Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Inhibition of alkali-aggregate reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

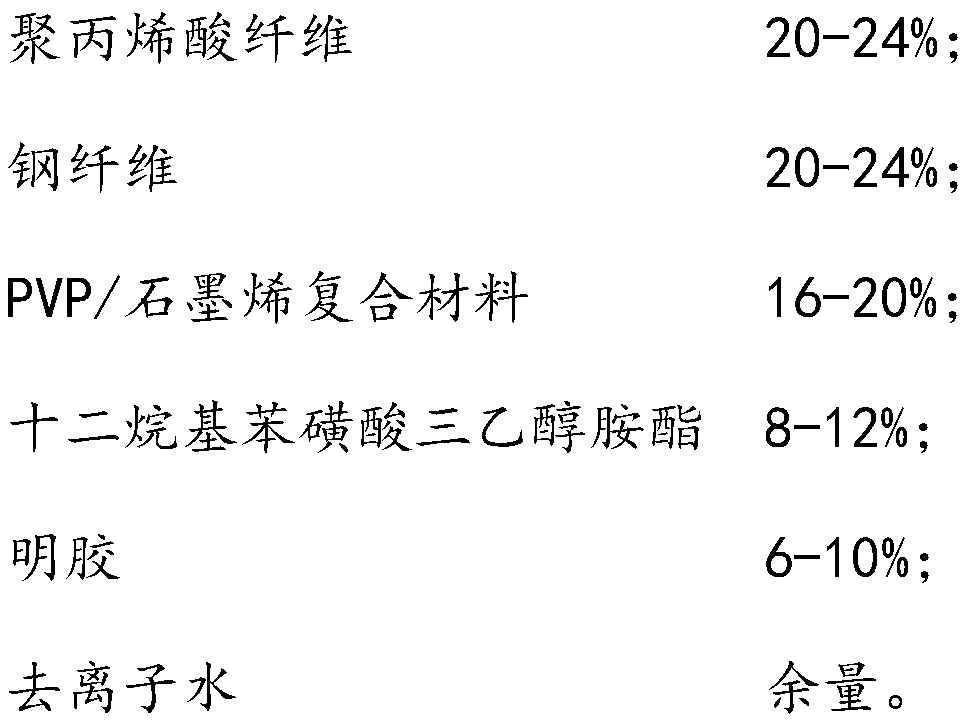

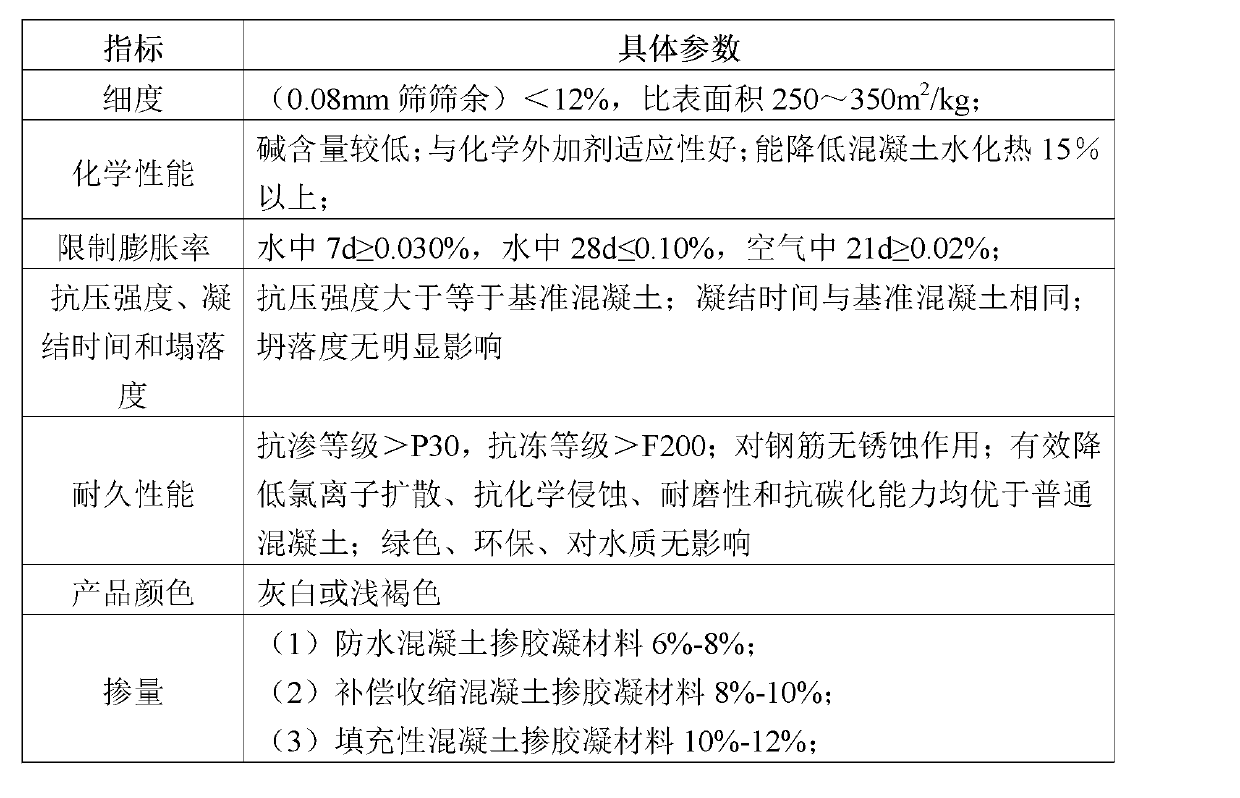

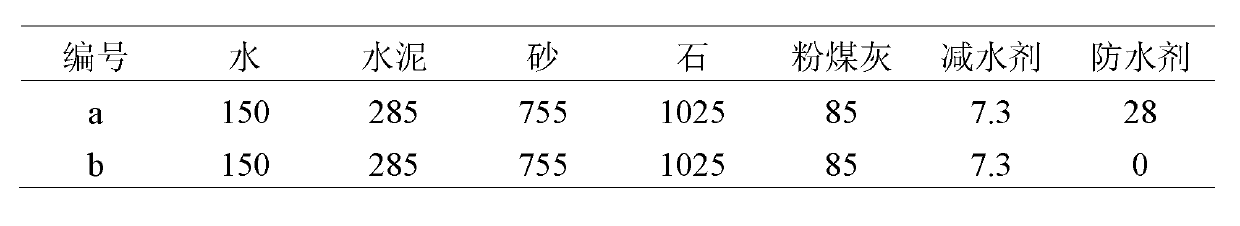

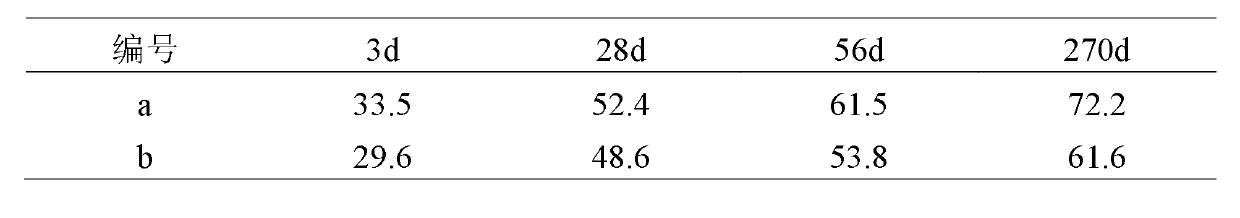

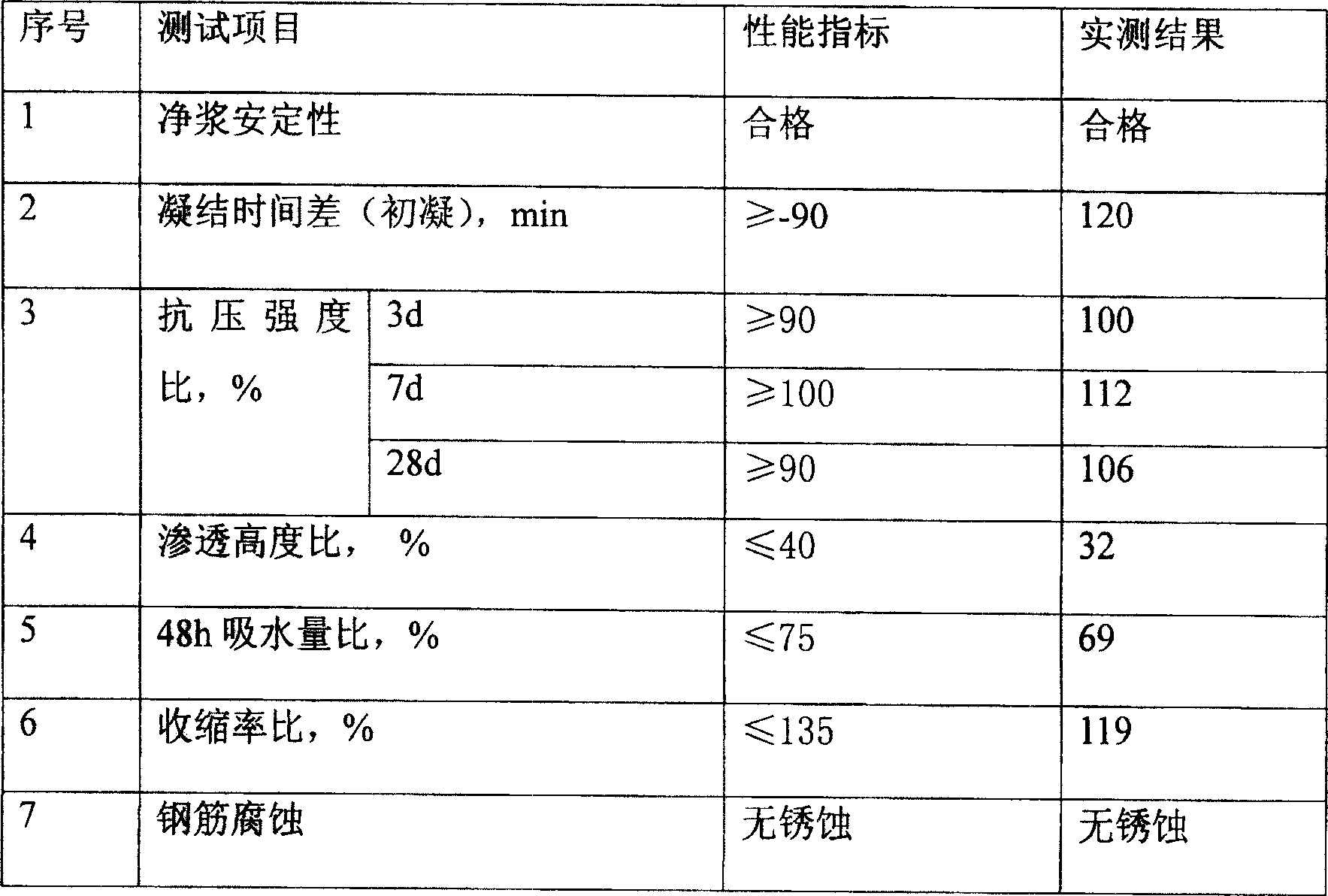

Sand pulp concrete waterproof agent and method for making same

ActiveCN101117280AInhibition of alkali-aggregate reactionReduce expansionCrack resistanceAlkylphenol

The invention discloses a mortar and concrete waterproofer. The waterproofer is characterized in that: the waterproofer comprises (part by weight) 70 to 90 parts of activation zeolite power, 0.3 to 2 parts of silane resin acceptor, 2 to 5 parts of stearic acid, 0.007 to 0.05 parts of alkylphenols polyethenoxy ether, 3 to 10 parts of magnesium lime, 1 to 6 parts of plaster, 5 to 10 parts of mekralon. The invention further relates to a preparation method for the mortar and concrete waterproofer. The waterproofer not only can increase the compactness, the pressive strength and the waterproof impermeability of the concrete, but also can prevent temperature difference gap through the delay and reduction of heat release of hydration, reduce the shrinkage of the cement gelatin to reduce the drying shrinkage of the concrete. A slight expansion of the concrete a compensation of a shrinking gap can increase the cracking resistance. The invention can also improve the operation performance of the mortar and the concrete, restrain an alkali-aggregate reaction and increase long term strength of the concrete and enhance the wear, and is particularly suited to serving as an admixture of the mortar and the concrete.

Owner:JINHUA XINSHENG ZEOLITE DEV

Special cement and its production process

The specific cement is produced with cement clinker, mineral slag, flyash and gypsum in certain weight proportion, and the cement clinker is produced with limestone, loess, silica and iron ore in certain weight proportion and through calcination. The production process of the specific cement includes high temperature calcination of raw material at 1400-1500 deg.c to produce cement clinker while controlling exhaust temperature not lower than 900 deg.c for exhausting alkali to alkali content not more than 0.4 %; and pulverizing cement clinker, mineral slag, flyash and gypsum while controlling specific surface area not smaller than 350 sq m / Kg to obtain the specific cement. The specific cement has low alkali content, high wear resistance, high strength, fast coagulation and other advantages.

Owner:TONGHUA SPECIAL CEMENT GROUP JILIN PROV

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

High-durability concrete for road

The invention discloses high-durability concrete for a road. The concrete is prepared from Portland cement, coarse sand, medium-coarse sand, gravel, water, coal ash powder, blast furnace slag, glass bead, natural zeolite ultrafine powder, steel slag, aluminum oxide powder, sodium molybdate, sodium chromate, sodium thiosulfate, triethanolamine, a maleic anhydride water reducing agent, an air entraining agent and mixed fiber. The high-durability concrete for the road is high in mechanical property, not prone to cracking and high in durability such as impermeability, corrosion resistance and freezing resistance on the basis of ensuring strength and greatly prolongs the service life of the road.

Owner:蚌埠市宝运商品混凝土有限公司

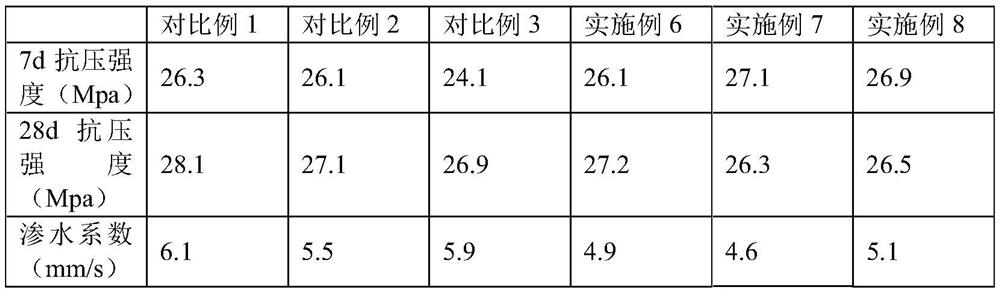

Method for producing concrete channel prefabricated part from mineral slag

InactiveCN106007593AImprove anti-seepage effectImprove flexibilitySolid waste managementAluminateSlag

The invention relates to a method for producing a concrete channel prefabricated part from mineral slag. The method is characterized in that the concrete channel prefabricated part is prepared from the following raw materials in parts by weight: 60-70 parts of fine and coarse aggregate, 10-20 parts of 42.5 sulfoaluminate cement, 5-10 parts of fly ash, 5-10 parts of slag micropowder, 1-3 parts of early-strength admixture, 1-3 parts of high efficiency water reducing agent and 0.1-0.5 part of defoaming agent. The high efficiency water reducing agent is a calcium lignosulphonate water reducing agent. The concrete channel prefabricated part has the advantages of low cost, excellent properties, stable quality, excellent compression strength, excellent compression strength, excellent freeze resistance and excellent water impermeability. The method aims to further enhance the standard construction of irrigation projects, comprehensively enhance the construction level and management and protection level of agricultural hydraulic engineering in China, increase the utilization ratio of irrigation water and implement high-efficiency utilization of water resources.

Owner:象州县科学技术局

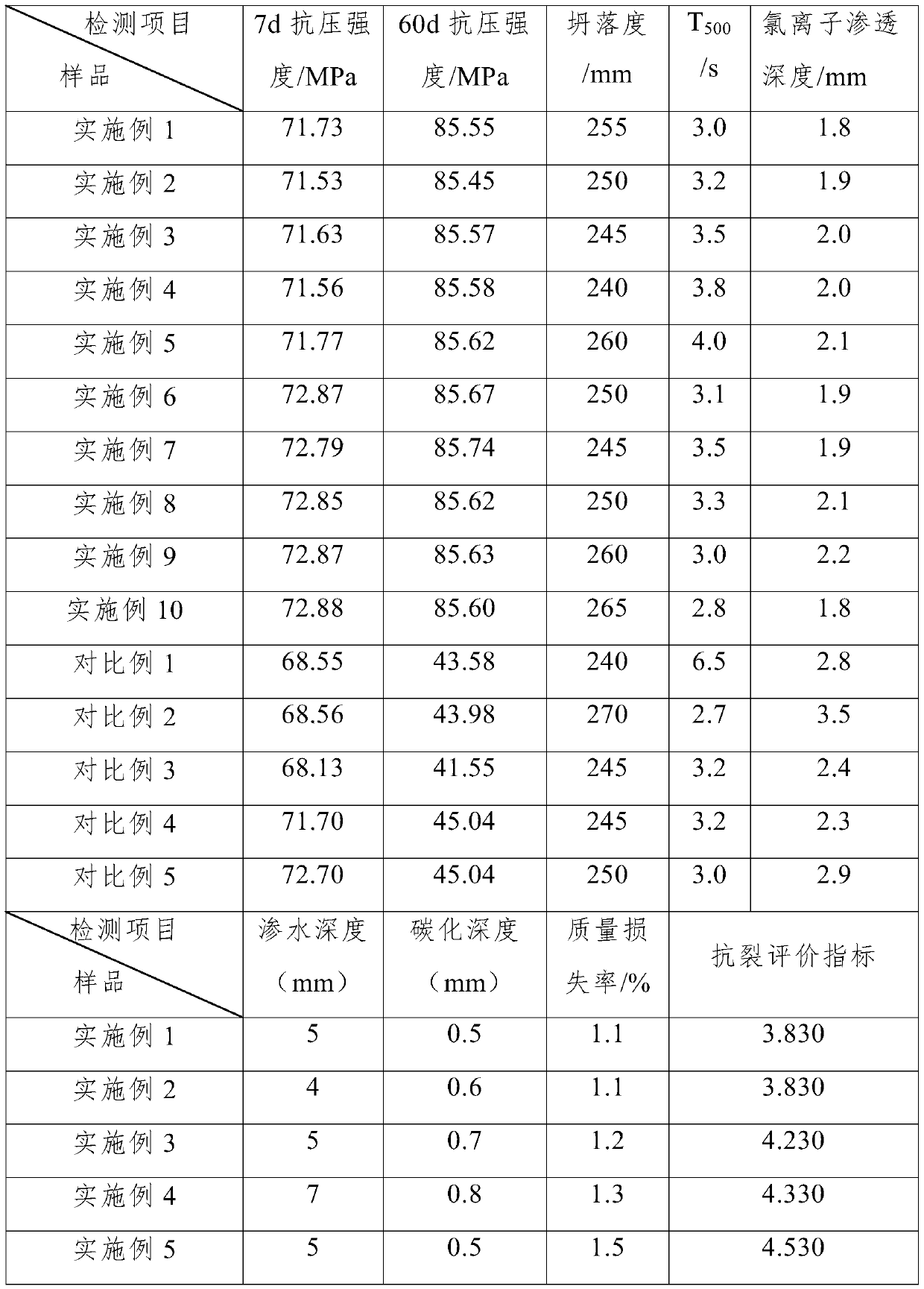

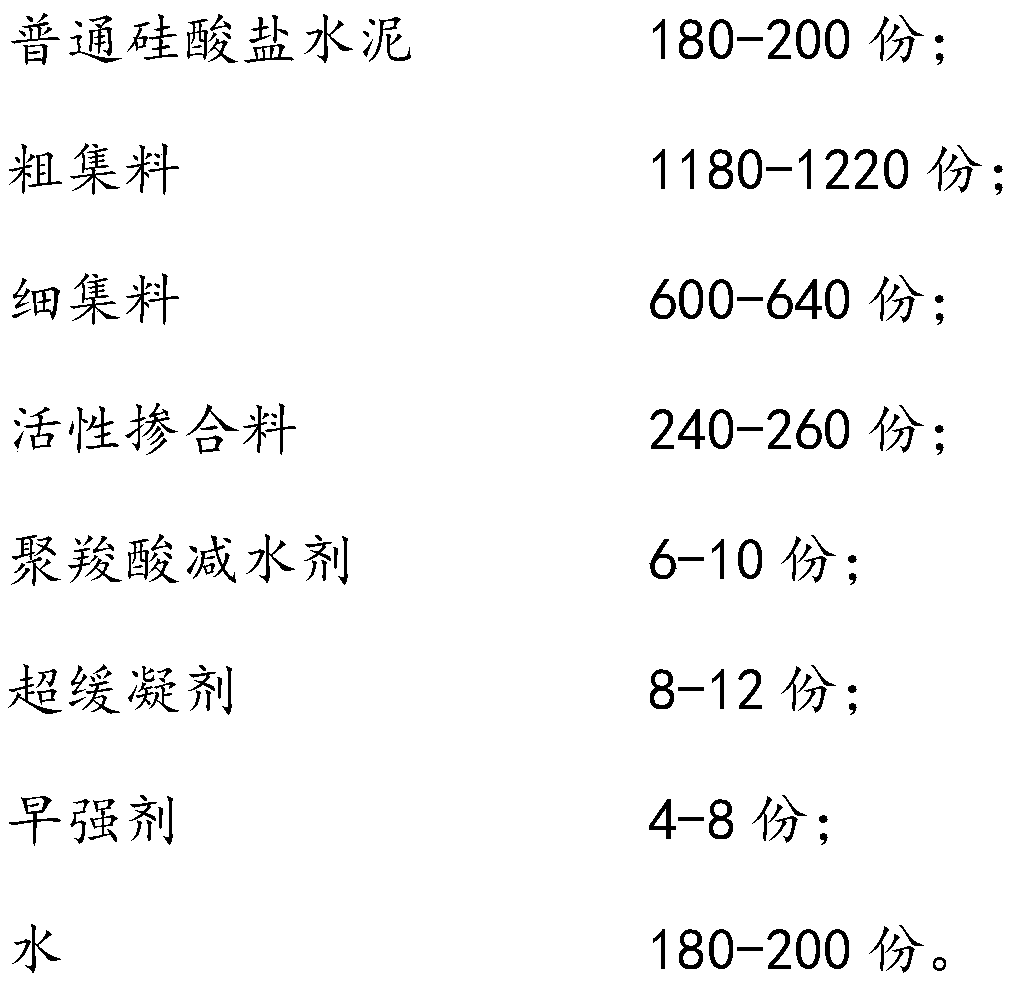

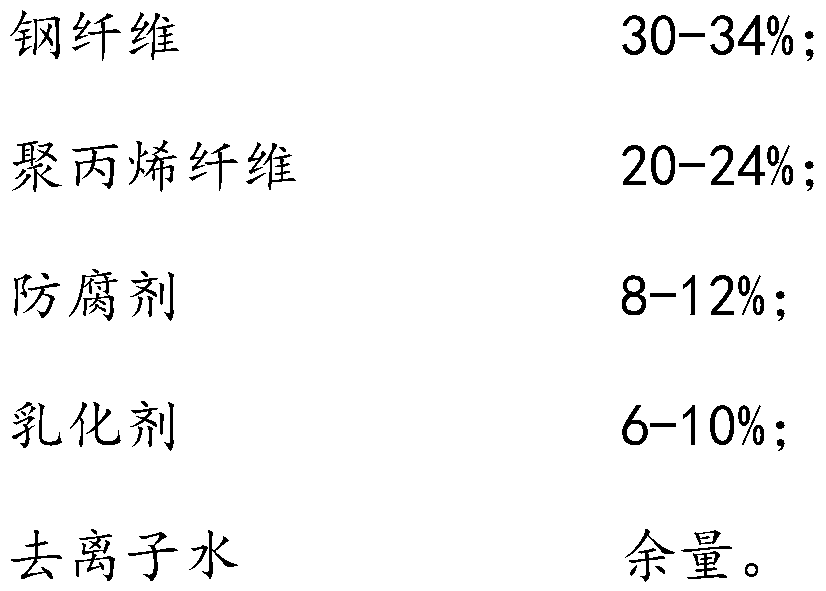

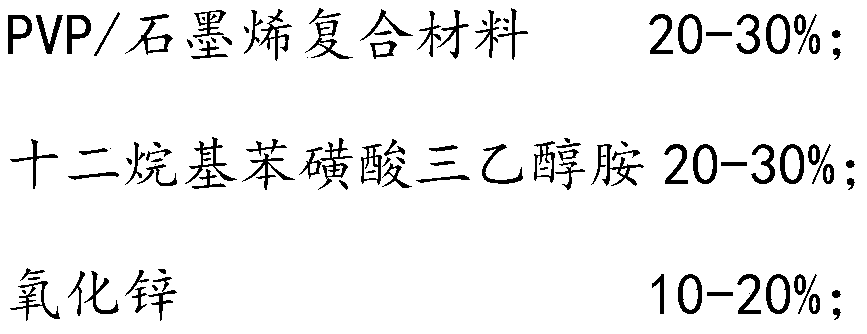

Early strength concrete with super retarding effect, and preparation process thereof

InactiveCN111116135ALarge specific surface areaImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsPortland cementSuperplasticizer

The invention relates to an early strength concrete with a super retarding effect, and a preparation process thereof, and relates to the technical field of concrete preparation. The early strength concrete is prepared from, by weight, 180-200 parts of ordinary Portland cement, 1180-1220 parts of coarse aggregate, 600-640 parts of fine aggregate, 240-260 parts of an active admixture, 6-10 parts ofa polycarboxylate superplasticizer, 8-12 parts of a super retarder, 4-8 parts of an early strength agent and 180-200 parts of water. Addition of the super retarder and the early strength agent prolongs the initial setting time of the concrete and improves the early strength of the concrete.

Owner:杭州三中新型建材科技有限公司

Cement material fly-ash activity excitant

The activity excitant for flyash as cementing material may be used to make the flyash adding amount as high as 70 % without affecting the early strength of cement and concrete. The activity excitant consists of iron powder in 20-50 wt%, calcium oxide in 20-40 wt%, densifying agent 0.05-0.5 wt% and flyash 10-40 wt%, and is added into cement and concrete in the amount of 1-3 % of cementing material. The production process includes air drying and sieving iron powder, milling calcium oxide to obtain calcium oxide powder, and mixing the said material in the said ratio.

Owner:王杰

Technology for producing slag micro powder and application of slag micro powder in cement production

The invention discloses a technology for producing slag micro powder and application of the slag micro powder in cement production. The cement comprises the following raw materials in part by weight: 25 to 30 parts of slag micro powder, 45 to 55 parts of clinker, 3 to 8 parts of desulfurized gypsum, 5 to 10 parts of coal gangue, and 5 to 10 parts of fly ash. The technology is low in investment and quick in response, a large quantity of blast furnace slag can be digested, and the produced cement product has excellent performance. When the slag micro powder is applied to common cement concrete, the consumption of the cement can be reduced, and the cost of the concrete is reduced.

Owner:HENAN HAIHUANG CEMENT

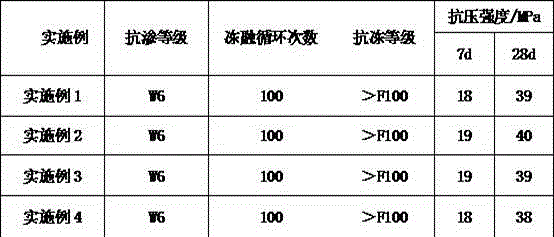

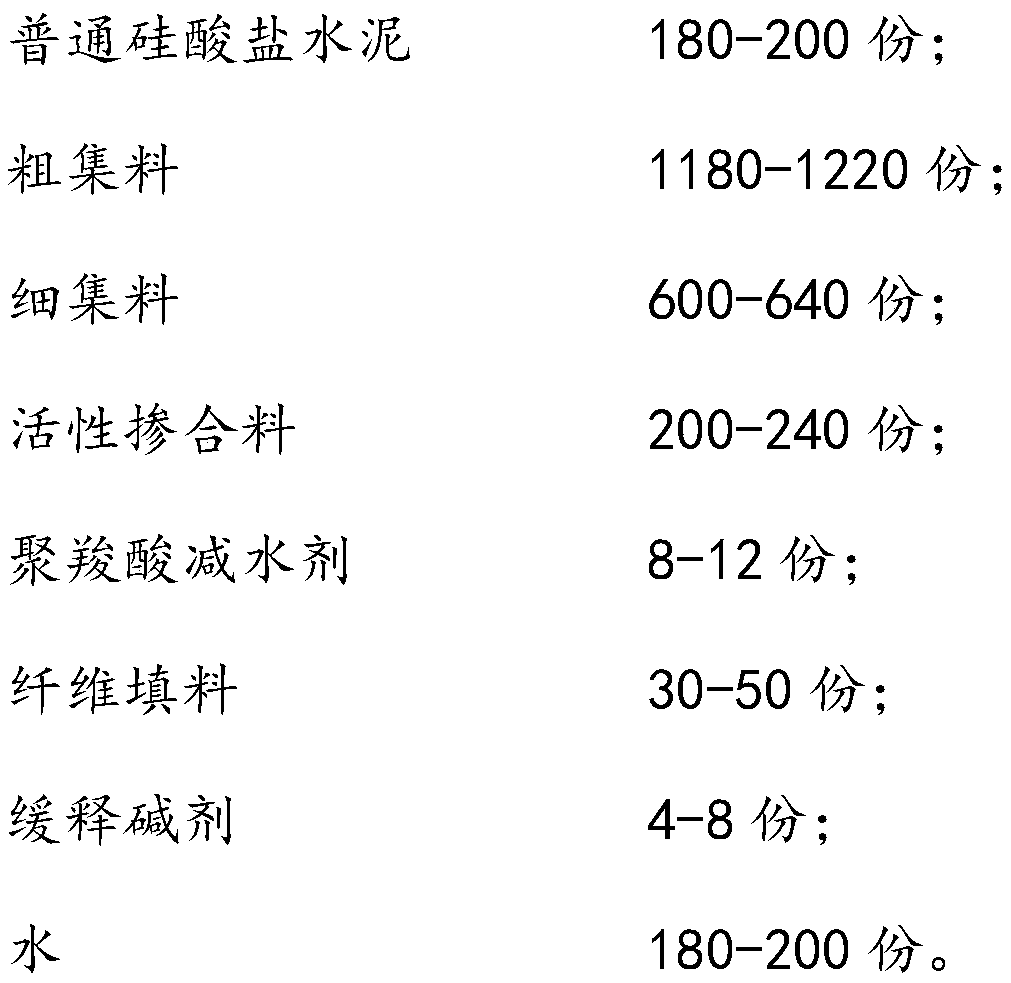

High-strength anti-crack concrete and preparation process thereof

The invention relates to high-strength anti-crack concrete and a preparation process thereof. The high-strength anti-crack concrete is prepared from the following raw materials in parts by weight: 180-200 parts of ordinary Portland cement; 1180-1220 parts of coarse aggregate; 600-640 parts of fine aggregate; 200-240 parts of an active admixture; 8-12 parts of a polycarboxylate superplasticizer; 30-50 parts of fiber filler; 4-8 parts of a slow-release alkaline agent; 180-200 parts of water. The fiber filler is added to toughen the concrete, so that the anti-cracking effect and strength of the concrete are improved.

Owner:杭州三中新型建材科技有限公司

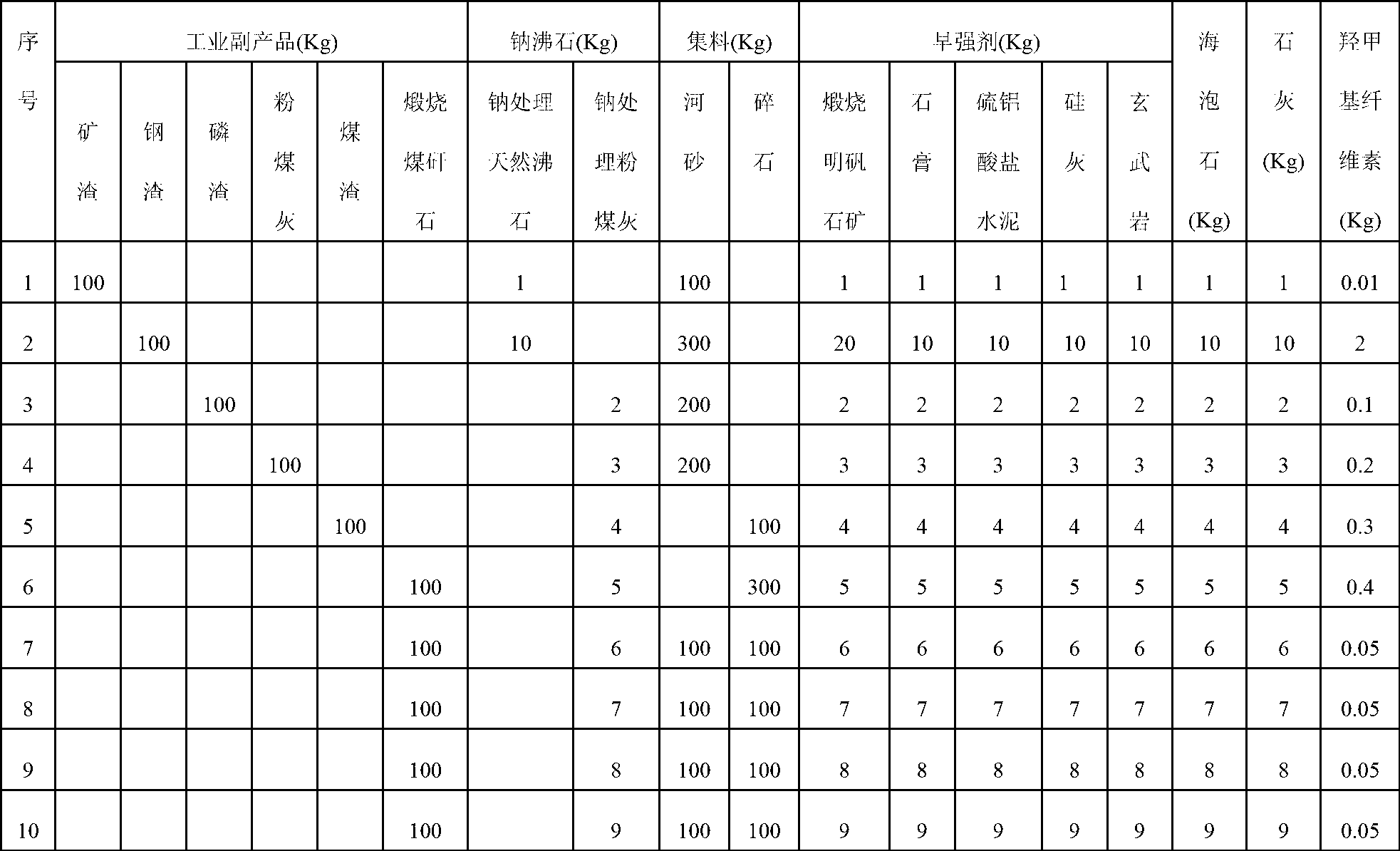

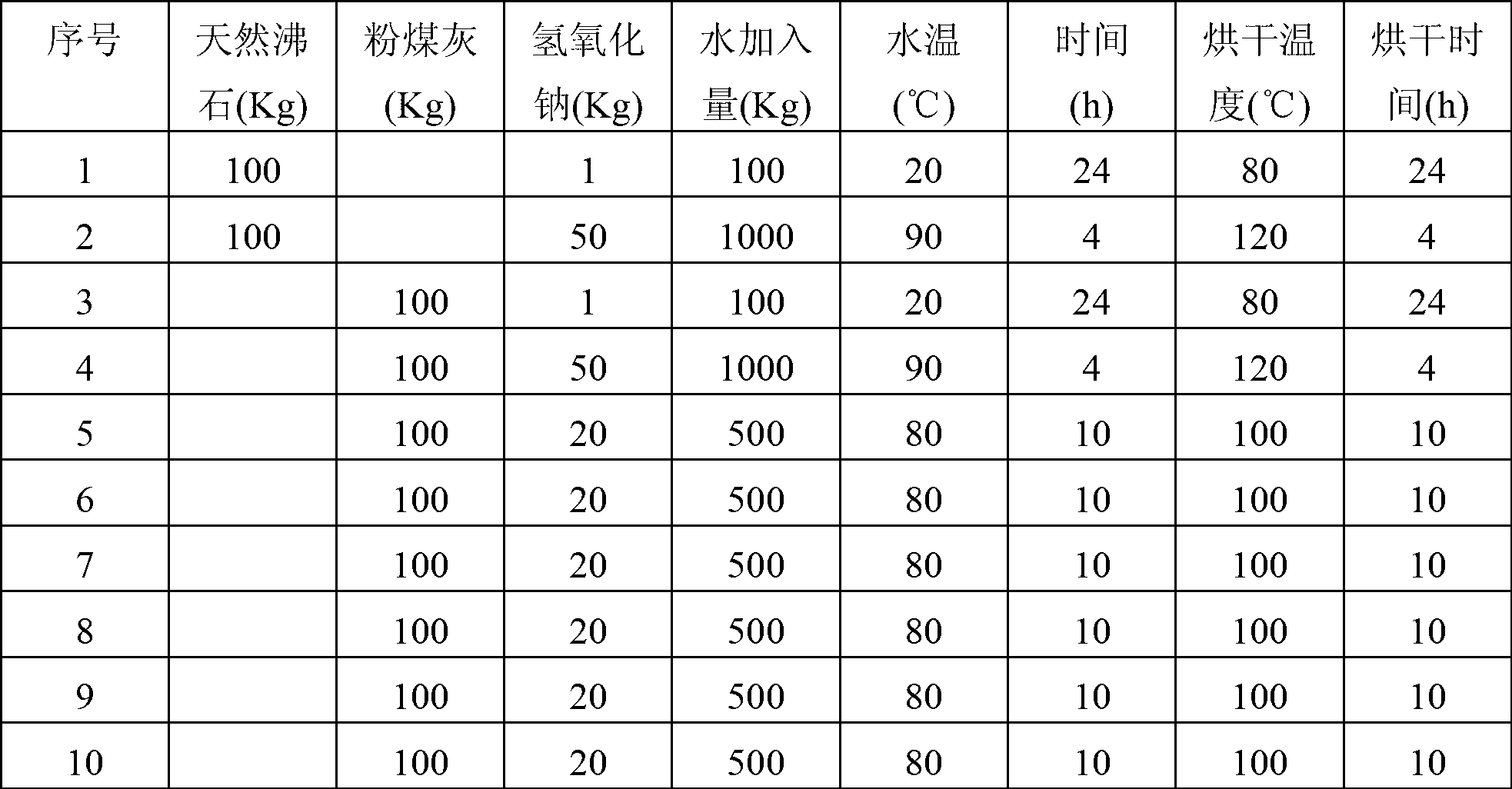

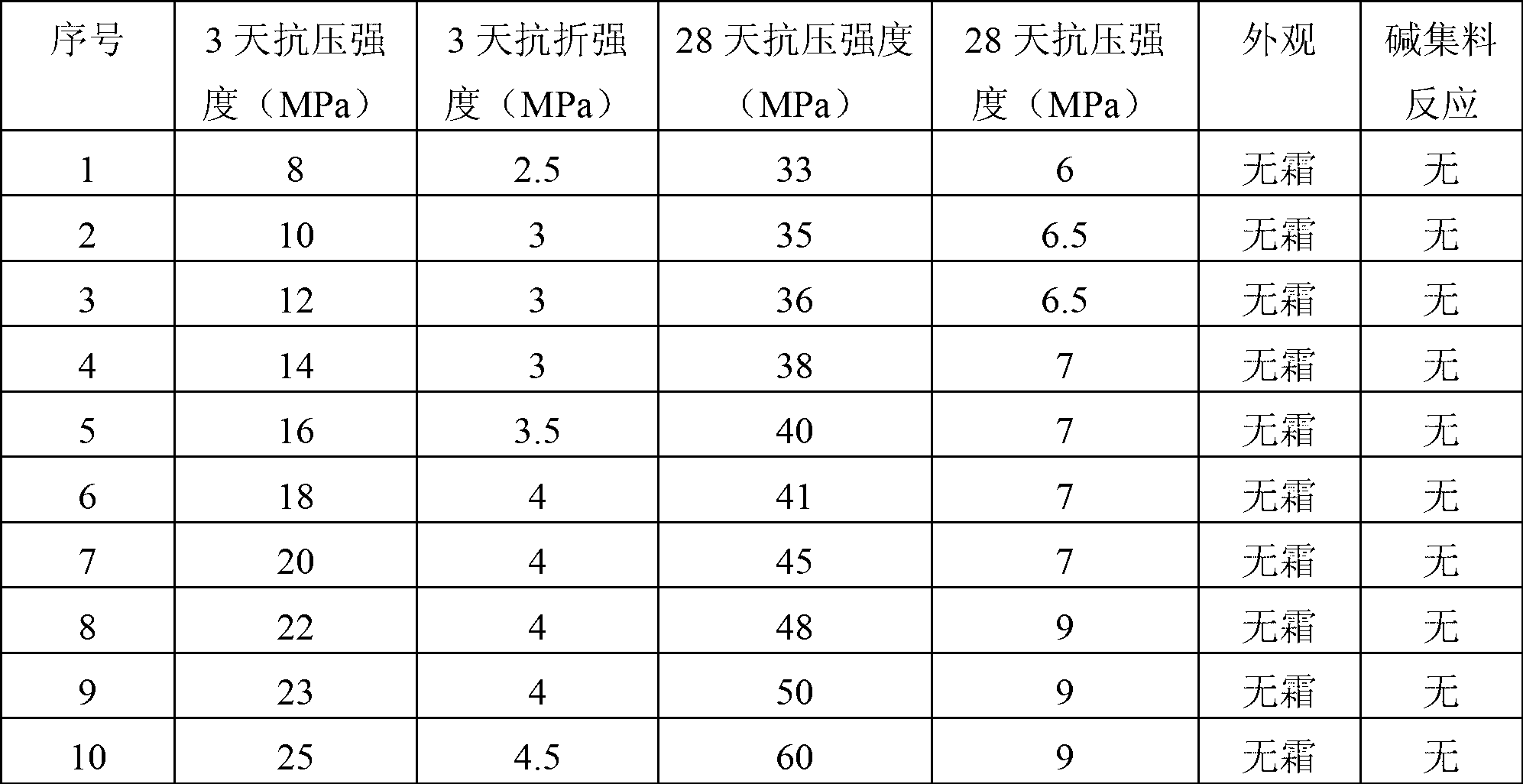

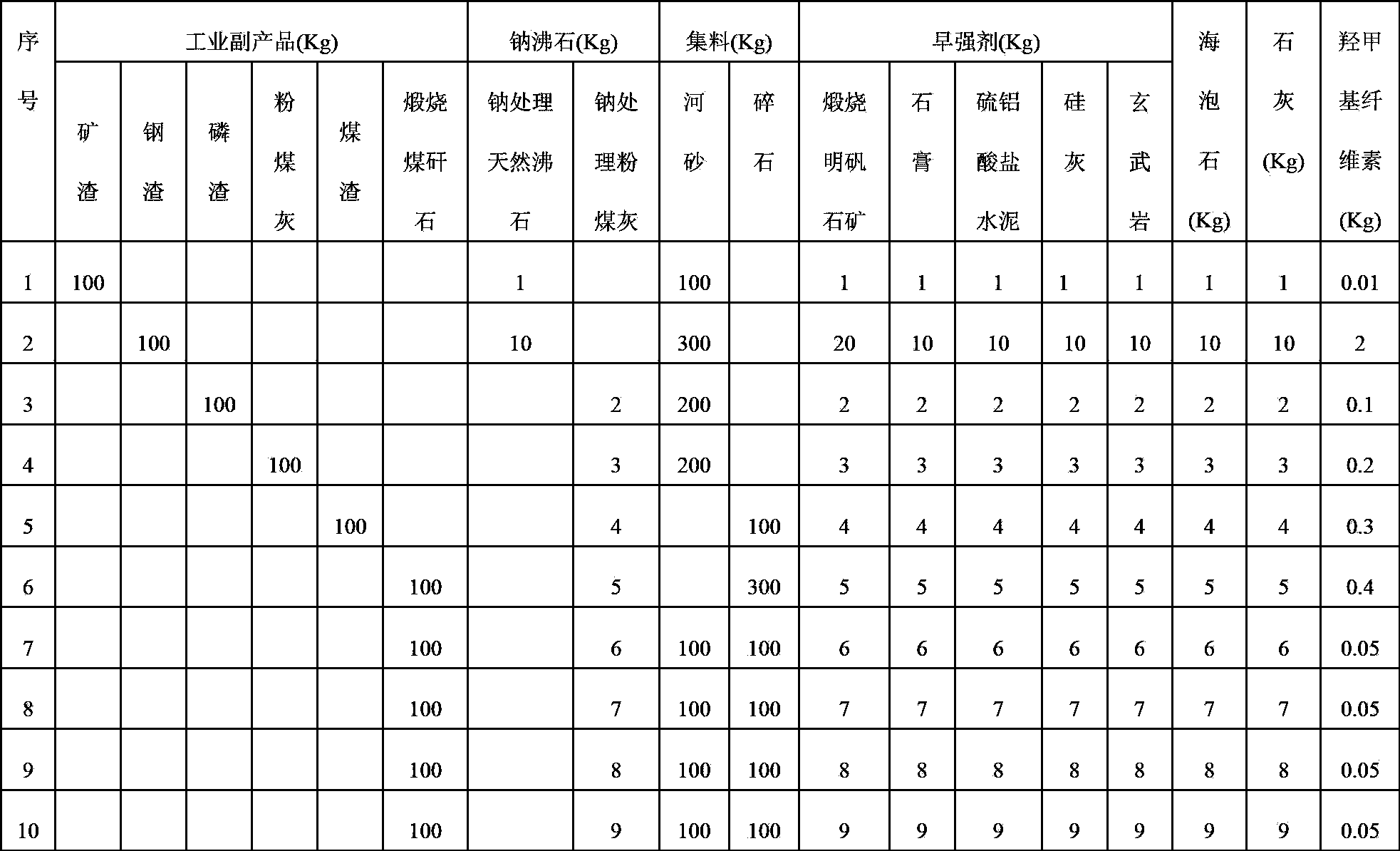

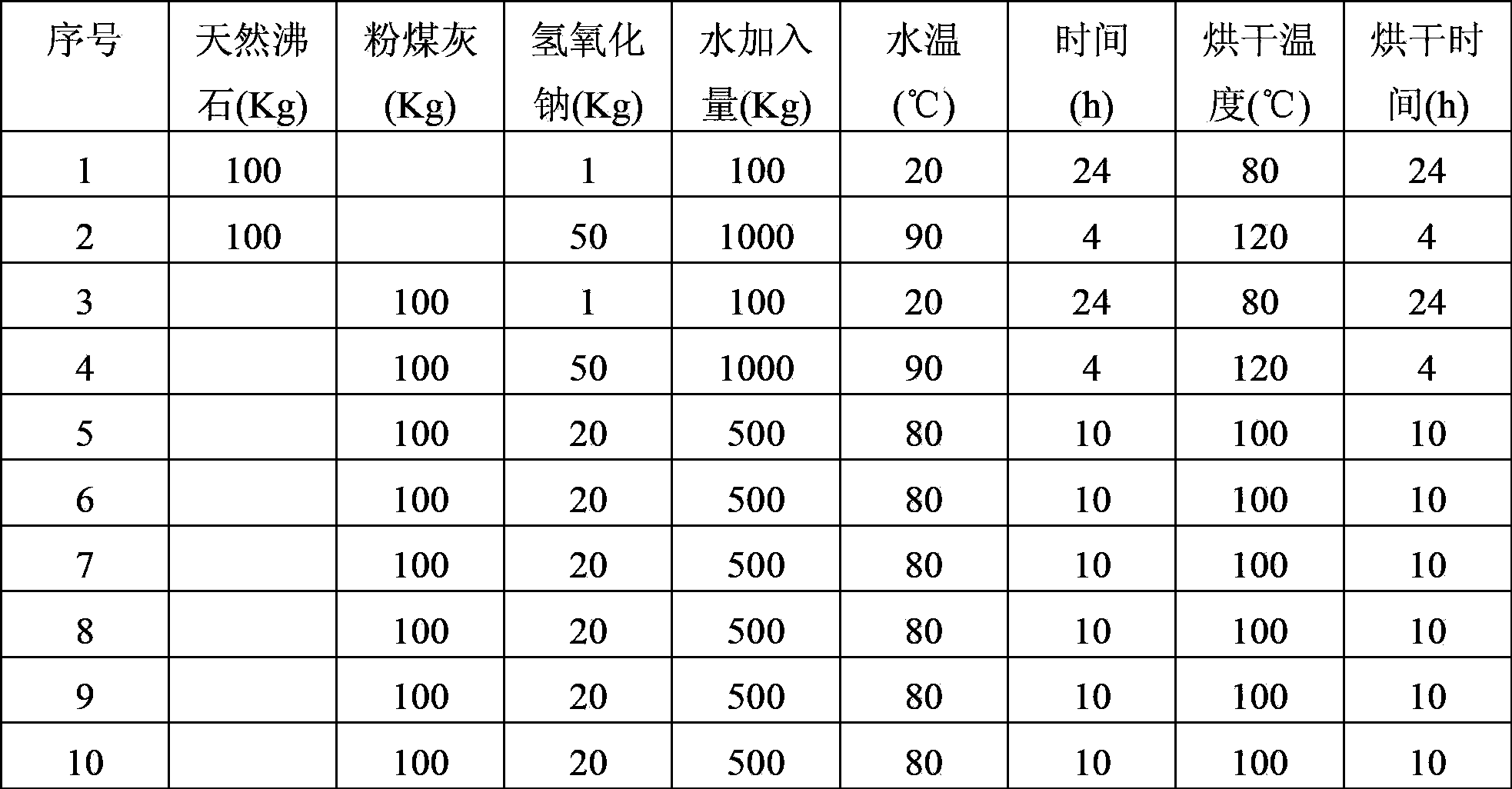

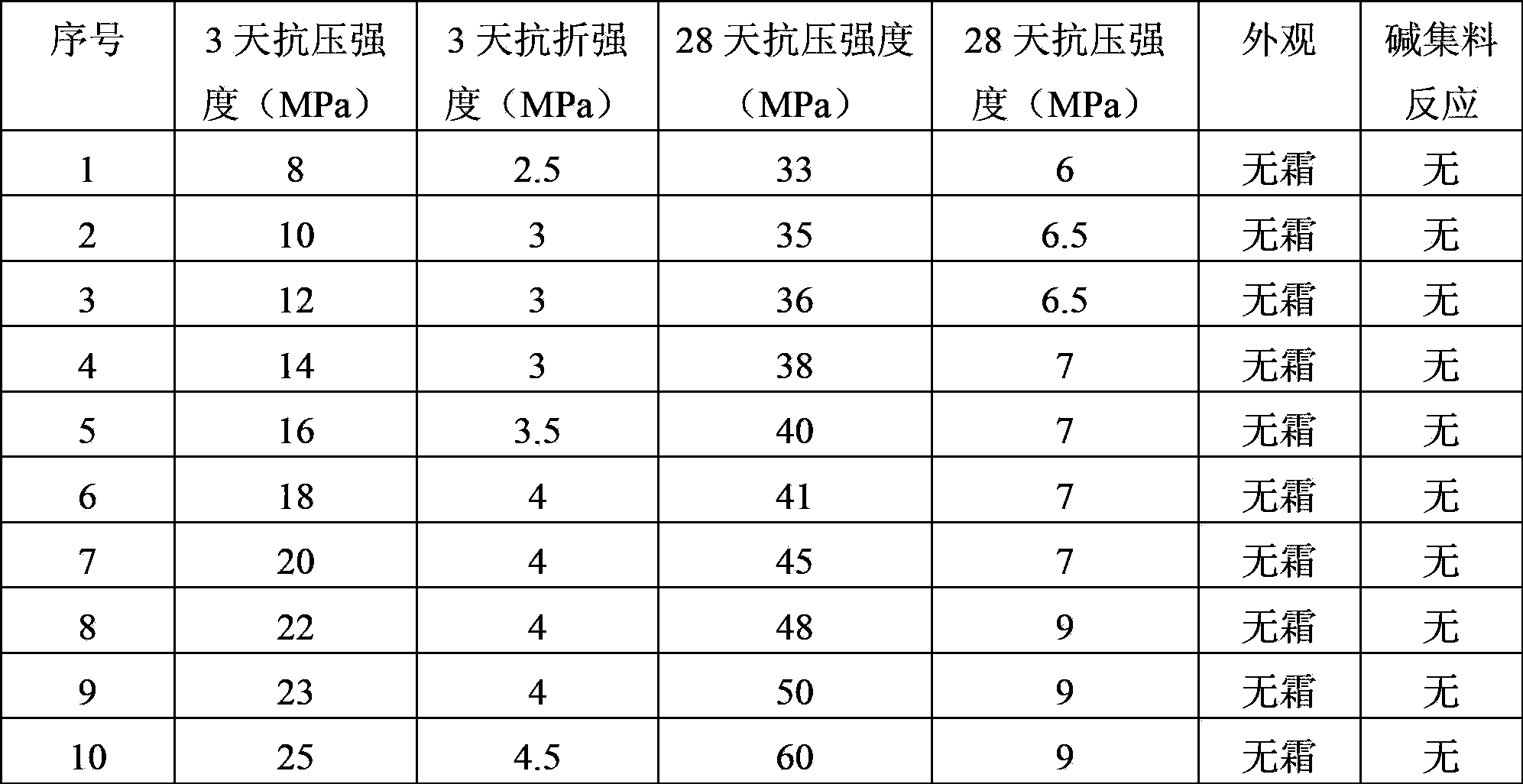

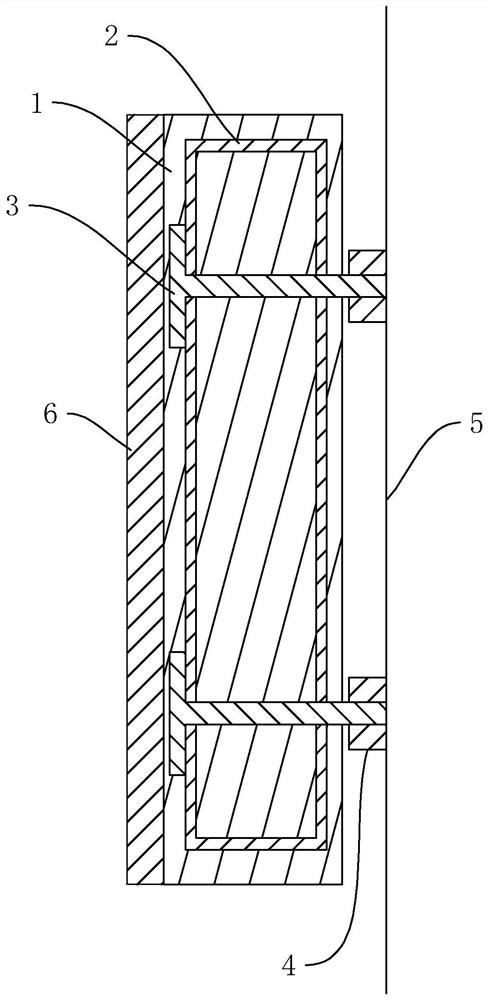

Preparation process of natrolite inorganic artificial stone

InactiveCN103011743AImprove utilization efficiencyPerformance is not affectedNatroliteArtificial stone

The invention discloses a preparation process of a natrolite inorganic artificial stone. The process is characterized by: adding natrolite, aggregate, an early strength agent, sepiolite, lime, and hydroxymethyl cellulose into an industrial by-product, and stirring them evenly to obtain natrolite inorganic artificial stone precursor powder, adding water into the natrolite inorganic artificial stone precursor powder, stirring them uniformly, pouring the mixture into a die, and performing natural curing for 28d, thus obtaining the natrolite inorganic artificial stone, which has the characteristics of high early strength, no frosting, and no alkali-aggregate reaction.

Owner:SHAANXI UNIV OF TECH

Cement admixture for inhibiting alkali-aggregate reaction, and preparation method thereof

The invention discloses a cement admixture for inhibiting alkali-aggregate reaction. The cement admixture comprises the following components in parts by weight: 30-40 parts of waste glass powder, 15-20 parts of furnace slag, 15-20 parts of mineral slag, 3 parts of wool, 0.3-0.5 part of gelatin, 3-5 parts of alkyl benzene sulfonate sulfate and 10-22 parts of lithium sulfate. The method comprises the following steps: cleaning, airing and grinding waste glass bottles, mixing the waste glass bottles with furnace slag and mineral slag, and performing ball milling to obtain a waste mixture; and uniformly mixing the waste mixture with wool, alkylbenzene sulfonate sulfate, gelatin and lithium sulfate to obtain the cement admixture capable of inhibiting the alkali-aggregate reaction. The preparation process is simple, the use is convenient, the inhibition effect on the alkali aggregate reaction is obvious, the green and environment-friendly effects are realized, and the prepared concrete has excellent performance.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

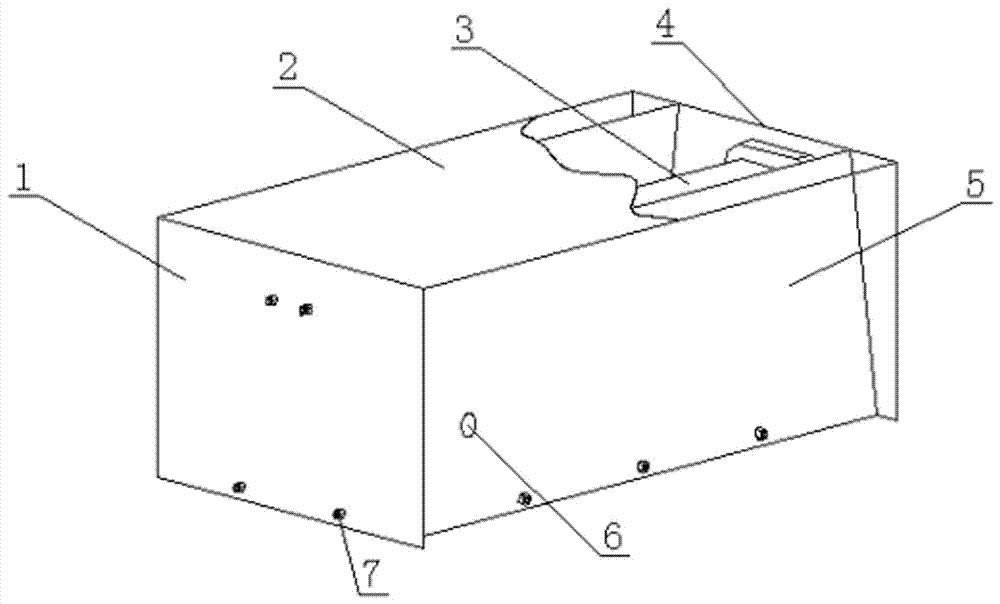

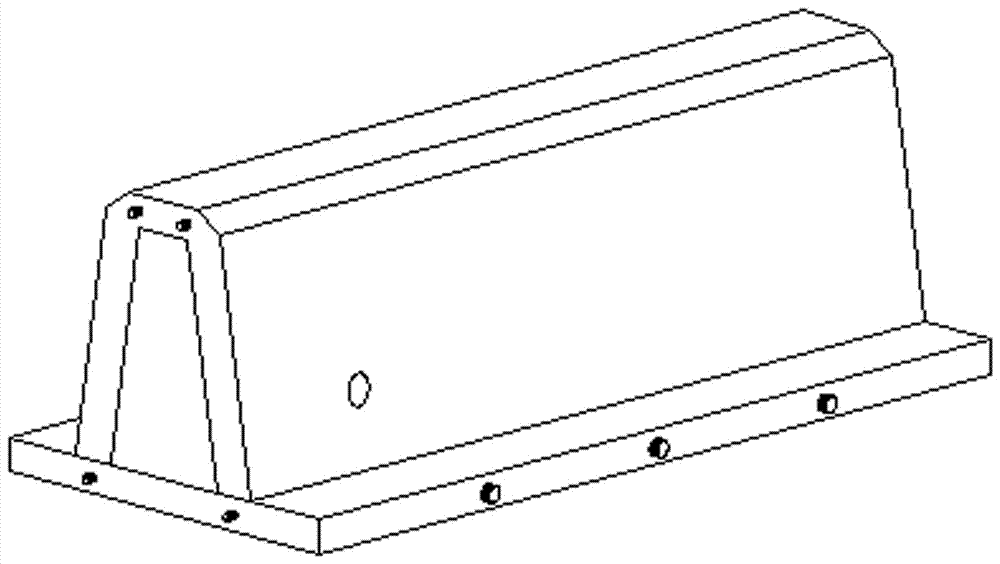

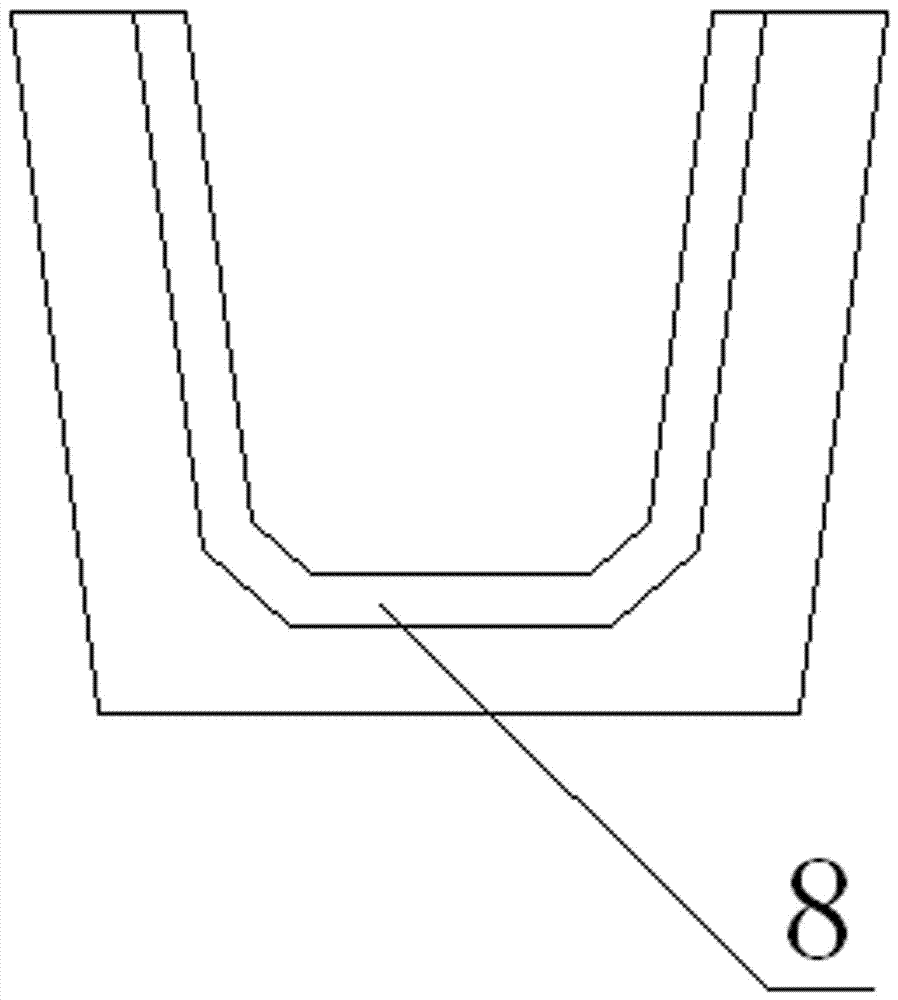

Production method of canal groove side penetration prefabricated part

PendingCN107471404AHighlight substantiveSignificant progressMouldsClimate change adaptationRebarPlastic film

The invention discloses a production method of a canal groove side penetration prefabricated part. The production method comprises the steps that (1) a required mold with the same shape of a canal prefabricated part is manufactured, the mold is placed upside down, and concrete is poured from the bottom; (2) the inner side of the mold is uniformly smeared with demolding oil or a plastic film is put on the inner side of the mold; (3) a manufactured rebar skeleton is arranged in the pouring mold in a sleeving manner, and a concrete protection layer is adjusted; (4) concrete required by pouring is manufactured on site, concrete is poured into the mold, is uniformly flattened to the two ends, and is vibrated for 1 min to 3 min through a vibrator, the upper surface of the mold is finished, and a mold cover plate is closed; and (5) the canal prefabricated parts subjected to concrete pouring are maintained on site, side molds are disassembled after the time.temperature of maintenance is larger than 500 h.DEG C, an inner mold is disassembled after the time.temperature of watering maintenance is larger than 1500 h.DEG C, after mold disassembly, the prefabricated parts are stacked concentratedly, and the prefabricated parts are discharged and utilized after the time.temperature of maintenance is 2000 h.DEG C or above. The production method has the characteristic that construction efficiency can be greatly improved.

Owner:潘春光

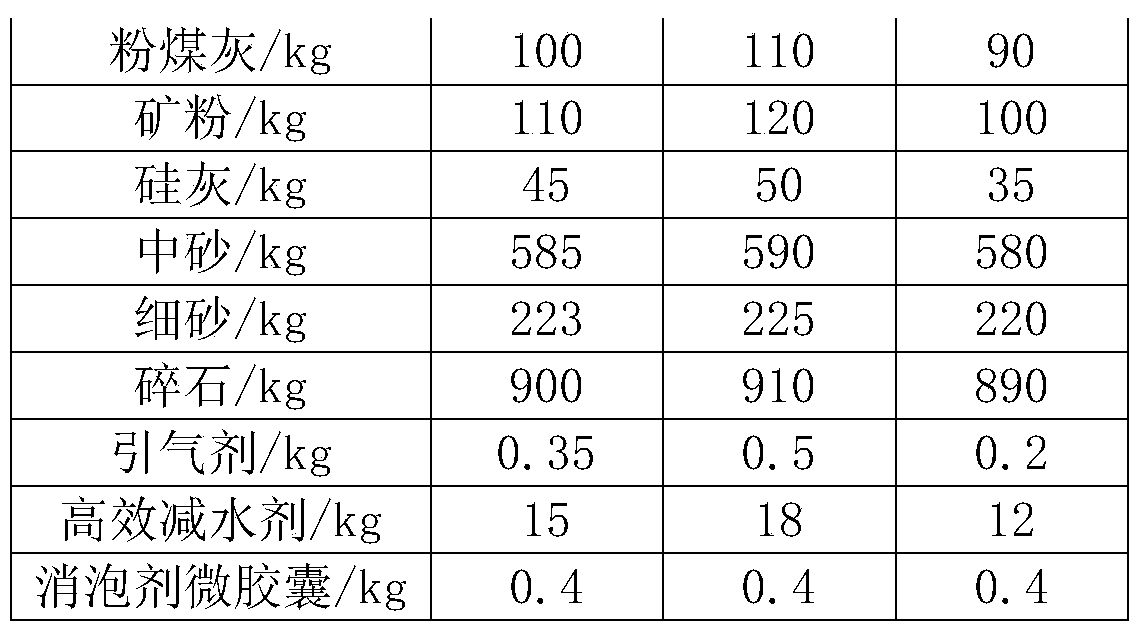

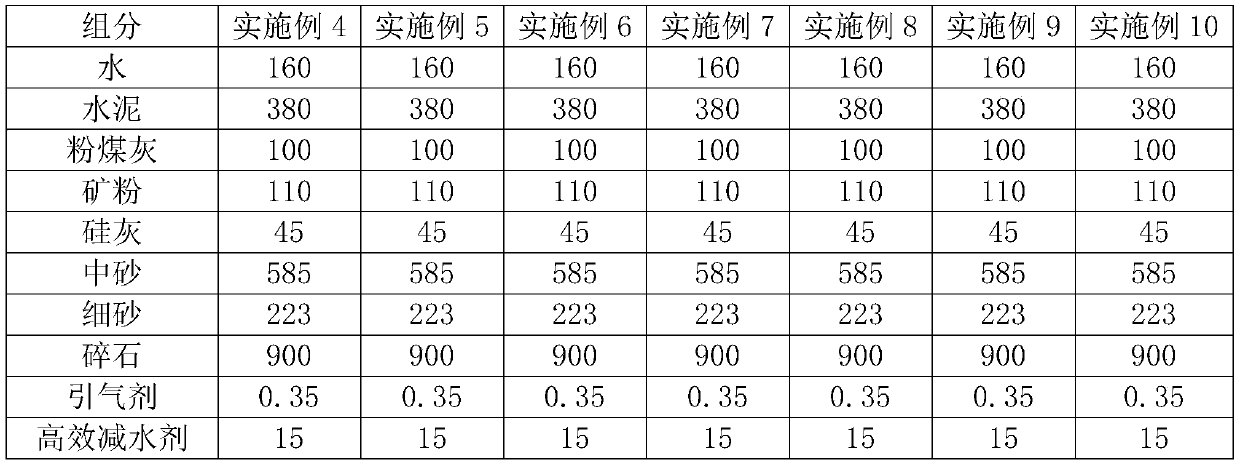

C70 self-compacting concrete and preparation method thereof

ActiveCN111592304AHigh compressive strengthInhibition of alkali-aggregate reactionSilica fumeDefoaming Agents

The invention discloses a C70 self-compacting concrete and a preparation method thereof, and relates to the technical field of concretes. The C70 self-compacting concrete is prepared from, by weight,370 to 390 parts of cement, 800 to 815 parts of sand, 890 to 910 parts of broken stone, 90 to 110 parts of fly ash, 100 to 120 parts of mineral powder, 35 to 50 parts of silicon powder, 12 to 18 partsof a high-efficiency water reducing agent, 0.2 to 0.5 part of an air entraining agent, 0.1 to 0.6 part of a defoaming agent microcapsule and 150 to 165 parts of water. The preparation method comprises the following steps: 1, uniformly stirring and mixing the broken stone, the sand, the cement, the fly ash, the mineral powder and the silicon powder to obtain a first mixture; 2, uniformly mixing water, a superplasticizer and an air entraining agent, adding the obtained mixture into the first mixture, and uniformly stirring to obtain a second mixture; and 3, adding the defoaming agent microcapsule into the second mixture, and stirring for 13-17 S to obtain the C70 self-compacting concrete. The preparation method has the advantages of ensuring the flowability of the concrete and improving thestrength of the concrete, and the preparation method is simple and easy to implement.

Owner:陕西宏基混凝土构件有限责任公司

Production method of water channel groove prefabricated members

PendingCN107443548AImprove construction efficiencyShorten the construction period of the projectMouldsPlastic filmRebar

The invention discloses a production method of water channel groove prefabricated members. The production method comprises the following steps that (1) a pouring die needed by the water channel prefabricated members in same shapes is manufactured, the die is inversely placed, and the bottom of the die is upward; (2) the inner side of the die is evenly coated with mold oil, or a plastic thin film is paved on the inner side of the die; (3) a manufactured reinforcement cage is arranged in the pouring die in a sleeved manner, and a concrete protection layer is adjusted well; (4) concrete needed by pouring is manufactured on site, wherein the concrete is poured in from the middle of the bottom of the die and is evenly spread to the two ends, a tamping device is used for vibrating for 1 minute to 3 minutes, then the upper surface of a groove opening of the die is troweled, and a die cover plate is closed; and (5) the water channel prefabricated members obtained after concrete pouring are maintained on site, during maintenance, edge dies can be detached after the time.temperature is larger than 500 h.DEG C, during watering maintenance, an inner die can be detached after the time.temperature is larger than 1500 h.DEG C, the prefabticated members are stacked in a concentrated manner after the inner die is detached, and during maintenance, factory leaving for use can be achieved after the time.temperature is larger than 2000 h.DEG C. The production method has the beneficial effect that the construction efficiency can be greatly improved.

Owner:潘春光

Manufacturing method for ultrafine powder enhanced composite board

The invention provides a manufacturing method for ultrafine powder enhanced composite board. The manufacturing method is characterized in that a board having the characteristics similar to natural stone materials and elegant texture is prepared by mixing tree waste raw materials such as construction wastes, slag ultrafine powder and fly ash, a proper amount of magnesia, and a trace amount of boric oxide, water and cement. Since the slag ultrafine powder is obtained by grinding blast-furnace slag and has high specific surface area and high fineness, the slag ultrafine powder can be modified to be a potential self-gelating material. In an alkaline condition, activity can be fully played, so that a plurality of performances of concrete and cement are greatly improved and increased. The manufacturing method is an environment-friendly technology, and has wide sources of materials and low cost. The composite board has good use performance, low toxicity, moisture resistance, corrosion resistance and no pollution, integrates the advantages of ceramic and glass ceramics, has the advantages of no radiation, pollution resistance and corrosion resistance, and has relatively good processability.

Owner:SHENZHEN KENAILE NEW MATERIAL

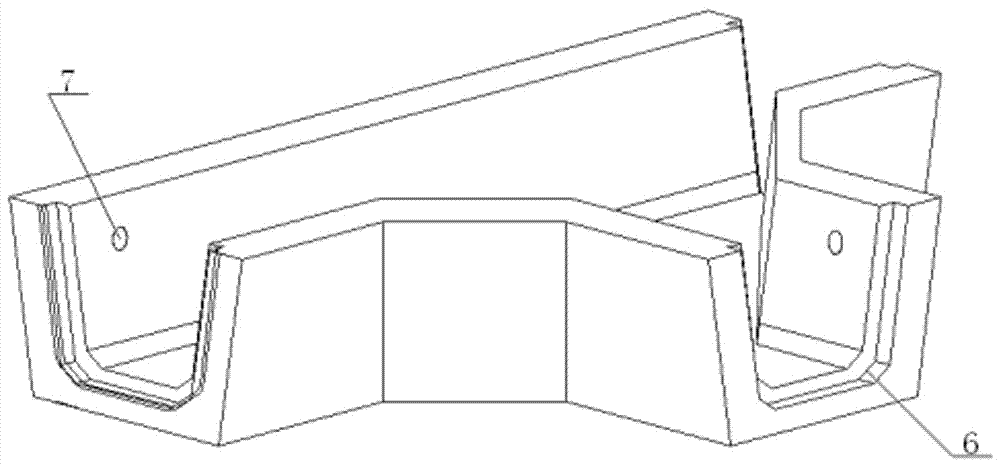

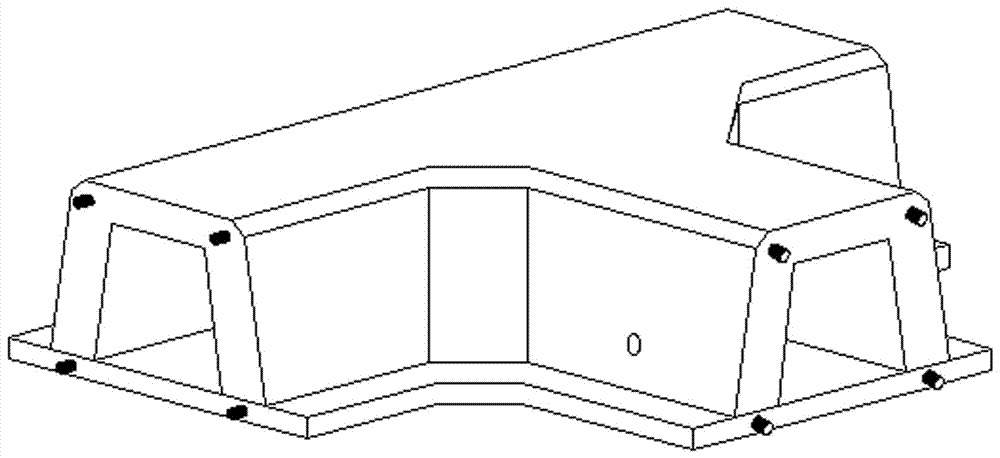

Production method of canal tee prefabricated part

PendingCN107471425AImprove construction efficiencyShorten the construction period of the projectMould fastening meansEngineeringPlastic film

The invention discloses a production method of a canal tee prefabricated part. The production method comprises the steps that (1) a required pouring mold with the corresponding shape of the canal tee prefabricated part is designed; (2) the inner side of the mold is uniformly smeared with demolding oil or a plastic film is put on the inner side of the mold; (3) a mold cavity is fixed, side wall molds sleeve the mold cavity, end cover molds at the two ends are mounted, and a rebar structure which strengthens the canal corner strength is put and is arranged on the mold cavity in a sleeving manner; (4) concrete required by pouring is manufactured on site, concrete is poured into the mold from the middle of the bottom of the mold, vibration is carried out for 1 min to 3 min through a vibrator, the upper surface of the mold is finished, and a mold cover plate is closed; and (5) the canal prefabricated parts subjected to concrete pouring are maintained on site, the side molds of the mold are disassembled after the time.temperature of maintenance is larger than 500 h.DEG C, the mold cavity is disassembled after the time.temperature of watering maintenance is larger than 1500 h.DEG C, after the mold cavity is disassembled, the prefabricated parts are stacked concentratedly, and the prefabricated parts are discharged and utilized after time.temperature of maintenance is larger than 2000 h.DEG C. The production method has the characteristic that construction efficiency can be greatly improved.

Owner:潘春光

Admixture for pump-transporting and lifting poured concrete in arch rib steel pipe

The invention discloses an admixture for pump-transporting and lifting poured concrete in an arch rib steel pipe. The admixture is prepared from the following components in parts by weight: 30-50 parts of potassium sulphoaluminate, 10-30 parts of light calcined magnesia clinker, 10-30 parts of anhydrite, 10-30 parts of bentonite, 1-3 parts of alkylamine, 0.1-1 part of chitosan, 0.2-2 parts of a plastic gas former, 0.2-2 parts of fructo-oligosaccharide and 0.5-2 parts of silica. Compactness and strength of the concrete in the arch rib steel pipe during pouring by pump-transporting and lifting can be improved, the connection closeness between the steel pipe wall and concrete is improved, and cracking of the steel pipe wall and displacement of the steel pipe arch axis are avoided.

Owner:惠州大亚湾市政基础设施有限公司

Anti-cracking concrete and preparation method thereof

ActiveCN112341059AInhibition of alkali-aggregate reactionImprove crack resistanceChemistryEnvironmental geology

The invention relates to the technical field of concrete, in particular to anti-cracking concrete and a preparation method thereof. The anti-cracking concrete is prepared by stirring and mixing the following raw materials in parts by mass: 32-36 kg of cement, 24-28 kg of aggregate, 50-60 kg of water, 10-15 kg of fly ash and 10-15 kg of acrylic acid through. The raw materials can be used for preparing concrete and have the advantage of improving the strength of the concrete. In addition, the preparation method disclosed by the invention has the advantage of improving the permeability resistanceof the concrete.

Owner:唐山友顺混凝土有限公司

Low-alkali-content and crack-resistant water repellent and preparation process therefor

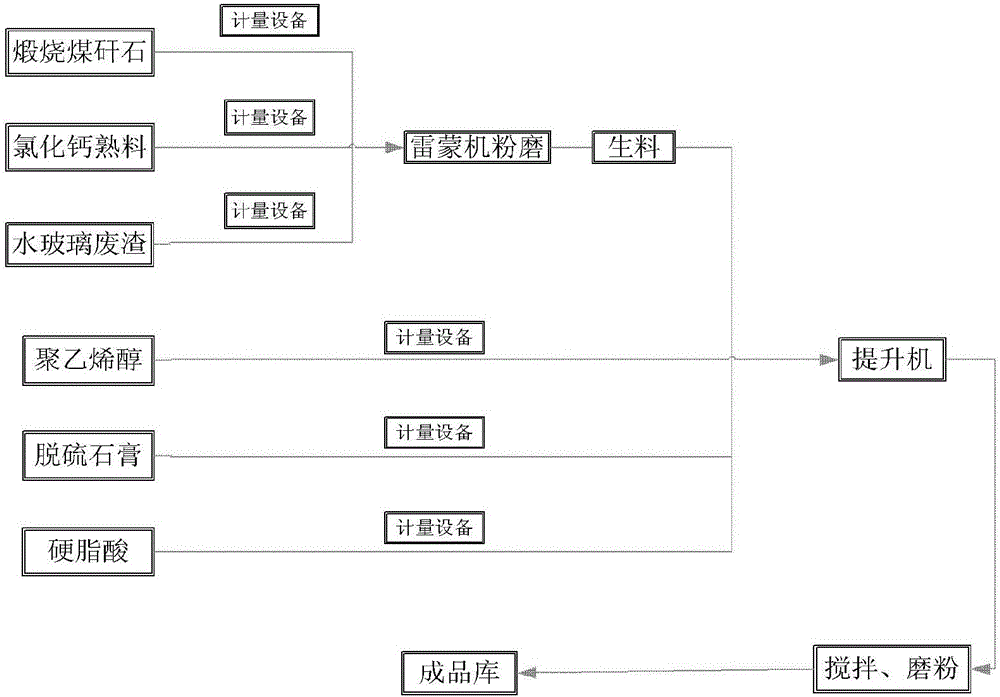

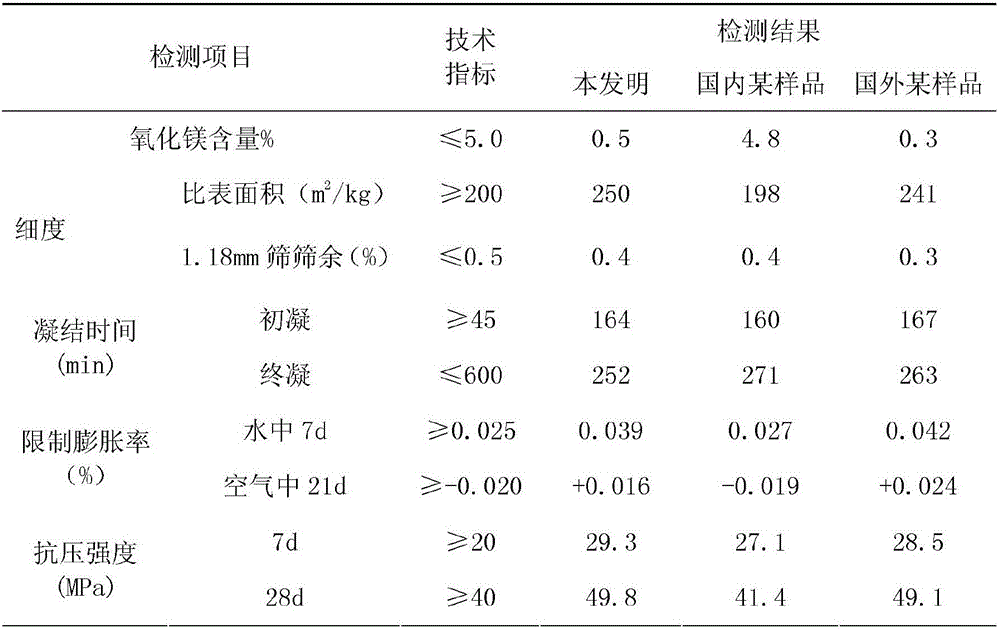

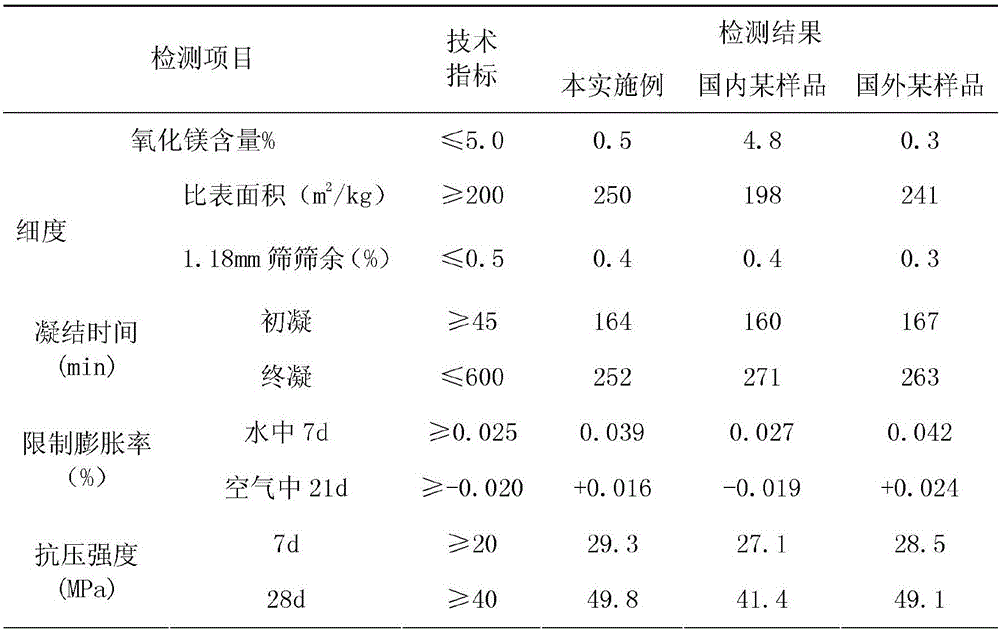

The invention specifically provides a low-alkali-content, environment-friendly and crack-resistant water repellent. The water repellent is prepared from the substances in mass ratio: calcined coal gangue, calcium oxide clinker, water glass waste residue, polyvinyl alcohol, desulfurized gypsum and stearic acid which are in the mass ratio of (40 to 50): (25 to 35): (10 to 15): (1.5 to 4.5): (10 to 15): (0.5 to 1.0). A preparation process for the low-alkali-content and crack-resistant water repellent comprises the steps of carrying out baking, carrying out crushing, carrying out grinding, carrying out subpackaging, carrying out sealing, carrying out quality testing and carrying out warehousing. The low-alkali-content and crack-resistant water repellent is synthesized through proportioning the waste coal gangue, the water glass waste residue and calcareous mineral powder and carrying out grinding. According to the low-alkali-content and crack-resistant water repellent and the preparation process therefor, the coal gangue and the water glass waste residue, which are extremely high in harmfulness and are refractory, are comprehensively utilized, so that the waste is changed into the valuable; and the low-alkali-content and crack-resistant water repellent has a variety of characteristics such as environmental protection and mineral resource reutilization, and good economic and social benefits are achieved.

Owner:沈阳市百德旺建筑材料科技有限公司

Lightweight composite concrete external wall and production method

ActiveCN108975814ALow densityImprove stress resistanceForms/shuttering/falseworksCeramicwarePortland cementCrushed stone

The invention relates to lightweight concrete external walls and discloses a lightweight composite concrete external wall and a production method. The lightweight composite concrete external wall comprises a steel bar bracket, an embedded part fixed in the steel bar bracket, a concrete matrix which is used for filling and cladding the steel bar bracket and a coating layer which is coated on the outer side of the concrete matrix; the lightweight composite concrete external wall is prepared from the following raw materials in parts by mass: 100 parts of portland cement, 100 parts of water, 80 parts of crushed stone aggregate, 8 to 12 parts of strongly acidic action exchange resin, 30 to 40 parts of natural sand and 7 to 10 parts of polytetrafluoroethylene filler. The production method comprises the following steps: pouring lightweight composite concrete obtained by mixing the raw materials into an external wall mold provided with the steel bar bracket and the embedded part; after the lightweight composite concrete is solidified and cured, obtaining the concrete matrix; coating the concrete matrix with a coating layer, so as to obtain the lightweight composite concrete external wall.The carrying load of an external wall fixing bracket is reduced, and the compression resistance and bending strength of the lightweight composite concrete are improved; the possibility that the external wall is fractured or crushed when being impacted is reduced.

Owner:浙江高盛钢结构有限公司

Nanometer composite type expansion anti-cracking waterproofing agent

The invention relates to a nanometer composite type expansion anti-cracking waterproofing agent. The nanometer composite type expansion anti-cracking waterproofing agent comprises the following components and contents: 9.2%-27.5% of calcium sulphoaluminate, 6.8%-11.2% of calcium aluminate, 7.1%-15.4% of calcium hydroxide, 4.8%-13.6% of PSP organic silicon powder, 3.6%-7.5% of sodium silicate, 0.1%-3.2% of ethanediamine sodium phosphate, 0.5%-2.5% of iron powder, 1.0-3.3% of borate, 0.1%-0.5% of manganese dioxide, 0.1%-2.4% of polypropylene fiber, 0.1%-0.8% of disodium ethylene diamine tetraacetate, 1.8%-4.3% of sodium tripolyphosphate, 15.2%-22.5% of pulverized fuel ash, 5.3%-11.6% of aminophenoxy naphthalene sulfonate and 5.1-8.5% of FP nanometer polymer. The expansion generated by the nanometer composite type expansion anti-cracking waterproofing agent and the contraction of concrete synchronously develop; and fillers generated by the nanometer composite type expansion anti-crackingwaterproofing agent can be used for effectively filling apertures of the concrete at different periods and different quantity values and under different action mechanisms of different crystal minerals. When the nanometer composite type expansion anti-cracking waterproofing agent is restrained by steel bars and adjacent positions, the 0.38MPa-0.8MPa prestressing stress can be generated; and different expansion mineral phases are generated at different ages of the concrete, thereby very effectively controlling the generation and development of non-structural cracks such as the early-stage plastic shrinkage and air shrinkage of the concrete and the cement plaster.

Owner:QINGDAO BRANCH TIANJIN TAIKE BUILDING TECHCO

Additive for inhibiting efflorescence of non-metallic material products, its production method and use

The invention discloses an additive capable of inhibiting the whiskering of a non-metal material product and a preparation method and application thereof, and belongs to the technical field of inorganic non-metal materials. Because the additive contains industrial salt and is prepared through blending, drying, grinding, inspection and packaging, the additive can be used for inhibiting the phenomena of alkali-aggregate reaction of a concrete product and whiskering of a gypsum product. The additive disclosed by the invention is extensive in raw material, simple in preparation method, low in cost and extensively used for an overpass, a road, a building or a gypsum product industry, and can be used for greatly prolonging the service life of the concrete product, enhancing the radiation resistance and prolonging the coagulation time when used for the concrete product, thereby being convenient for modern concrete construction; in addition, the additive disclosed by the invention can be used for greatly enhancing the whiteness and strength of the gypsum product when used for the gypsum product.

Owner:深圳市凌烁家具工艺有限公司

Highly-effective anti-cracking waterproofing agent and production method thereof

ActiveCN100506736CTemperature drop and shrinkage are beneficialImprove work performanceCrack resistanceSuperplasticizer

The invention discloses a anticracking water proofer, which comprises the following steps: 1) allocating component and mass content as 60%-76% activatable zeolitic powder, 5%-15% silica ash, 3%-8% calcium oxide, 3%-8% magnesium oxide, 3%-8% anhydrous sodium sulfate, 2%-6% cement group osmosis crystallization masterbatch, 1. 0%-3. 0% silane coupling agent, 2%-4% high-strength high elasticity modulus polyethelene alcohol fibre and 5%-8% naphthalene system highly effective dehydragent; mixing the activatable zeolitic powder and the silane coupling agent; proceeding modified reaction; getting modified powder; 2) cooling the modified powder; adding into the silica ash, calcium oxide, magnesium oxide, anhydrous sodium sulfate, cement group osmosis crystallization masterbatch and naphthalene system highly effective dehydragent; mixing; getting mixture; 3) putting the mixture into zero gravity agitator; adding into high-strength high elasticity modulus polyethelene alcohol fibre; stirring to non-cluster. This invention possesses good dewatering property and high crack resistance.

Owner:俞锡贤

Additive capable of inhibiting whiskering of non-metal material product and preparation method and application thereof

ActiveCN104446083AExtended service lifeElimination of ubiquitous alkaloidsMetallic materialsProcess engineering

The invention discloses an additive capable of inhibiting the whiskering of a non-metal material product and a preparation method and application thereof, and belongs to the technical field of inorganic non-metal materials. Because the additive contains industrial salt and is prepared through blending, drying, grinding, inspection and packaging, the additive can be used for inhibiting the phenomena of alkali-aggregate reaction of a concrete product and whiskering of a gypsum product. The additive disclosed by the invention is extensive in raw material, simple in preparation method, low in cost and extensively used for an overpass, a road, a building or a gypsum product industry, and can be used for greatly prolonging the service life of the concrete product, enhancing the radiation resistance and prolonging the coagulation time when used for the concrete product, thereby being convenient for modern concrete construction; in addition, the additive disclosed by the invention can be used for greatly enhancing the whiteness and strength of the gypsum product when used for the gypsum product.

Owner:深圳市凌烁家具工艺有限公司

Preparation process of natrolite inorganic artificial stone

InactiveCN103011743BImprove utilization efficiencyPerformance is not affectedNatroliteArtificial stone

Owner:SHAANXI UNIV OF TECH

A kind of lightweight composite concrete exterior wall and its production method

ActiveCN108975814BInhibition of agglomerationHigh bonding strengthForms/shuttering/falseworksCeramicwareAggregate (composite)Portland cement

The invention relates to lightweight concrete external walls and discloses a lightweight composite concrete external wall and a production method. The lightweight composite concrete external wall comprises a steel bar bracket, an embedded part fixed in the steel bar bracket, a concrete matrix which is used for filling and cladding the steel bar bracket and a coating layer which is coated on the outer side of the concrete matrix; the lightweight composite concrete external wall is prepared from the following raw materials in parts by mass: 100 parts of portland cement, 100 parts of water, 80 parts of crushed stone aggregate, 8 to 12 parts of strongly acidic action exchange resin, 30 to 40 parts of natural sand and 7 to 10 parts of polytetrafluoroethylene filler. The production method comprises the following steps: pouring lightweight composite concrete obtained by mixing the raw materials into an external wall mold provided with the steel bar bracket and the embedded part; after the lightweight composite concrete is solidified and cured, obtaining the concrete matrix; coating the concrete matrix with a coating layer, so as to obtain the lightweight composite concrete external wall.The carrying load of an external wall fixing bracket is reduced, and the compression resistance and bending strength of the lightweight composite concrete are improved; the possibility that the external wall is fractured or crushed when being impacted is reduced.

Owner:浙江高盛钢结构有限公司

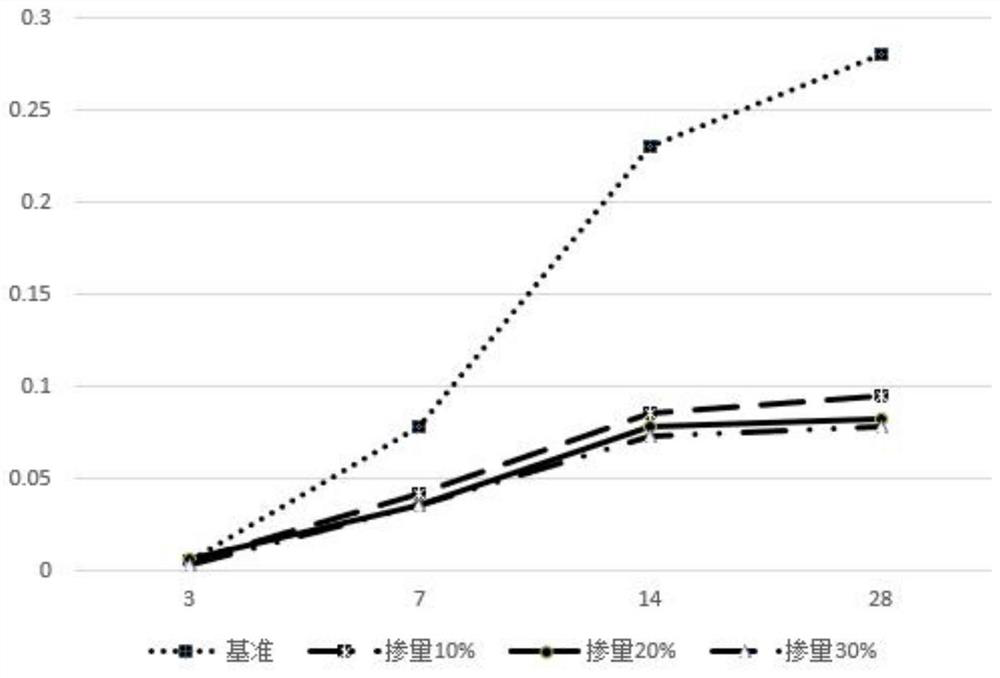

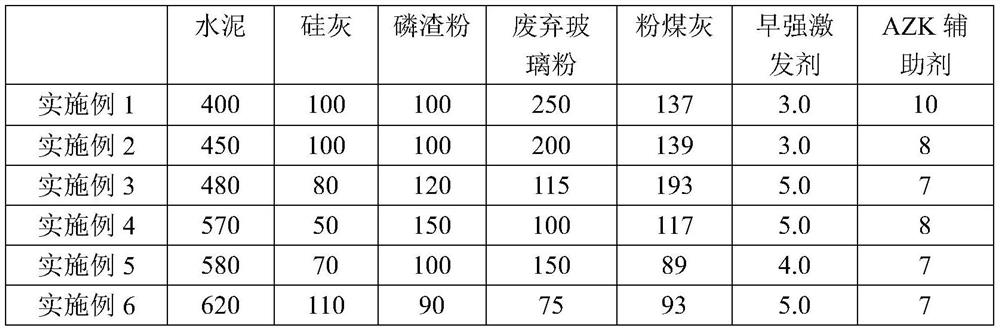

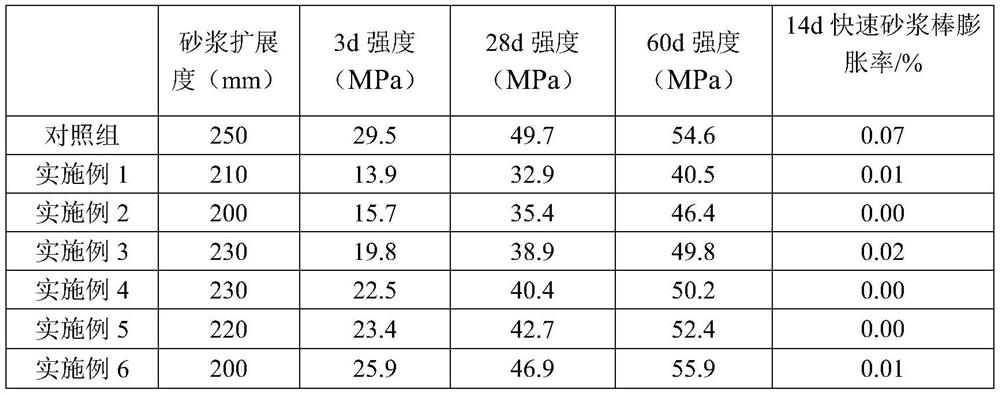

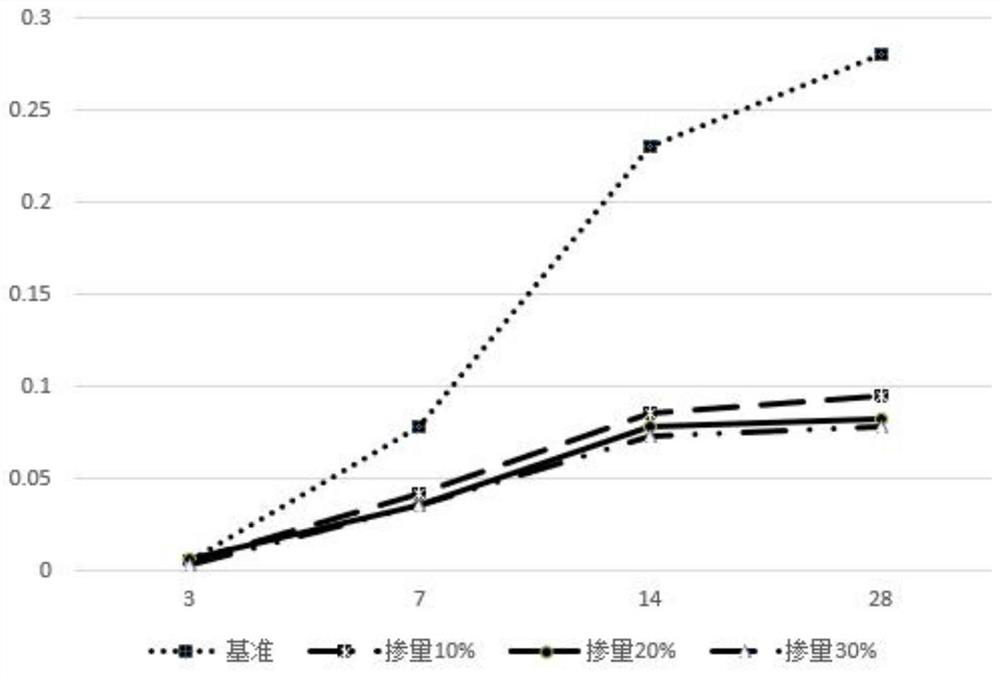

Cementing material for inhibiting metamorphic rock alkali aggregate reaction and preparation method thereof

The invention relates to a cementing material for inhibiting metamorphic rock alkali aggregate reaction and a preparation method thereof. The cementing material comprises the following components: cement, silica fume, phosphorus slag powder, waste glass powder, fly ash, an early strength activator and an AZK auxiliary agent according to a mass ratio of (400-620): (50-100): (90-105): (75-250): (89-193): (3.0-5.0): (7.0-10.0). The cementing material for inhibiting metamorphic rock alkali aggregate reaction is developed through a creative synergistic effect of a cementing material compounding technology, a cementing material secondary hydration process control technology and a cementing material excitation technology, the performance of inhibiting metamorphic rock alkali aggregate reaction is excellent, the comprehensive utilization of industrial wastes such as silica fume, fly ash, phosphorus slag powder and waste glass powder is further enhanced, and the cementing material is green and environment-friendly.

Owner:贵阳中建西部建设有限公司 +1

Fine improved wood

InactiveCN101570409AModerate alkali aggregate reactionAlkali-aggregate reaction is easySolid waste managementChipsealRebar

A fine improved wood belongs to the field of building materials. The constituents and weight percentages of the wood are as follows: 10-40% of natural sand, 10-40% of machine processed sand and 20-60% of industrial residues. The wood also comprises gravels with content not more than 54% and 0.003-0.5% of alkali organic compound. The fine improved wood can be obtained by evenly mixing the above constituents in a mixer. The fine improved wood can effectively inhibit alkaline-aggregate reaction of concrete, improve the strength of concrete, have excellent effects on passivation, anti-corrosion and protection of reinforcing bars and prolong lives of buildings. The fine improved wood is mainly used as mortar materials, foundation improve wood, light-weight concrete aggregate, concrete precast elements and sewer fillers, and can also be used as vegetation soil improved wood.

Owner:福州海旺建材有限公司

Cement admixture for inhibiting alkali-aggregate reaction and preparation method thereof

The invention discloses a cement admixture for inhibiting alkali-aggregate reaction. The composition is as follows in parts by weight: 30-40 parts of waste glass powder, 15-20 parts of slag, 15-20 parts of slag, 3 parts of wool, 0.3-0.5 parts of gelatin, 3-5 parts of alkylbenzenesulfonate, 10-22 parts of lithium sulfate. After cleaning, airing and grinding waste glass bottles, mix them with slag and slag, and get the waste mixture through ball milling; mix the waste mixture with wool, alkylbenzene sulfonate, gelatin, and lithium sulfate evenly to obtain the inhibition Cement admixture for alkali-aggregate reaction. The invention has a simple preparation process, is convenient to use, has an obvious inhibitory effect on alkali aggregate reaction, is environmentally friendly, and the prepared concrete has excellent performance.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com