Production method of water channel groove prefabricated members

A production method and prefabricated parts technology, applied in the manufacture of tools, ceramic molding machines, molds, etc., can solve the problems of not being able to maximize the use of water sources, waste of labor and working time, and affect the service life of beams and grooves, so as to improve alkali resistance Aggregate reaction performance, improvement of work efficiency and shortening of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

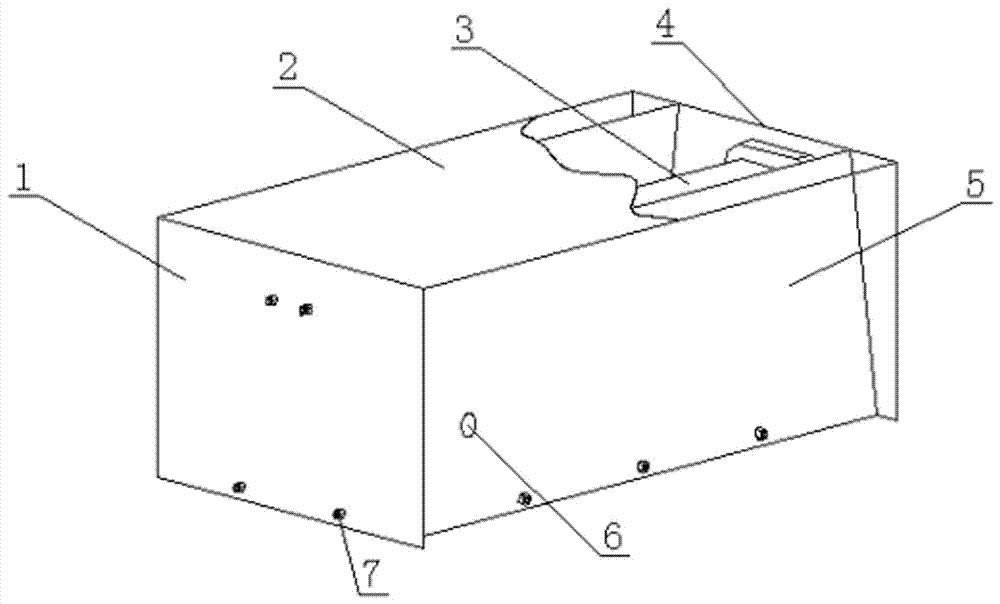

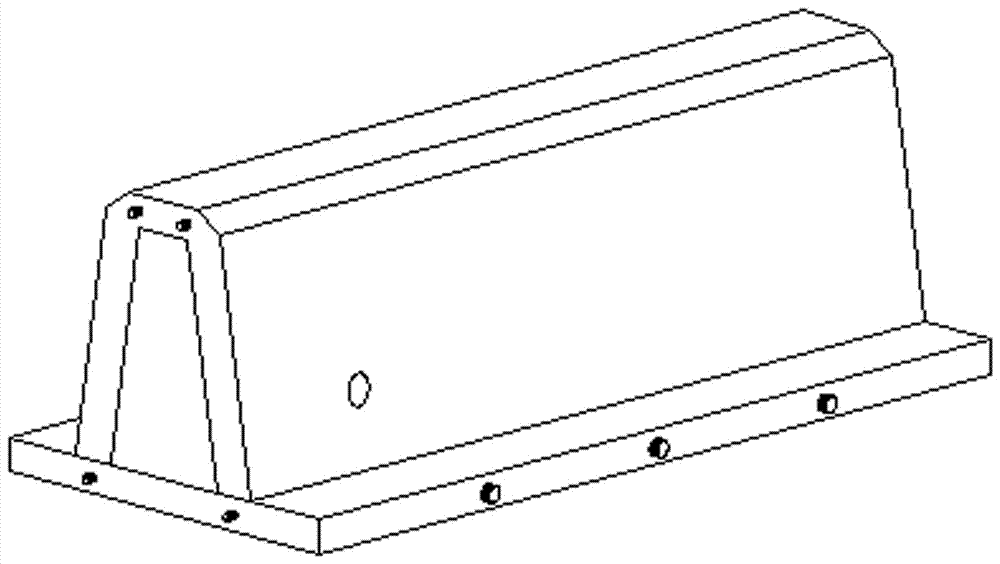

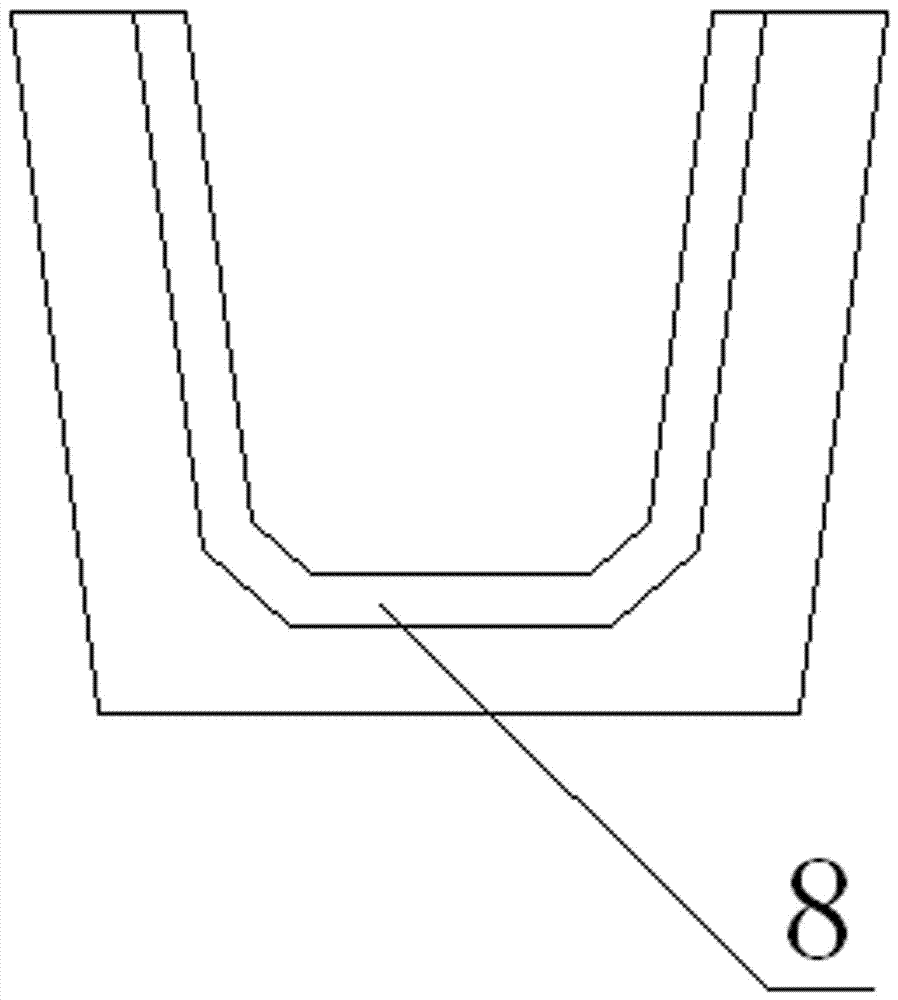

[0050] see Figures 1 to 7 Shown, a kind of production method of drain channel prefabricated part, described method comprises the following steps:

[0051] (1) Make the mold required for the same shape as the prefabricated part of the canal, place the mold upside down, with the bottom of the mold facing up, and pour concrete from the bottom;

[0052] (2) Evenly spray release oil or pad plastic film on the inside of the mold;

[0053] (3) Put the prepared steel bar skeleton into the pouring mold, and adjust the concrete protective layer. The groove edge of the steel bar structure is equipped with stress bars according to the internal and external stress conditions, and the bottom of the groove is pressed according to the upper and lower loads. The force situation configures the stress bars, decomposes the configured steel bars into shapes that can be processed, and then welds them into unit components, welds several unit components with longitudinal steel bars to form a reinfo...

Embodiment 2

[0065] see Figures 1 to 7 Shown, a kind of production method of drain channel prefabricated part, described method comprises the following steps:

[0066] (1) Make the mold required for the same shape as the prefabricated part of the canal, place the mold upside down, with the bottom of the mold facing up, and pour concrete from the bottom;

[0067] (2) Evenly spray release oil or pad plastic film on the inside of the mold;

[0068] (3) Put the prepared steel bar skeleton into the pouring mold, and adjust the concrete protective layer. The groove edge of the steel bar structure is equipped with stress bars according to the internal and external stress conditions, and the bottom of the groove is pressed according to the upper and lower loads. The force situation configures the stress bars, decomposes the configured steel bars into shapes that can be processed, and then welds them into unit components, welds several unit components with longitudinal steel bars to form a reinfo...

Embodiment 3

[0080] see Figures 1 to 7 Shown, a kind of production method of drain channel prefabricated part, described method comprises the following steps:

[0081] (1) Make the mold required for the same shape as the prefabricated part of the canal, place the mold upside down, with the bottom of the mold facing up, and pour concrete from the bottom;

[0082] (2) Evenly spray release oil or pad plastic film on the inside of the mold;

[0083] (3) Put the prepared steel bar skeleton into the pouring mold, and adjust the concrete protective layer. The groove edge of the steel bar structure is equipped with stress bars according to the internal and external stress conditions, and the bottom of the groove is pressed according to the upper and lower loads. The force situation configures the stress bars, decomposes the configured steel bars into shapes that can be processed, and then welds them into unit components, welds several unit components with longitudinal steel bars to form a reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com