Nanometer composite type expansion anti-cracking waterproofing agent

A kind of anti-cracking waterproofing agent and composite technology, which is applied in the field of swelling anti-cracking waterproofing agent, can solve the problems of large slump loss, shortened setting time, and reduced bleeding rate, etc., to achieve fast hydration speed, improve mechanical properties, The effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] 1. Preparation of PSP silicone powder:

[0016] PSP silicone powder is a mixture of polysiloxane and aminopolyether silicone (the mass percentage of polysiloxane is 68.5%, and aminopolyether silicone is 31.5%). Among them, polysiloxane is composed of methyl chloride and SiO 2 The powder (according to mass ratio 3:1) is reacted at 230°C for 12 hours under the catalysis of copper sulfate. Add solvent xylene (solvent is methyl chloride and SiO2) in the kettle 2 15% of the mass of powder reaction raw materials), so that dimethyl dihydroxysilane is subjected to condensation polymerization reaction at 85°C to obtain cross-linked polymer polysiloxane;

[0017] Amino polyether silicone is obtained by addition reaction of hydrogen silicone oil with allyl polyether (volume ratio 1.3:1) under the catalysis of metal platinum at 105°C for 8 hours to obtain polyether modified silicone, and then polyether modified Amino polyether silicone was prepared by reacting silicone with diet...

Embodiment 1

[0024] A nanocomposite expansion anti-crack waterproofing agent of the present invention, its components and mass percent content are as follows: 24% calcium sulfoaluminate, 10% calcium aluminate, 15% calcium hydroxide, 5% PSP organic silicon powder, silicon 6% sodium phosphate, 2% sodium ethylenediamine phosphate, 1% iron powder, 2.5% borax, 0.4% manganese dioxide, 1.5% polypropylene fiber, 0.5% disodium edetate, 1.8% sodium tripolyphosphate , fly ash 15.2%, aminophenoxy naphthalene sulfonate 11.6%, FP nanopolymer 8.5%.

[0025] Its preparation method is as follows, after mixing calcium sulfoaluminate, calcium aluminate, fly ash, calcium hydroxide, iron powder, PSP organic silicon powder and aminophenoxynaphthalene sulfonate according to the above content, the method of ball milling Grind until the size is 3.5μm, then add sodium ethylenediamine phosphate, sodium tripolyphosphate, borax, sodium silicate, manganese dioxide, polypropylene fiber, disodium edetate, and FP nano Af...

Embodiment 2

[0027] Another nano-composite expansion anti-cracking waterproofing agent, its components and weight percentages are as follows: 10% calcium sulfoaluminate, 8% calcium aluminate, 15% calcium hydroxide, 11% PSP organic silicon powder, sodium silicate 7%, sodium ethylenediamine phosphate 2%, iron powder 2%, borax 2.5%, manganese dioxide 0.5%, polypropylene fiber 2.0%, disodium edetate 0.5%, sodium tripolyphosphate 3%, powder Coal Ash 22.5%, Aminophenoxynaphthalene Sulfonate 8%, FP Nanopolymer 6%.

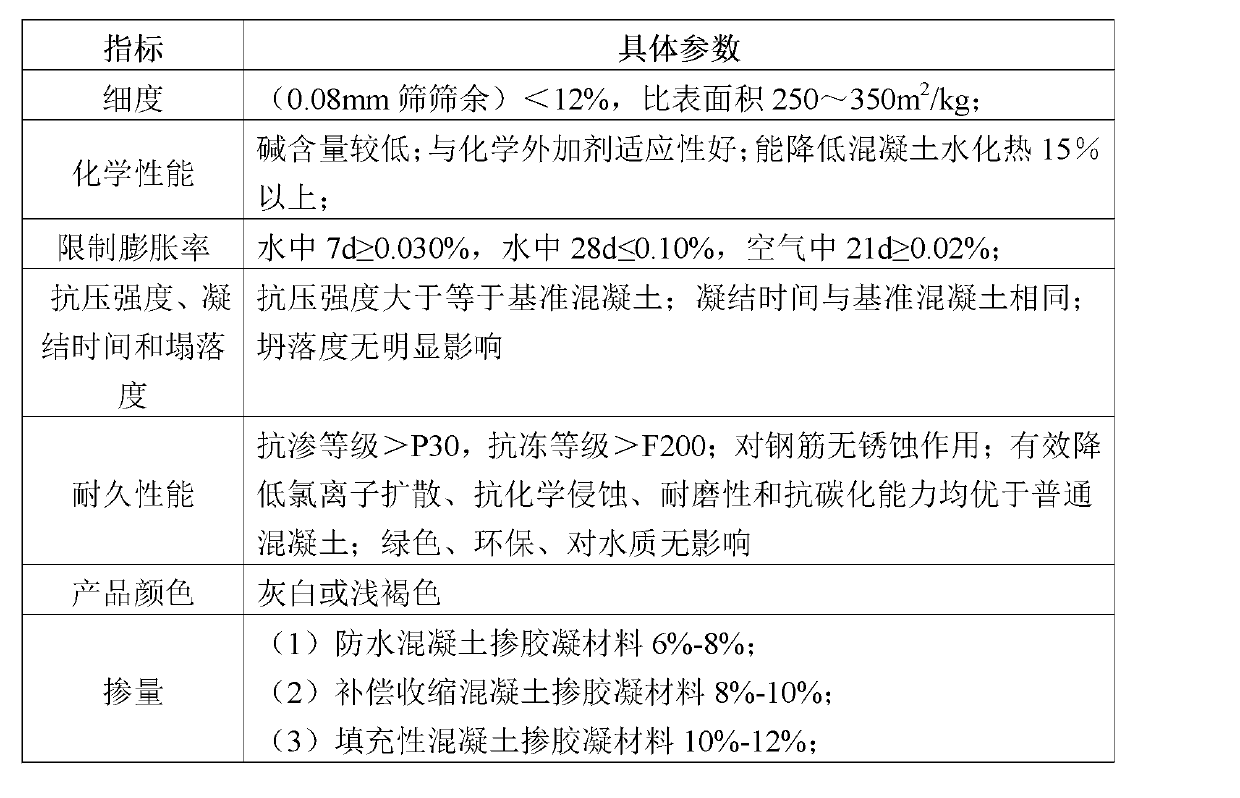

[0028] The nanocomposite expansion anti-crack waterproofing agent of present embodiment 2, its specific technical index is as shown in table 1:

[0029] Table 1 Technical indicators of nanocomposite intumescent anti-crack waterproofing agent

[0030]

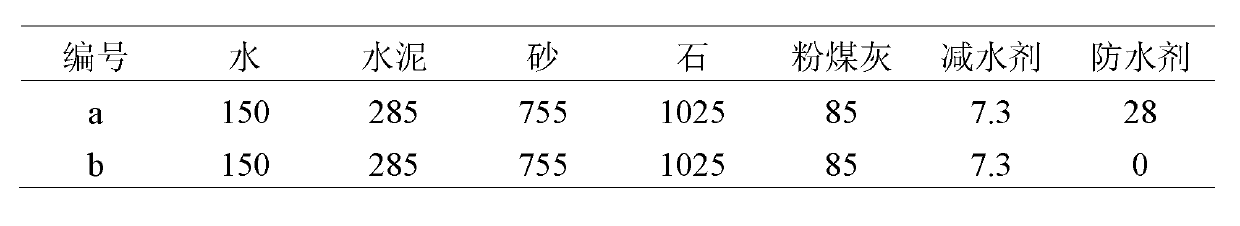

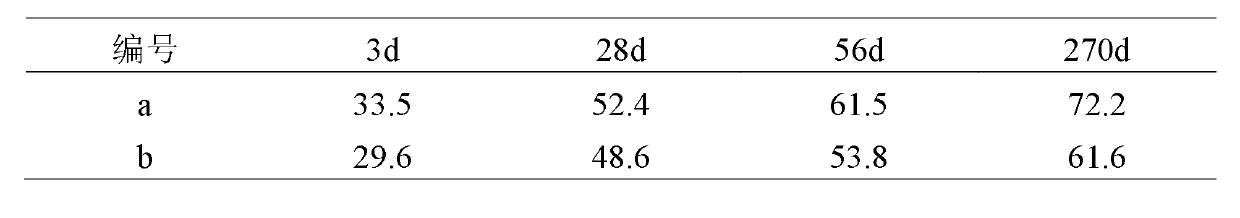

[0031]The cement adopts P·O 42.5R grade; the fine aggregate has an apparent density of 2.58g / cm 3 river sand (fineness modulus is 2.7); coarse aggregate has an apparent density of 2.65 g / cm 3 Granite; fly ash is Class II ash; wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com