Preparation process of natrolite inorganic artificial stone

A preparation process and a technology for sodium zeolite, applied in the field of artificial stone, can solve the problems of affecting alkali on the excitation of by-products of cement stone industry, affecting the later strength of cement stone, etc., and achieve the effects of low cost, high early strength, and avoiding bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific examples.

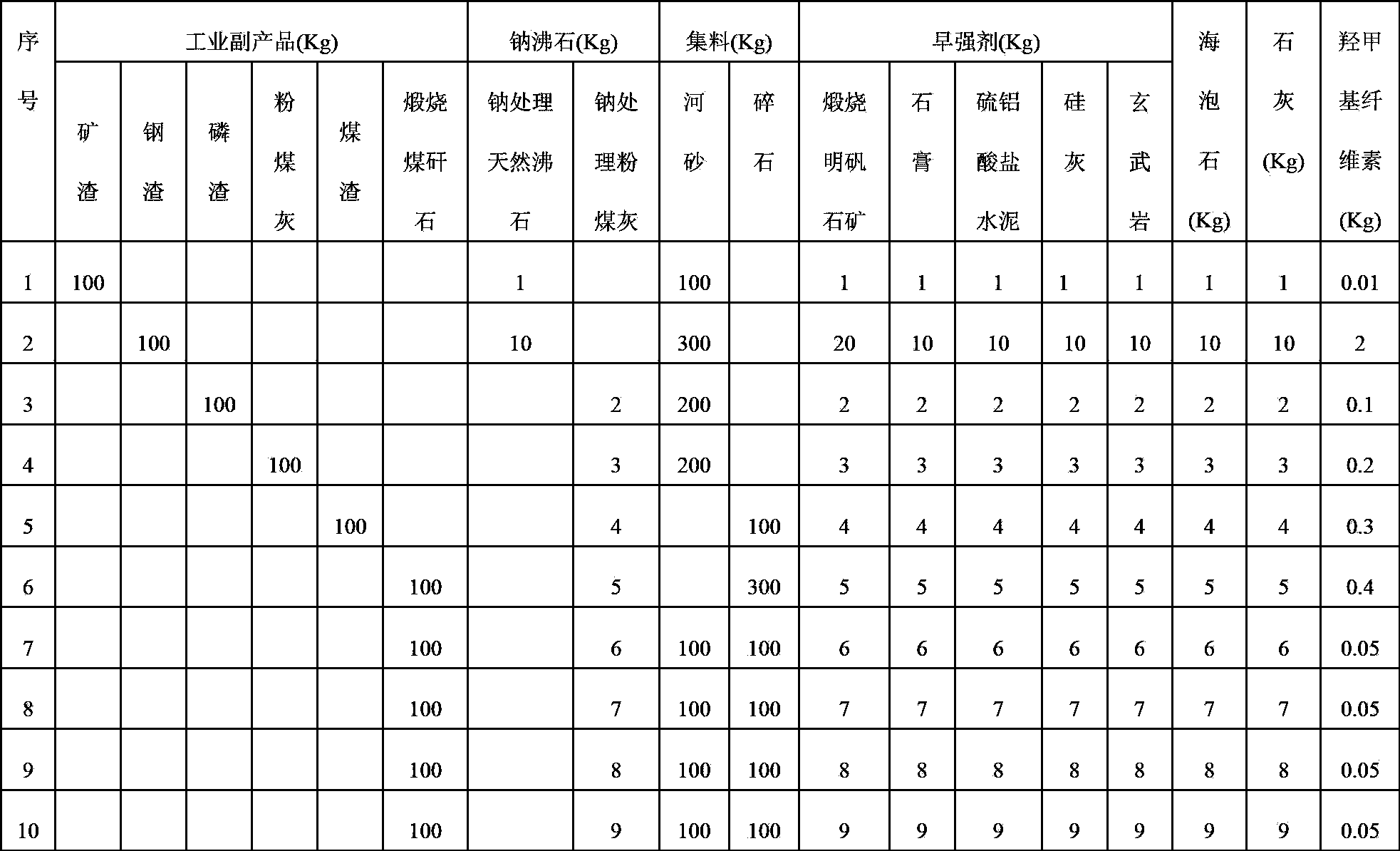

[0031] Table 1 lists the formulation compositions of 10 examples numbered 1-10. According to the different examples in Table 1, the amount of industrial by-products, sodium zeolite, aggregate, early strength agent, sepiolite, lime, and hydroxymethyl cellulose was determined to prepare inorganic artificial stone precursor powder.

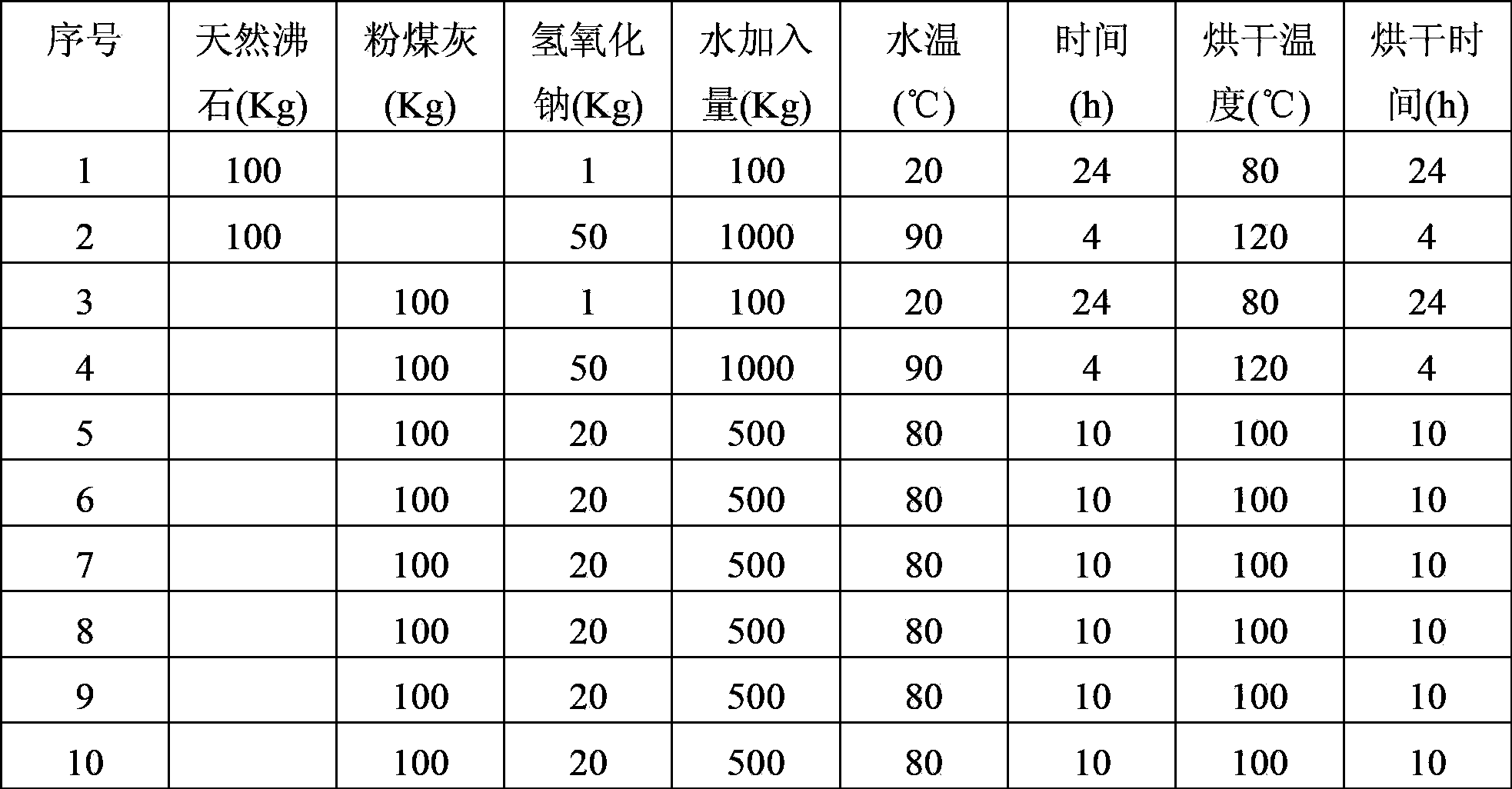

[0032] Table 2 has listed the preparation technology of the sodium zeolite used in table 1

[0033] Table 3 has listed the preparation technology of the calcined alunite used in table 1

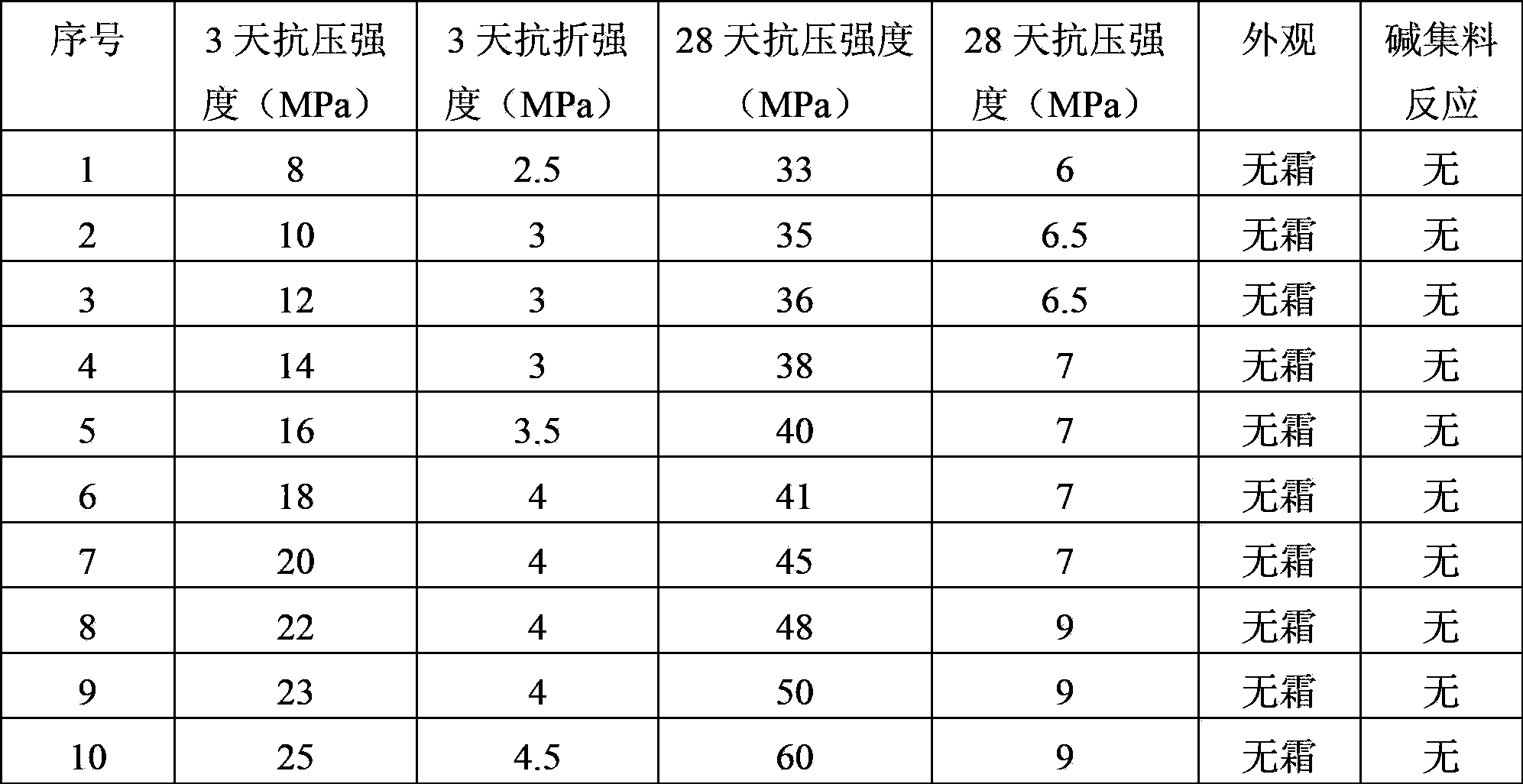

[0034] Table 4 lists the properties of the sodium zeolite inorganic artificial stone prepared in Examples 1-10 of the present invention.

[0035] As can be seen from Table 4, the artificial stone prepared by the method of the present invention using industrial by-products as the main raw material has high early strength, no frosting, and no alkali-aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com