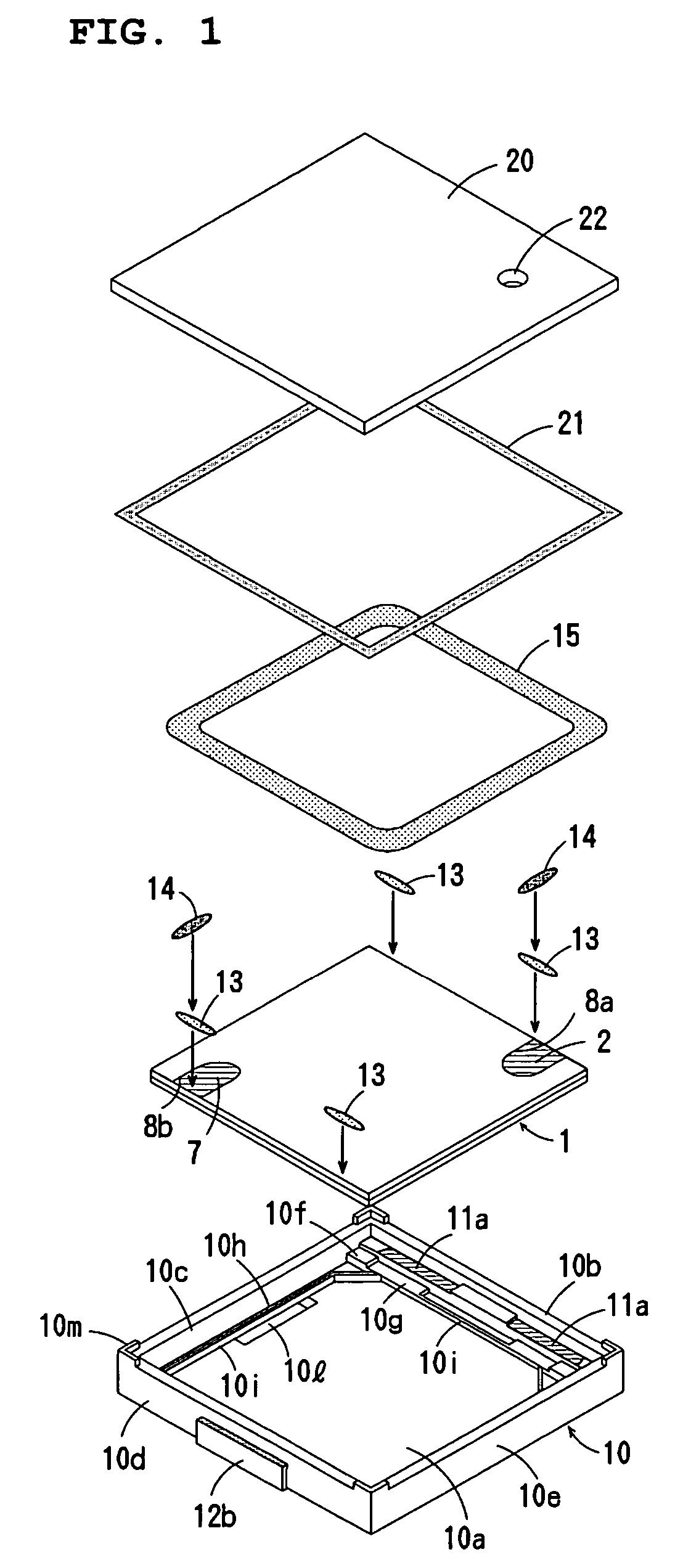

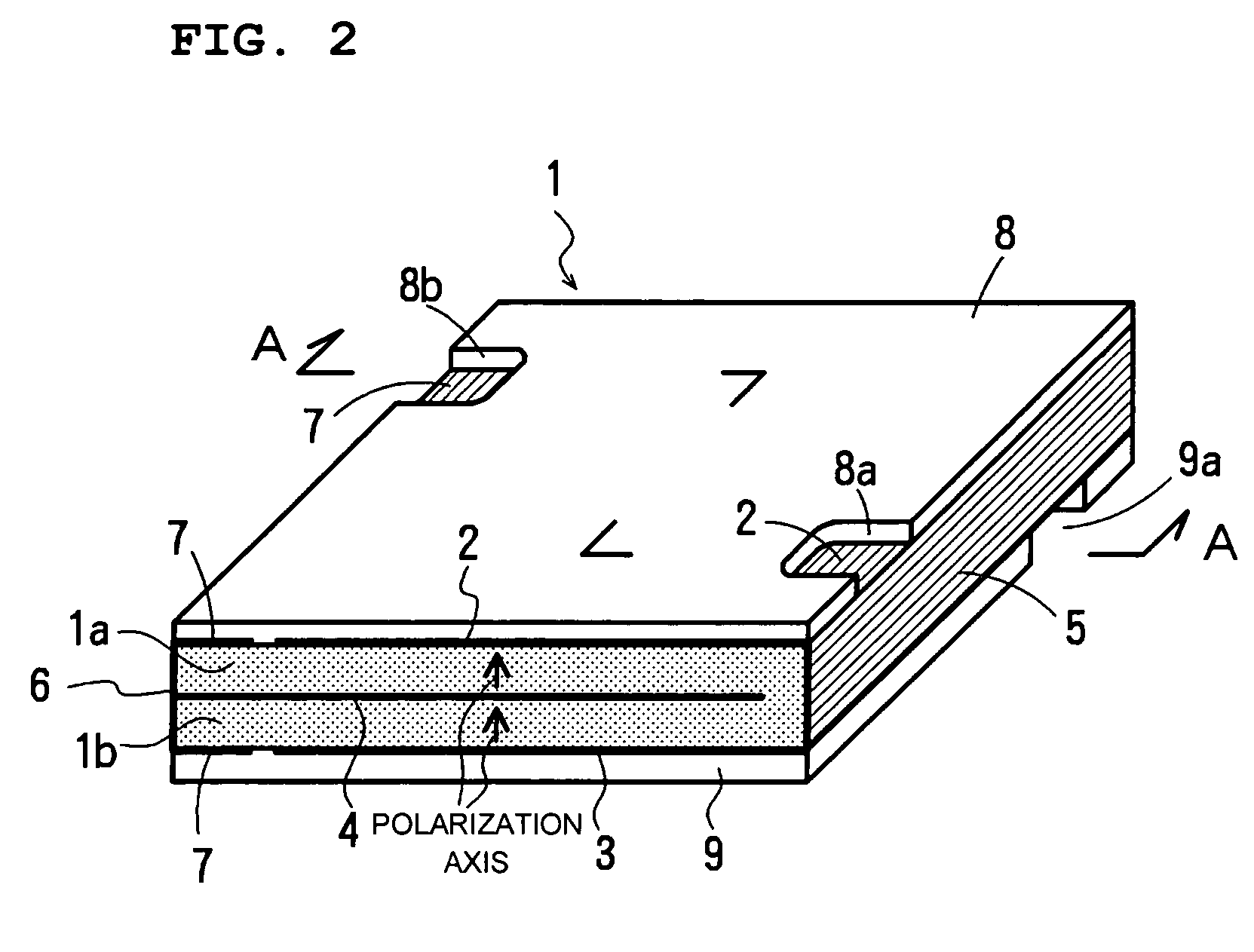

Piezoelectric acoustic transducer

InactiveUS7042138B2Sound pressureReduce dispersionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersTectorial membraneTransducer

A piezoelectric type electroacoustic transducer includes a piezoelectric vibrating plate including a plurality of piezoelectric ceramic layers laminated to each other with an internal electrode being interposed between the piezoelectric ceramic layers, and main surface electrodes disposed on the main surfaces on the front and back sides of the piezoelectric vibrating plate, whereby the piezoelectric vibrating plate is surface-flexural-vibrated in the thickness direction thereof with an AC signal applied between the main surface electrodes and the internal electrode, and a box having supporting portions on which the outer peripheral portions on the back side of the piezoelectric vibrating plate is supported, the piezoelectric vibrating plate having a protecting film substantially on the entire surface on the back-side only or on the front and back sides of the piezoelectric vibrating plate, and the protecting film being formed by applying a resin in a film-shape and hardening the resin, or by bonding an adhesive sheet and hardening the sheet, and the piezoelectric vibrating plate being warped on the front-side thereof by utilization of the hardening shrink stresses of the protecting films.

Owner:MURATA MFG CO LTD

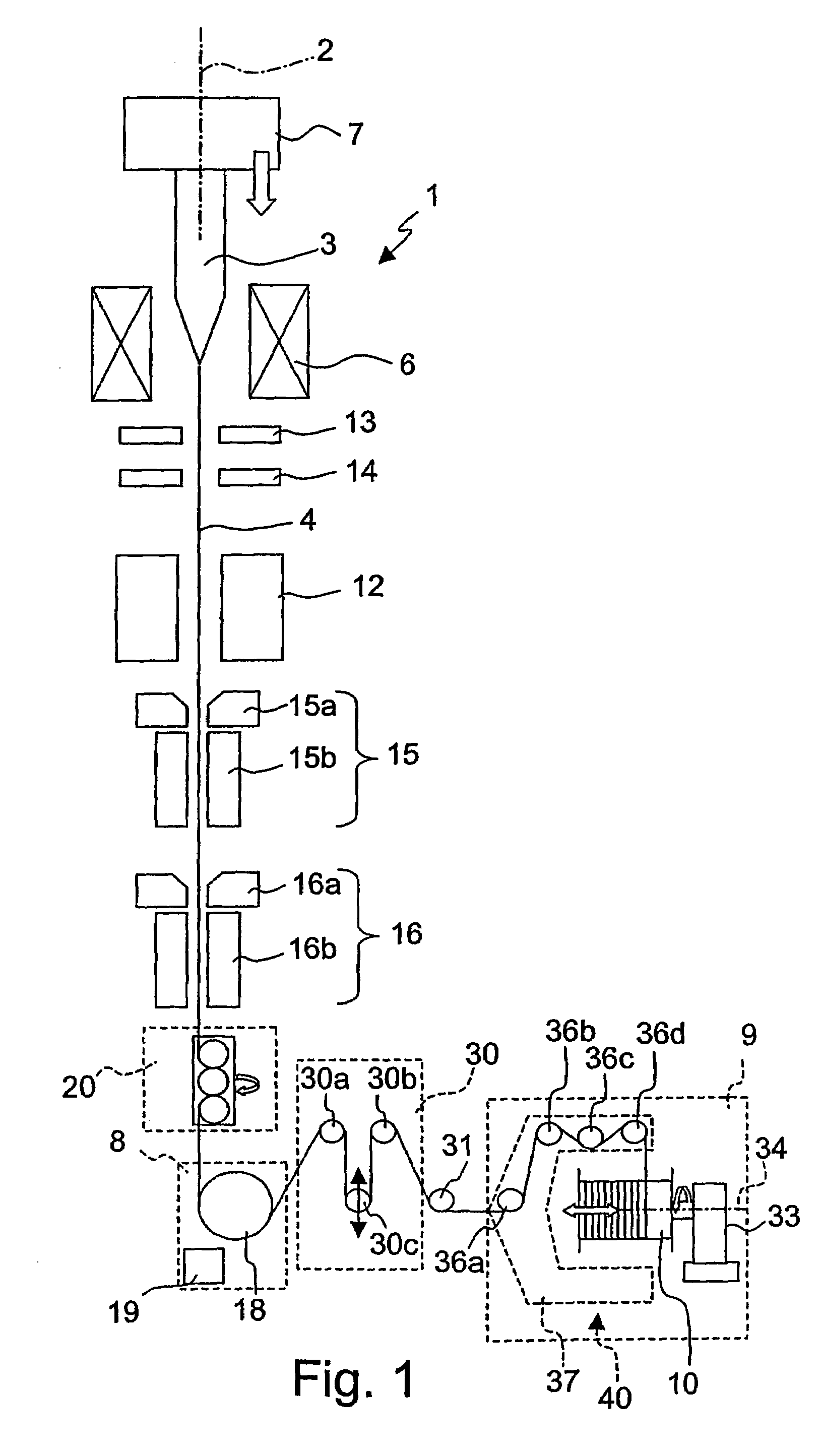

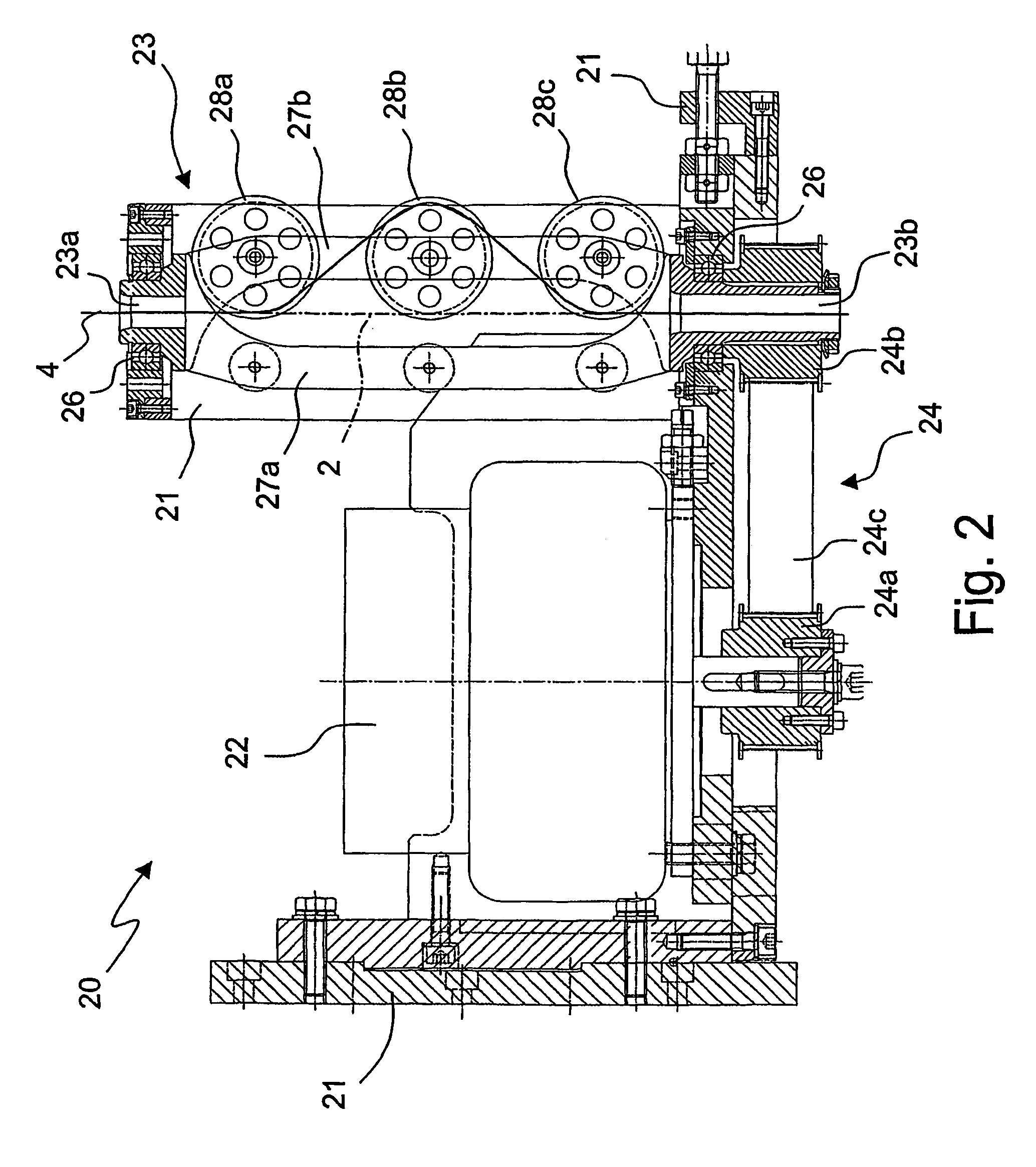

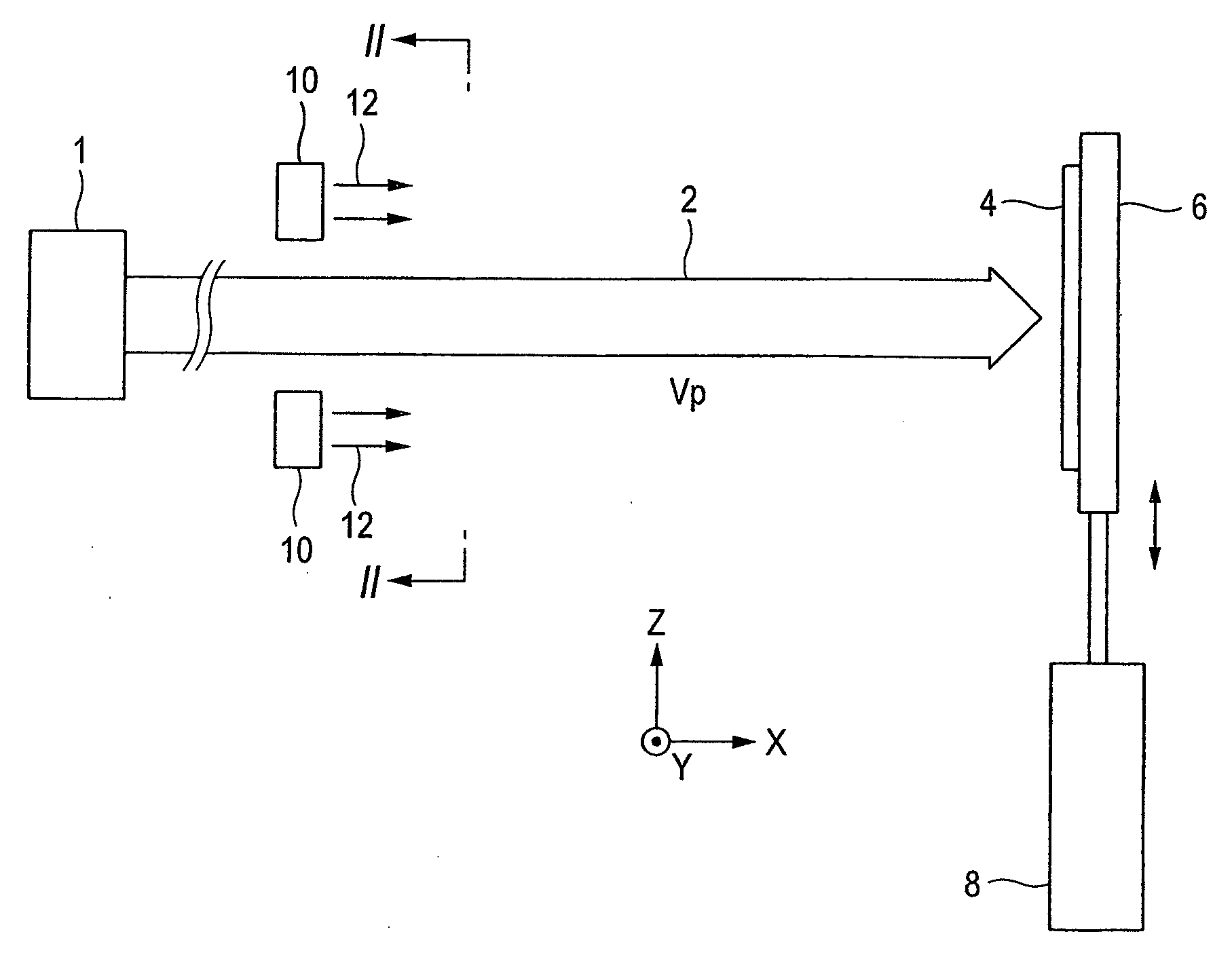

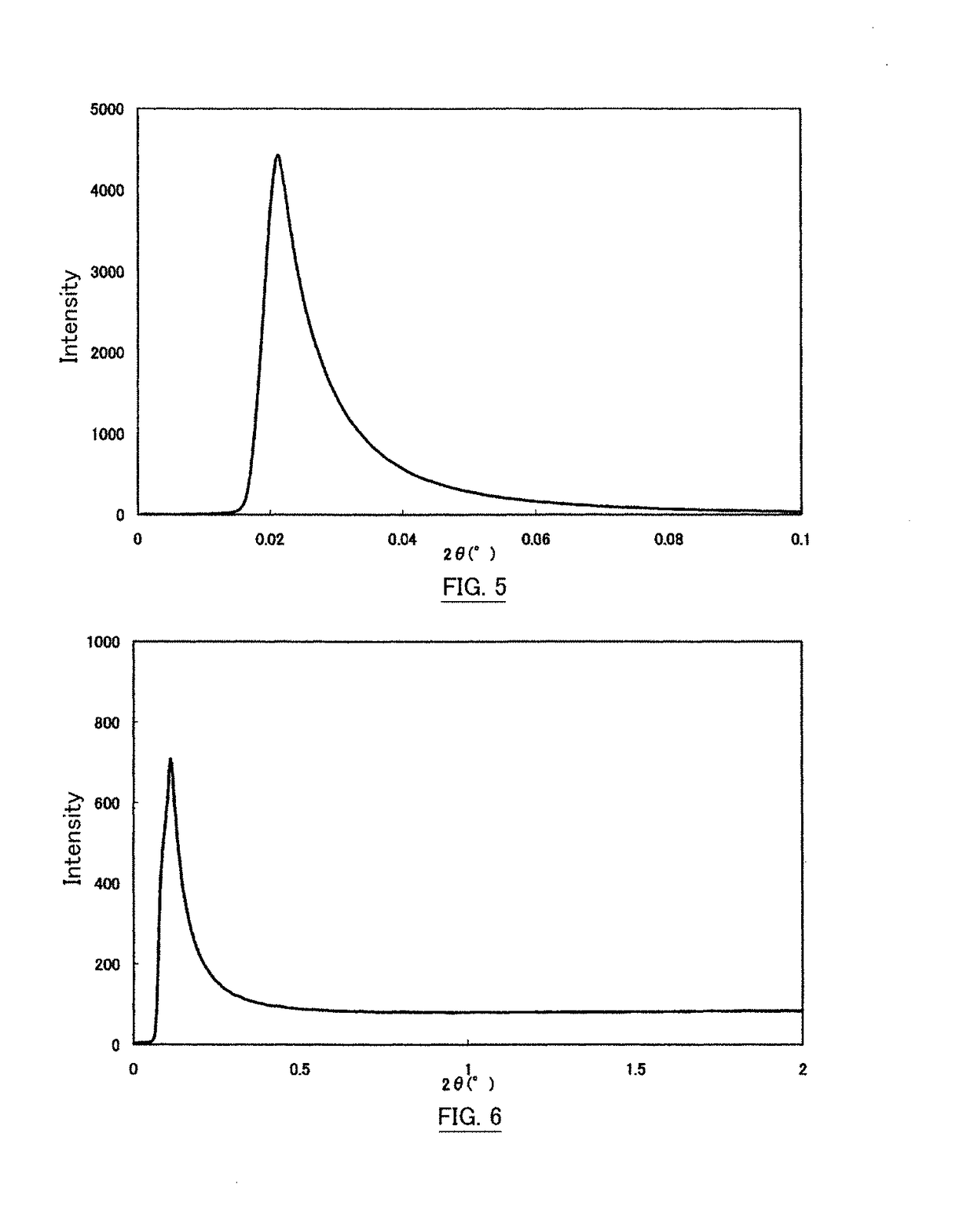

Optical fiber having a low polarization mode dispersion and process and apparatus for producing it

InactiveUS7409126B2Reduce PMDLess dispersionCladded optical fibreGlass fibre drawing apparatusFiberEngineering

An apparatus for producing a low-PMD optical fiber having a furnace for melting a lower portion of an optical preform; a traction device for pulling an optical fiber from the lower portion of an optical preform; a spinning device for imparting a substantially constant and unidirectional spin to the optical fiber as it is pulled, which causes the fiber to undergo an elastic torsion; a winding device for winding the optical fiber onto a reel; and a twisting device for imparting to the spun optical fiber a unidirectional twist in a direction opposite the elastic torsion, so as to control the residual twist in the optical fiber. A process for producing the fiber, an optical fiber and a cable are also provided.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

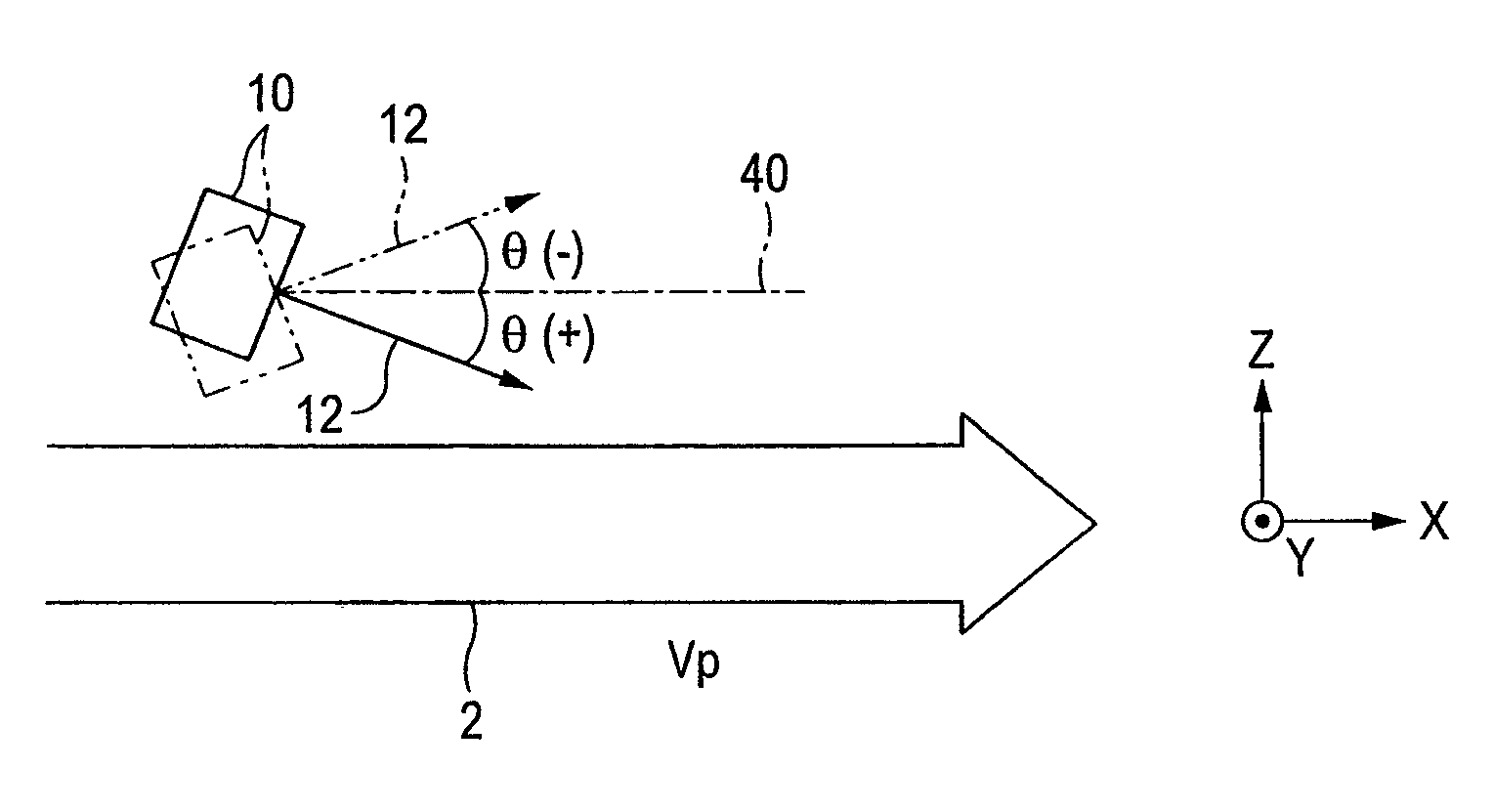

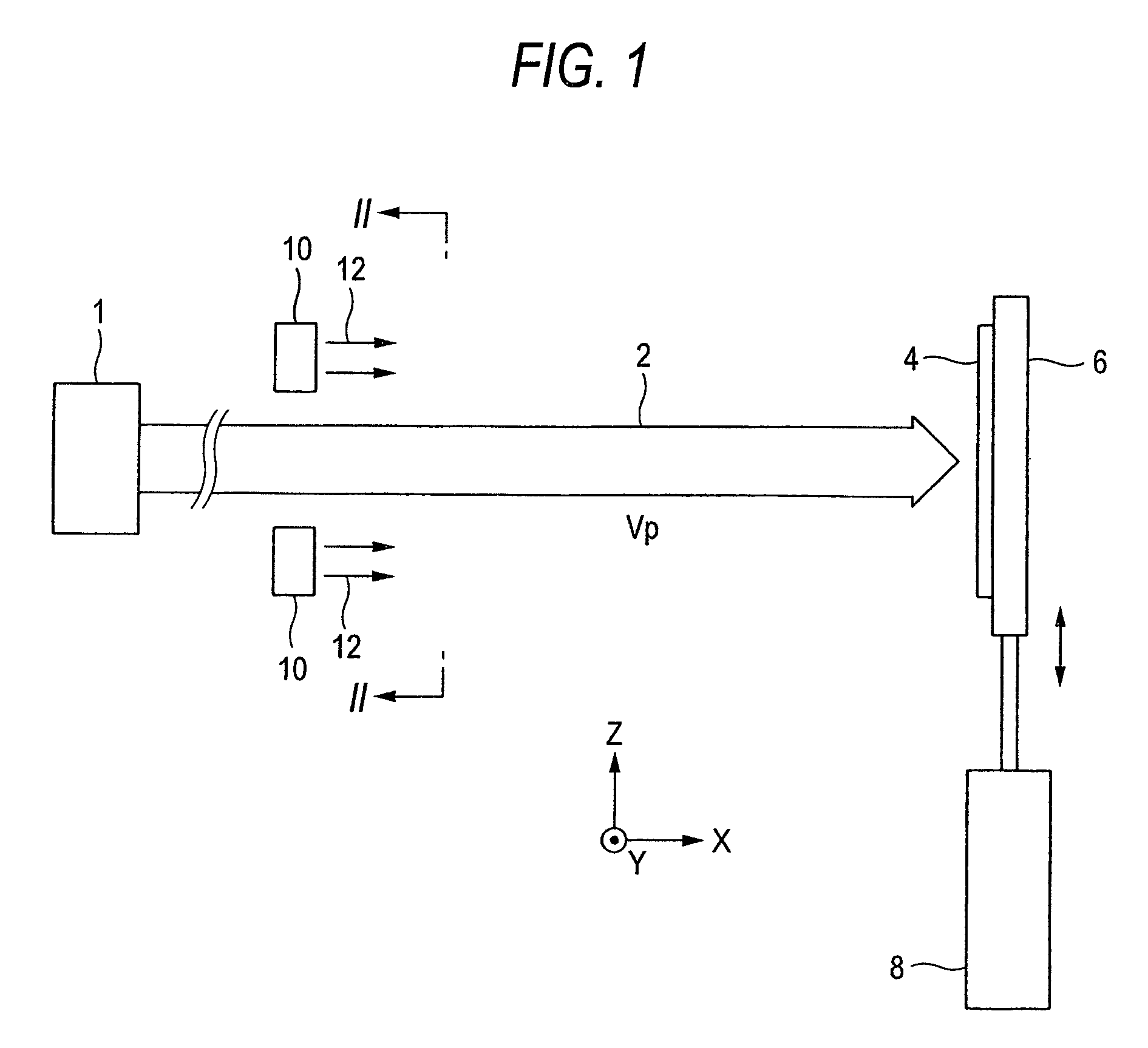

Ion beam irradiating apparatus, and method of producing semiconductor device

InactiveUS20090203199A1Dispersion suppressionLess dispersionLaser detailsMaterial analysis by optical meansElectron sourceSemiconductor device

An ion beam irradiating apparatus has a field emission electron source 10 which is disposed in a vicinity of a path of the ion beam 2, and which emits electrons 12. The field emission electron source 10 is placed in a direction along which an incident angle formed by the electrons 12 emitted from the electron source 10 and a direction parallel to the traveling direction of the ion beam 2 is in the range from −15 deg. to +45 deg. (an inward direction of the ion beam 2 is +, and an outward direction is −).

Owner:KYOTO UNIV +1

Optical compensation film, polarizing plate, and liquid-crystal display device

InactiveUS7929089B2Reduce colorColor shiftNon-linear opticsOptical elementsLiquid-crystal displayLength wave

Disclosed is an optical compensation film comprising first and second optically-anisotropic layers, wherein retardation in plane at a wavelength of 550 nm, Re(550), of the first optically-anisotropic layer is from 20 to 40 nm, the first optically-anisotropic layer does not have any direction in which its retardation at a wavelength of 550 nm is 0 nm, the direction in which the absolute value of retardation of the first optically-anisotropic layer is the smallest is neither in the normal line direction of the layer nor in the in-plane direction thereof, and Re(550) of the second optically-anisotropic layer is from 20 to 150 nm and retardation along thickness direction at a wavelength of 550 nm, Rth(550), thereof is from 40 to 110 nm.

Owner:FUJIFILM CORP

Pressure sensor, and its manufacturing method

InactiveUS6915698B2Small dispersionSimple structureFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement using capacitance variationLower faceForce sensor

A small-sized pressure sensor having smaller numbers of parts and assembling steps, a simple structure, a high assembly precision, and little dispersion in the operation characteristics, and a method for manufacturing the pressure sensor. The pressure sensor comprises: a base member; a stationary electrode molded so integrally as is exposed from the bottom face of a recess formed in the upper face of the base member; moving electrode receiving portions and molded so integrally in the bottom face of the recess of the base members as are arranged in the periphery of the stationary electrode and as are higher by a predetermined inter-electrode gap than the upper face of the stationary electrode; a moving electrode opposed to the upper face of the stationary electrode through a predetermined inter-electrode gap; and a diaphragm fixed of the open edge portion of the recess of the base member and adhered integrally at the central portion of its lower face to the upper face of the moving electrode.

Owner:ORMON CORP

Manufacturing method of the semiconductor device and the semiconductor device

InactiveUS20050189596A1Less dispersionWell formedTransistorSemiconductor/solid-state device manufacturingDopantGate dielectric

A method to impede the constitution of the area wherein the silicide film that is defying to form on a gate electrode. Form an element isolation film, and then a gate dielectric film in a P-channel and an N-channel transistor forming region respectively. Then form a semiconductor film that constructs part of a gate electrode over the P-Type and the N-Type element regions through the element isolation film. Implant a dopant into the region, including the part over the P-channel transistor forming region and form a P-Type gate region, and then implant a dopant into the region, including the part over the N-channel transistor forming region and form a N-Type gate region. At this time, form the region so part of the P-Type gate region and the N-Type gate region overlap. Then, form the silicide film that constructs the part of the gate electrode over the semiconductor film.

Owner:SEIKO EPSON CORP

Ion beam irradiating apparatus, and method of producing semiconductor device

InactiveUS7935944B2Dispersion suppressionLess dispersionLaser detailsConversion outside reactor/acceleratorsElectron sourceSemiconductor device

An ion beam irradiating apparatus has a field emission electron source 10 which is disposed in a vicinity of a path of the ion beam 2, and which emits electrons 12. The field emission electron source 10 is placed in a direction along which an incident angle formed by the electrons 12 emitted from the electron source 10 and a direction parallel to the traveling direction of the ion beam 2 is in the range from −15 deg. to +45 deg. (an inward direction of the ion beam 2 is +, and an outward direction is −).

Owner:KYOTO UNIV +1

Electrically conductive polymer films and process for making same

InactiveUS20060063875A1Low viscosityLess dispersionConductive materialSynthetic resin layered productsPolymer scienceElectronic systems

A self-supporting conductive polymer film having distributed therein an electrically conductive polymer composition containing linearly conjugated π-electron systems and residues of sulfonated lignin or a sulfonated polyflavonoid. The conductive polymer film preferably has a surface resistivity of from about 102 ohms per square to about 1010 ohms per square and is preferably formed from a liquid dispersion of thermoplastic polymer having the electrically conductive polymer composition distributed therein. In a preferred embodiment, heat sealable conductive fluoropolymer films are prepared.

Owner:EI DU PONT DE NEMOURS & CO

Impactor Spray Atmospheric Pressure Ion Source with Target Paddle

ActiveUS20160365232A1Improves ion signal intensityImprove interfaceSamples introduction/extractionIon sources/gunsChemistryIon source

An ion source is provided comprising one or more nebulisers and one or more targets, wherein the one or more nebulisers are arranged and adapted to emit, in use, a stream predominantly of droplets which are caused to impact upon the one or more targets and to ionise the droplets to form a plurality of ions. The ion source further comprises one or more electrodes arranged adjacent to and / or attached to the one or more targets wherein the one or more electrodes comprise one or more apertures, notches or cut-outs wherein at least some of the plurality of ions pass, in use, through the one or more apertures, notches or cut-outs.

Owner:MICROMASS UK LTD

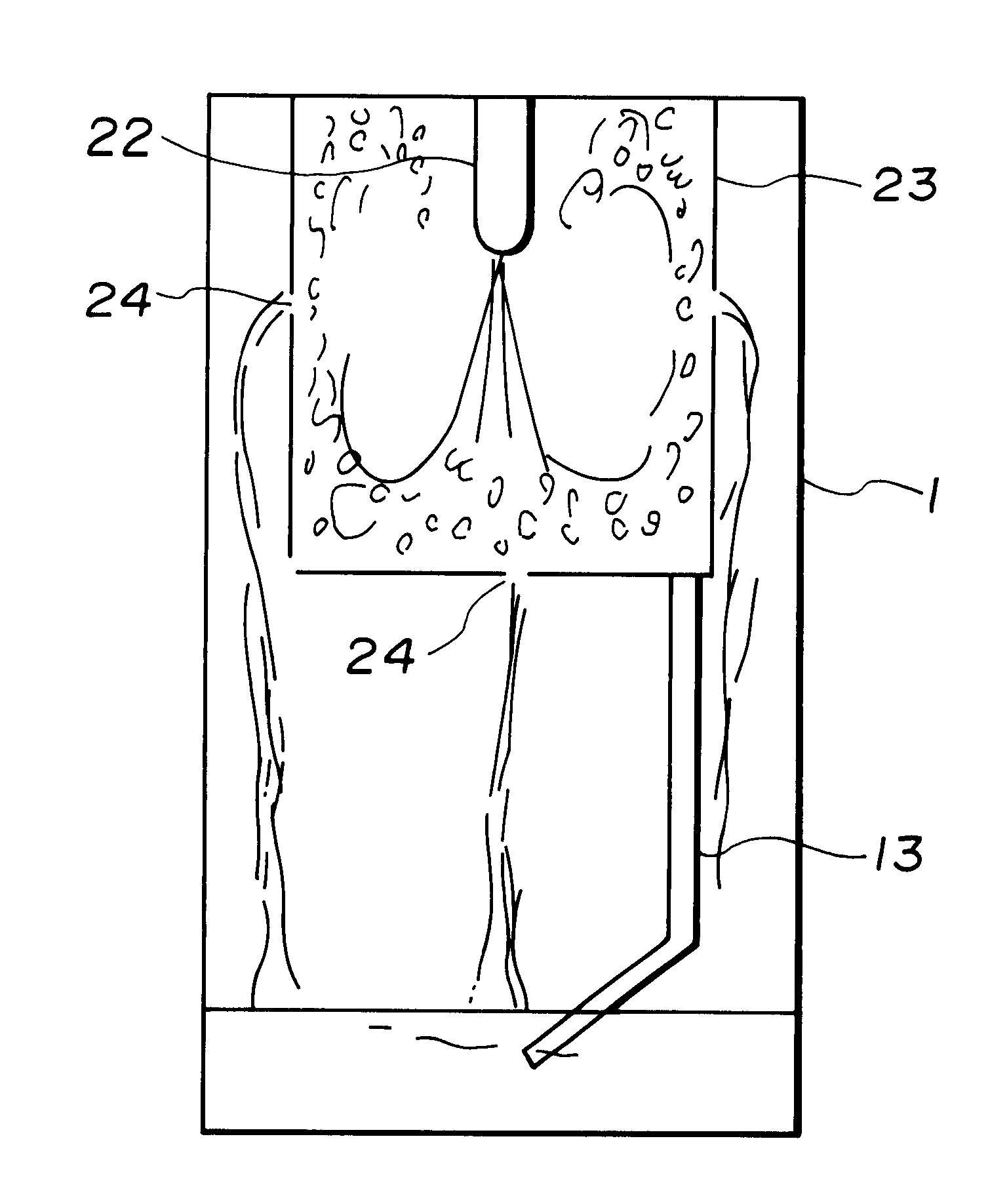

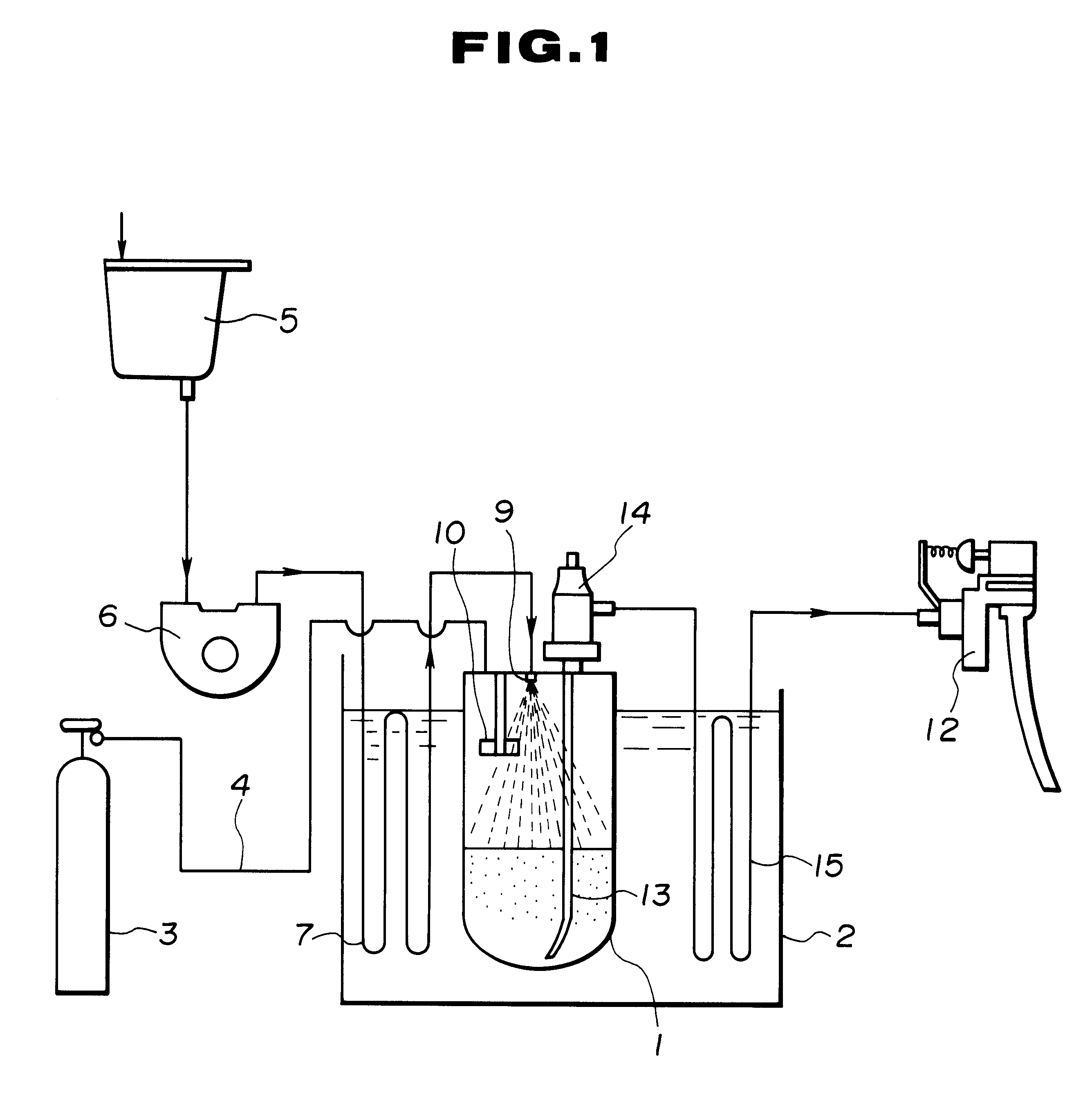

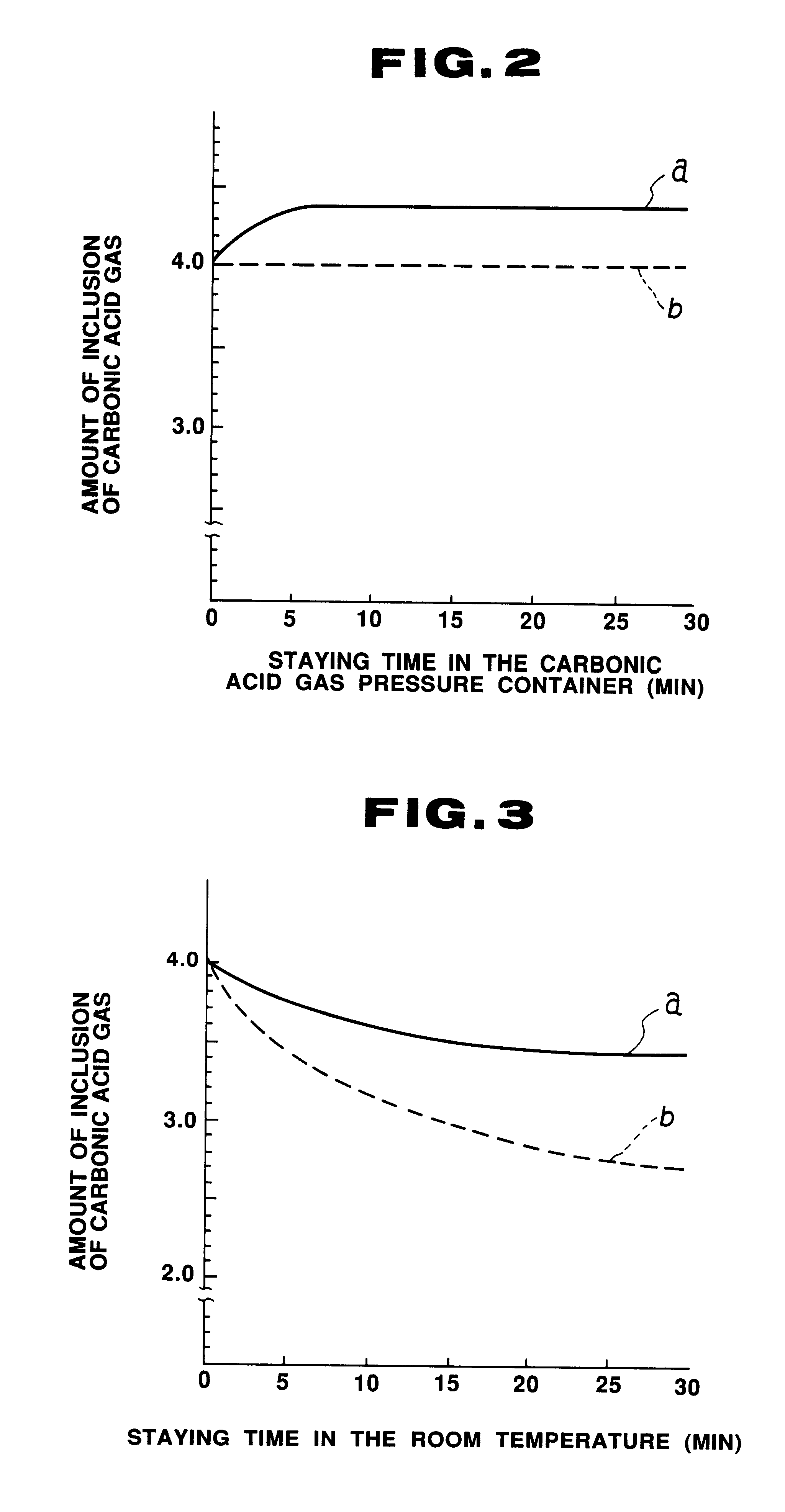

Apparatus for manufacturing carbonated water

InactiveUSRE37499E1High inclusion rateLess dispersionCarburetting airUsing liquid separation agentWater storageHigh rate

An apparatus <DEL-S DATE="20020108" ID="DEL-S-00001">is<DEL-E ID="DEL-S-00001"> <INS-S DATE="20020108" ID="INS-S-00001">and method are <INS-E ID="INS-S-00001">provided for manufacturing carbonated water rapidly with a high rate of inclusion of carbonic acid gas in the carbonated water and having a reduced dispersion, the manufacture taking place in a water storage container in which a perforated bowl is connected to an upper surface thereof with water being sprayed into the bowl from a water supply line. The water sprayed into the bowl has droplets from about 0.01 to 0.5 mm in diameter and from about 3 to 30% of the water sprayed into the bowl flows outwardly through ports in the bottom wall of the perforated bowl. From about 70 to 97% by weight of the water supplied to the bowl flows outward through ports in the side walls of the bowl.

Owner:SANYO ELECTRIC CO LTD

Semiconductor device with a gate region having overlapping first conduction type and second conduction type dopants

InactiveUS20080087964A1Less dispersionWell formedTransistorSemiconductor/solid-state device manufacturingDopantGate dielectric

A method to impede the constitution of the area wherein the silicide film that is defying to form on a gate electrode. Form an element isolation film, and then a gate dielectric film in a P-channel and an N-channel transistor forming region respectively. Then form a semiconductor film that constructs part of a gate electrode over the P-Type and the N-Type element regions through the element isolation film. Implant a dopant into the region, including the part over the P-channel transistor forming region and form a P-Type gate region, and then implant a dopant into the region, including the part over the N-channel transistor forming region and form a N-Type gate region. At this time, form the region so part of the P-Type gate region and the N-Type gate region overlap. Then, form the silicide film that constructs the part of the gate electrode over the semiconductor film.

Owner:TAKAHASHI HIROTSUGU

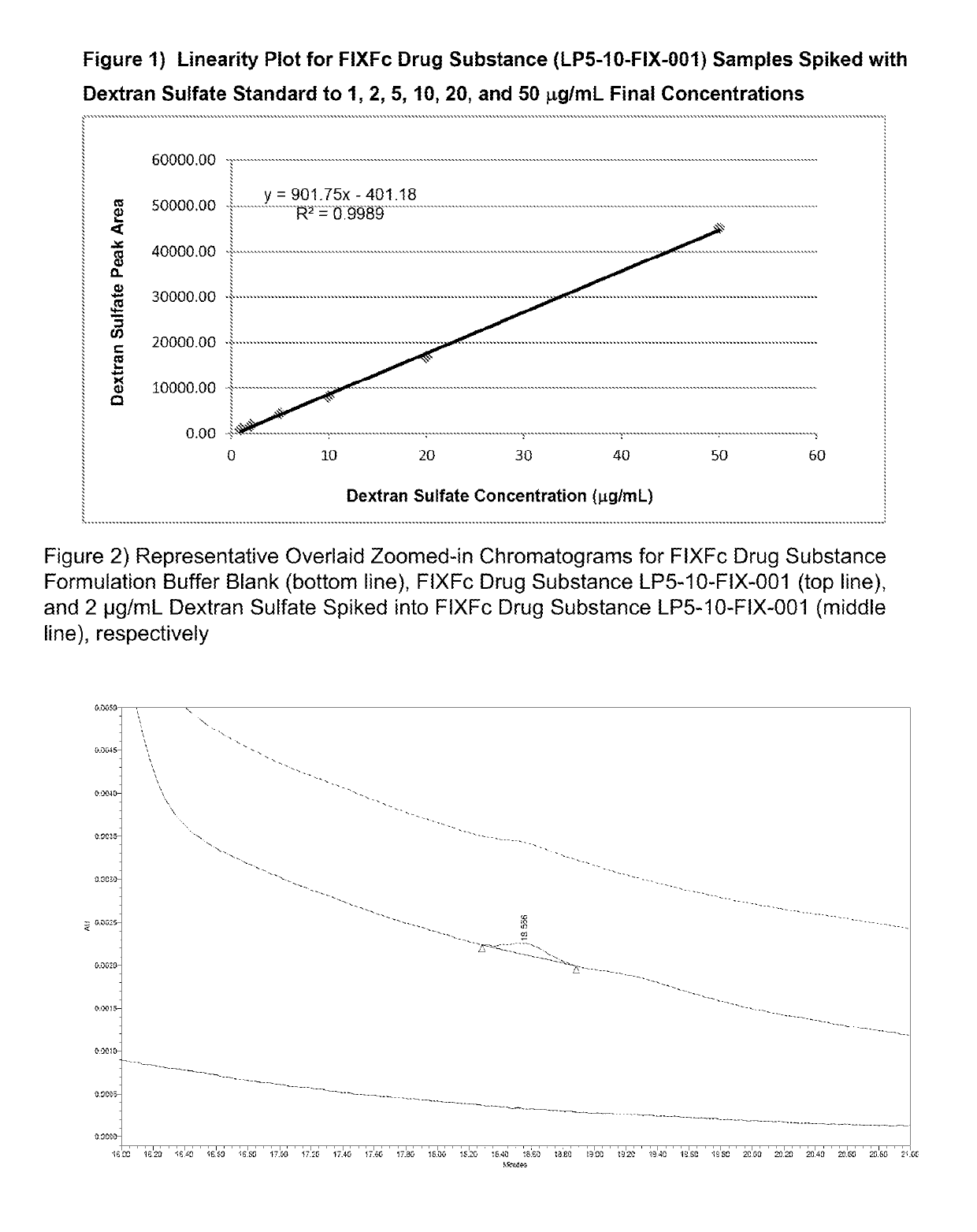

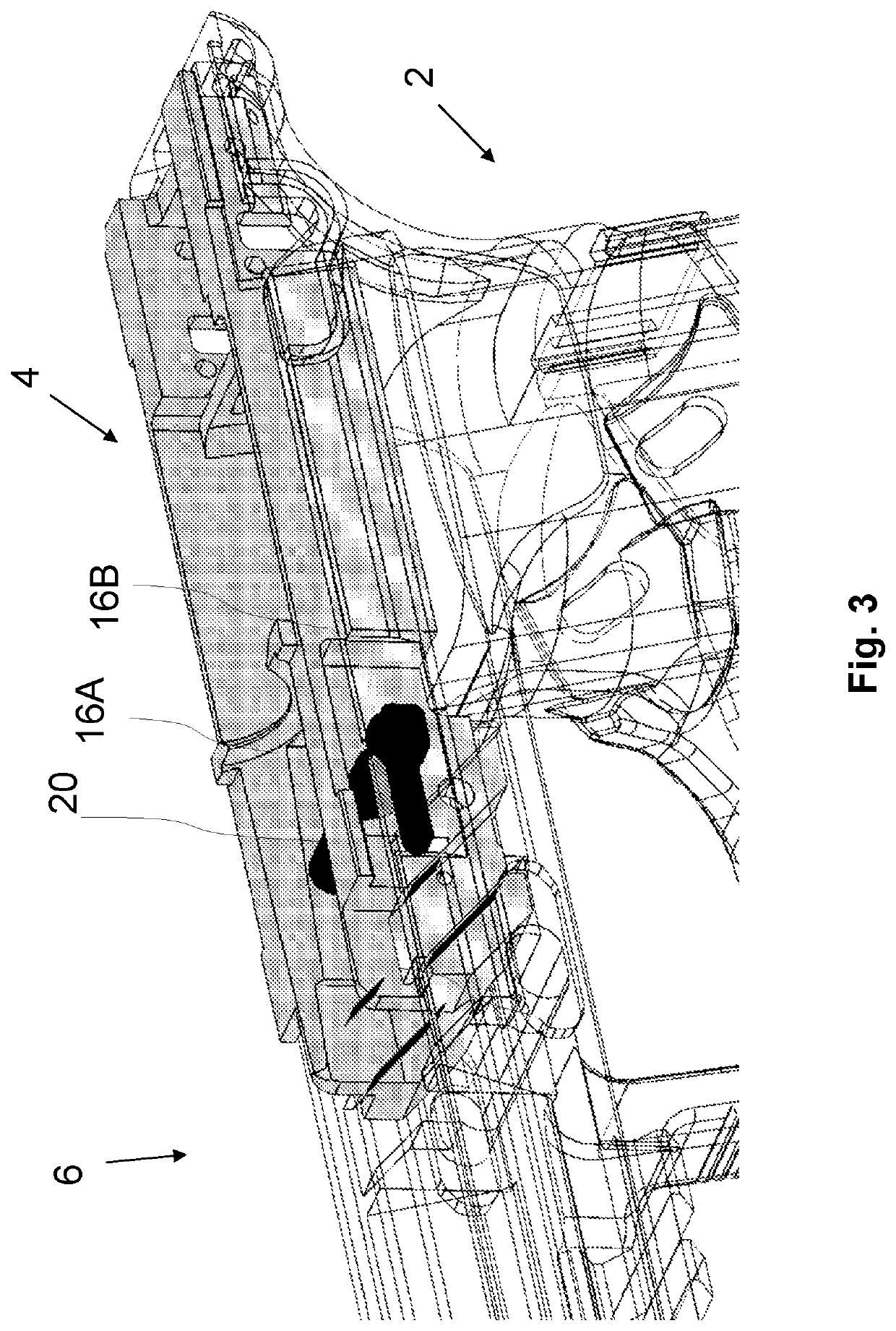

Methods of detecting glycosaminoglycans

InactiveUS10317376B2Promote migrationLess dispersionComponent separationBiological material analysisElutionSize-exclusion chromatography

In one aspect, the disclosure provides methods of distinguishing a glycosaminoglycan from one or more other components in a sample by subjecting the sample to size-exclusion chromatography using a mobile phase having a pH of 6.8 or lower. A mobile phase having a pH of 6.8 or lower is found to improve the separation of glycosaminoglycans from proteins during size exclusion chromatography. In some embodiments, improved separation is due to the low pH of the mobile phase causing elution of less dispersed fractions of the protein and / or glycosaminoglycan. In some embodiments, the overlap between protein and / or glycosaminoglycan fractions is reduced.

Owner:BIOVERATIV THERAPEUTICS INC

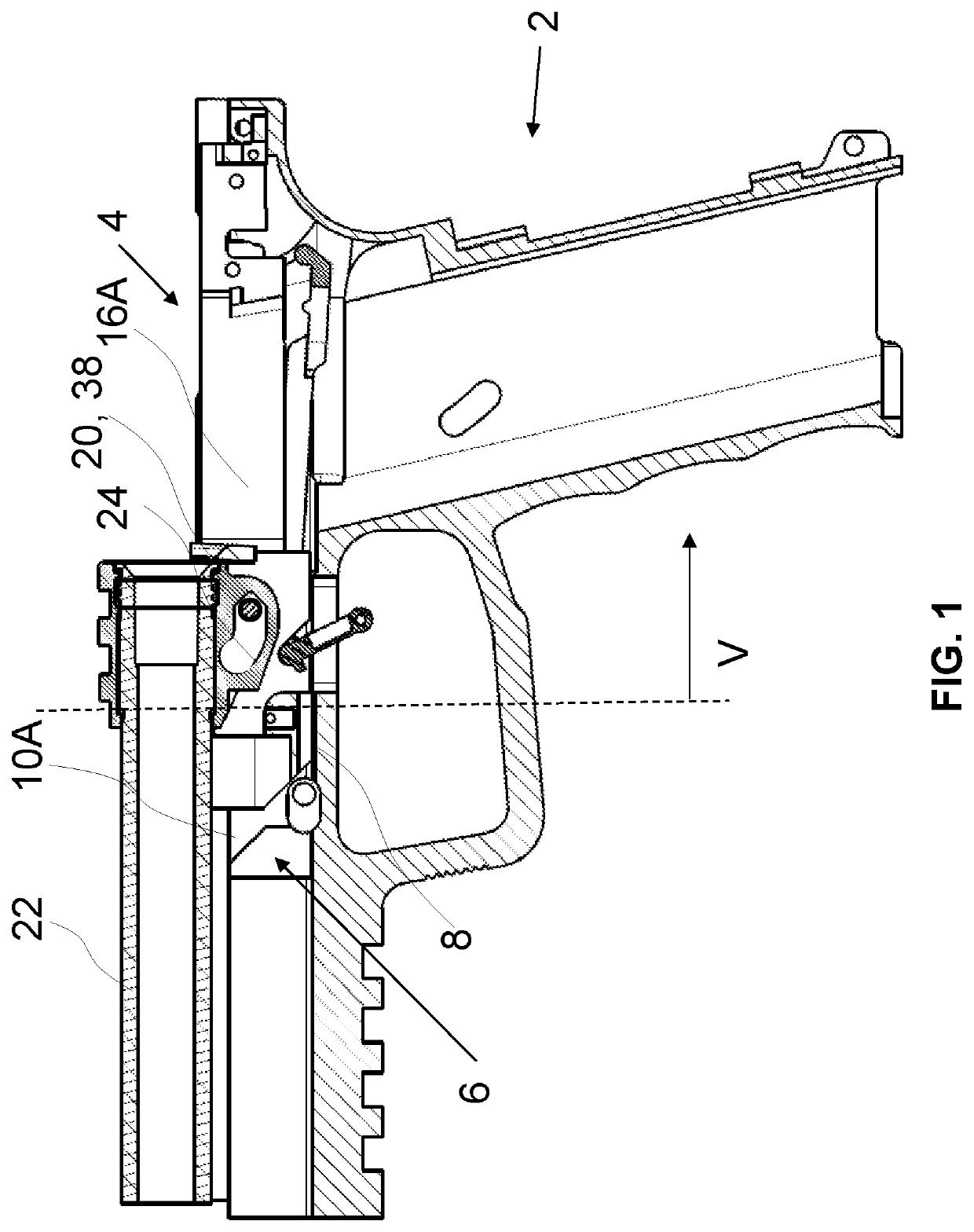

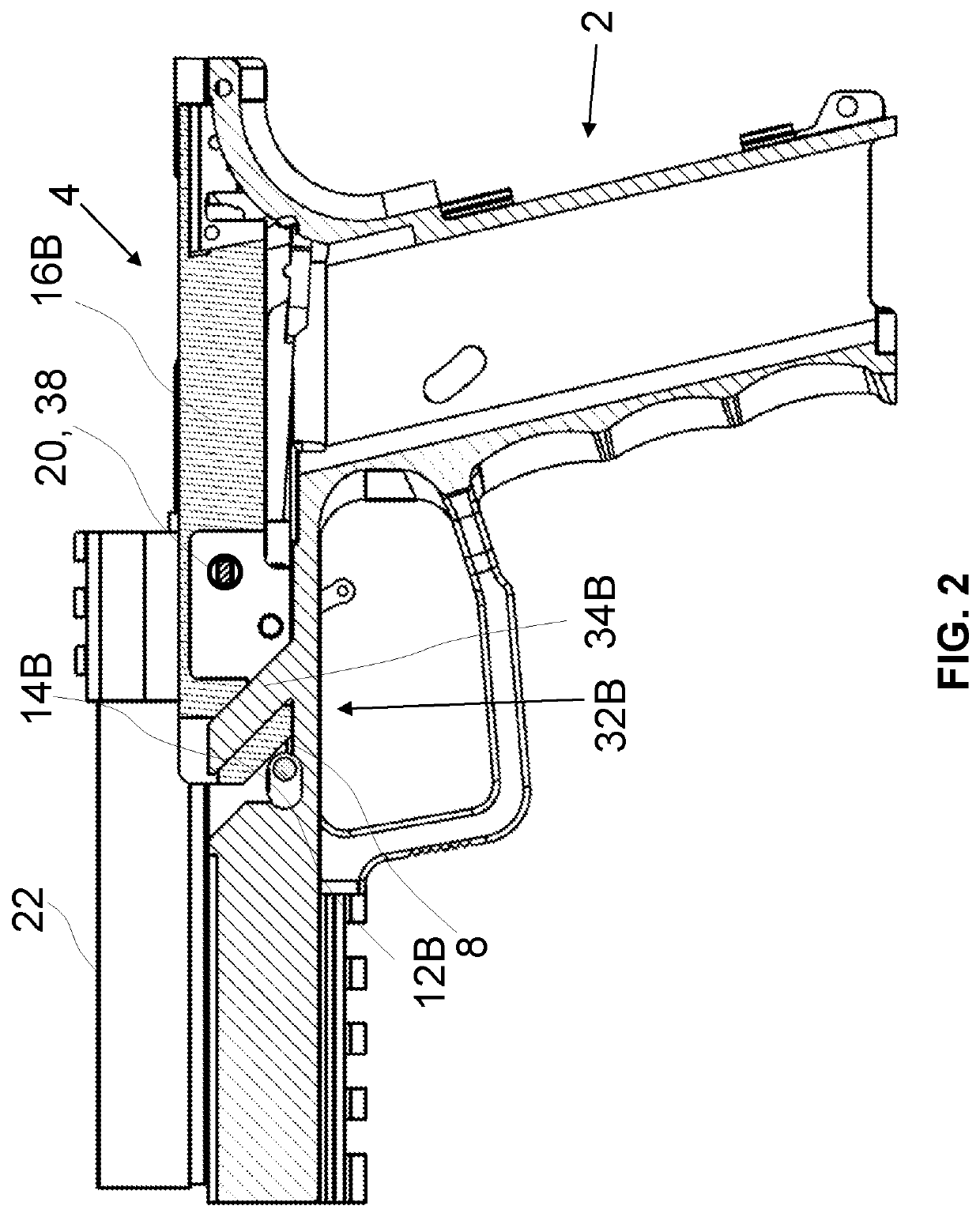

Pistol with optimized chassis anchoring

PendingUS20220341687A1High mechanical strengthOptimize general geometryBreech mechanismsClassical mechanicsRolling chassis

A pistol is disclosed, including a body made from synthetic material having a channel formed inside the body. A slide is guided in a longitudinal direction of the body, the slide including a barrel and a breech. A single-block chassis having an elongated shape extends from a central portion of the body to a rear end of the body. The chassis further includes guiding elements for guiding the slide. The pistol is configured such that the channel is designed to receive the chassis removably, and the chassis is fastened to the body using a formfitting, sliding connection.

Owner:FN HERSTAL

Pullulan-containing powder, method for producing the same and use thereof

PendingUS20190085367A1Quality improvementHigh breaking strengthCosmetic preparationsMicroorganismsParticulatesPullulan

The present invention aims to provide a particulate composition containing pullulan, which can be produced without employing any complicated purification step such as solvent precipitation and, when formed into a film, exhibits a higher rupture strength compared to conventional ones; a process for producing the same; and uses thereof. The present invention solves the above object by providing a particulate composition containing pullulan which is produced from a culture obtained by culturing a mutant of a microorganism of the species Aureobasidium pullulans in a culture medium containing glucose and maltose as carbon sources, without employing a step of removing concomitant saccharides; contains a pullulan fraction and a concomitant saccharide fraction that are respectively insoluble and soluble in 75% by volume of methanol in water; has a percentage of 3% by weight or lower of the content of concomitant saccharides contained in the concomitant saccharide fraction against the content of total saccharides contained in the whole particulate composition, when determined based on the anthrone sulfuric acid method; and contains mannitol; and by providing the process of the same and uses thereof.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

Semiconductor integrated circuit card manufacturing method, and semiconductor integrated circuit card

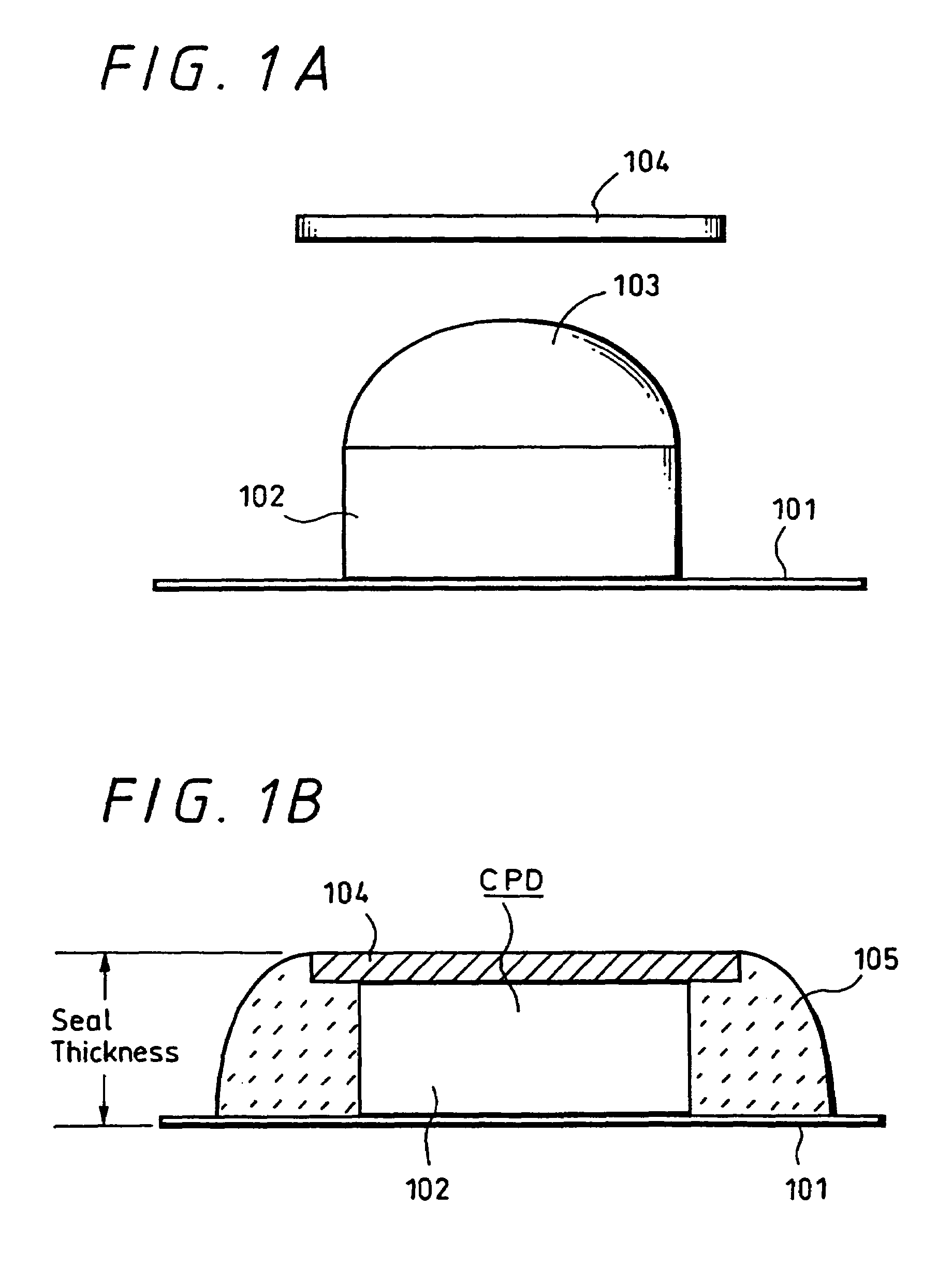

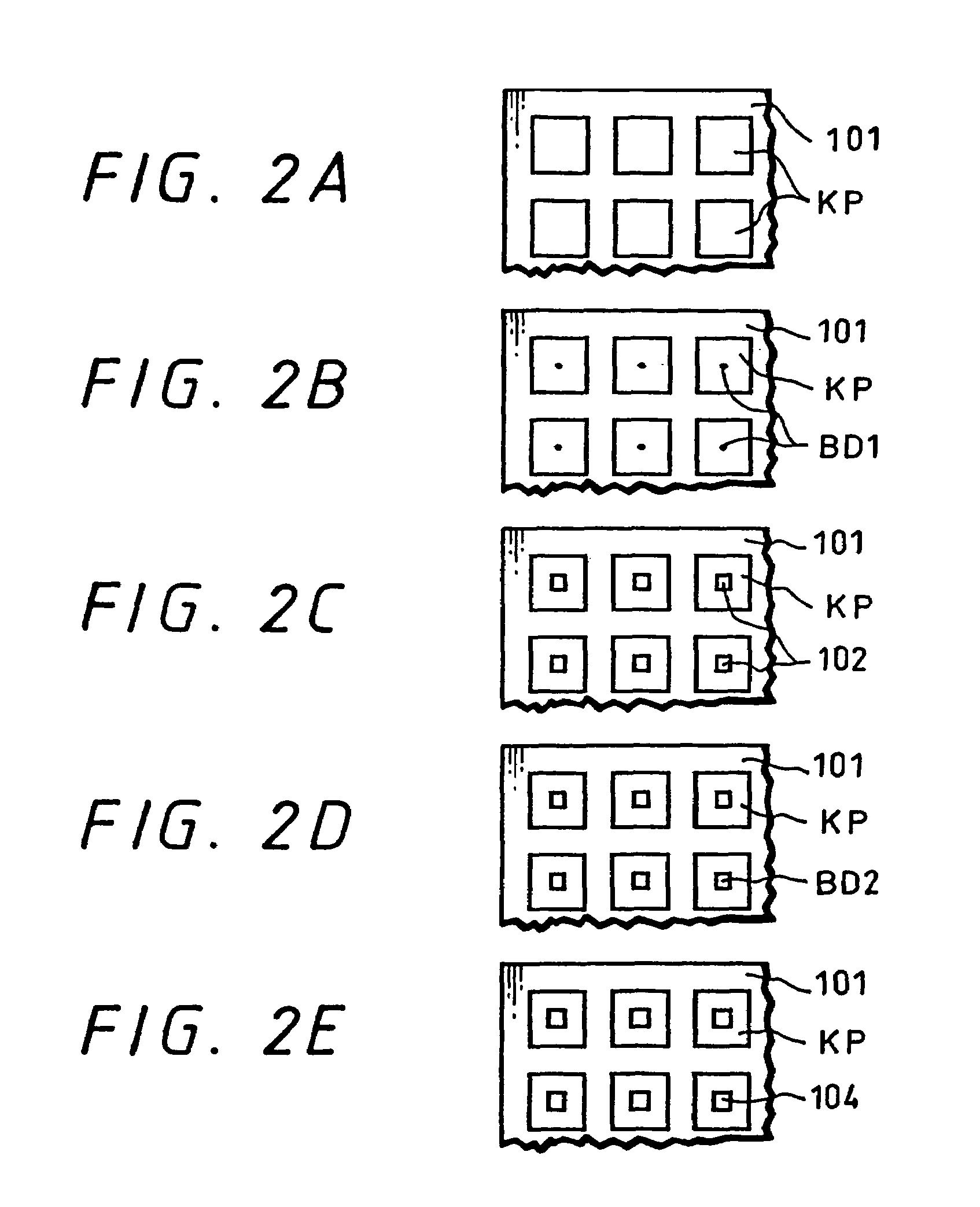

InactiveUS7041536B2High strengthLess dispersionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor integrated circuit card is disclosed in which such a semiconductor integrated circuit chip device comprising a substrate having a circuit pattern formed thereon, a semiconductor circuit chip bonded onto the substrate and having an electrode connected to the circuit pattern, a reinforcement metal plate, and a seal resin portion for covering a peripheral face of the semiconductor integrated circuit chip and sticking the reinforcement metal plate onto the semiconductor integrated circuit chip is mounted within a card substrate.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com