Low-alkali-content and crack-resistant water repellent and preparation process therefor

An anti-cracking waterproofing agent and preparation technology, which is applied in the field of building materials, can solve problems such as the influence of surrounding residents and pollution of the atmospheric environment, and achieve the effects of small strength influence, low alkali content, and good expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

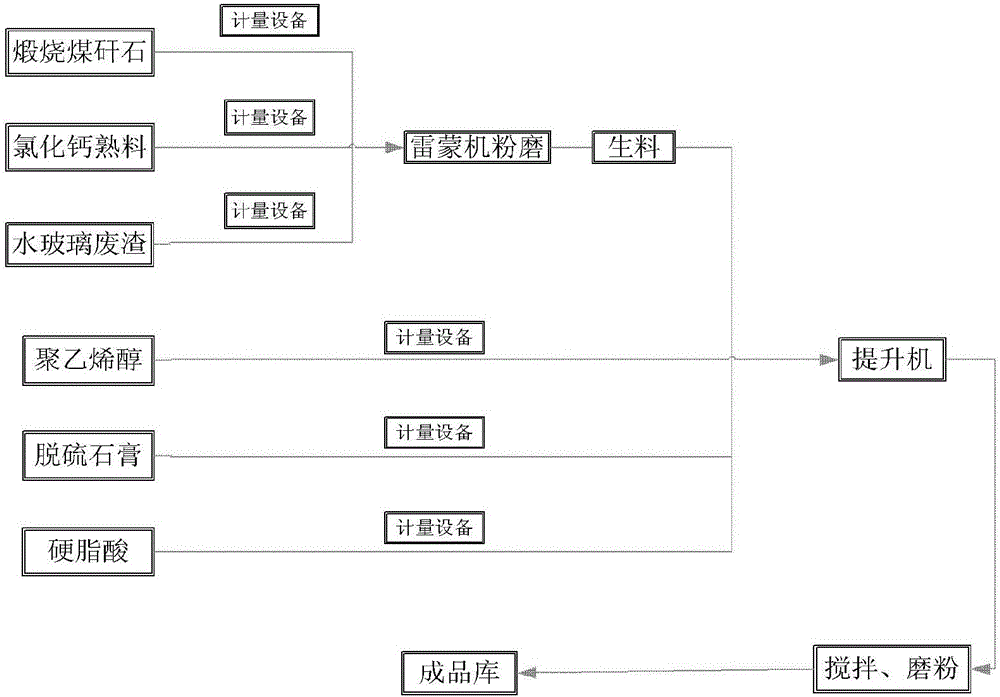

Method used

Image

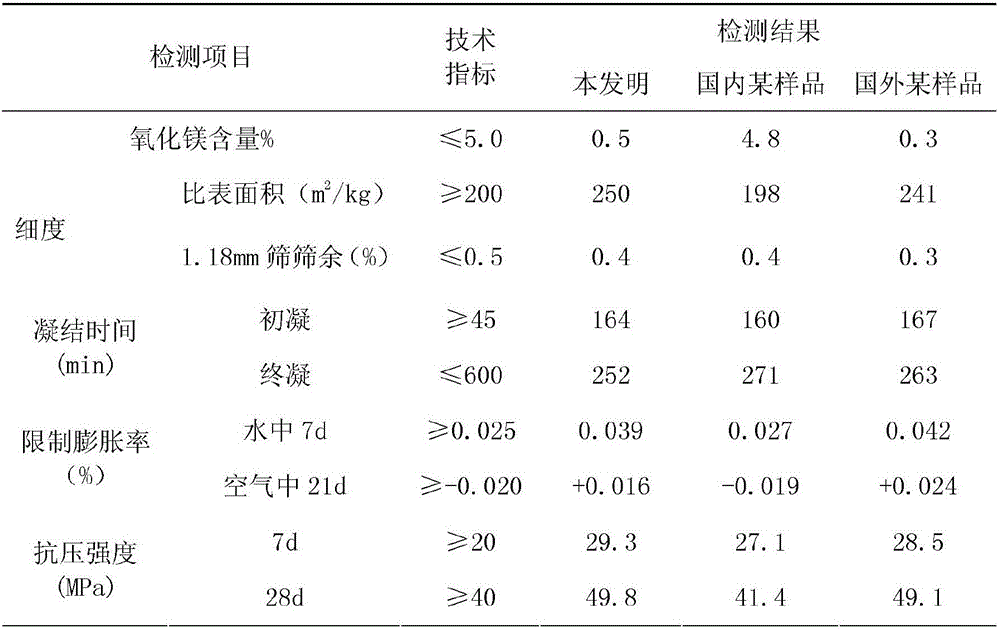

Examples

Embodiment 1

[0037] The purpose of this embodiment is to provide a low-alkali anti-cracking waterproofing agent synthesized by using waste coal gangue and water glass slag liquid and its preparation process.

[0038] This embodiment specifically provides a low-alkali environment-friendly anti-cracking waterproofing agent, which is composed of the following mass ratios: calcined coal gangue: calcium oxide clinker: waste slag of water glass: polyvinyl alcohol: desulfurized gypsum: stearic acid 20-70: 5-55: 1-30: 0.5-7.0: 1-30: 0.1-5.0.

[0039] Concrete, the material composition of following mass ratio: calcined coal gangue: calcium oxide clinker: waste slag of water glass: polyvinyl alcohol: desulfurized gypsum: stearic acid is 30~60:15~45:5~20:1.0~ 6.0: 5-20: 0.2-2.5.

[0040] However, in order to obtain a high-quality low-alkali environment-friendly anti-crack waterproofing agent, the present embodiment is specifically composed of the following mass ratios: calcined coal gangue: calcium ...

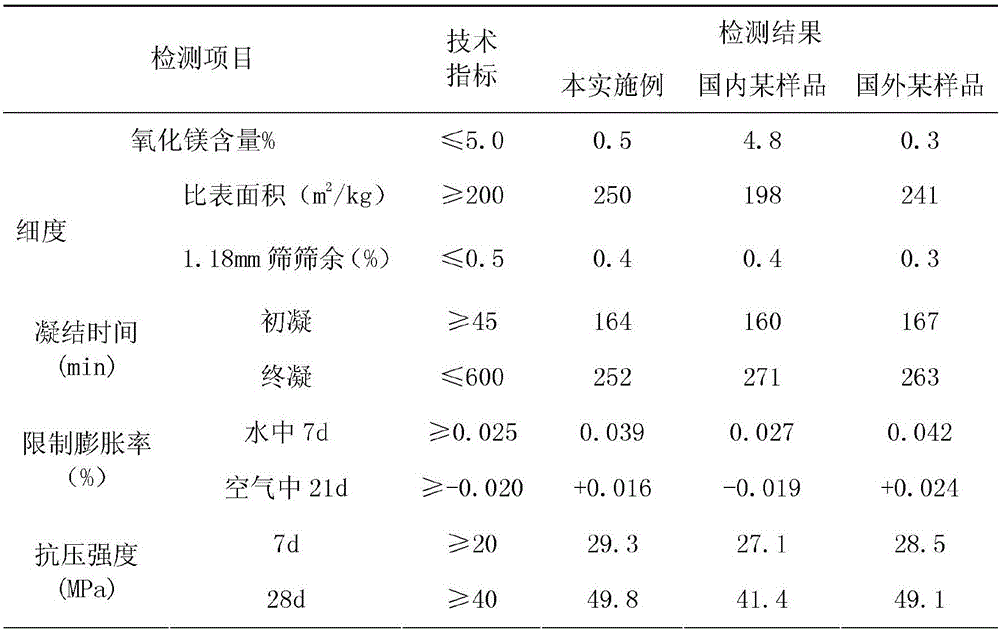

Embodiment 2

[0069] In this embodiment, except that the ratio of raw materials is as follows, the rest of the production process and technical scheme are the same as in Embodiment 1.

[0070] The ratio of raw materials in this embodiment is: calcined coal gangue: calcium oxide clinker: waste slag of water glass: polyvinyl alcohol: desulfurized gypsum: stearic acid is 50:35:10:0.5:4:0.5.

Embodiment 3

[0072] In this embodiment, except that the ratio of raw materials is as follows, the rest of the production process and technical scheme are the same as in Embodiment 1.

[0073] The ratio of raw materials in this embodiment is: calcined coal gangue: calcium oxide clinker: waste slag of water glass: polyvinyl alcohol: desulfurized gypsum: stearic acid is 50:35:5:0.5:9:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com