Production method of canal tee prefabricated part

A production method and technology for prefabricated parts, applied in the direction of manufacturing tools, auxiliary parts of moulds, mould fixing devices, etc., can solve the problems of many steps in the process of prefabricated parts of canal corners, not being able to make maximum use of water sources, wasting labor and working time, etc. Achieve the effect of improving alkali-resistant aggregate reaction performance, inhibiting alkali-aggregate reaction, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

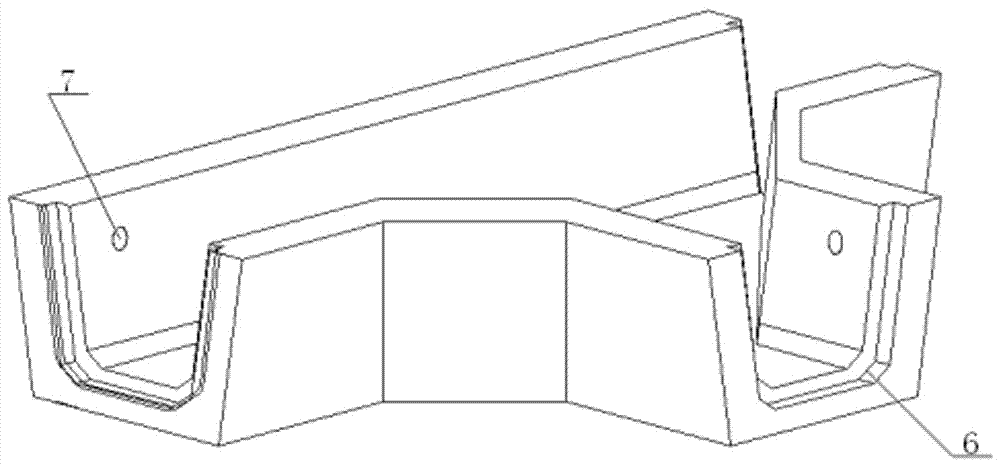

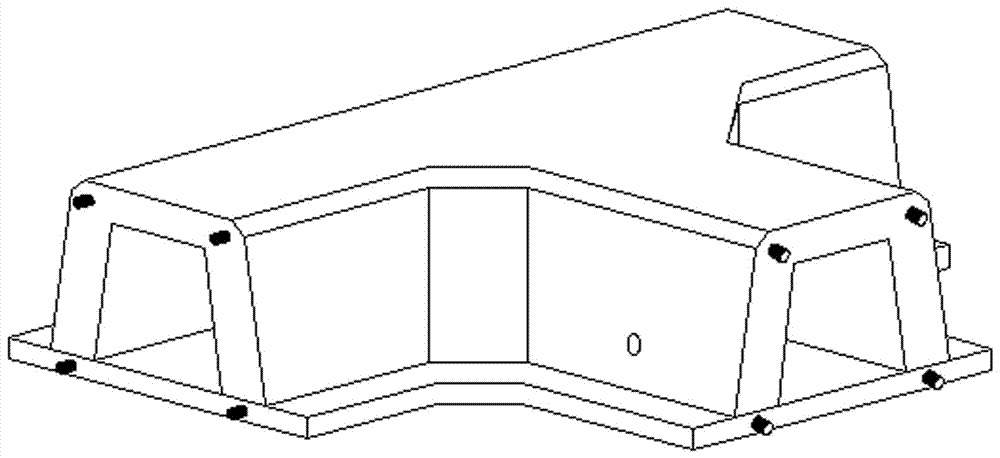

[0051] see Figures 1 to 6 Shown, a kind of production method of drain tee prefabricated part, described method comprises the following steps:

[0052] (1) Design the pouring mold required for the corresponding shape of the prefabricated part of the water channel tee;

[0053] (2) Evenly apply release oil or pad plastic film on the inside of the mold;

[0054] (3) Fix the mold cavity, put on the side wall mold, install the end cover molds at both ends, put in the steel structure to enhance the corner strength of the water channel, put it on the mold cavity, and fix the steel structure; the steel structure is at the bottom There are two layers of distributed steel bars to enhance the force-bearing capacity of the bottom, and use longitudinal tension bars to connect a single U-shaped steel bar member into a whole steel bar structure. Through the anti-extrusion ability of prefabricated parts, the stability of the overall structure is improved, and it is resistant to falling and...

Embodiment 2

[0072] see Figures 1 to 6 Shown, a kind of production method of drain tee prefabricated part, described method comprises the following steps:

[0073] (1) Design the pouring mold required for the corresponding shape of the prefabricated part of the water channel tee;

[0074] (2) Evenly apply release oil or pad plastic film on the inside of the mold;

[0075] (3) Fix the mold cavity, put on the side wall mold, install the end cover molds at both ends, put in the steel structure to enhance the corner strength of the water channel, put it on the mold cavity, and fix the steel structure; the steel structure is at the bottom There are two layers of distributed steel bars to enhance the force-bearing capacity of the bottom, and use longitudinal tension bars to connect a single U-shaped steel bar member into a whole steel bar structure. Through the anti-extrusion ability of prefabricated parts, the stability of the overall structure is improved, and it is resistant to falling and...

Embodiment 3

[0093] see Figures 1 to 6 Shown, a kind of production method of drain tee prefabricated part, described method comprises the following steps:

[0094] (1) Design the pouring mold required for the corresponding shape of the prefabricated part of the water channel tee;

[0095] (2) Evenly apply release oil or pad plastic film on the inside of the mold;

[0096] (3) Fix the mold cavity, put on the side wall mold, install the end cover molds at both ends, put in the steel structure to enhance the corner strength of the water channel, put it on the mold cavity, and fix the steel structure; the steel structure is at the bottom There are two layers of distributed steel bars to enhance the force-bearing capacity of the bottom, and use longitudinal tension bars to connect a single U-shaped steel bar member into a whole steel bar structure. Through the anti-extrusion ability of prefabricated parts, the stability of the overall structure is improved, and it is resistant to falling and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com