Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Increase flue gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

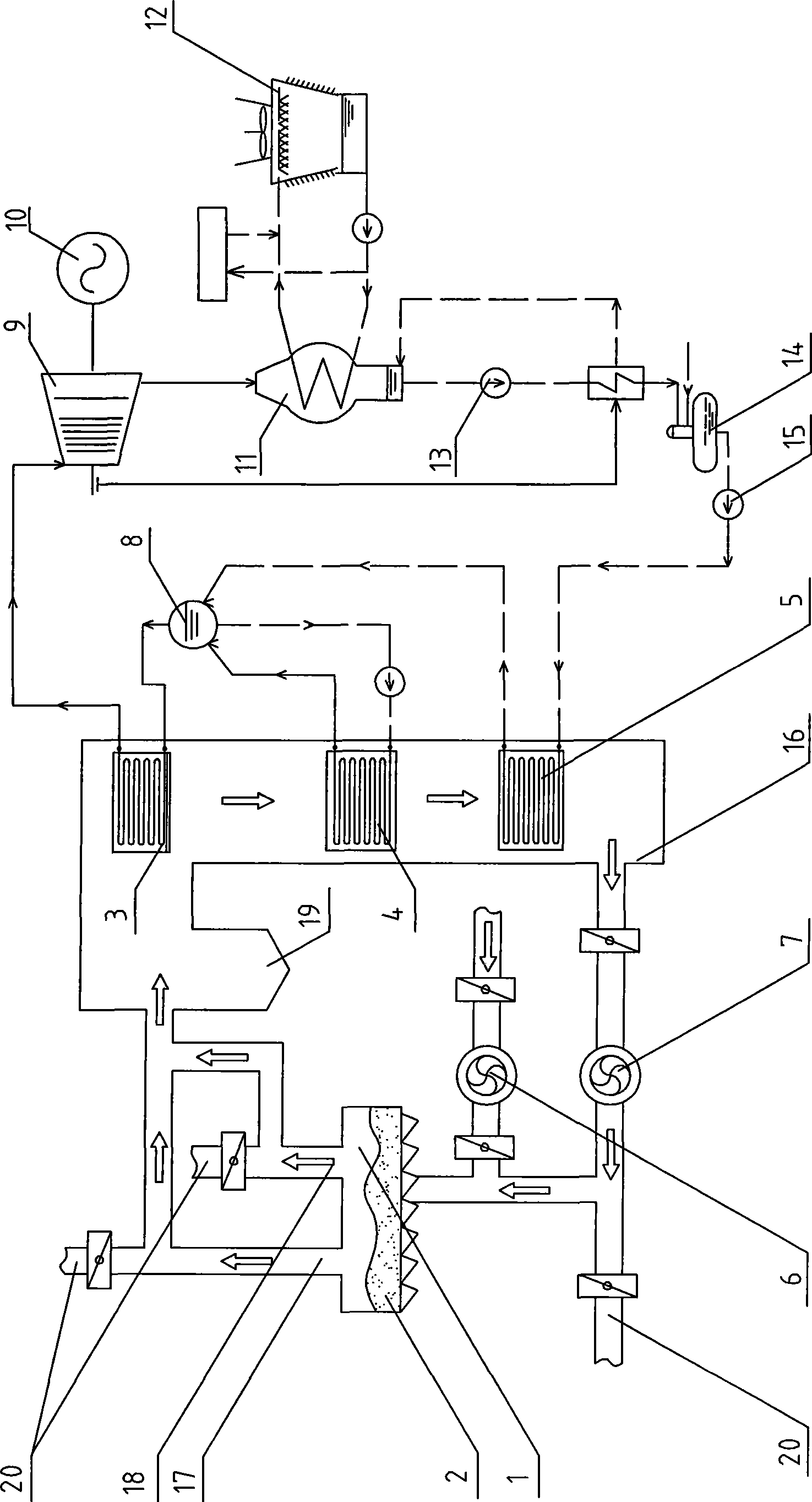

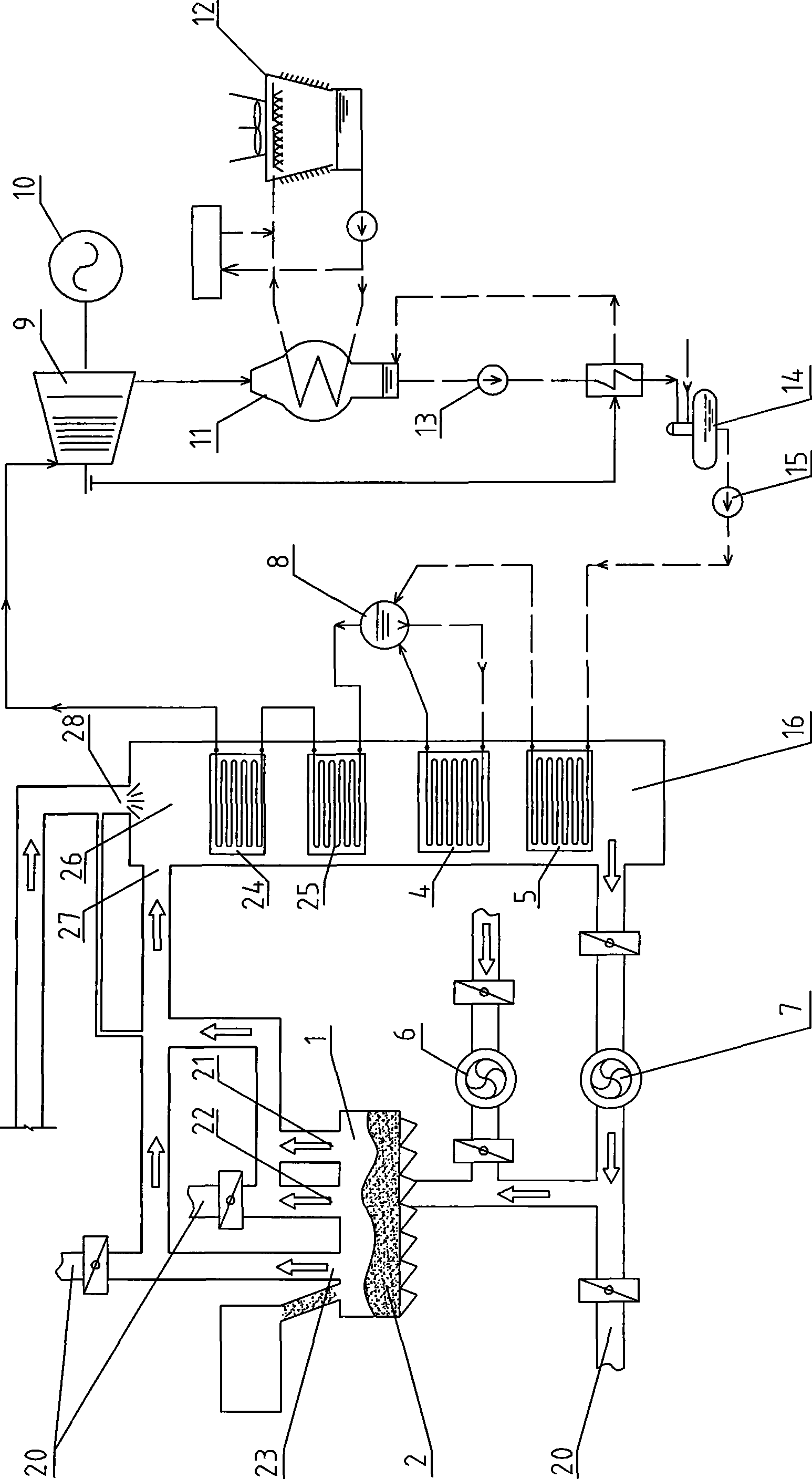

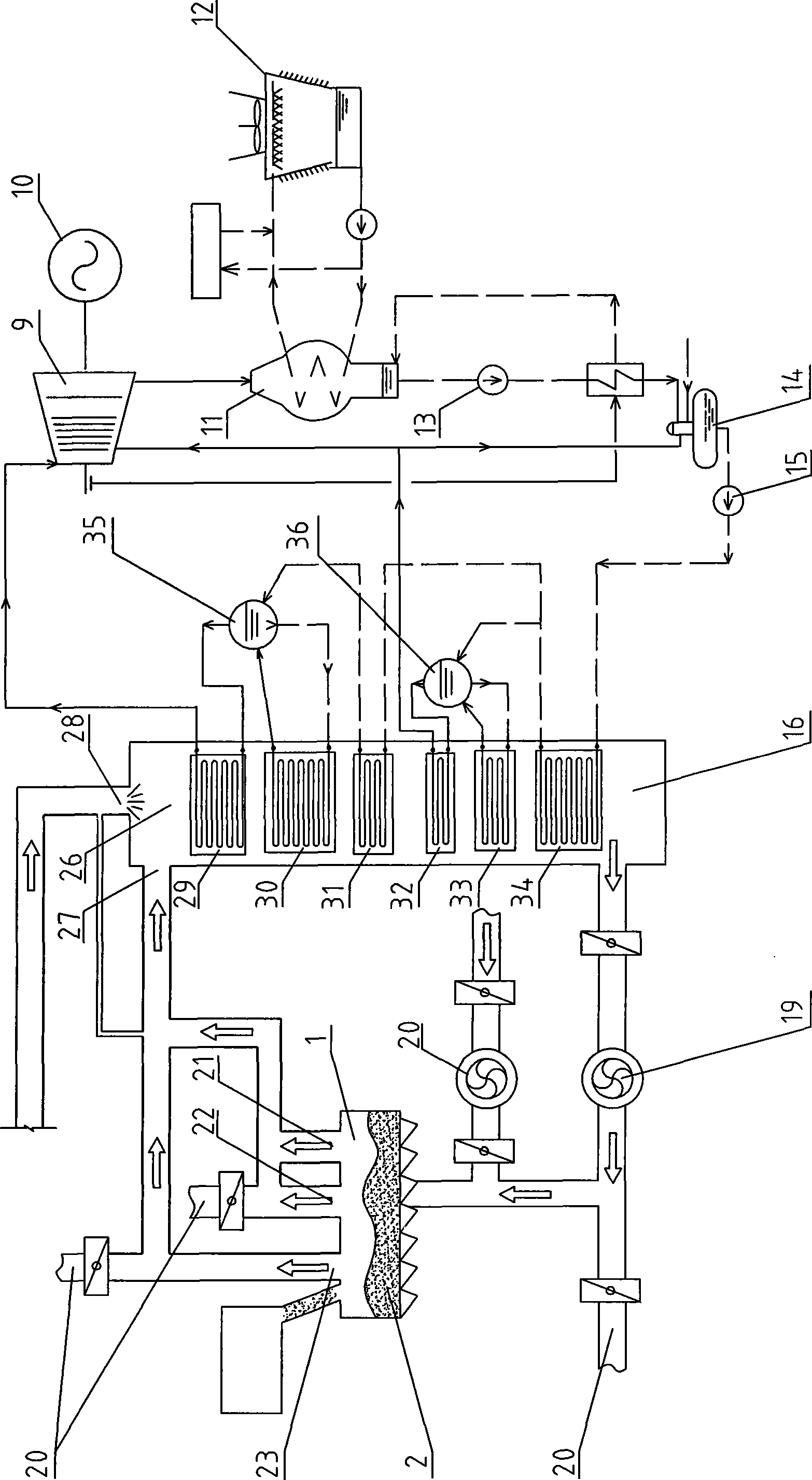

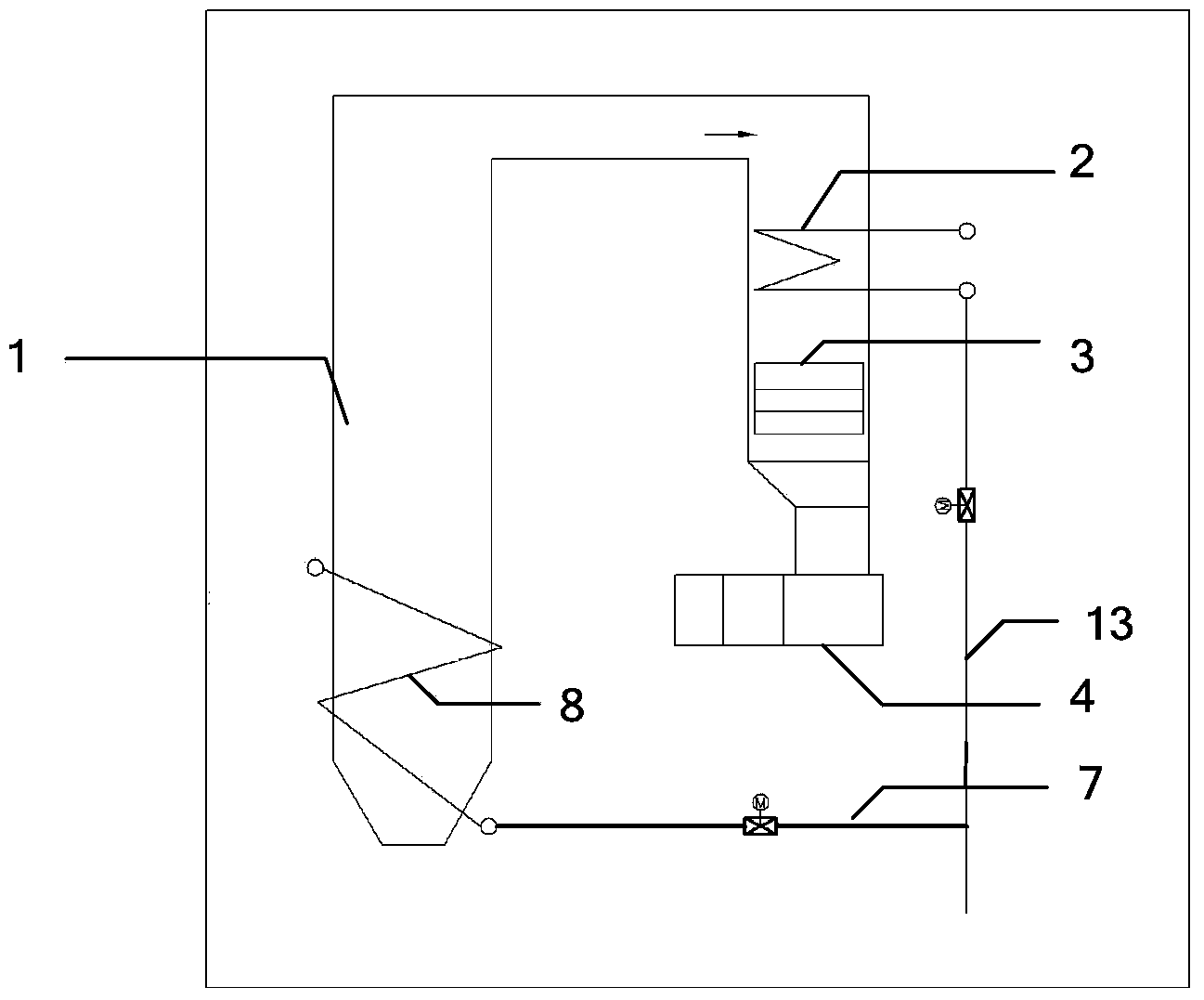

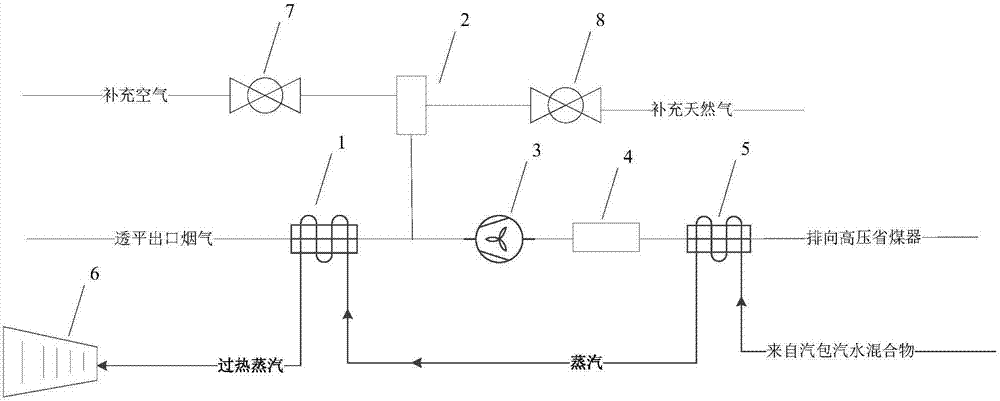

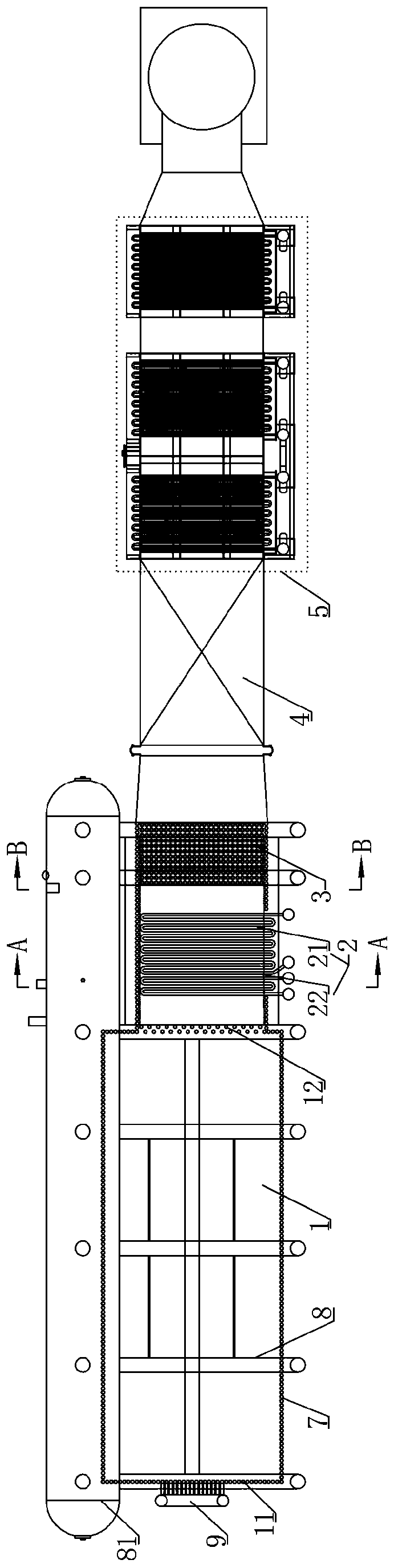

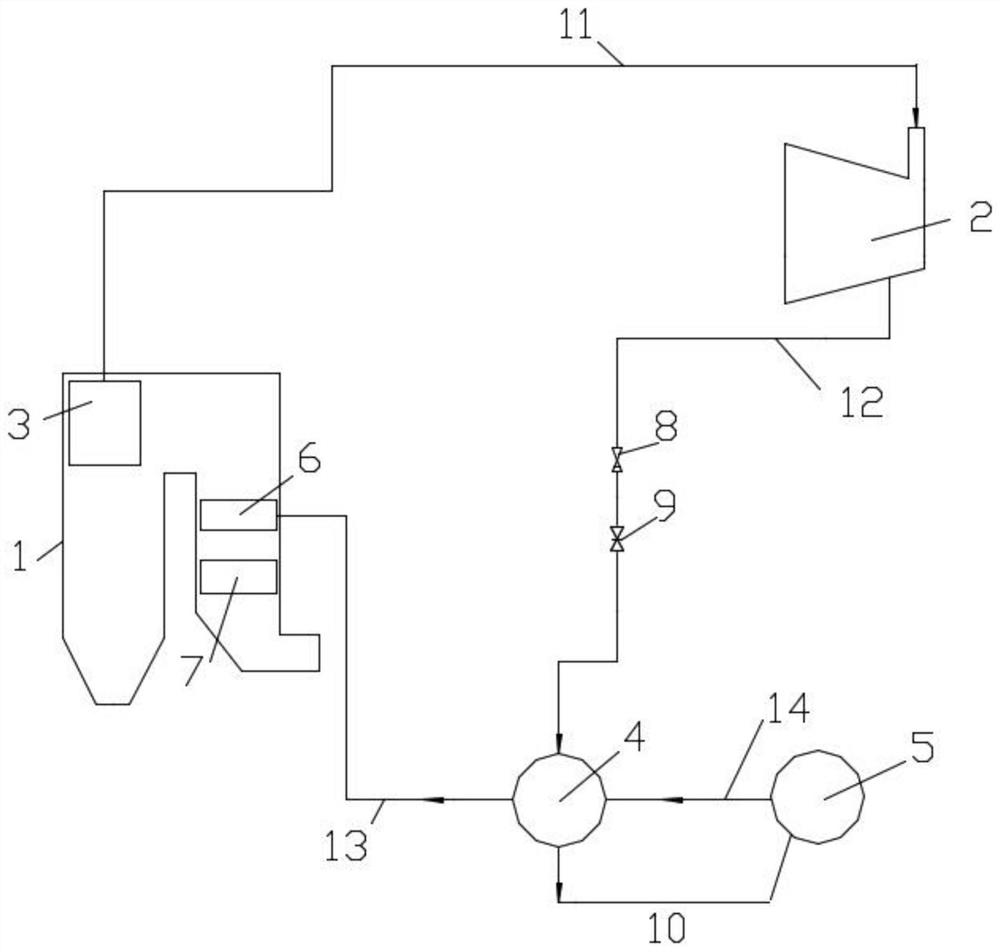

Sintered power generation by waste heat system with by-product gas afterburning

InactiveCN101509729AIncrease flue gas temperatureImprove steam parametersIncreasing energy efficiencySteam engine plantsSuperheaterEvaporator

The invention relates to a residual heat power generation system which is a power generation system with by-product gas supplemental combustion by sintering residual heat. The power generation system comprises a cooling machine, a waste heat boiler, a steam drum, a steam turbine, a boiler feed pump, an induced draft fan, an air blower and a chimney. A combustion hearth, a high-temperature superheater, a low-temperature superheater, an evaporator and an economizer are sequentially arranged on the waste heat boiler from top to bottom; the outlet of the high-temperature superheater and the steam inlet of the steam turbine are connected with each other by a pipeline; the waste heat boiler is provided with a sintering waste gas inlet and a by-product gas inlet; and the upper part of the cooling machine is provided with a high-temperature waste gas outlet, a middle-temperature waste gas outlet and a low-temperature waste gas outlet. The residual heat power generation system can greatly increase the temperature of the smoke and the temperature and the pressure of the overheated steam at the inlet of the steam turbine, and can improve the power generation capability.

Owner:江苏东能环保能源科技有限公司

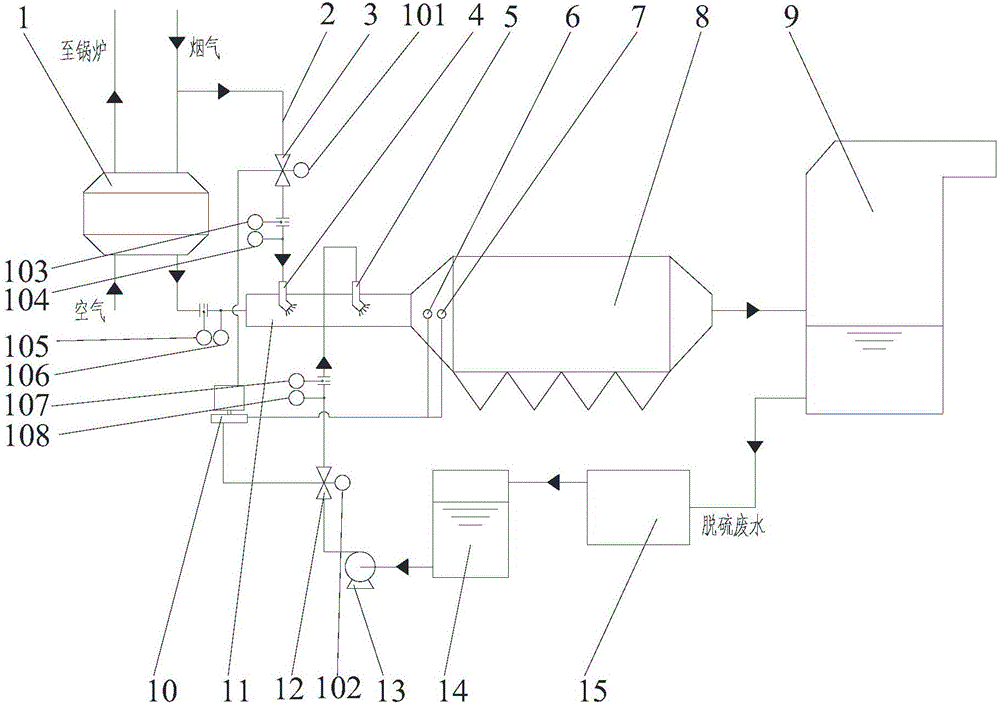

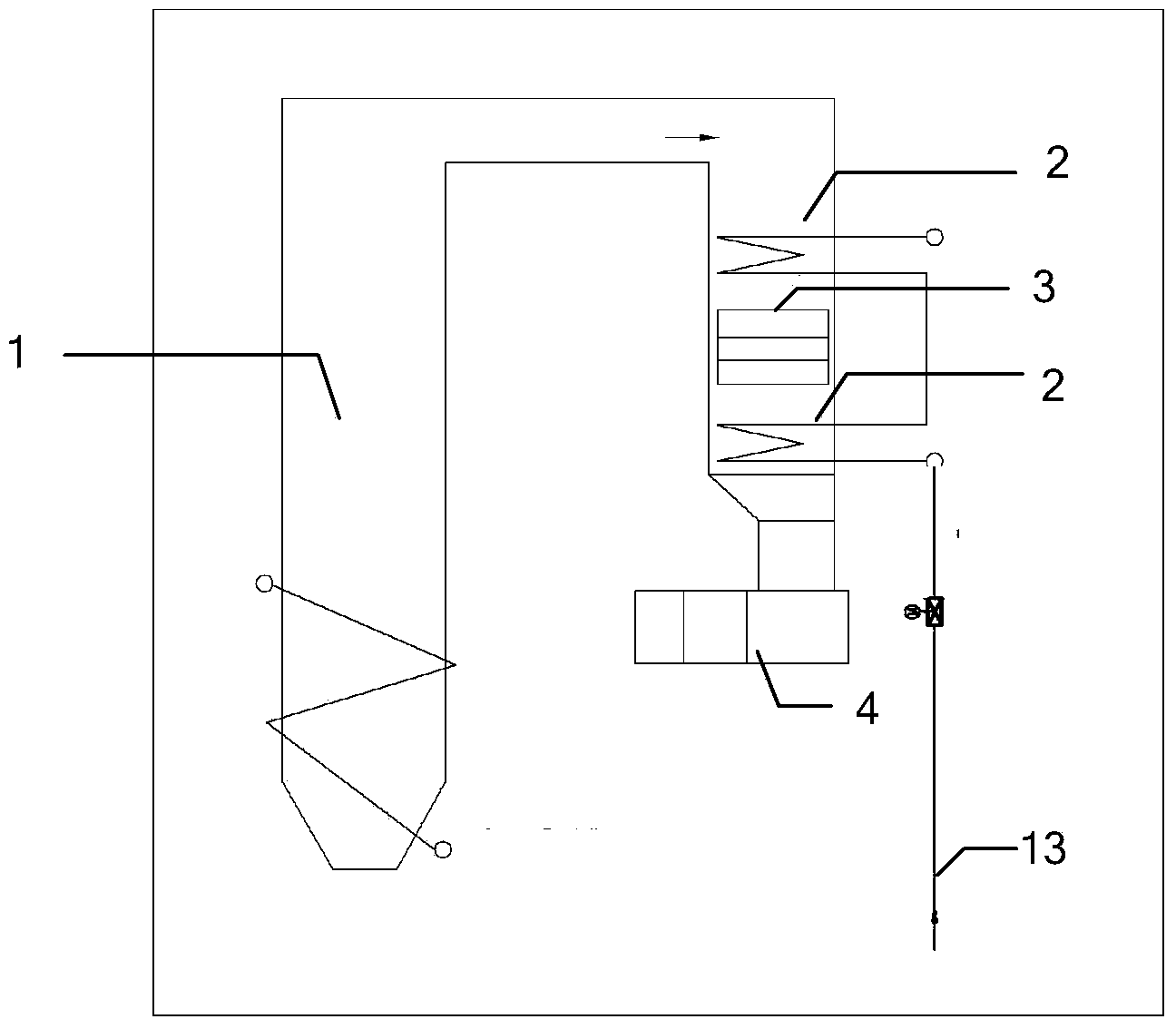

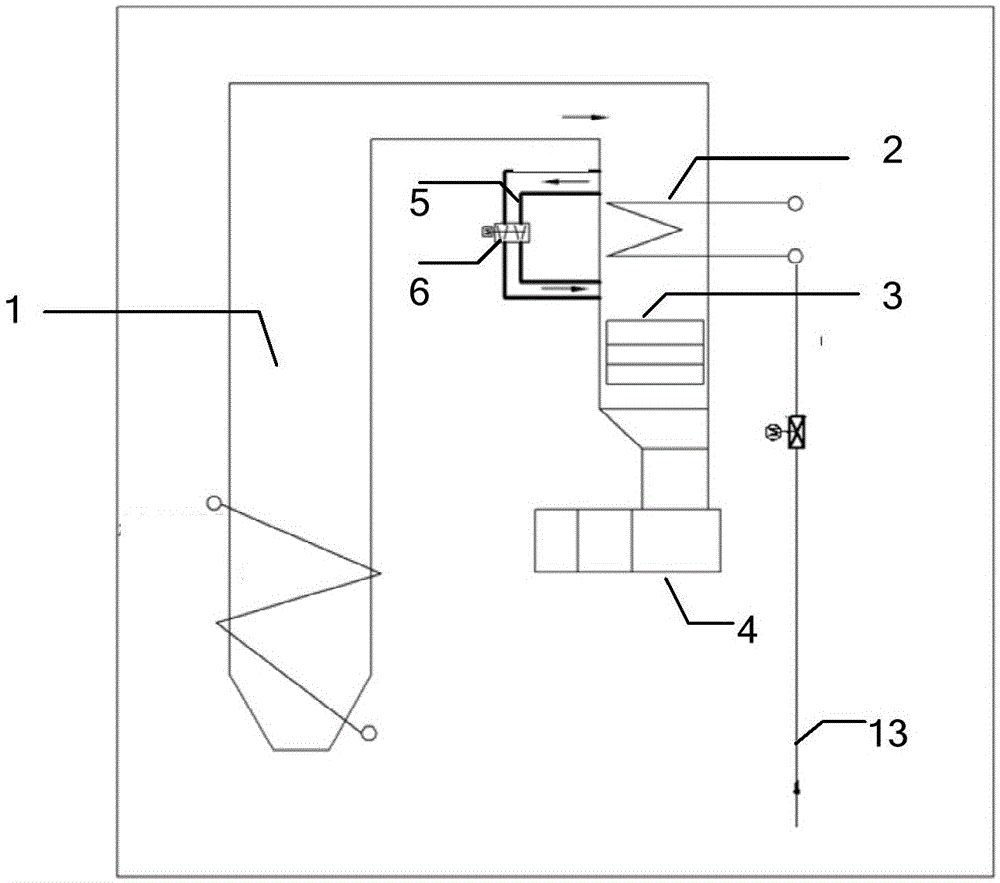

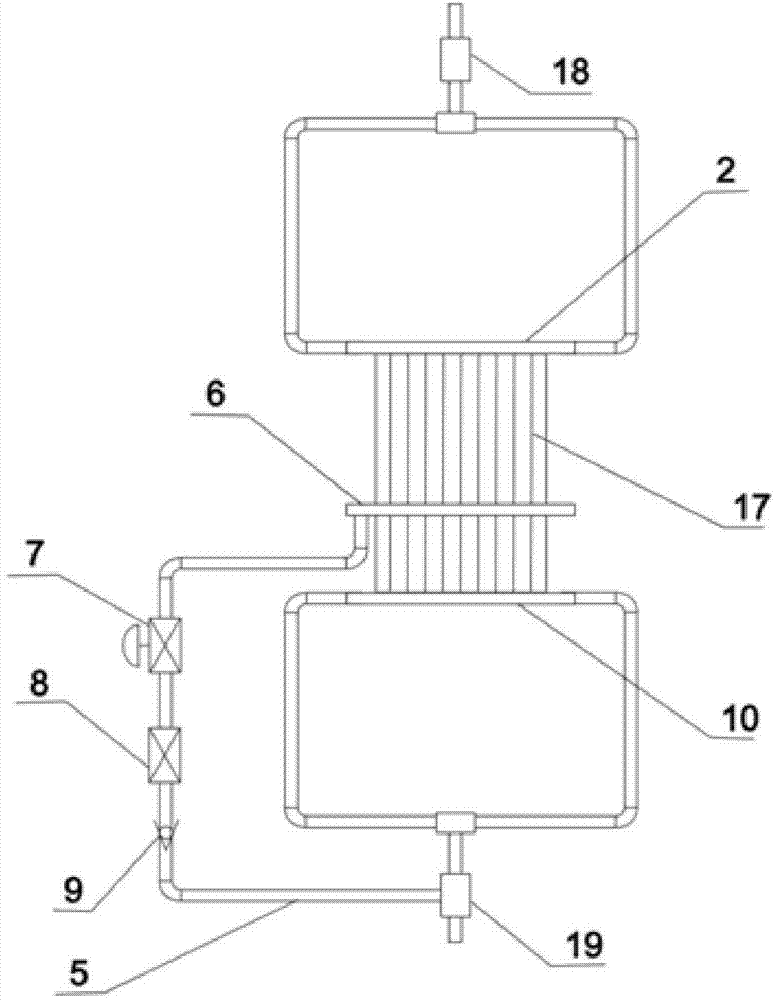

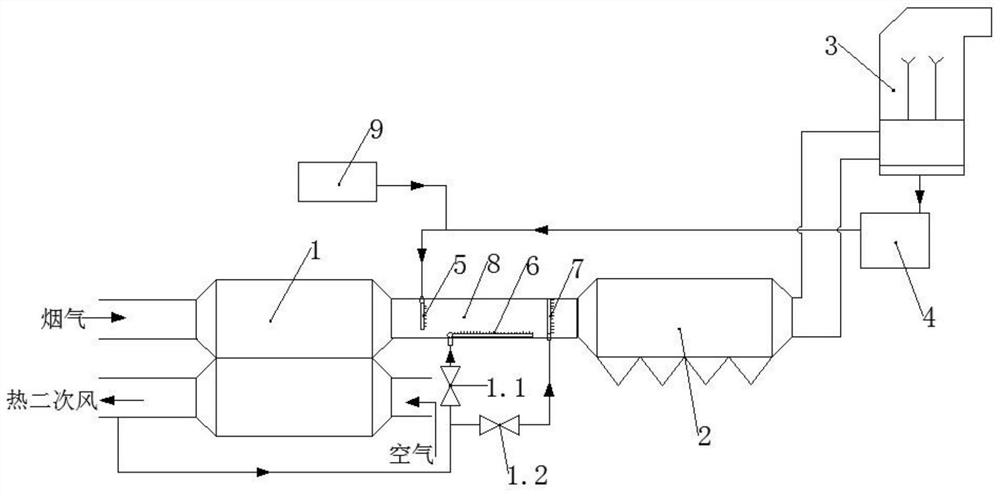

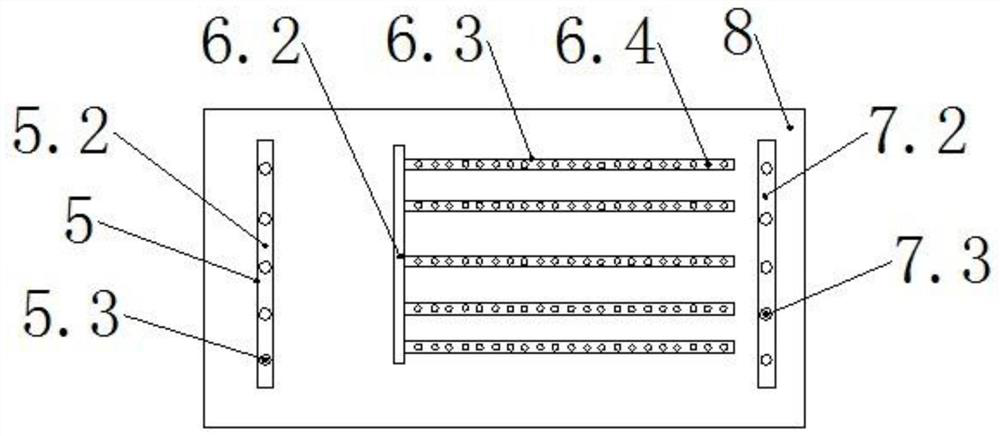

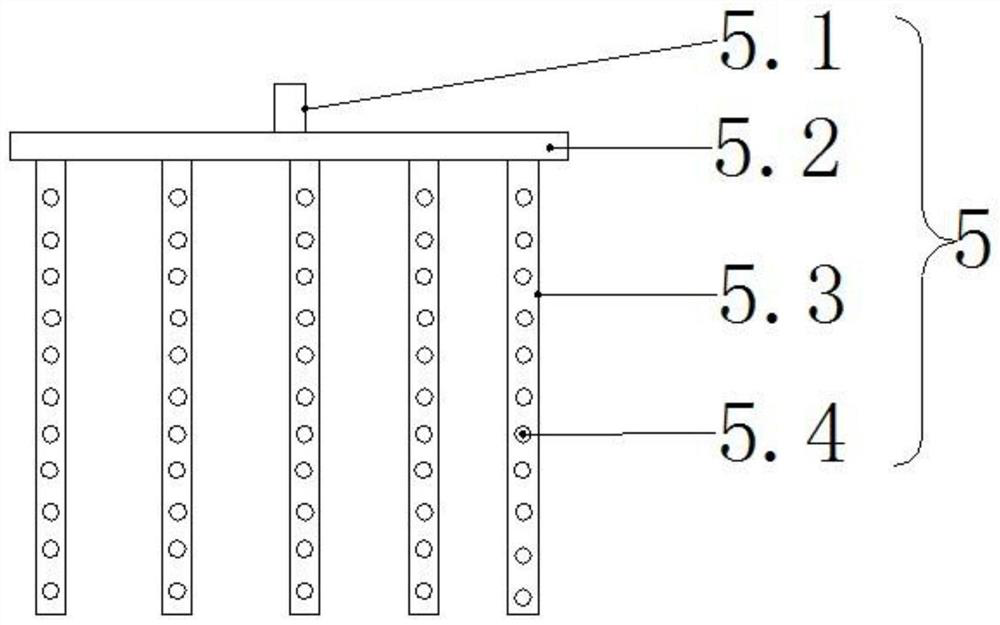

Desulfurized wastewater spray evaporation treatment device with bypath system

PendingCN106115829APrecise control of spray volumeAchieving zero emissionsWater/sewage treatmentWaste water treatment from gaseous effluentsAir preheaterEvaporation

The invention provides a desulfurized wastewater spray evaporation treatment device with a bypath system and relates to zero-emission treatment of desulfurized wastewater of a thermal power plant. The desulfurized wastewater spray evaporation treatment device is provided with a bypath flue subsystem, a desulfurized wastewater spray evaporation subsystem and a control unit; the bypath flue subsystem is provided with a bypath flue, a bypath flue regulating valve and a high-temperature flue gas nozzle; the desulfurized wastewater spray evaporation subsystem is provided with a spraying device, a desulfurized wastewater pipeline regulating valve and a water pump; the control unit is provided with a control processor, a bypath flue electric executing mechanism, a desulfurized wastewater pipeline electric executing mechanism, a bypath flue flow transmitter, a bypath flue temperature transmitter, an air pre-heater outlet flue flow transmitter, an air pre-heater outlet flue temperature transmitter, a desulfurized wastewater pipeline flow transmitter and a desulfurized wastewater pipeline temperature transmitter. The desulfurized wastewater spray evaporation treatment device has a relatively good effect of heat exchange on desulfurized wastewater, is safer and more reliable and saves more power; the desulfurized wastewater spray evaporation treatment device has no nitrogen oxide standard-exceeding risks, a simple structure and no heat exchange loss and partial resistance. Power units including a draught fan and the like do not need to be additionally arranged so that the cost is low.

Owner:福建龙净环保智能输送工程有限公司

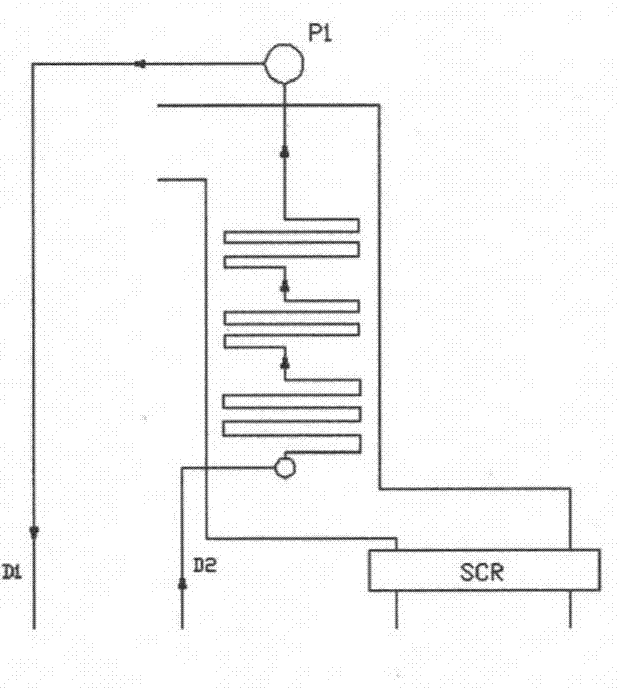

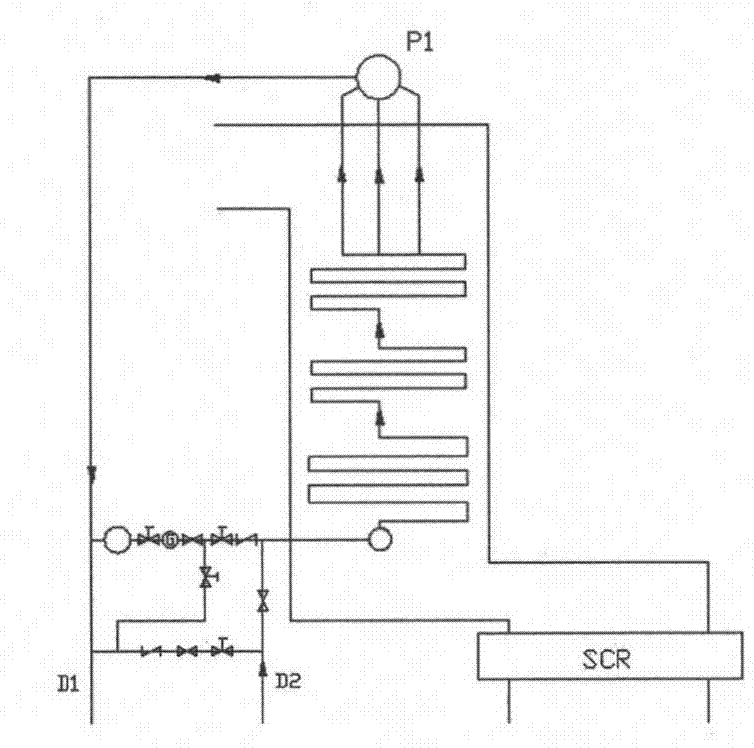

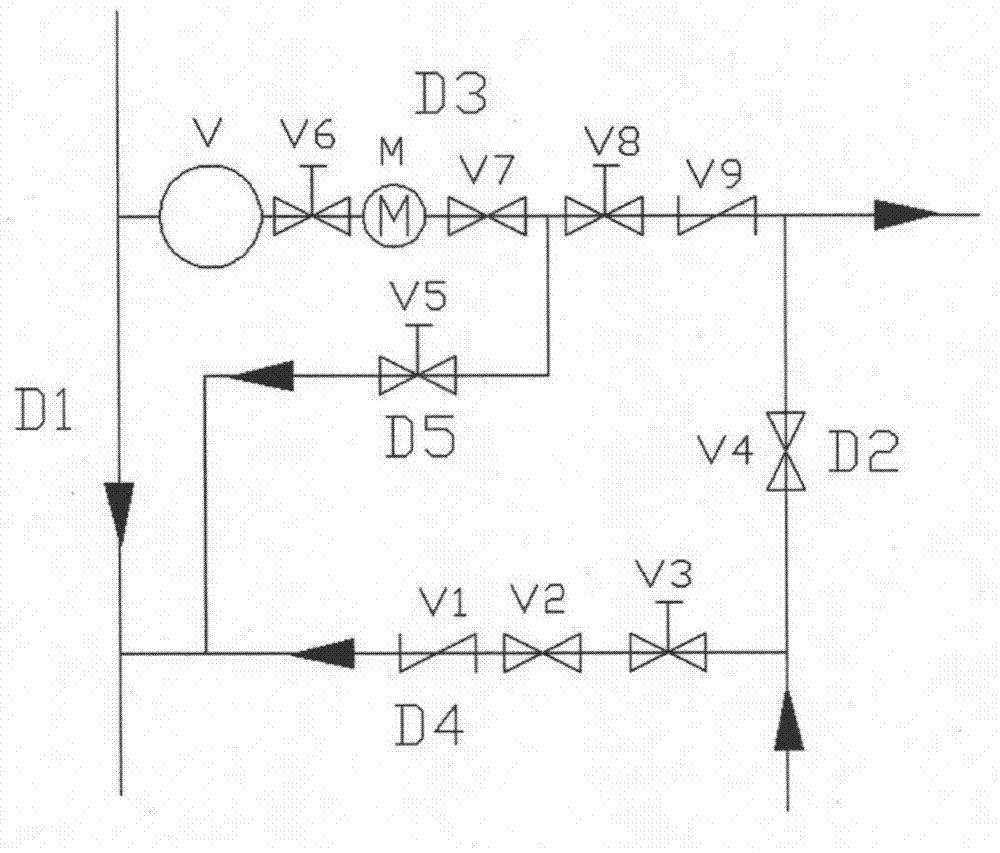

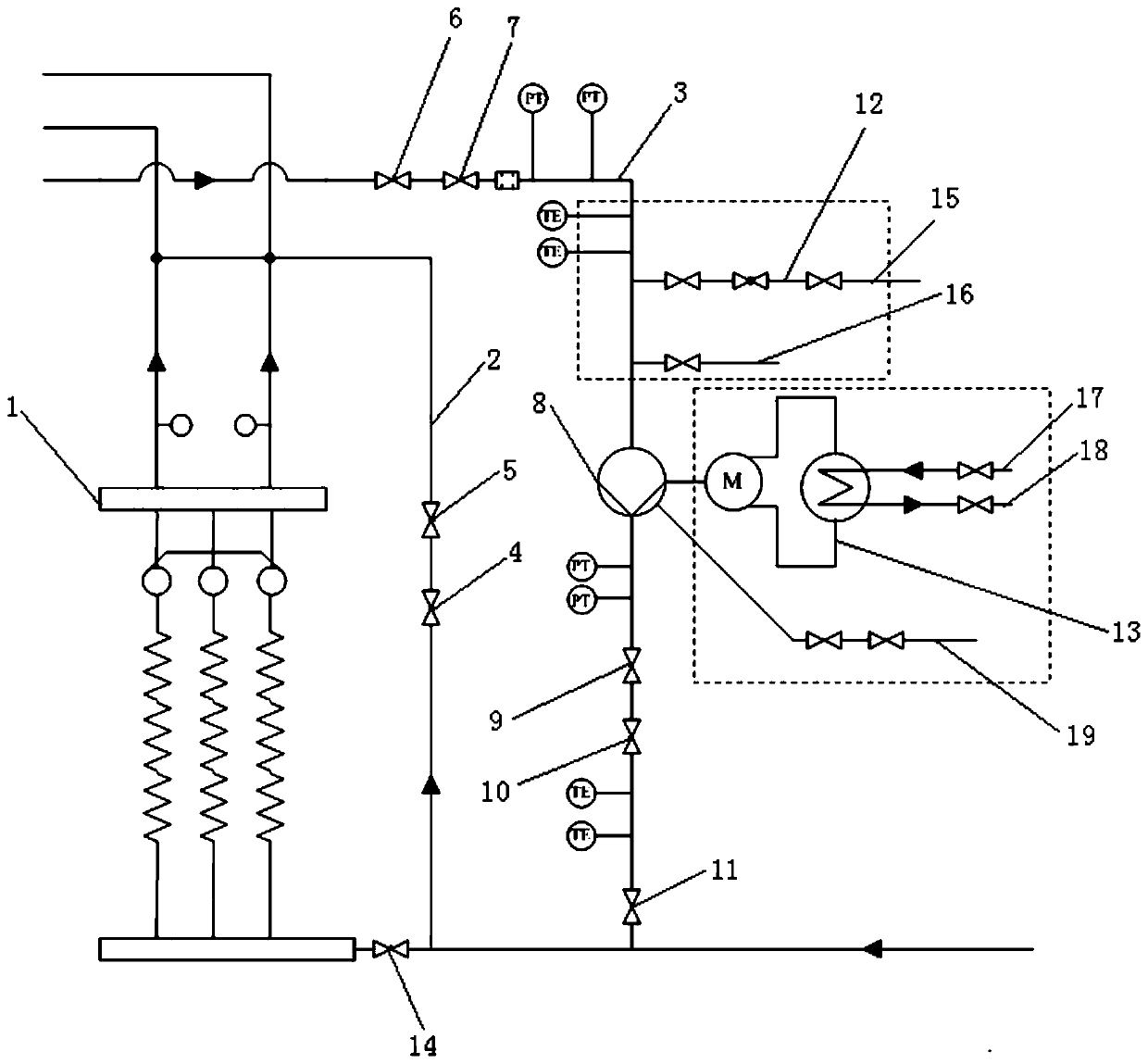

Feedwater replacement type economizer system for whole commissioning of denitration device

The invention provides a feedwater replacement type economizer system for whole commissioning of a denitration device. The feedwater replacement type economizer system is characterized in that the feedwater replacement type economizer system comprises a first bypass, a second bypass and a third bypass, the first bypass and the second bypass are arranged between a downcomer and a feedwater pipeline, the first bypass is provided with a vessel pot, a stop valve, a circulating pump, a flow control valve, a stop valve and a check valve in sequence from the downcomer to the feedwater pipeline, the second bypass is provided with a stop valve, a flow control valve and a check valve in sequence from the feedwater pipeline to the downcomer, one end of the third bypass is in the position between the flow control valve and the stop valve of the first bypass, the other end of the third bypass is connected with the downcomer, the third bypass is provided with a stop valve, and a flow control valve is arranged between the first bypass and the second bypass in the feedwater pipeline. By means of the feedwater replacement type economizer system, economy of a boiler is not sacrificed under heavy load, the smoke temperature of an inlet of the denitration device can be increased under low load, and the feedwater replacement type economizer system is suitable for boilers with the smoke temperature of the denitration device inlet under low load reaching 40 DEG C.

Owner:SHANGHAI POWER EQUIP RES INST +1

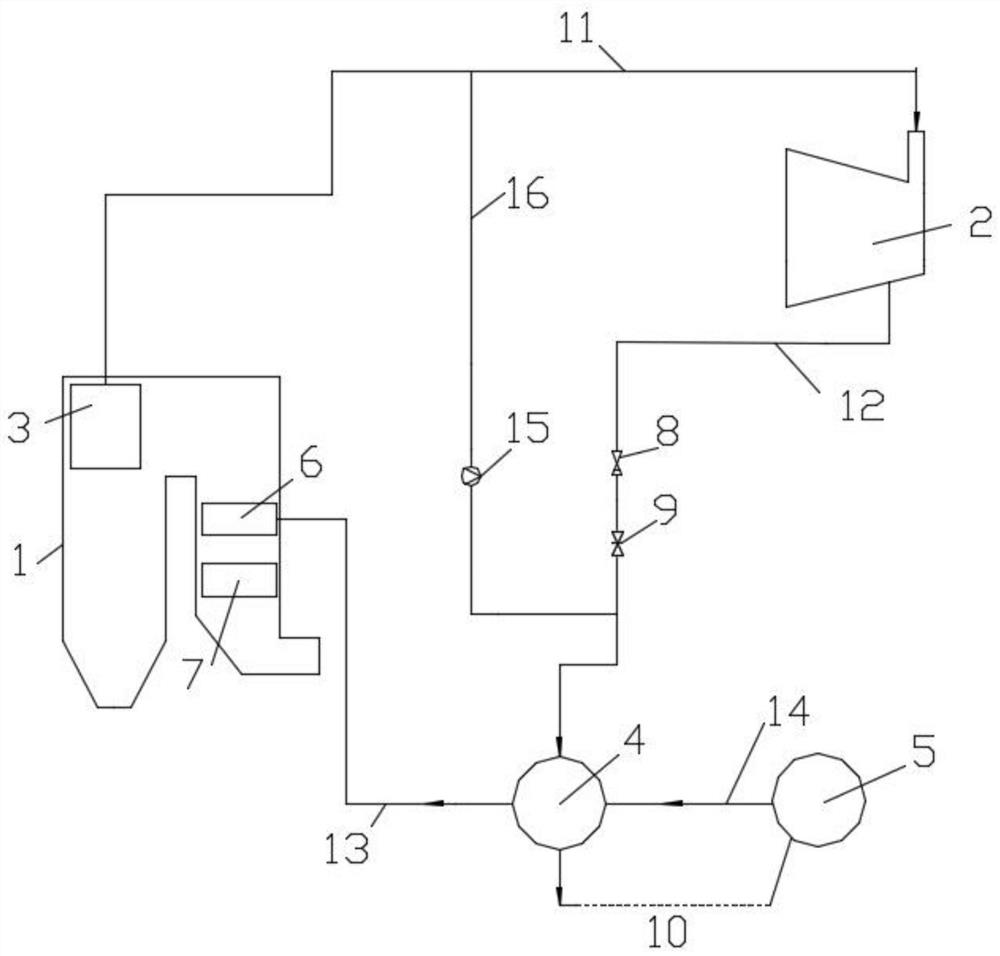

Denitration device with economizer re-circulating system and generator unit

ActiveCN104028104AAvoid boilingSafe and stable operationDispersed particle separationFeed-water heatersLow loadFlue gas

The invention relates to a denitration technology, and discloses a denitration device with an economizer re-circulating system for a boiler. The temperature of a water side of an economizer is raised by using the economizer re-circulating system, so that the flue gas temperature of an outlet of the economizer can be raised under the low-load working condition, and requirements on lowermost ammonia spraying under the full-load working condition are met; the flow of the water side of the economizer keeps unchanged or is slightly increased under the control of a circulating pump of the re-circulating system, so that the phenomenon of boiling on the water side of the economizer is avoided, and the economizer can operate safely and stably.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

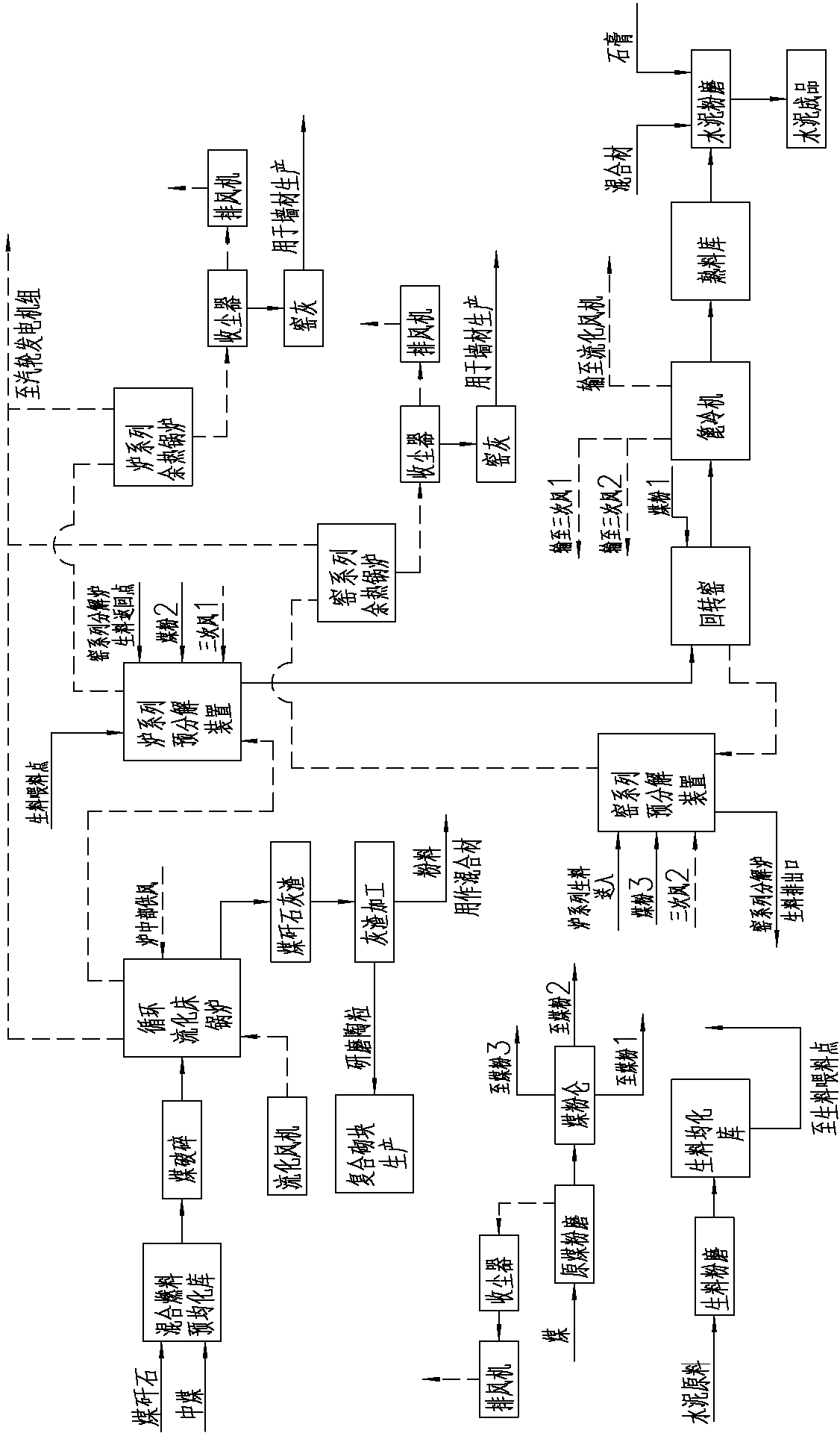

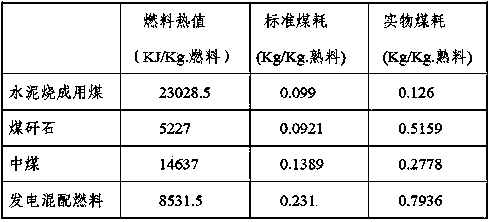

Multi-product cleaning and producing method with coal gangue comprehensive utilization

ActiveCN102703157AEasy to produceAvoid "secondary volatilizationSteam generation heating methodsSolid fuelsCoalPollution

The invention relates to a multi-product cleaning and producing method comprehensive utilization; coal carbon production, power generation by burning coal gangue, cement production, power generation by cement afterheat and wall material production technology are combined in a same industrial symbiont by using industrial symbiosis; optimal configuration between working procedures is realized; processing procedures of raw materials are converted into processing working procedures capable of separating raw materialsand fuels into different material flows and power flows which have different transport directions; mutually beneficial relationship is established between working procedures; a predetermined downstream working procedure is directly capable of digesting ''pollutant'' of an upstream working procedure; each working procedure utilizes different raw material component and different gradient energy source so as to produce multiple products; so that energy and matter flow in a multi-channel manner; and a little-pollution multi-prduct cleaning and producing technology is formed.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

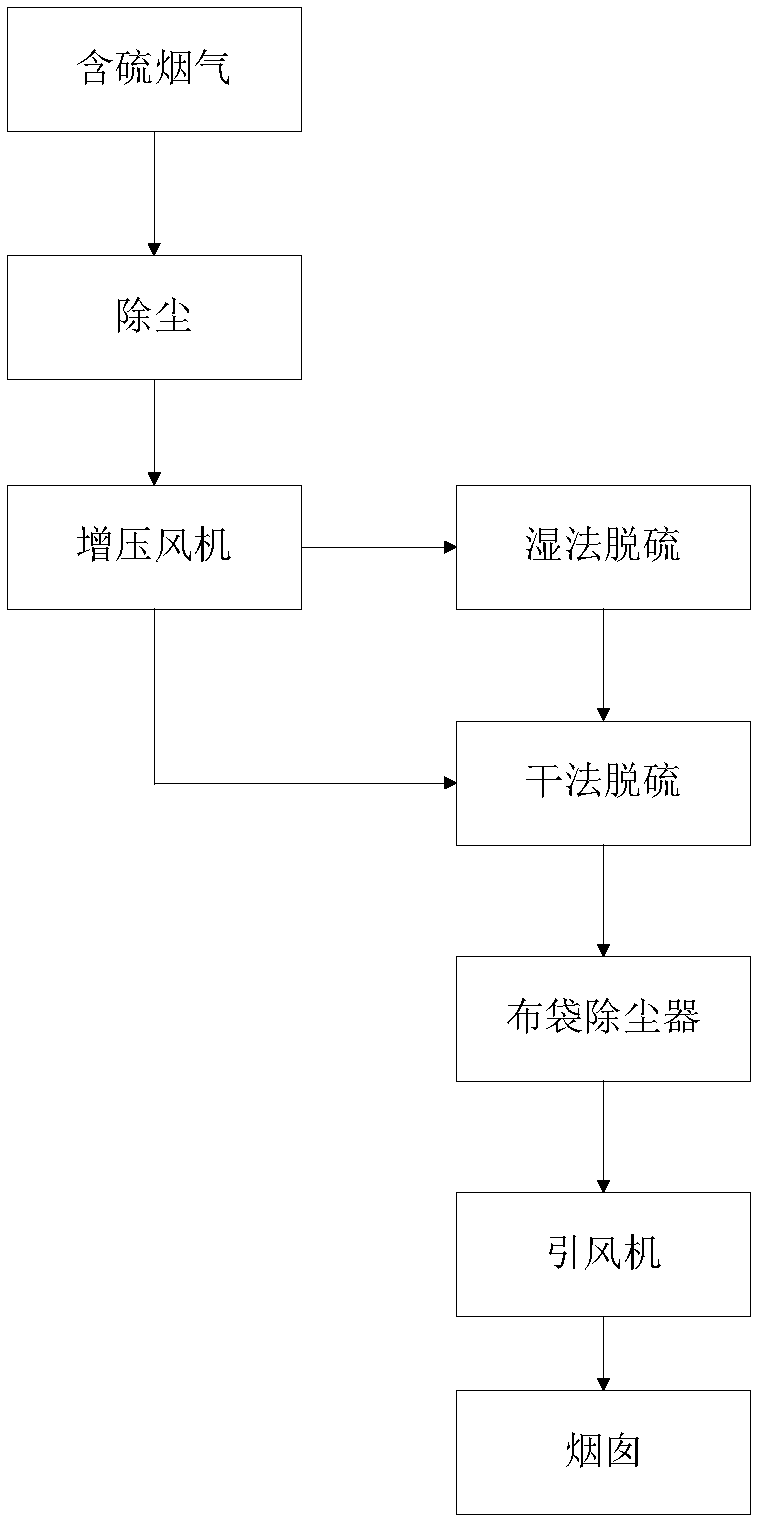

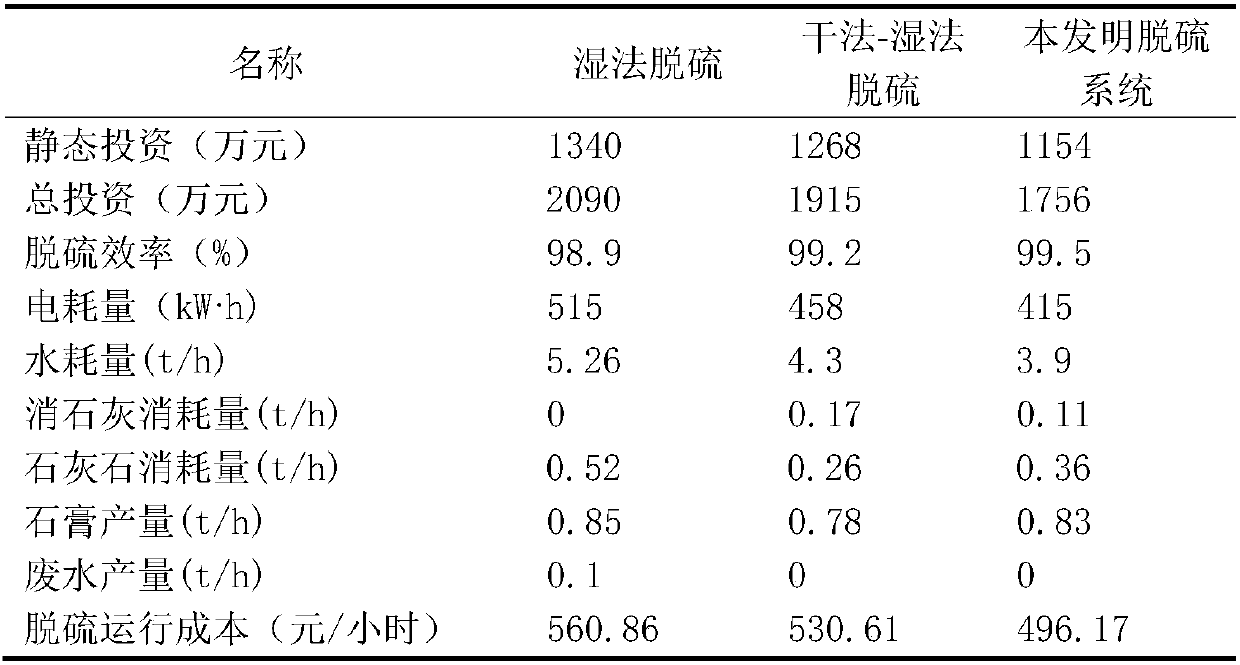

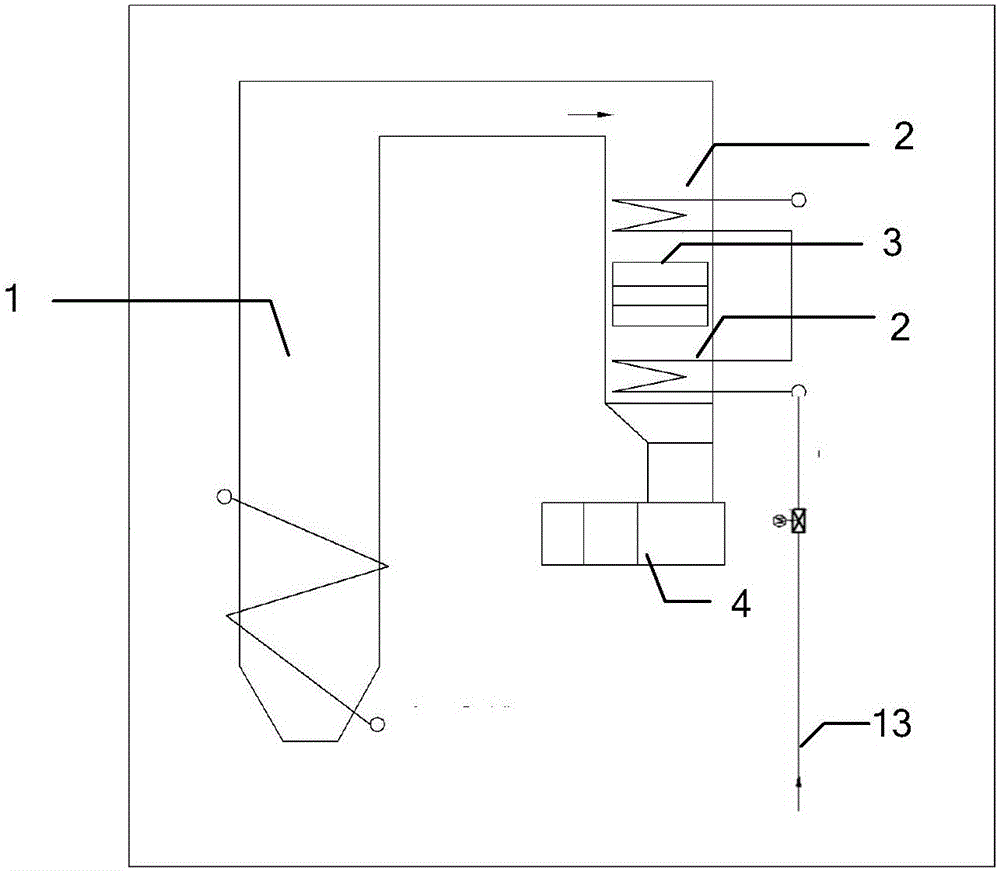

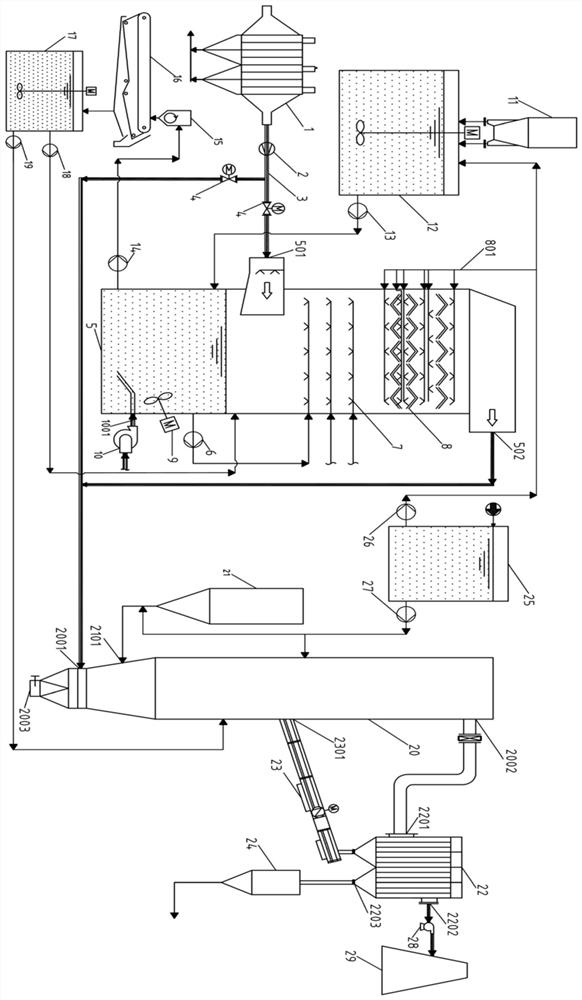

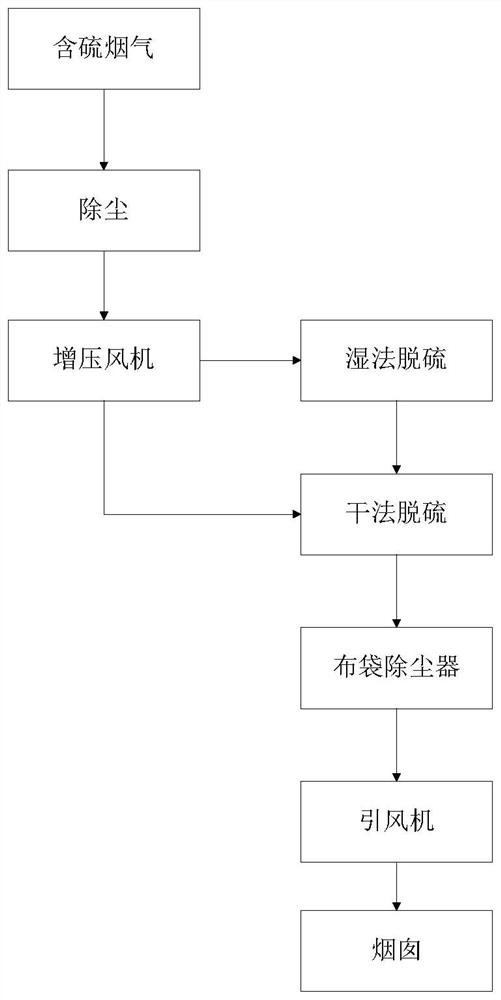

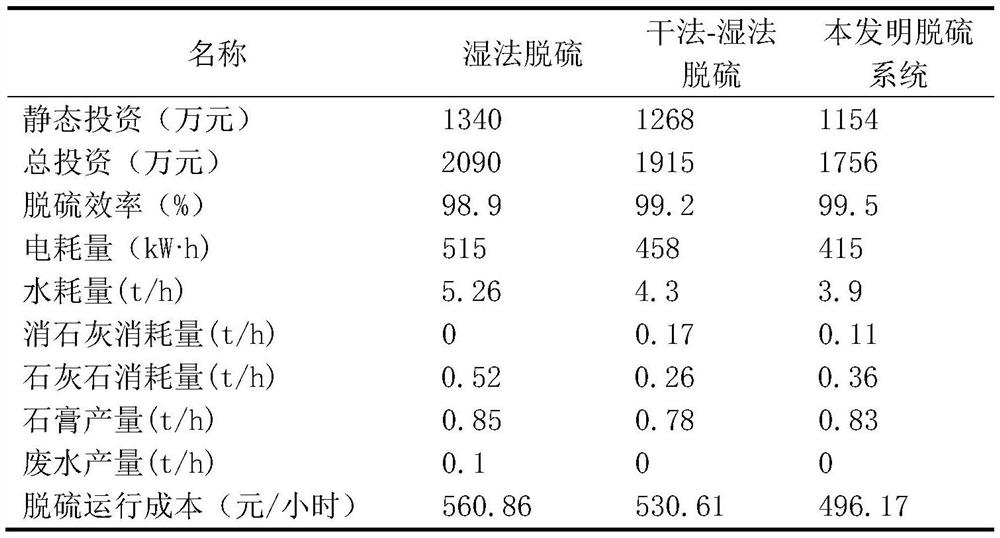

Wet-process and dry-process combined flue gas desulfurization system and desulfurization method

ActiveCN107899408AIncrease flue gas temperatureImprove adaptabilityGas treatmentDispersed particle separationMulti pollutantSulfur containing

The invention discloses a flue gas desulfurization system and a desulfurization method thereof. The desulfurization system comprises a dust-removing and pressurizing system, a wet-process desulfurization system and a dry-process desulfurization system, wherein the outlet end of the dust-removing and pressurizing system is connected with the inlet ends of the wet-process desulfurization system andthe dry-process desulfurization system; and the outlet end of the wet-process desulfurization system is connected with the inlet end of the dry-process desulfurization system. When the flue gas desulfurization system and the desulfurization method thereof are used for desulfurizing sulfur-containing flue gas, a variety of pollutants can be synergistically removed and the environmental problems caused by discharge from a wet chimney are fundamentally eliminated.

Owner:NANJING NORMAL UNIVERSITY

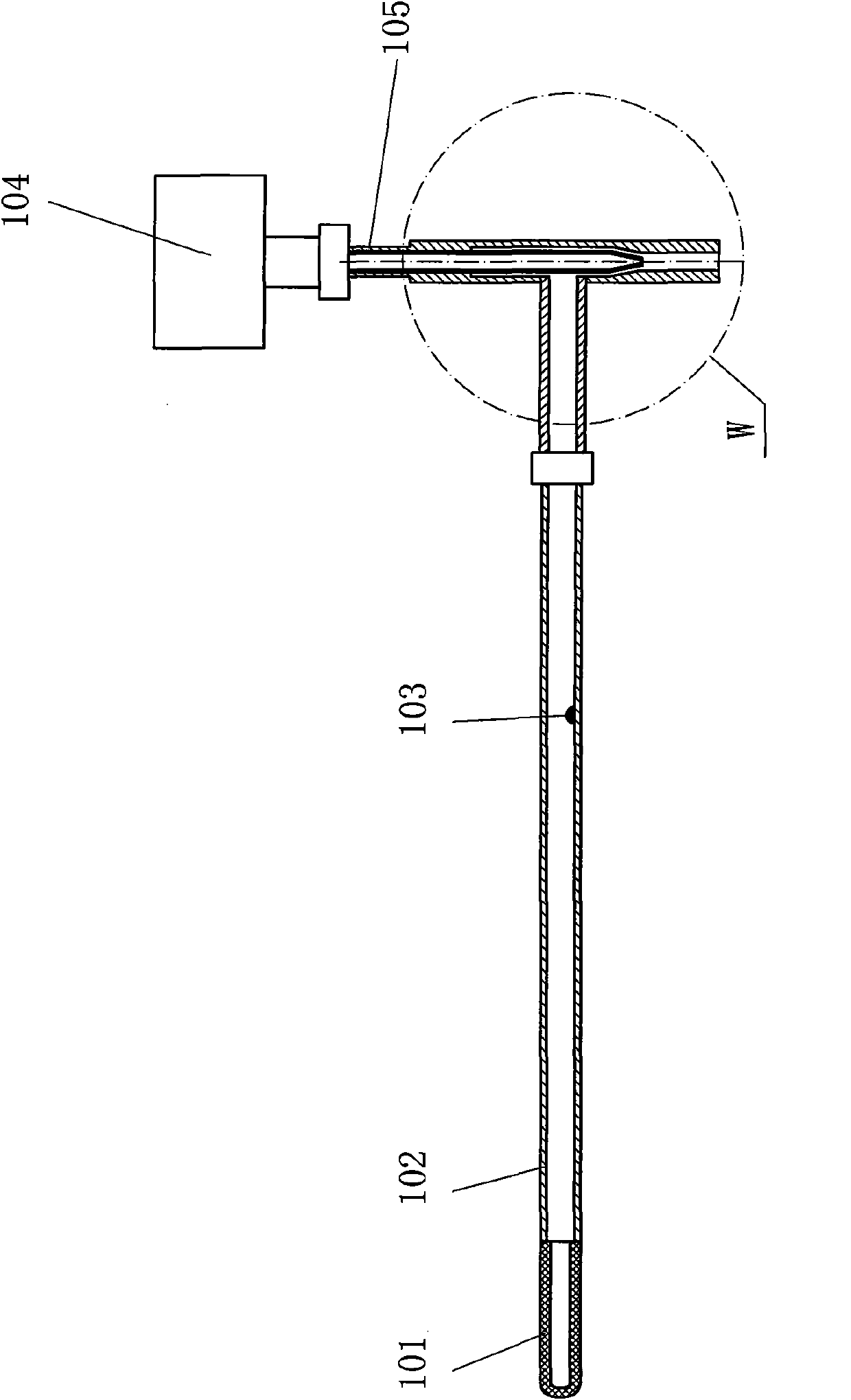

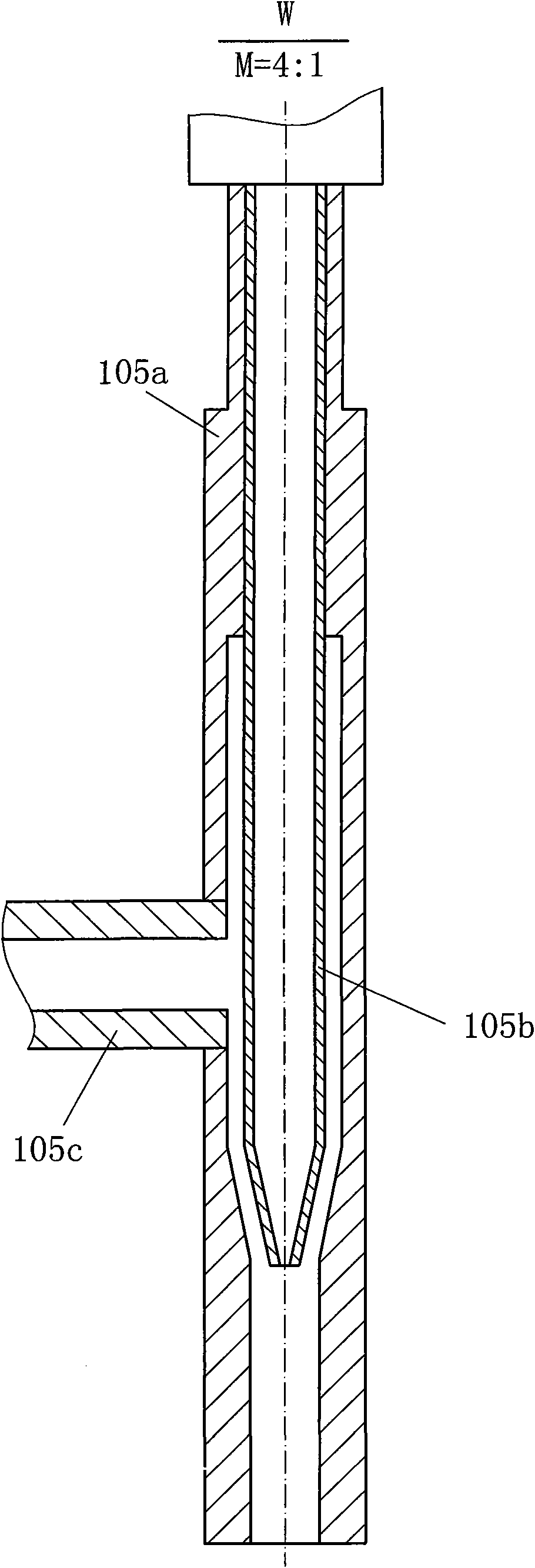

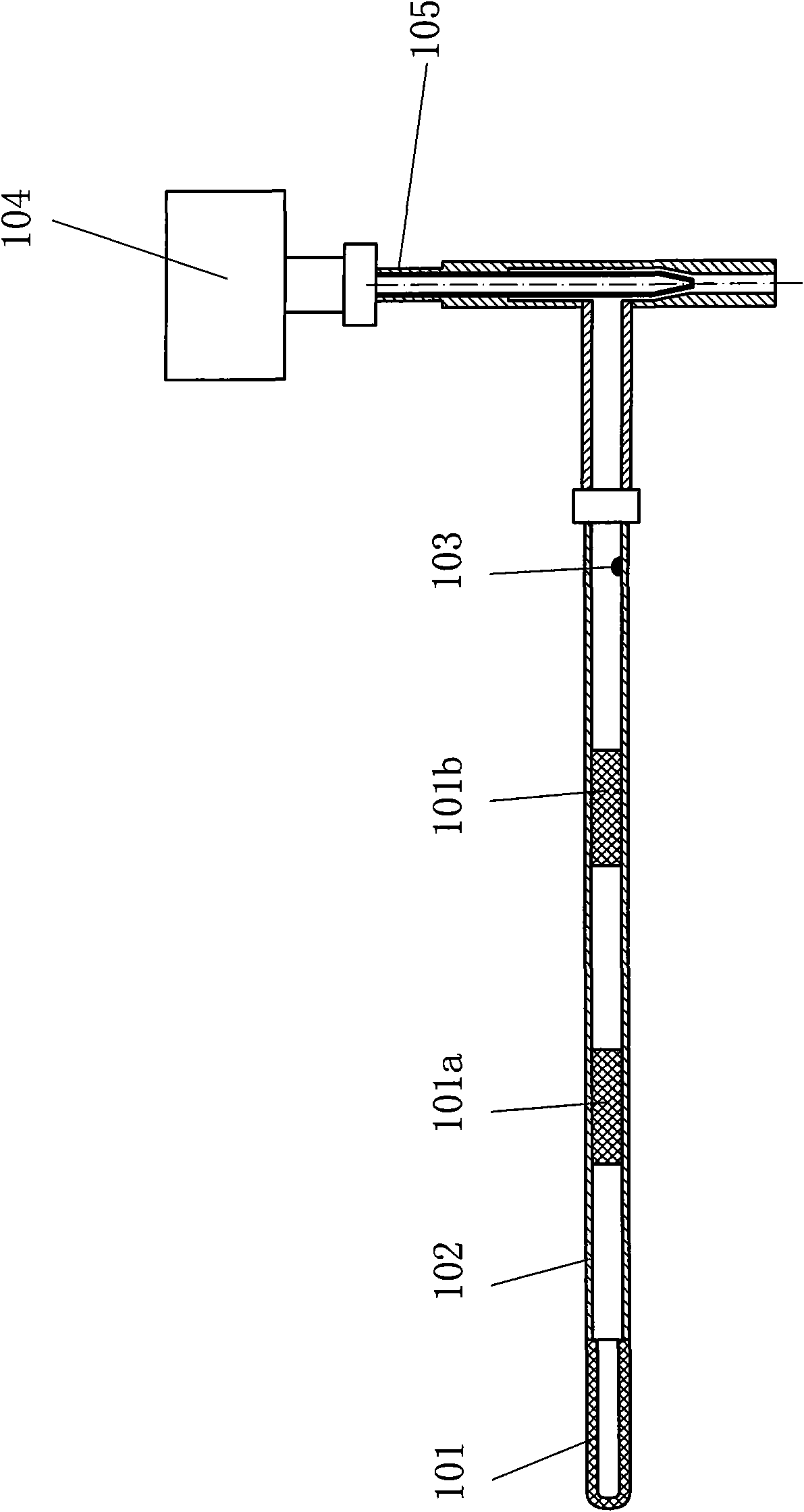

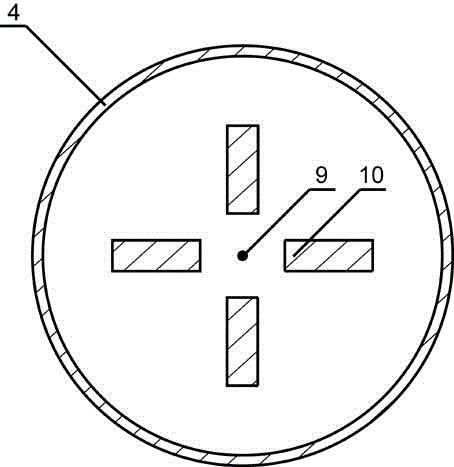

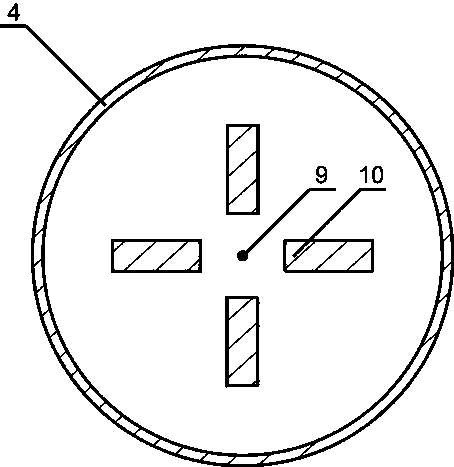

Flue gas sampling device

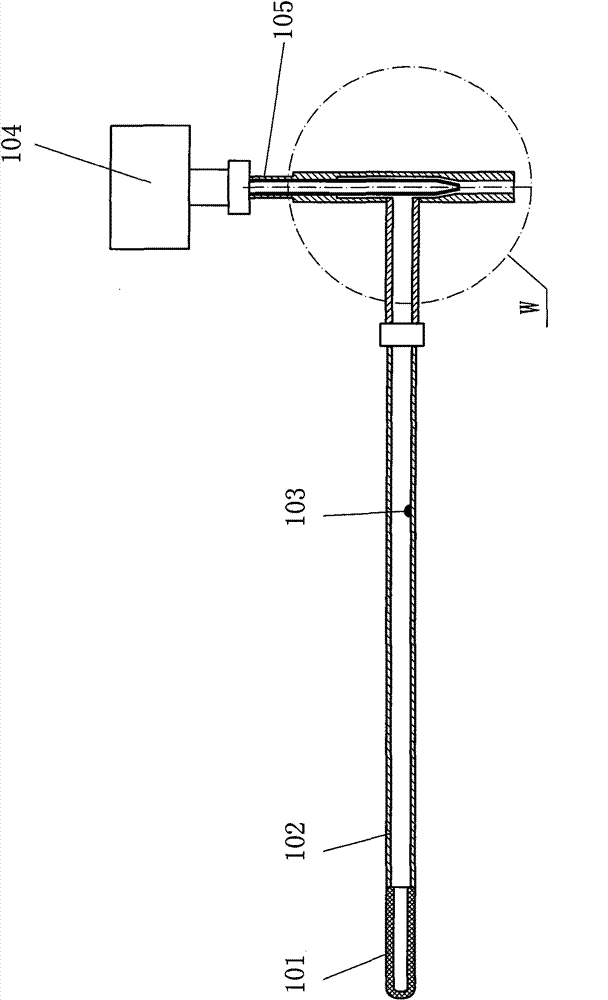

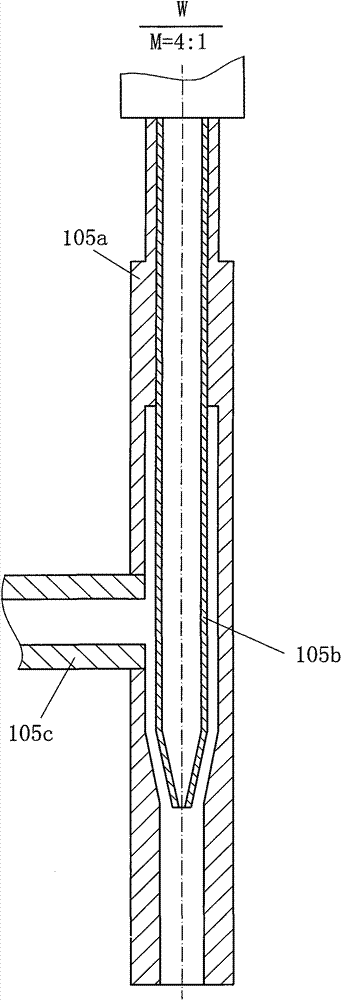

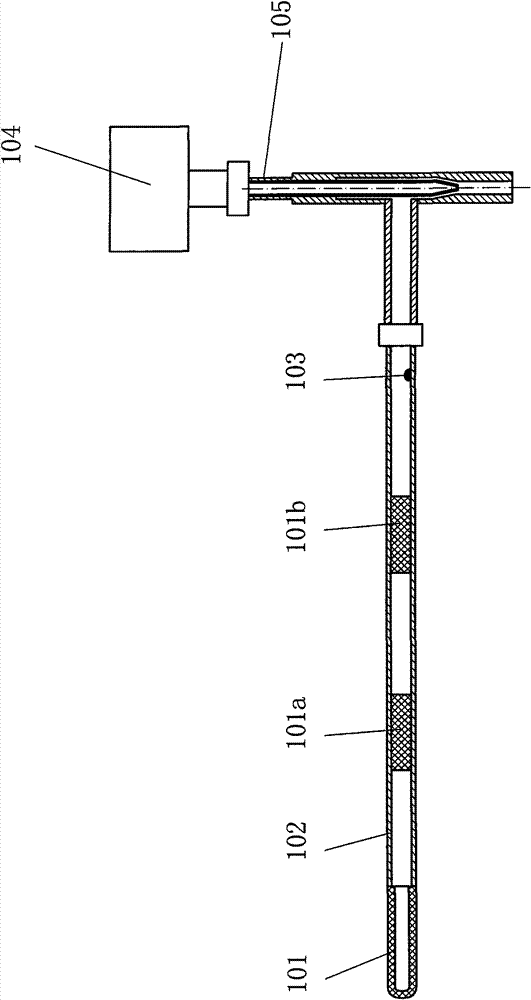

ActiveCN102004047AWork reliablyNo cloggingWithdrawing sample devicesPreparing sample for investigationSpray nozzleAirflow

The invention relates to the technical field of sampling, detection and analysis of gas and discloses a flue gas sampling device. For solving the problems of short service life and the like of a sampling pump, the invention provides the following technical scheme. The flue gas sampling device is characterized in that a driving mechanism comprises a gas source machine (104) for providing a gas source and a jet injector (105) for driving flue gas to flow in a drainage manner, wherein air current provided by the gas source machine (104) enters a spray nozzle (105b) from top to bottom and is sprayed out at the lower retracted part of the spray nozzle (105b) so as to form a vacuum trend, thereby attracting sampling gas to enter from the second gas inlet end of the jet injector (105); and two strands of air current is mixed in a hollow-out cavity and is exhausted to the atmosphere through the gas outlet end of the jet injector (105). The invention has the benefits that the jet injector is provided with a movable component without the maintenance, repair and replacement and can work reliably for a long term; the pressure and the flow speed of the sampling gas are stable; the phenomenon that fine particles are blocked can be avoided; and the jet injector made of all metal can bear high temperature of the flue gas.

Owner:上海北分科技股份有限公司

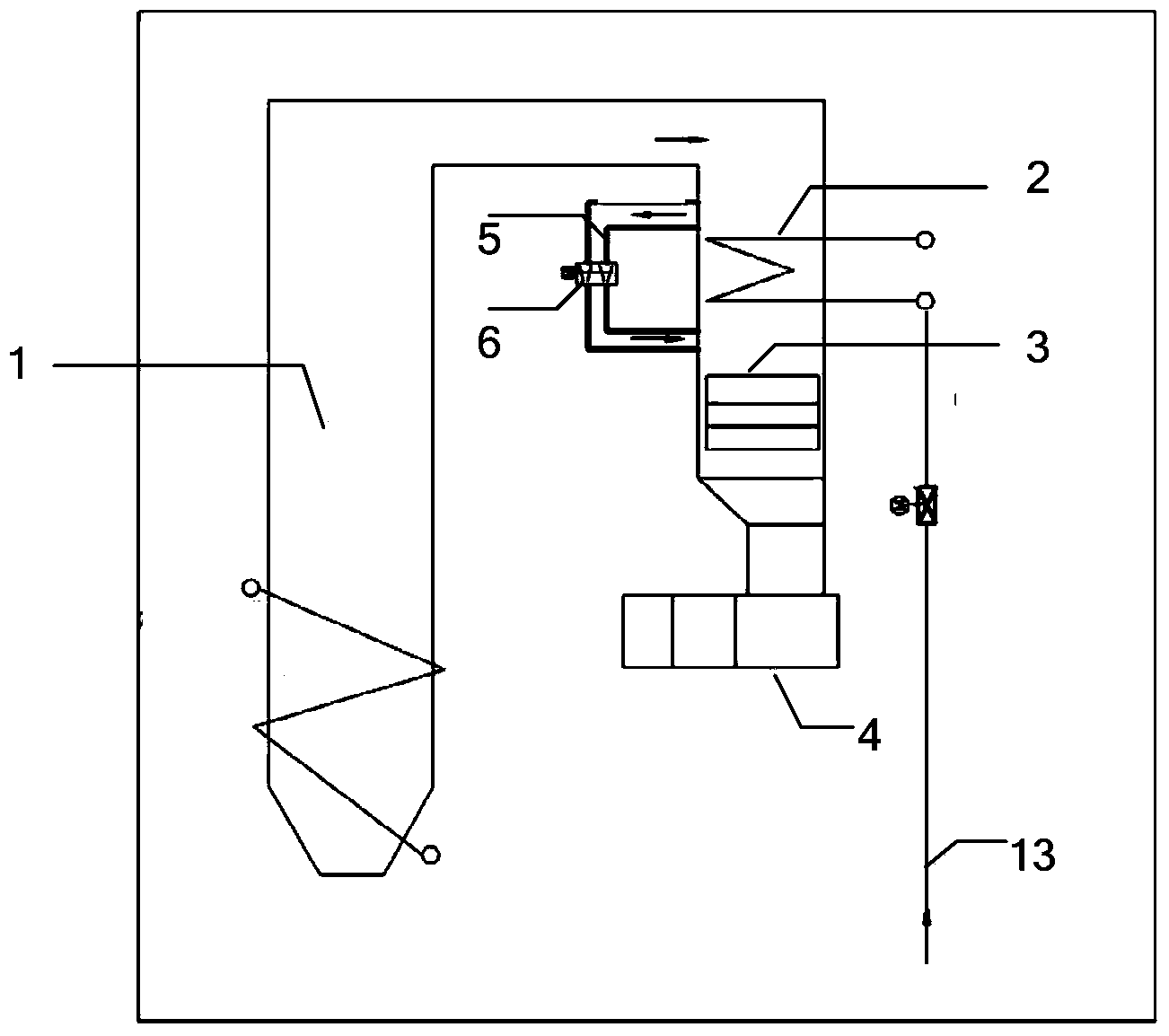

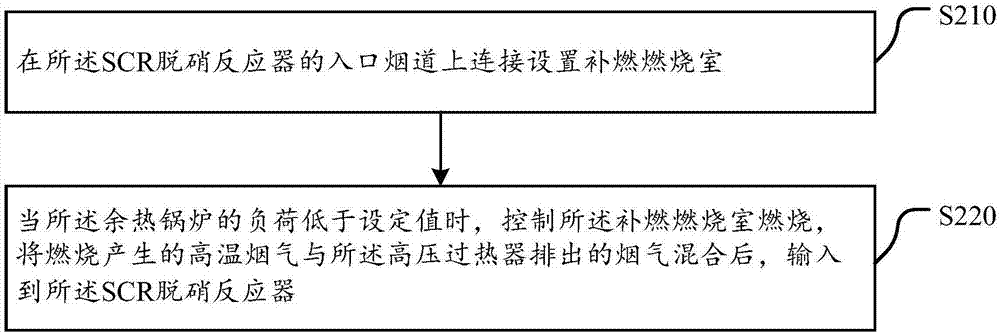

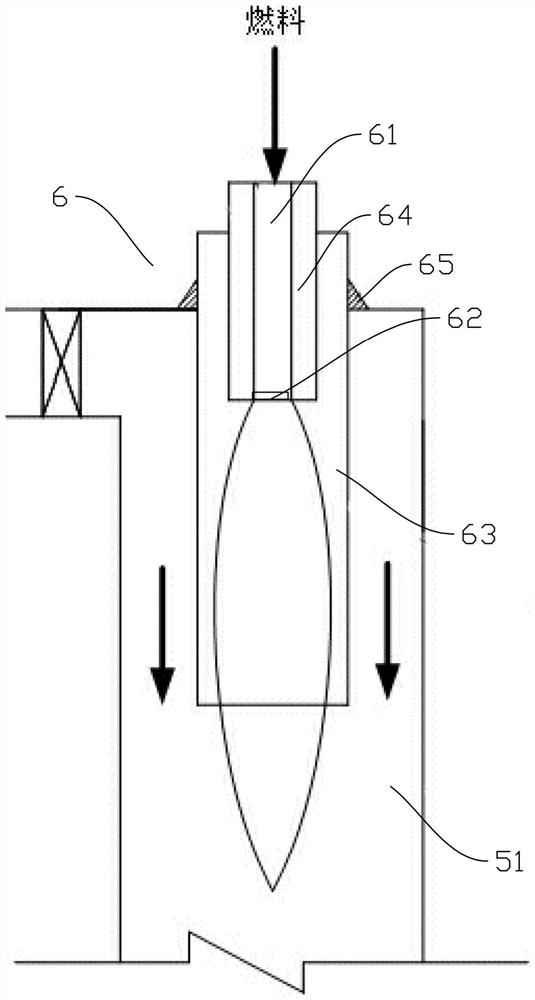

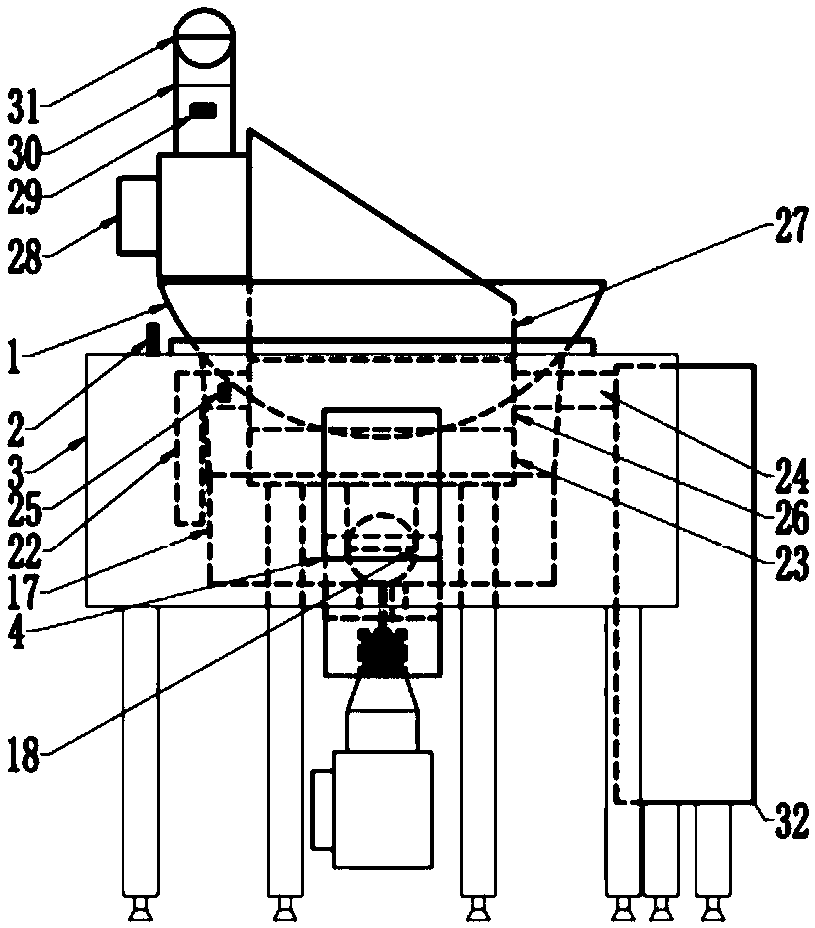

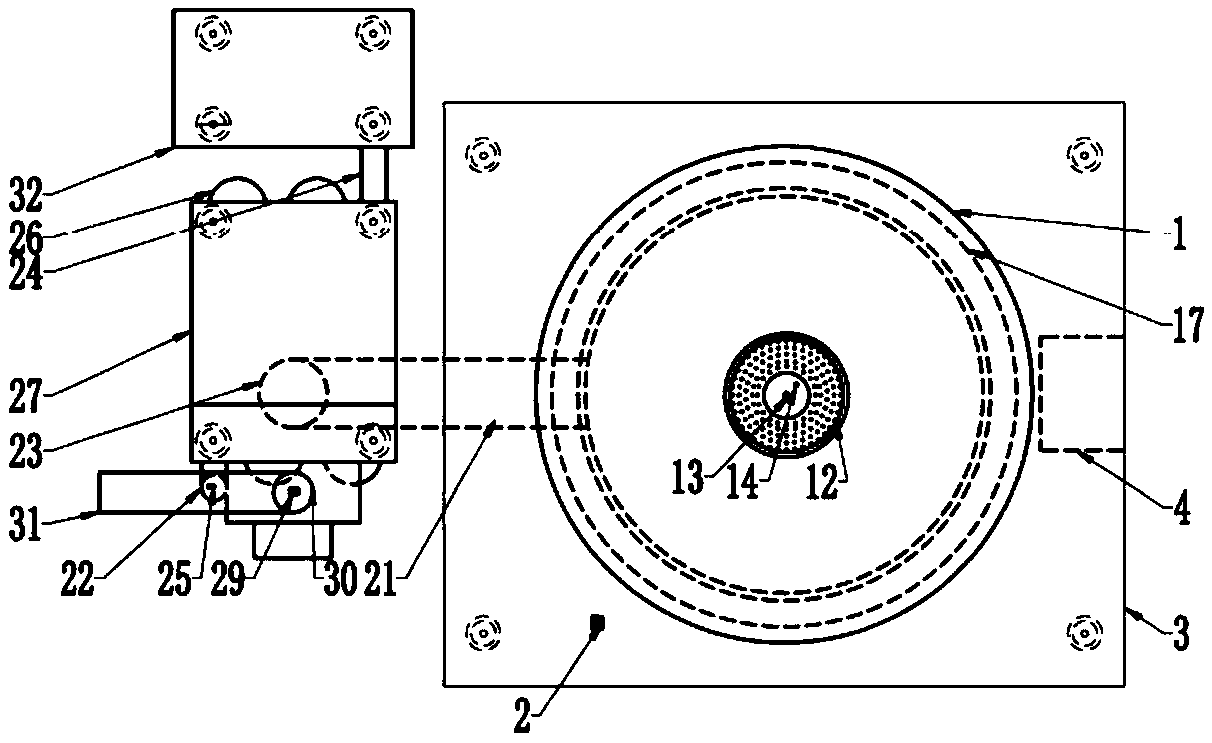

Adjusting device and method for selective catalytic reduction (SCR) flue gas denitration efficiency of waste heat boiler

InactiveCN107575882AIncrease flue gas temperatureImprove denitrification efficiencyFuel supply regulationDispersed particle separationSuperheaterCombustion chamber

The invention discloses an adjusting device and method for selective catalytic reduction (SCR) flue gas denitration efficiency of a waste heat boiler. An SCR denitration reactor is connected to the back of a high-pressure superheater of the waste heat boiler. The adjusting device comprises an aftercombustion combustion chamber, wherein a flue gas outlet of the aftercombustion combustion chamber isconnected to an inlet flue of the SCR denitration reactor. When the load of the waste heat boiler is lower than a set value, the aftercombustion combustion chamber is opened and conducts combustion,and high-temperature flue gas discharged after combustion is mixed with flue gas discharged from the high-pressure superheater and then delivered into the SCR denitration reactor. The SCR denitrationreactor is connected to the back of the high-pressure superheater of the waste heat boiler, the aftercombustion combustion chamber is additionally arranged, when a unit operates in the low load, aftercombustion is conducted, a high-temperature combustion product and flue gas of an inlet of the SCR denitration reactor are mixed, the flue gas temperature is increased, the SCR flue gas denitration efficiency is improved, the concentration of NOx in flue gas at an outlet of the waste heat boiler is reduced, and the discharging standard exceeding condition under the low load working condition is avoided.

Owner:广州智光节能环保有限公司

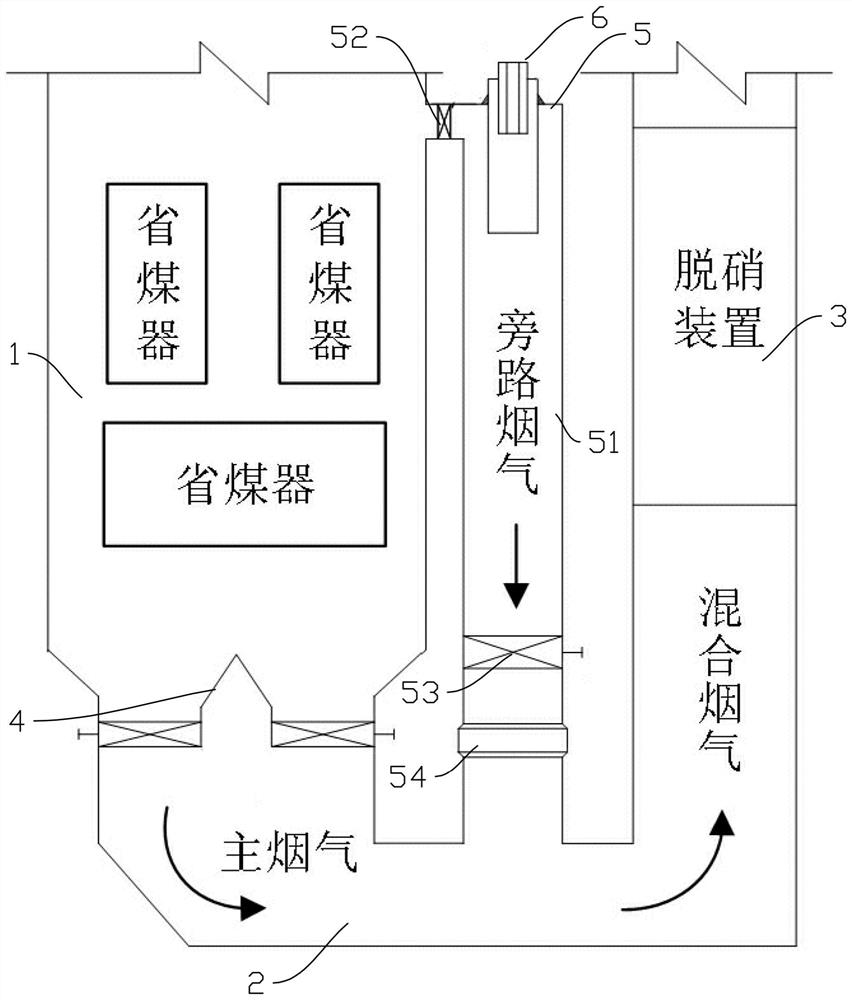

System and method for low-load denitration of boiler

PendingCN112050247AReduce minimum steady fire loadIncrease effective hoursEmission preventionDamper arrangementPhysicsFlue

The invention discloses a system and method for a low-load denitration of a boiler. The system comprises a hearth outlet flue, a low-temperature superheater flue, a low-temperature reheater flue, a bypass flue, an economizer flue and a denitration flue. The bypass flue is a bypass of a low-temperature reheater, a low-temperature superheater and an economizer. According to the method, mainly, whenthe smoke temperature of a denitration inlet is too low, some smoke enters the denitration inlet through the bypass flue, thus the smoke temperature of the denitration inlet rises, and thus the denitration system can achieve normal investment under the low-load circumstance of the boiler. The system and the method have environment-friendly and energy-saving effects, adjusting flexibility of a unitcan be improved, the utilization rate of the unit is increased, and economic benefits of the unit are increased.

Owner:XIAN THERMAL POWER RES INST CO LTD

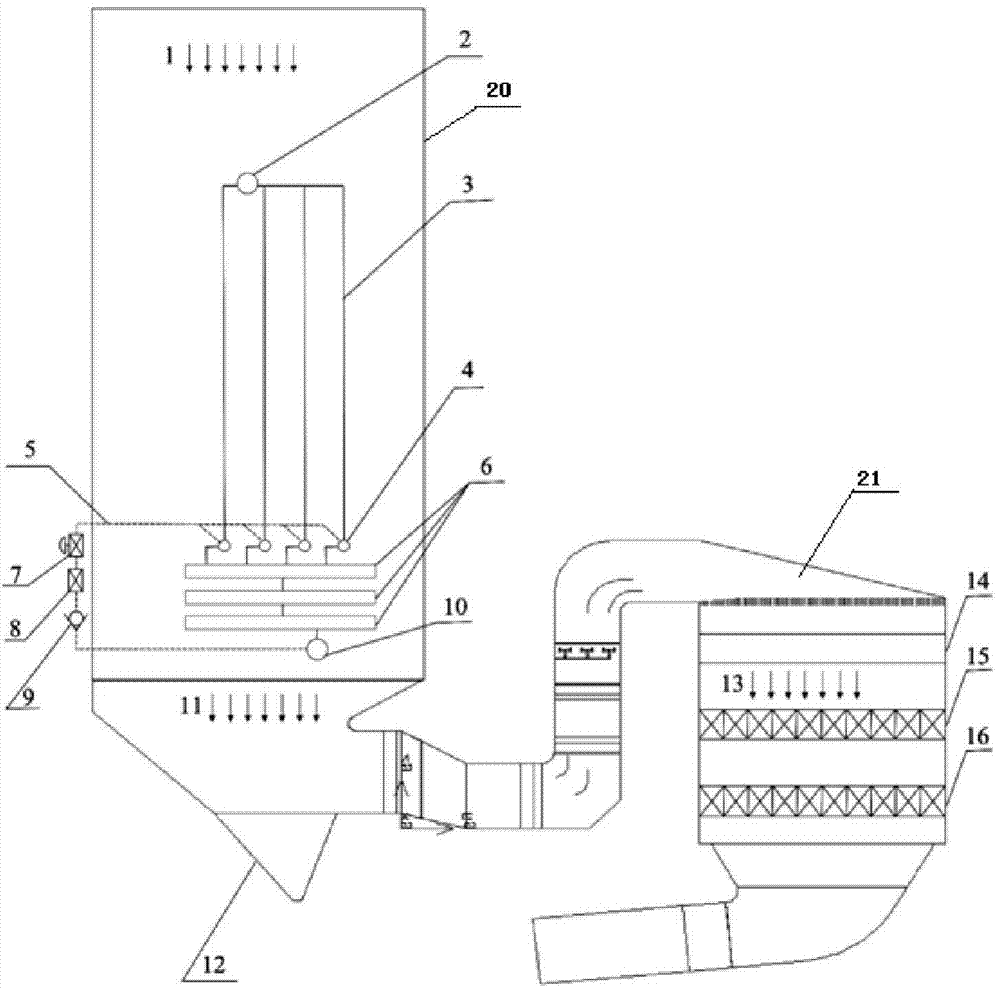

Compact distributed coal powder boiler with SCR (selective catalytic reduction device)

A compact distributed coal powder boiler with an SCR (selective catalytic reduction device) comprises a boiler hearth in integral n shape arrangement, a horizontal flue and a tail flue; an overheater is arranged at the upside position in the boiler hearth; an outlet of the overheater is connected with a high-temperature coal economizer arranged in the horizontal flue; a steering chamber is connected in front of the high-temperature coal economizer; a high-temperature air preheater, an SCR reactor, a low-temperature coal economizer and a low-temperature air preheater are sequentially arranged in the tail flue behind the steering chamber from top to bottom; a denitration agent spraying position is arranged in front of the high-temperature air preheater. According to the compact distributed coal powder boiler with the SCR, the manufacturing cost and the occupation area of the boiler are saved and the denitration efficiency of the SCR is further improved.

Owner:山西新唐工程设计股份有限公司

Wet-process deacidification flue gas white smoke removing system applied to hazardous waste incineration and application method of wet-process deacidification flue gas white smoke removing system

InactiveCN108151050AReduce flue gas temperatureIncrease flue gas temperatureLighting and heating apparatusCombustion technology mitigationFlue gasEngineering

The invention provides a wet-process deacidification flue gas white smoke removing system applied to hazardous waste incineration and an application method of the wet-process deacidification flue gaswhite smoke removing system. The system can be used for effectively removing white smoke, can also protect equipment from corrosion, prolongs the service life and reduces energy consumption; the system comprises a washing tower and a steam heater; the steam heater is connected with a chimney; the system also comprises a smoke-smoke heat exchanger which communicates with flue gas; and the smoke-smoke heat exchanger is connected with the steam heater after being cyclically connected with the washing tower.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

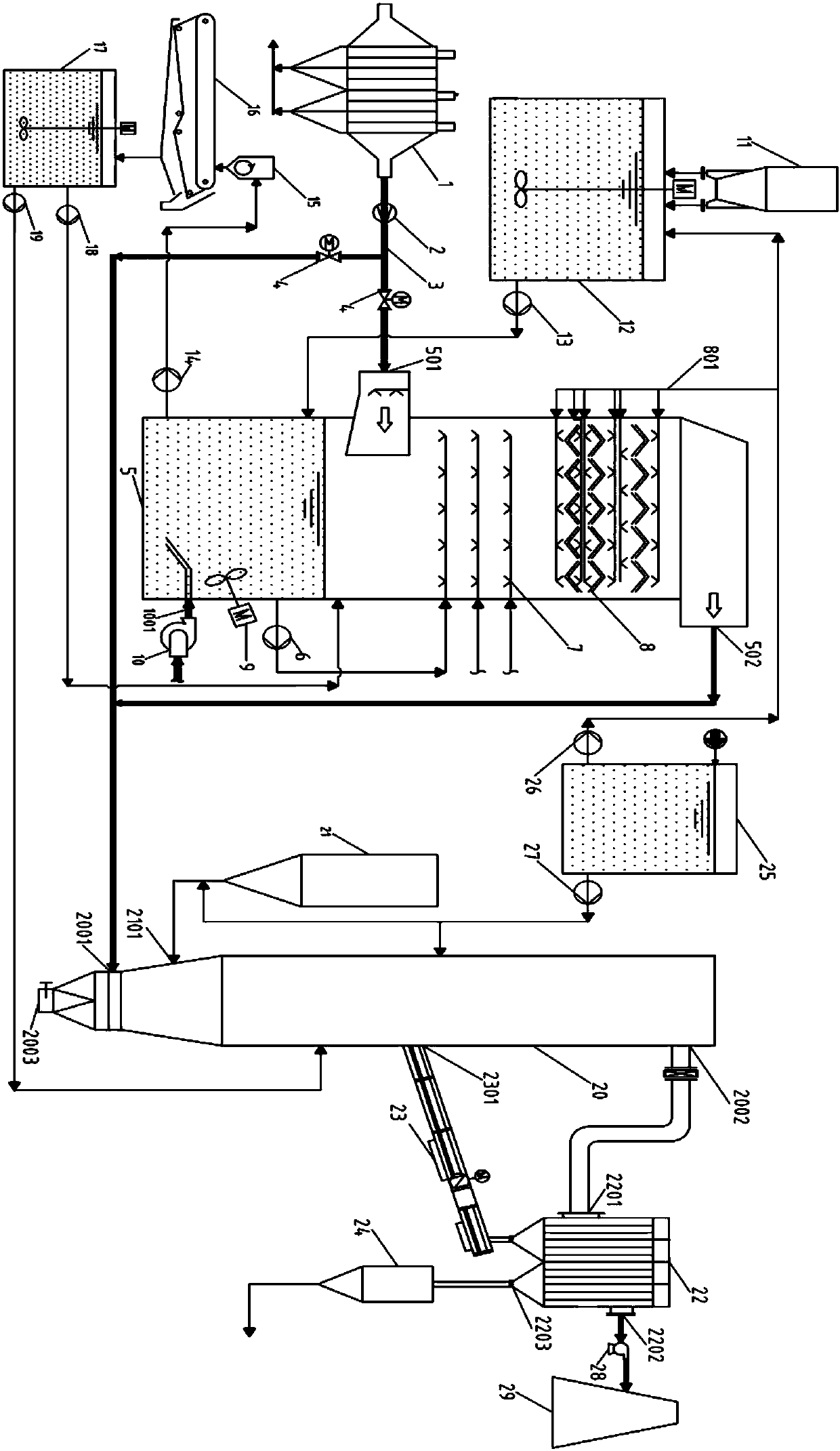

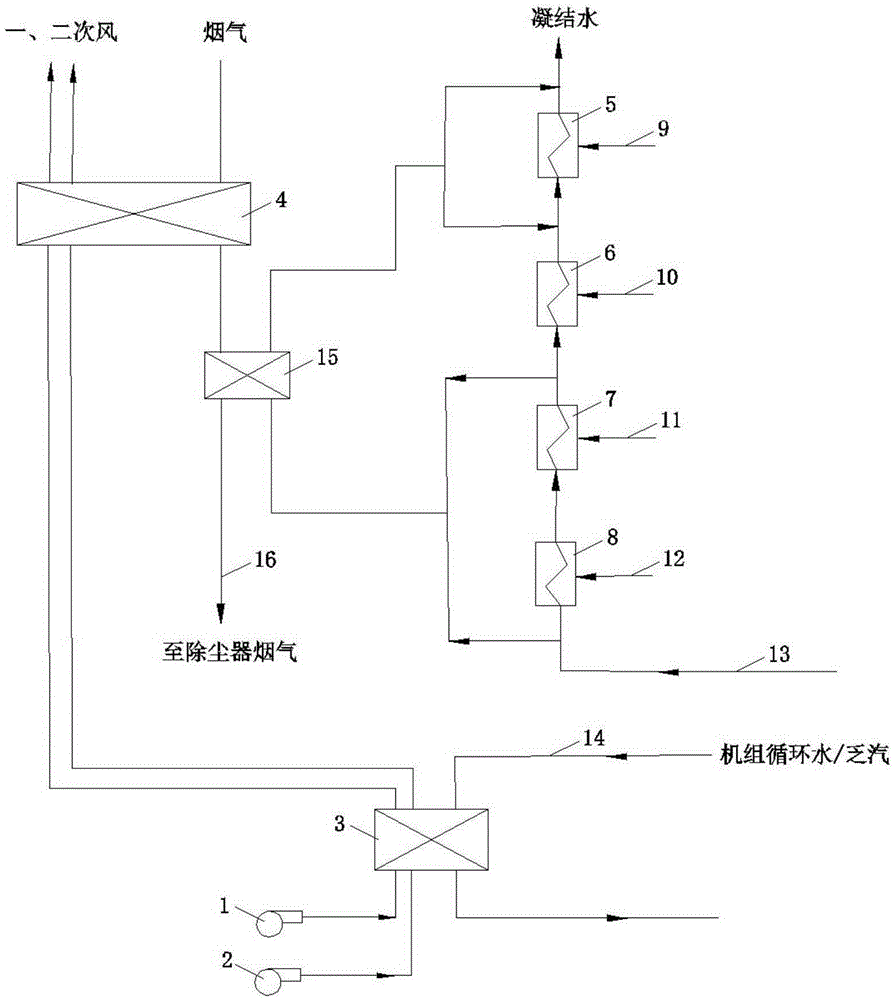

Deep coupling utilization system for turbine steam exhaust waste heat and boiler flue gas waste heat

InactiveCN105402761AIncrease flue gas temperaturePrevent Low Temperature CorrosionIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir heaterFlue gas

The invention aims to provide a deep coupling utilization system for turbine steam exhaust waste heat and boiler flue gas waste heat in order to improve the heat efficiency of a generator set, lower the energy consumption and reduce the pollution. The deep coupling utilization system for the turbine steam exhaust waste heat and the boiler flue gas waste heat comprises a primary fan and a secondary fan. An exhaust port of the primary fan is connected to an air inlet of a primary air conveying pipeline, and the middle of the primary air conveying pipeline penetrates through a primary air heat exchange channel of an air pre-heater. An exhaust port of the secondary fan is connected to an air inlet of a secondary air conveying pipeline, and the middle of the secondary air conveying pipeline penetrates through a secondary air heat exchange channel of the air pre-heater. A flue gas channel is formed in one side of the air pre-heater and is connected to the middle of a flue in series, and a dust remover is arranged at the outlet end of the flue. An air heater is connected to the parts, located at the air inlet section of the air pre-heater, of the primary air conveying pipeline and the secondary air conveying pipeline in series.

Owner:中国大唐集团科学技术研究总院有限公司

Denitrification device and generator set with economizer recirculation system

ActiveCN104028104BAvoid boilingSafe and stable operationDispersed particle separationFeed-water heatersFlue gasEngineering

The invention relates to a denitration technology, and discloses a denitration device with an economizer re-circulating system for a boiler. The temperature of a water side of an economizer is raised by using the economizer re-circulating system, so that the flue gas temperature of an outlet of the economizer can be raised under the low-load working condition, and requirements on lowermost ammonia spraying under the full-load working condition are met; the flow of the water side of the economizer keeps unchanged or is slightly increased under the control of a circulating pump of the re-circulating system, so that the phenomenon of boiling on the water side of the economizer is avoided, and the economizer can operate safely and stably.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

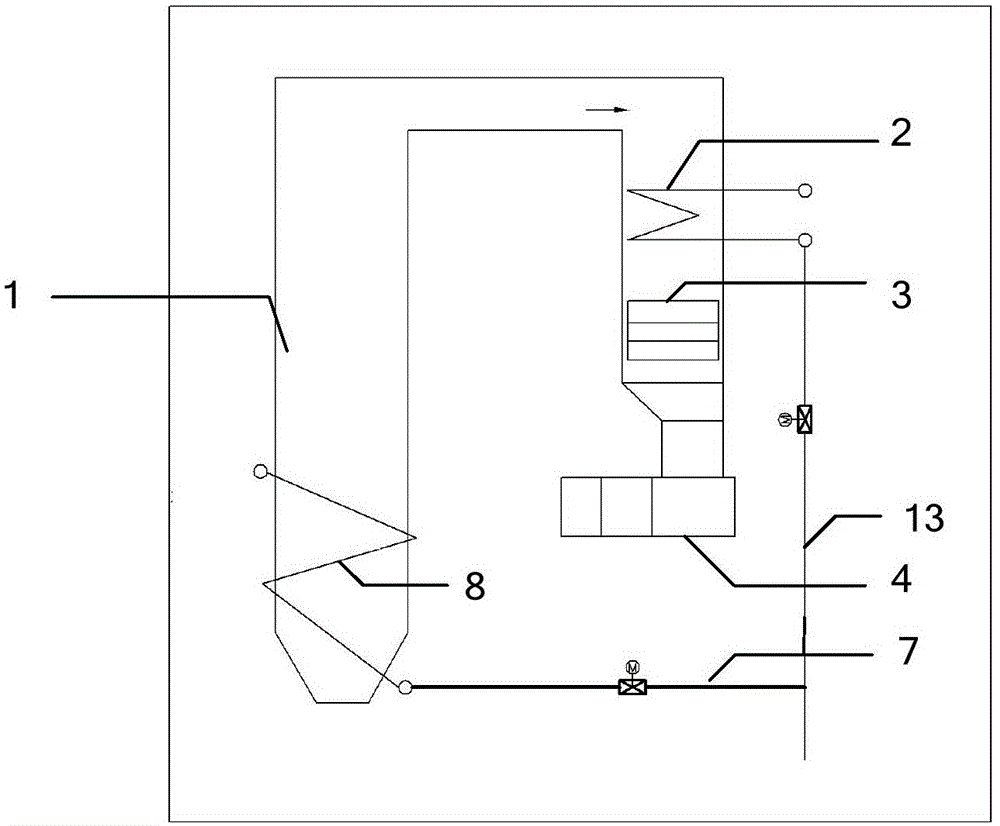

System and method capable of realizing zero discharge of desulfurization wastewater

PendingCN111943424AEfficient recyclingReduce usageSludge treatmentWaste water treatment from gaseous effluentsActivated carbonWastewater

The invention provides a system and method capable of realizing zero discharge of desulfurization wastewater. The discharge system comprises a pretreatment unit and an evaporation unit, wherein the pretreatment unit is used for reducing the hardness and impurity content of to-be-treated wastewater to obtain pretreated wastewater; the evaporation unit comprises a heat source system, a flash evaporation system and a flue evaporation system, wherein an air outlet of the heat source system communicates with an air inlet of the flash evaporation system, a liquid inlet of the flash evaporation system communicates with a liquid outlet of the pretreatment unit, and an air outlet of the flash evaporation system communicates with an inlet of the flue evaporation system; and the pretreated wastewaterenters the flash evaporation system, is in contact with a heat source provided by the heat source system for countercurrent evaporation, and then is subjected to secondary evaporation in the flue evaporation system. The system provided by the invention can utilize waste heat generated in the desorption process of activated carbon, thereby lowering operating cost and investment cost and ensuring stable operation of the system.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

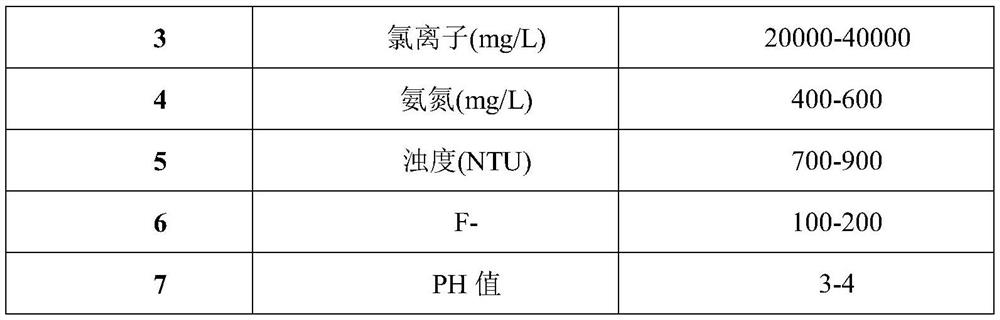

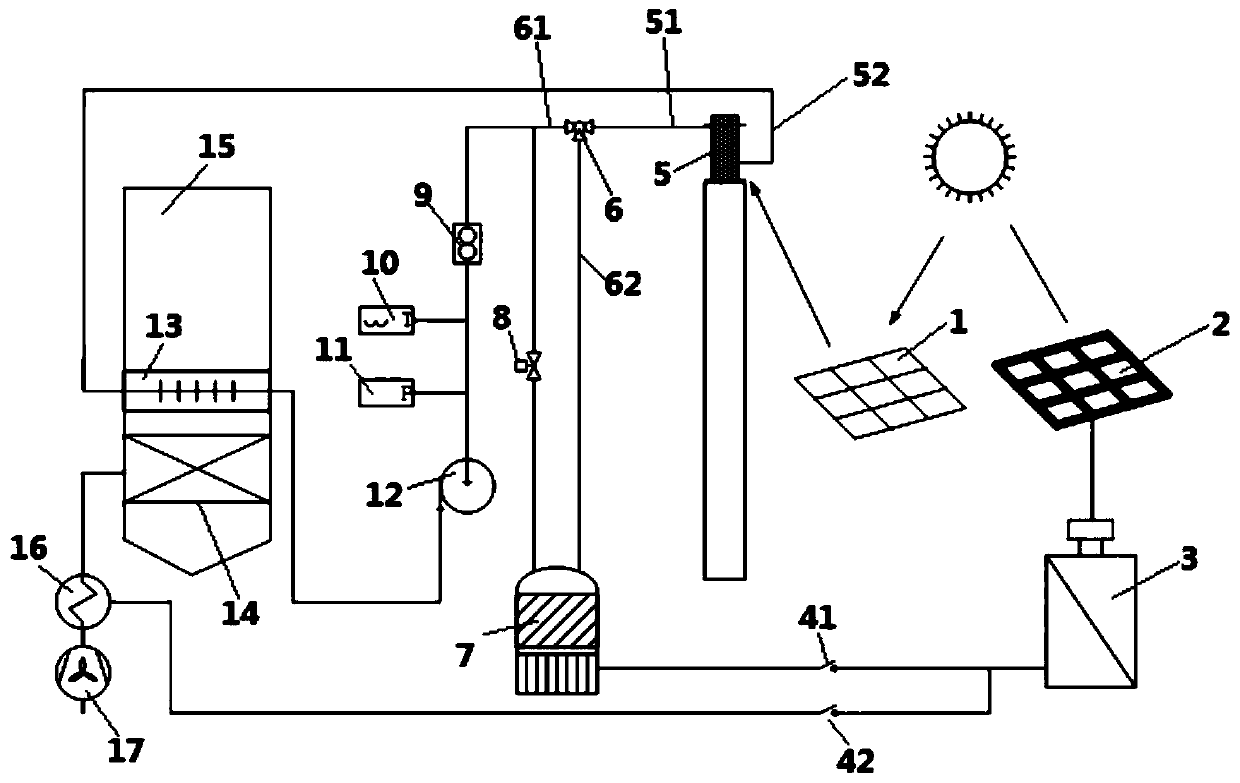

Heat conduction oil heat storage and boiler low temperature corrosion prevention device and working method

PendingCN111238039ANo reduction in thermal efficiencyIncrease temperatureSolar heating energyBatteries circuit arrangementsAir preheaterCells panel

The invention discloses a heat conduction oil heat storage and boiler low temperature corrosion prevention device and a working method. The device comprises a photovoltaic cell panel, wherein the photovoltaic cell panel is connected with a storage battery, the output end of the storage battery is connected with a heat conduction oil tank used for heating heat conduction oil or insulating the heatconduction oil, and in addition, a solar heat collector is arranged to provide heat for the heat conduction oil. An outlet of the heat conduction oil tank is connected with a heat conduction oil inletof an oil-smoke heat exchanger. The oil-smoke heat exchanger penetrates through a tail flue, and an air preheater is also arranged in the tail flue. The oil-smoke heat exchanger is located at the smoke inlet end of the air preheater, smoke absorbing heat conduction oil heat enters the air preheater, the device directly exchanges heat through the heat conduction oil and the smoke in the tail fluewithout contacting with the smoke, other structures of a boiler do not need to be adjusted, and expensive materials are not used for corrosion prevention. The heat conduction oil heat storage and boiler low temperature corrosion prevention device is low in cost, few in transformation, low in transformation cost, short in implementation period, simple in structure and capable of easily achieving industrialization.

Owner:HUANENG CLEAN ENERGY RES INST

Horizontal gas corner tube boiler

InactiveCN110822402AUniform temperatureLittle fluctuation of steam temperatureBoiler drums/headersSteam superheatersCombustorSuperheater

The invention provides a horizontal gas corner tube boiler, and relates to the technical field of boiler equipment. The horizontal gas corner tube boiler comprises a hearth, a superheater, an evaporator, a denitration box and an economizer which are horizontally connected in sequence, wherein the hearth, the superheater and the evaporator are all wrapped in a membrane type water cooling wall whichis formed by splicing flat steel and a light tube in a sealing mode; the membrane type water cooling wall is connected with the denitration box and the economizer through a boiler flue; the membranetype water cooling wall is connected to a water circulation pipe cage; and the superheater is arranged on the outer side of a rear wall of the hearth, and a combustor is mounted on a front wall of thehearth. According to the horizontal gas corner tube boiler, the problem that the heat of a corner tube boiler in the prior art cannot be fully and efficiently utilized is solved.

Owner:SICHUAN CHUANGUO BOILER

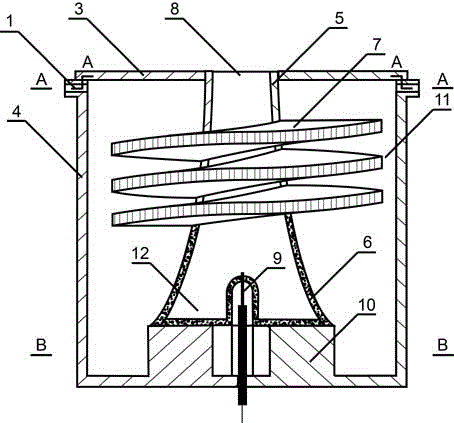

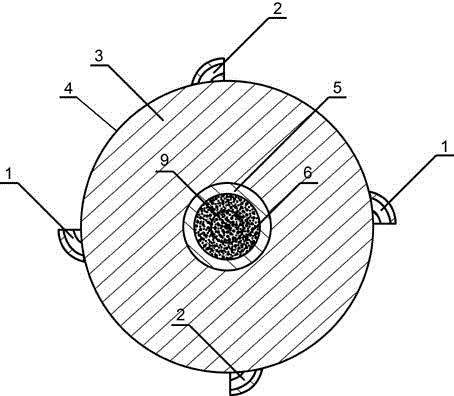

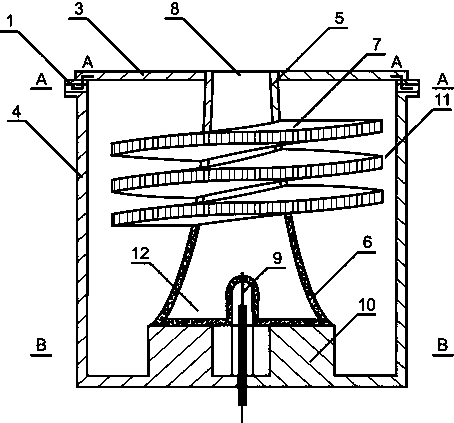

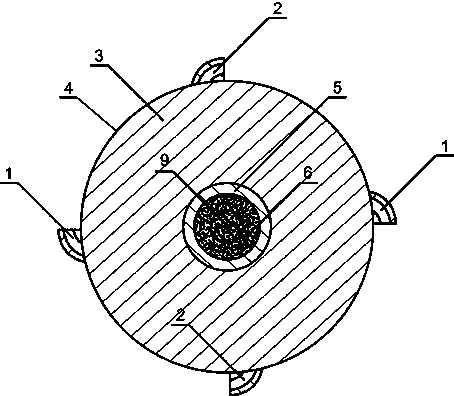

Miniature heat regeneration diffusion type uniform combustion device with combustion room shrunk gradually

InactiveCN105546583AExtend the motion pathImprove premix effectContinuous combustion chamberCombustion chamberEngineering

The invention provides a miniature heat regeneration diffusion type uniform combustion device with a combustion room shrunk gradually. The miniature heat regeneration diffusion type uniform combustion device comprises an ignition device, an outer sleeve, an inner sleeve and an upper panel. The inner sleeve is located in the outer sleeve. The combustion room is arranged in the inner sleeve. A preheating and premixing cavity is formed between the inner sleeve and the outer sleeve. The upper panel is arranged at the top end of the outer sleeve. A porous bottom plate is arranged at the lower end of the inner sleeve. The circumferential wall of the lower portion of the inner sleeve is a porous wall. An upper end opening of the inner sleeve serves as an exhaust opening. The combustion room communicates with the preheating and premixing cavity through the porous wall and the porous bottom plate. A plurality of air inlets and gas inlets are evenly distributed in the top end of the side wall of the outer sleeve in the circumferential direction. The combustion room of the miniature heat regeneration diffusion type uniform combustion device is in a reversely-buckled cylindrical inwards-concave horn shape so that fuel in the combustion room can be diffused, and inner combustion and temperature field distribution can be more uniform. According to the miniature heat regeneration diffusion type uniform combustion device, smoke waste heat is utilized, meanwhile, a porous material is adopted for multi-face air feeding, combustion is strengthened, a temperature field is more uniform, and therefore the power of the device is improved.

Owner:CHONGQING UNIV

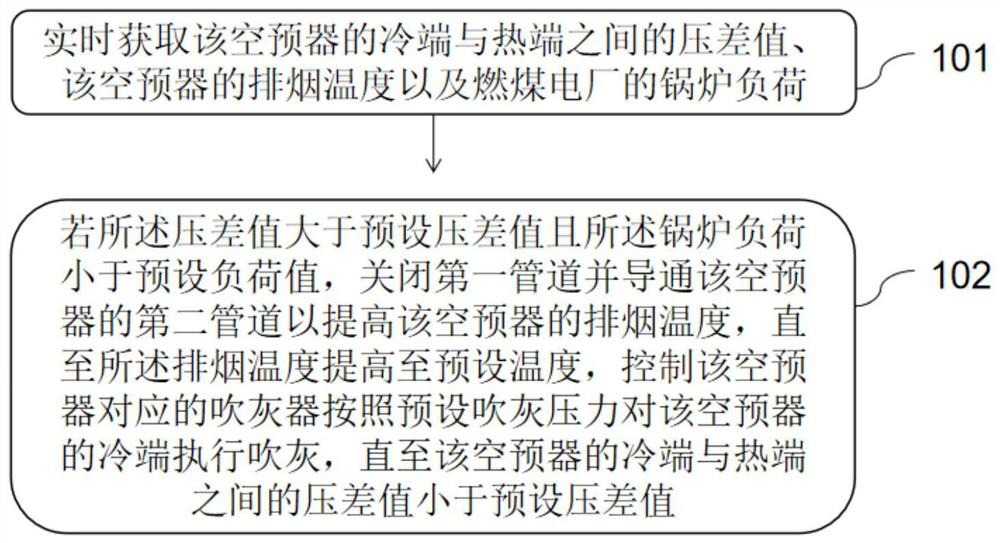

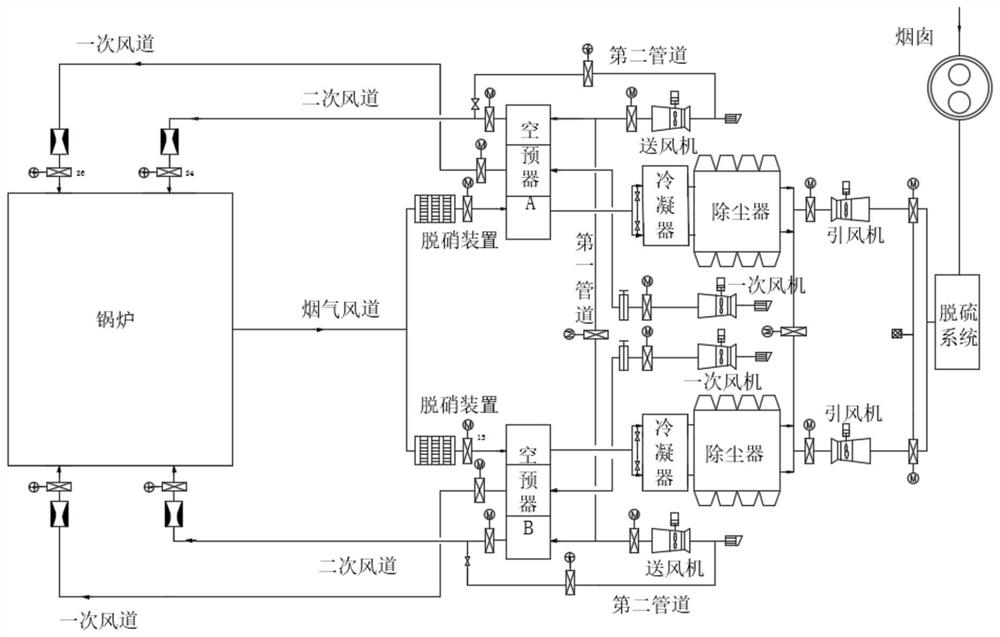

Pressure difference control method and control device for air pre-heaters of coal-fired power plant

PendingCN112902218AReduce differential pressureReduce outlet pressureIndirect carbon-dioxide mitigationAir/fuel supply for combustionTemperature controlEngineering

The invention provides a pressure difference control method and control device for air pre-heaters of a coal-fired power plant. The method comprises the steps that for each of the two air pre-heaters, the pressure difference value between the cold end and the hot end of the air pre-heater, the exhaust gas temperature of the air pre-heater and the boiler load of a coal-fired power plant are obtained in real time; if the pressure difference value is larger than a preset pressure difference value and the boiler load is smaller than a preset load value, a first pipeline is closed, and a second pipeline of the air pre-heater is connected to increase the smoke exhaust temperature of the air pre-heater till the smoke exhaust temperature is increased to a preset temperature; and a soot blower corresponding to the air pre-heater is controlled to conduct soot blowing on the cold end of the air pre-heater according to preset soot blowing pressure till the pressure difference value between the cold end and the hot end of the air pre-heater is smaller than the preset pressure difference value. The pressure difference control method and control device have the advantages that the soot blowing effect is remarkable, the soot blowing time can be effectively shortened, the pressure differences of the air pre-heaters can be reduced in time, the operation current of a draught fan can be reduced, and energy consumption is reduced.

Owner:浙江浙能兰溪发电有限责任公司

Wide load denitration system suitable for subcritical thermal power units and control method

PendingCN110227345ASafe and stable operationMeet the temperature requirementsGas treatmentDispersed particle separationAir preheaterCombustion

Belonging to the technical field of wide load denitration, the invention provides a wide load denitration system suitable for subcritical thermal power units and a control method. The system includesan SCR selective catalytic reduction denitration device, a coal economizer water bypass and a feed water flow recirculation device. The system is added with the coal economizer water bypass and the feed water flow recirculation device on the basis of an original SCR denitration device, and two working conditions are optional, i.e. only use of the coal economizer water bypass and simultaneous use of the coal economizer water bypass and the feed water flow recirculation device, the SCR denitration inlet flue gas temperature can be increased by 8DEG C-10DEG C, thus ensuring safe and stable operation of the SCR denitration device above a minimum stable combustion load and within a full load range, and meeting the indicator required by the SCR denitration inlet flue gas temperature, and solvingthe technical problems of low denitration efficiency, over-standard environmental protection parameters, ash clogging of air preheaters and the like in traditional SCR denitration devices.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

Coal-fired thermal power generating unit all-working-condition denitration system and adjusting method

PendingCN114749019ARealization of denitrification under all working conditionsIncrease flue gas temperatureGas treatmentLighting and heating apparatusFlueProcess engineering

The invention relates to a coal-fired thermal power generating unit full-working-condition denitration system and an adjusting method.The system comprises a coal economizer, a main flue and a denitration device which are sequentially communicated, and further comprises a main flue adjusting baffle, a bypass flue device and a bypass flue gas heating device, and the bypass flue device comprises a bypass flue, a bypass flue turn-off baffle and a bypass flue adjusting baffle; the bypass flue gas heating device is arranged in the bypass flue, and the control module is used for controlling the opening degrees of the main flue adjusting baffle, the bypass flue turn-off baffle and the bypass flue adjusting baffle and the working state of the bypass flue gas heating device according to the flue gas temperature at the inlet of the denitration device. The system has the advantages that all-working-condition denitration of the unit is achieved, including the start-stop stage, the low-load stage and the normal-load stage of the unit, the temperature of flue gas at an inlet of a denitration device reaches the allowable temperature of a catalyst or above, emission of NOx is reduced, and a key technology is provided for the coal-fired thermal power unit in the aspect of exploring the lower-load peak regulation capacity.

Owner:HUADIAN LAIZHOU POWER GENERATION +1

Economizer improving SCR commissioning rate under low load working condition

The invention discloses an economizer improving the SCR commissioning rate under the low load working condition. A water supply pipeline of an inlet of the economizer is provided with a by-pass. A by-pass pipeline is connected with a middle header of the economizer. The by-pass is sequentially provided with a one-way valve, a throttling valve and a flow adjusting valve in the medium flowing direction. According to the economizer, the opening degree of a by-pass valve is adjusted under the low load condition so as to reduce medium flow between an inlet header and the middle header of the economizer in a boiler, the heat output of the smoke side of the economizer can be reduced, the smoke temperature of an outlet of the economizer rises, and the commissioning rate of a power plant SCR under the low load condition can be effectively improved; the catalyst activity of the SCR is promoted due to rising of the temperature of an SCR system, the SCR system obtains the higher denitration capacity, and therefore a power plant can meet the environmental protection index requirement better over a much longer time period.

Owner:SOUTHEAST UNIV

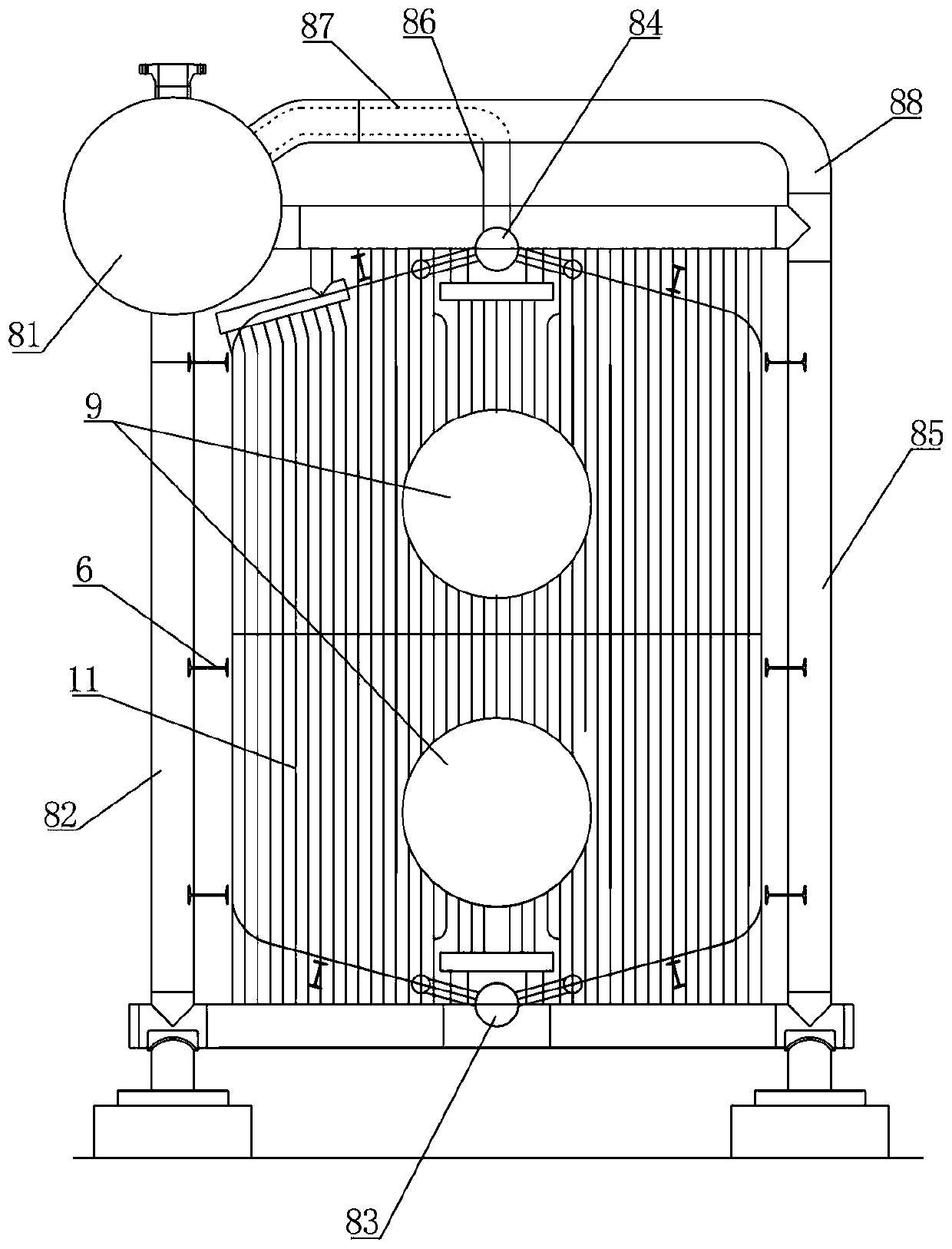

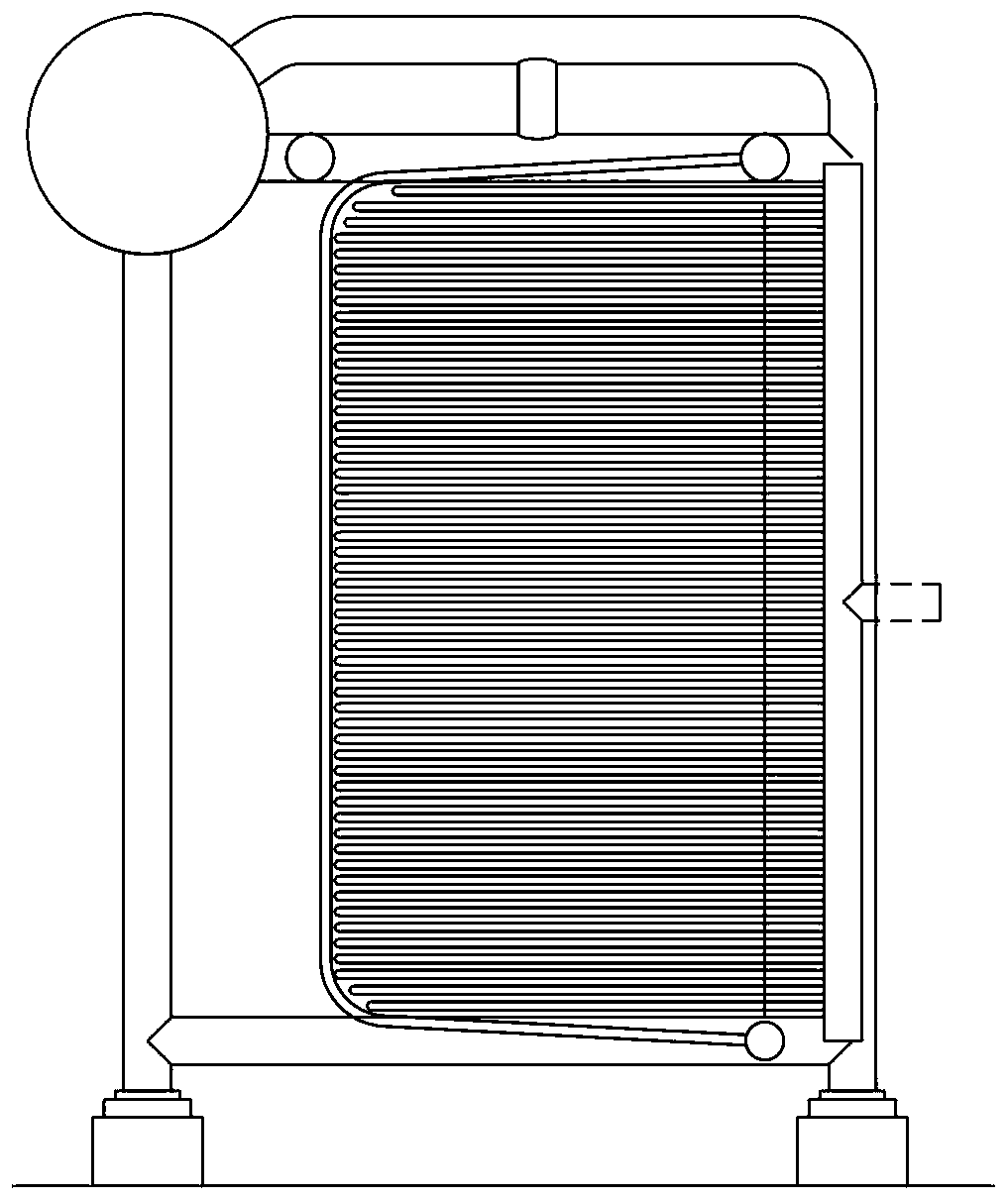

Waste heat boiler used for waste sulfuric acid cracking regeneration device and flue gas treatment method

PendingCN112682809AIncrease flue gas temperatureIncrease temperatureCombustion technology mitigationCoatingsThermodynamicsFlue gas

The invention discloses a waste heat boiler used for a waste sulfuric acid cracking regeneration device and a flue gas treatment method. The waste heat boiler comprises a front smoke box, a boiler body and a rear smoke box which are in sequential communication, multiple heat exchange pipes are arranged in the boiler body, a center pipe is arranged in the center in the boiler body, an adjusting valve is arranged at an outlet of the center pipe, inlets of the heat exchange pipes and an inlet of the center pipe communicate with the front smoke box, and outlets of the heat exchange pipes and the outlet of the central pipe communicate with the rear smoke box. The waste heat boiler can effectively avoid dew point corrosion of pipelines and equipment, the service life of the boiler is prolonged, construction cost is low, operation is convenient, and the occupied area is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-product cleaning and producing method with coal gangue comprehensive utilization

ActiveCN102703157BChange the status quo of accumulationEliminate emissionsSteam generation heating methodsSolid fuelsPollutionEnergy source

The invention relates to a multi-product cleaning and producing method comprehensive utilization; coal carbon production, power generation by burning coal gangue, cement production, power generation by cement afterheat and wall material production technology are combined in a same industrial symbiont by using industrial symbiosis; optimal configuration between working procedures is realized; processing procedures of raw materials are converted into processing working procedures capable of separating raw materialsand fuels into different material flows and power flows which have different transport directions; mutually beneficial relationship is established between working procedures; a predetermined downstream working procedure is directly capable of digesting ''pollutant'' of an upstream working procedure; each working procedure utilizes different raw material component and different gradient energy source so as to produce multiple products; so that energy and matter flow in a multi-channel manner; and a little-pollution multi-prduct cleaning and producing technology is formed.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

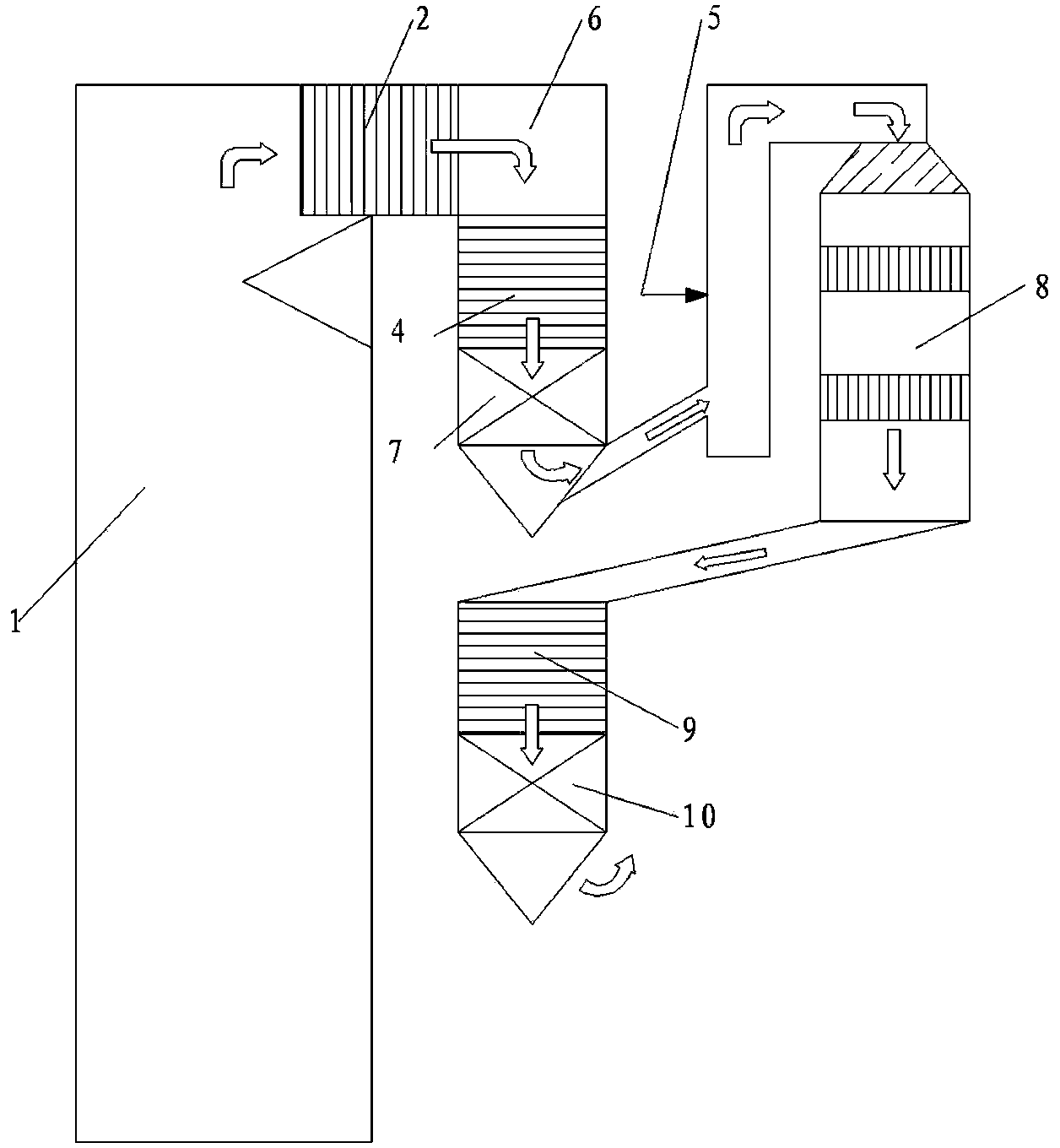

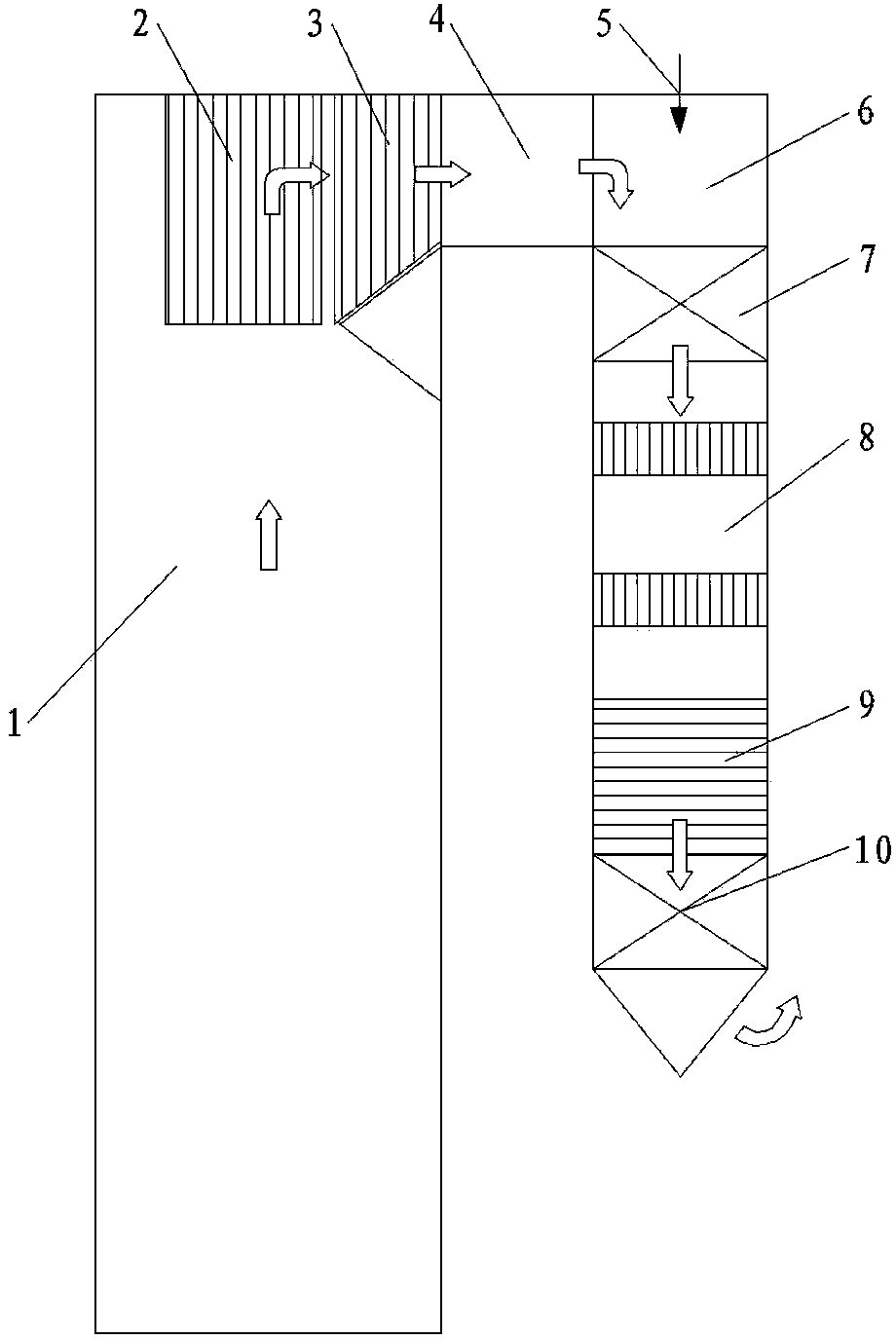

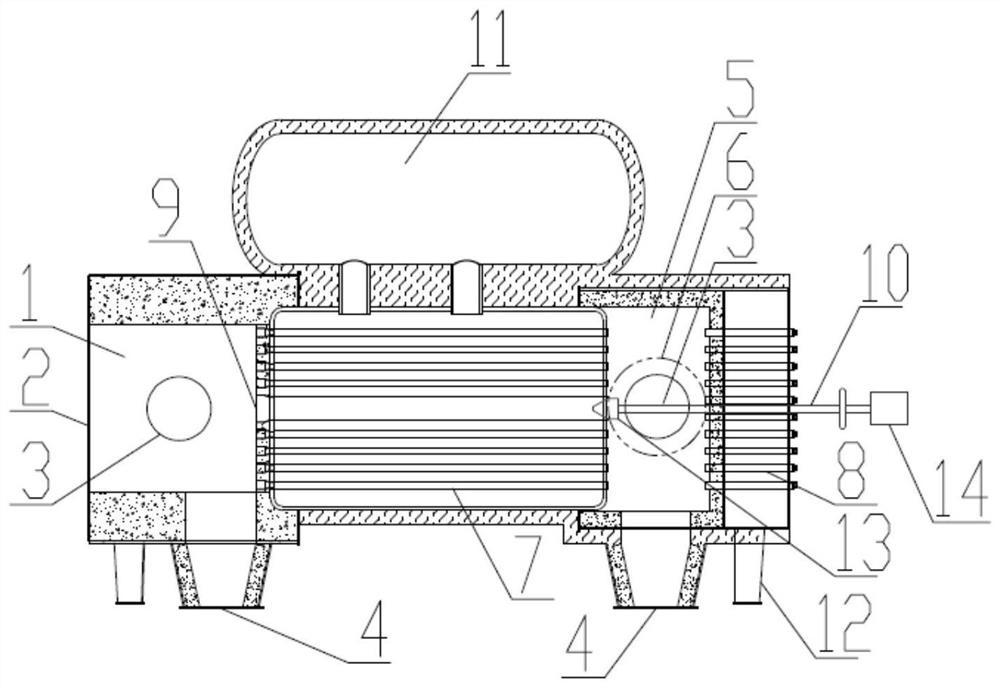

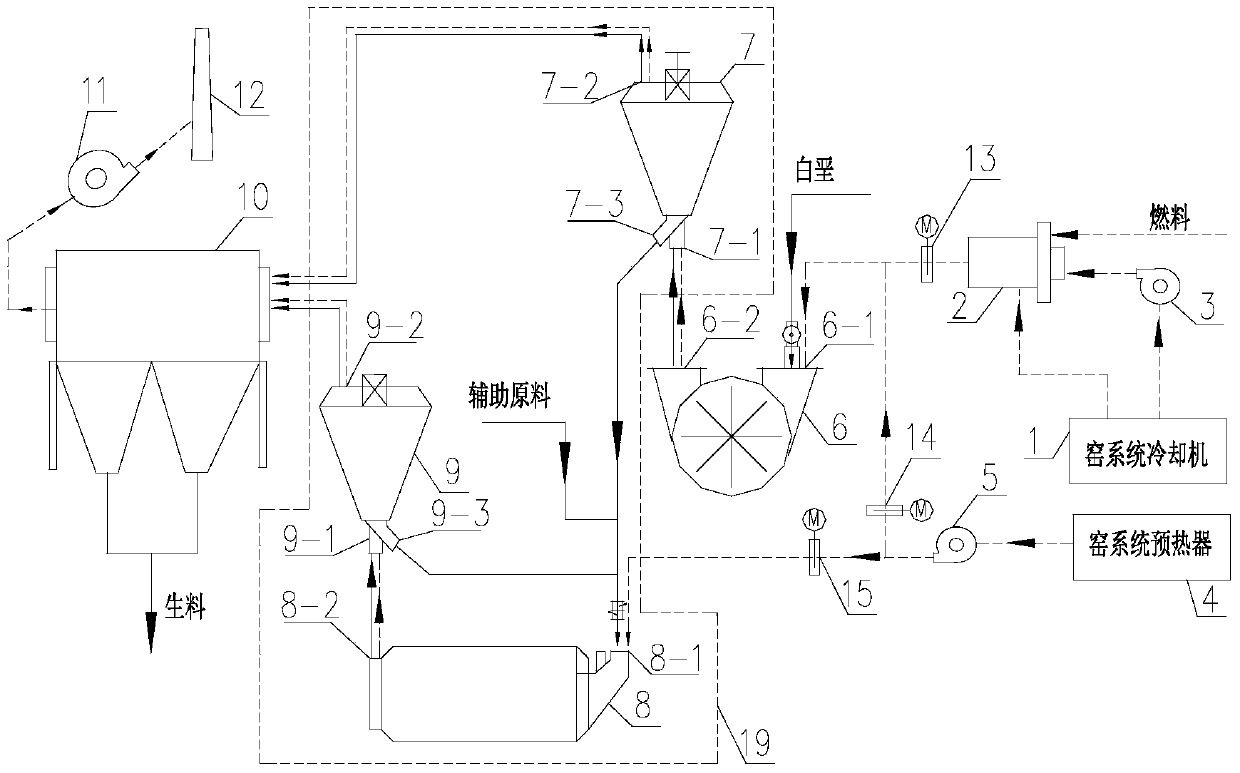

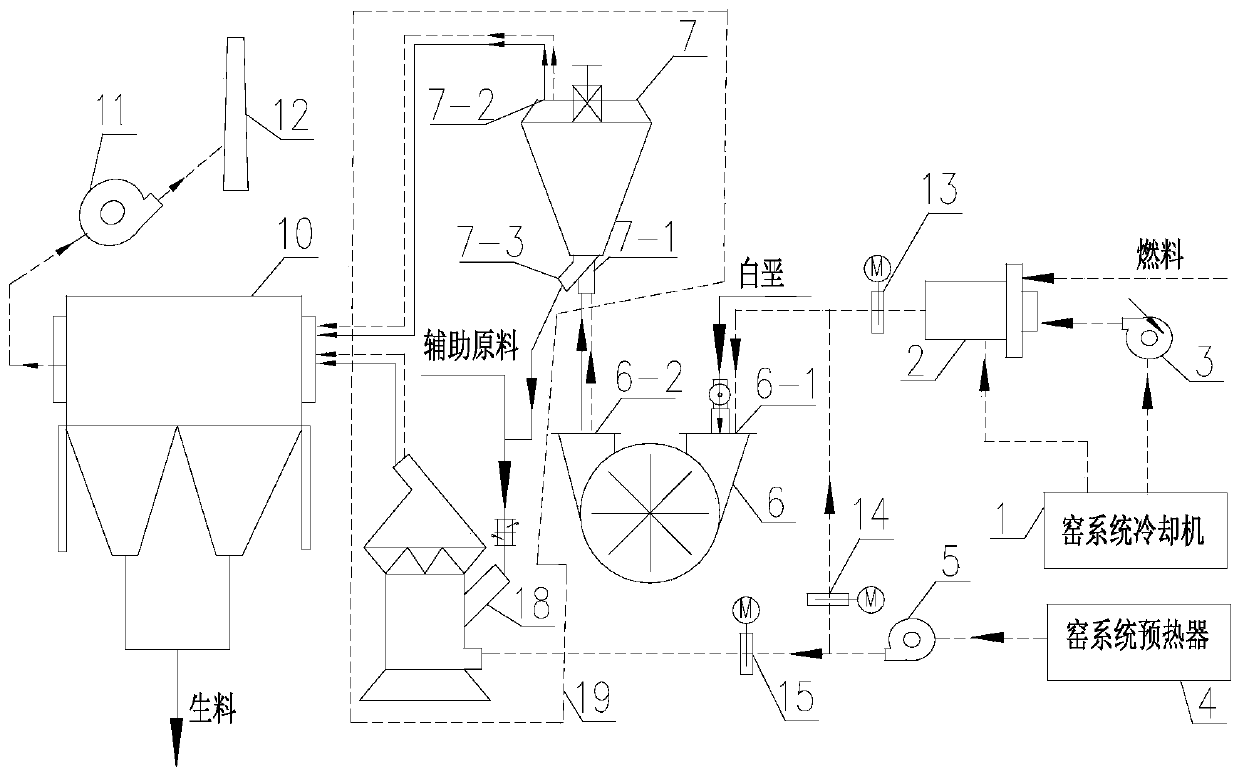

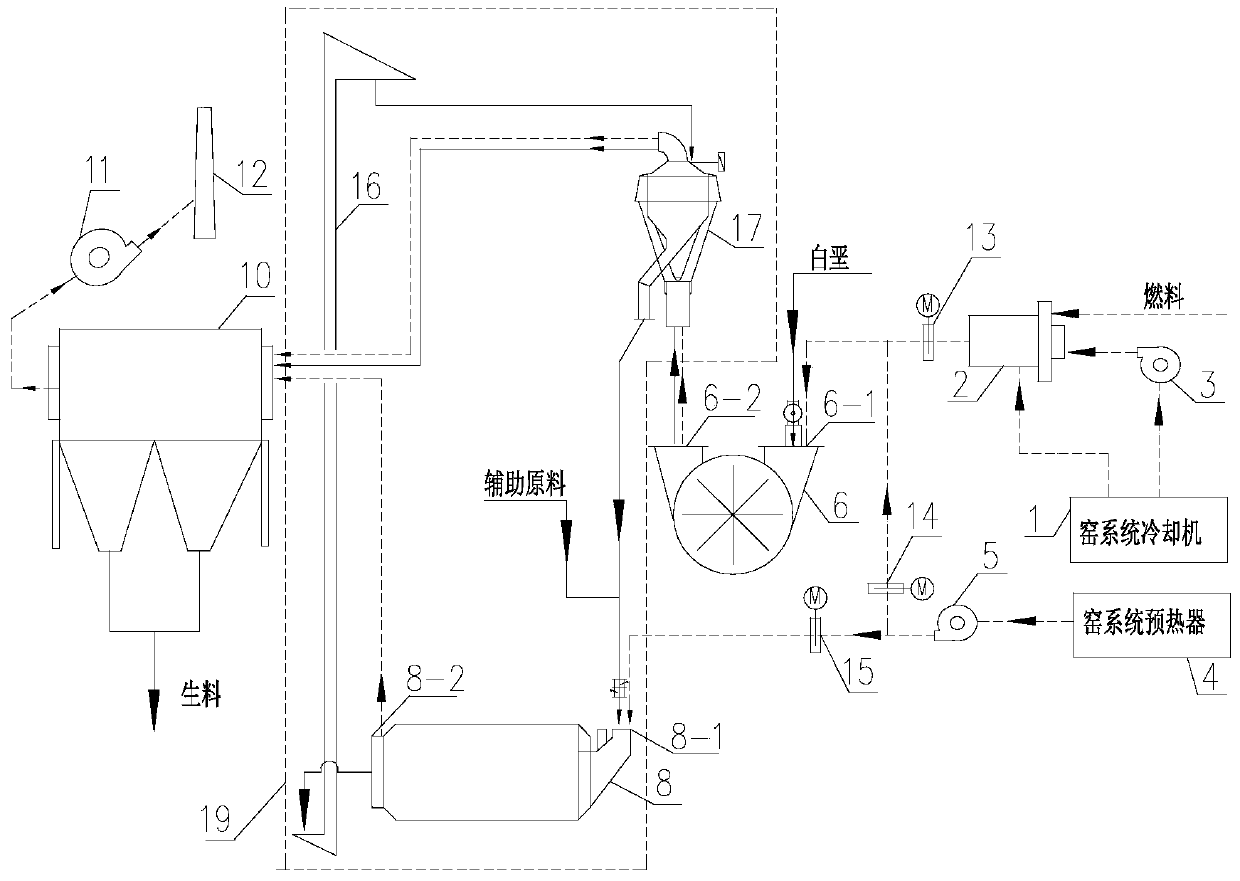

Chalk Preparation Raw Meal System

ActiveCN106630705BImprove drying efficiencyImprove grinding efficiencyProcess systemsScattering function

The invention relates to a system for preparing cement raw materials from chalk, and in particular to a process system for preparing raw materials from fine powdery chalk materials with high water content. The system comprises a kiln system cooling machine, a draught fan, a hot air furnace, a kiln system preheater, a drying crushing machine, a powder grinding and powder selecting device and a dust collector. In the technical scheme, according to the physical properties of chalk and auxiliary raw materials, the drying and scattering function of the drying crushing machine and the efficient powder grinding function of the powder grinding device are sufficiently achieved; the efficient drying and scattering of the chalk can be realized; meanwhile, auxiliary blocky materials are crushed and dried; the preparation process of high efficiency and low consumption of the raw materials are realized; the system belongs to an energy-saving system for preparing the raw materials from the chalk.

Owner:NANJING KISEN INT ENG

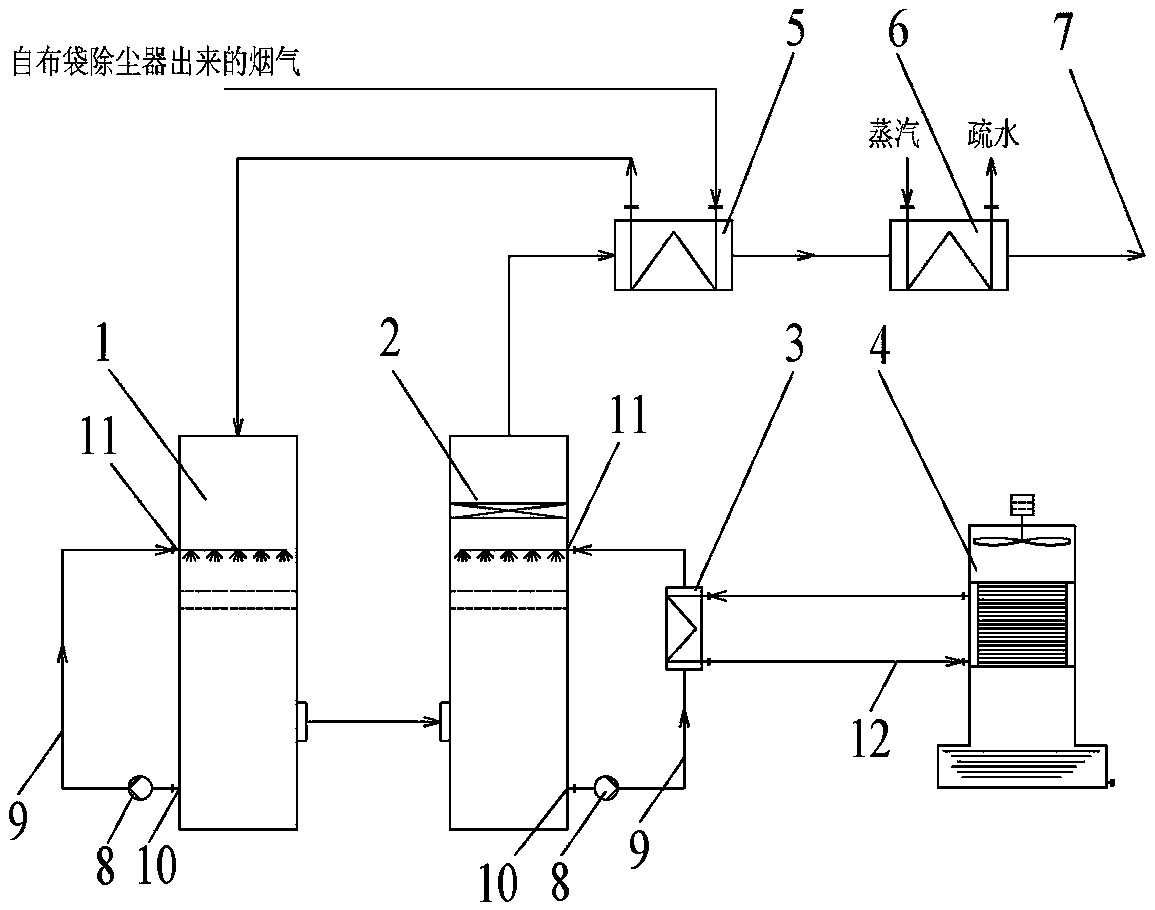

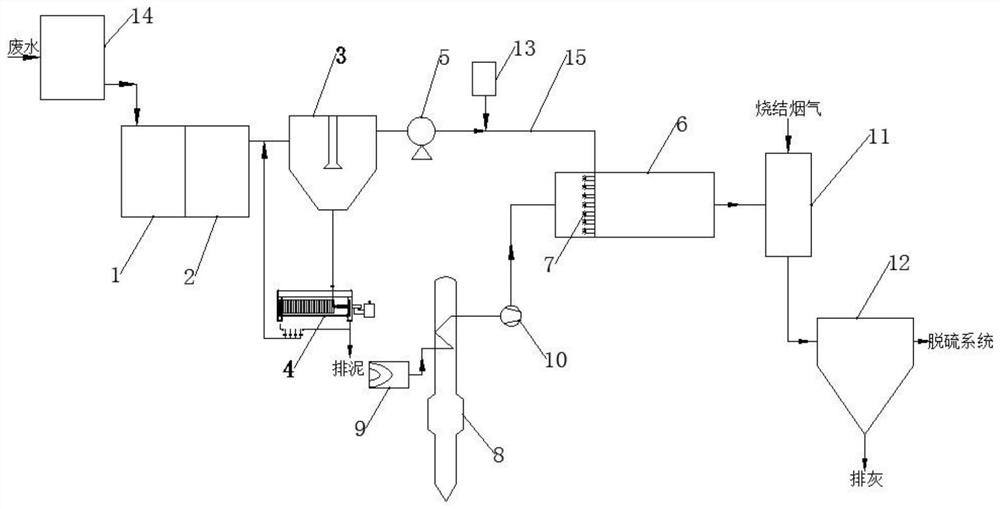

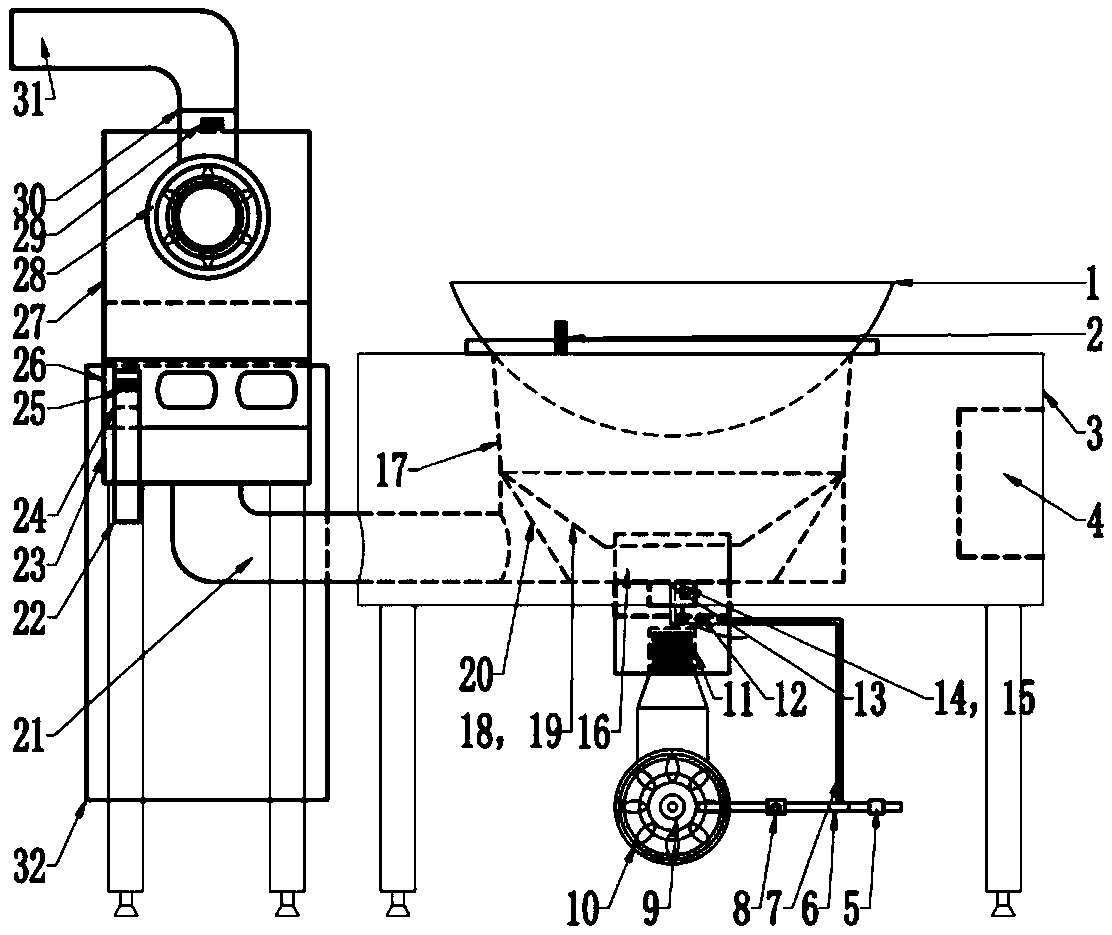

System and method for evaporating desulfurization wastewater by utilizing waste heat in flue

PendingCN112479295AGood effectAvoid cloggingWater/sewage treatmentWaste water treatment from gaseous effluentsAir preheaterFlue gas

The invention provides a system and method for evaporating desulfurization wastewater by utilizing waste heat in a flue. The system comprises an air preheater, the flue, an electrostatic dust collector and a desulfurization tower which are sequentially arranged along a flue gas circulation direction; the desulfurization tower is connected with a triple box to obtain pretreated desulfurization wastewater; the air preheater is used for generating hot secondary air by utilizing flue gas waste heat; a desulfurization wastewater atomization assembly is arranged in the flue, and the triple box communicates with the desulfurization wastewater atomization assembly; a first hot secondary air injection pipe assembly is further arranged in the flue, and a first hot secondary air injection pipe assembly is transversely arranged at the bottom of the flue and connected with the air preheater; and the electrostatic dust collector is used for capturing crystalline salt formed after the desulfurizationwastewater is dried and dust in flue gas. The system is simple in structure, convenient to manufacture, capable of effectively improving evaporation of desulfurization wastewater and precipitation ofcrystalline salt, capable of avoiding corrosion of the bottom of the flue and the electrostatic dust collector, capable of saving cost and high in practicability.

Owner:GUODIAN LONGYUAN POWER TECH ENG

System for increasing low-load feed water temperature of power station boiler

PendingCN113654019ABroaden the scope of technologyKeep aliveSteam generation using pressureBoiler controlSteam pressurePtru catalyst

The invention discloses a system for increasing the low-load feed water temperature of a power station boiler. A method for increasing the feed water temperature of the power station boiler comprises the following steps that under the low-load working condition of the boiler, the SCR (Selective Catalytic Reduction) flue gas temperature is lower than a temperature window required by a catalyst; a steam source of a first high-pressure heater of a unit regenerative system is changed into extracted steam of a boiler superheater system or a main steam pipeline from an original high-pressure cylinder, so that the pressure of steam entering the first high-pressure heater of the unit regenerative system is increased; the temperature of saturated steam corresponding to the steam inlet pressure rises due to rising of the steam inlet pressure of the first high-pressure heater of the unit regenerative system, so that the temperature of feed water at a first high-pressure heater outlet of the unit regenerative system rises, the temperature of the feed water entering a boiler economizer rises, and finally the temperature of flue gas entering an SCR reactor is increased; and thus, the purpose of low-load denitration of the boiler is achieved. The flue gas temperature at an inlet of the low-load SCR reactor of the boiler is increased, the activity of the SCR catalyst under the low load is guaranteed, and the technical range of low-load denitration of the boiler is widened.

Owner:江苏慧峰仁和环保科技有限公司 +1

Energy-saving Chinese food cooking gas cooker

InactiveCN109282323ASatisfy the requirements of "high fire" cookingIncrease flue gas temperatureLighting and heating apparatusWater heating stoves/rangesHearthElectric control

The invention relates to a Chinese food cooking gas cooker. The Chinese food cooking gas cooker can achieve full pre-mixing and has a constant air-fuel ratio, flue gas waste heat at the tail can be recovered, and electric regulation is achieved. The Chinese food cooking gas cooker comprises a cooker body support, a controller, a burner, a main cooker body, a wok, an inductor, a radiation plate, anair-fuel proportional valve, an air blower, an exhaust fan, an inlet air uniformizing device, an exhaust flue gas uniformizing device and a waste heat recovery device. The main cooker body adopts a full pre-mixing and constant air-fuel ratio combustion mode, and the radiation plate is mounted in a hearth to enhance radiant heat exchange. Fuel gas waste heat at the tail is recovered, so that the heat efficiency of a cooker body is improved, and the working environment of cooks is improved. An anti-idling distance meter is mounted on the cooker surface, and the inductor judges the state of thegas cooker in the cooking process and generates a signal to cut off a main flame, so that gas waste is avoided. Electronic elements in a system are connected through an electric control system, so that operation of the cooker is simplified, and the using safety, convenience and control accuracy of the cooker are improved. The Chinese food cooking gas cooker has the characteristics of being high inefficiency, capable of saving energy, environmentally friendly, safe, easy and convenient to operate and the like.

Owner:CHONGQING UNIV

A miniature regenerative diffused uniform combustion device with a tapered combustion chamber

InactiveCN105546583BExtend the motion pathImprove premix effectContinuous combustion chamberCombustion chamberEngineering

The invention provides a miniature heat regeneration diffusion type uniform combustion device with a combustion room shrunk gradually. The miniature heat regeneration diffusion type uniform combustion device comprises an ignition device, an outer sleeve, an inner sleeve and an upper panel. The inner sleeve is located in the outer sleeve. The combustion room is arranged in the inner sleeve. A preheating and premixing cavity is formed between the inner sleeve and the outer sleeve. The upper panel is arranged at the top end of the outer sleeve. A porous bottom plate is arranged at the lower end of the inner sleeve. The circumferential wall of the lower portion of the inner sleeve is a porous wall. An upper end opening of the inner sleeve serves as an exhaust opening. The combustion room communicates with the preheating and premixing cavity through the porous wall and the porous bottom plate. A plurality of air inlets and gas inlets are evenly distributed in the top end of the side wall of the outer sleeve in the circumferential direction. The combustion room of the miniature heat regeneration diffusion type uniform combustion device is in a reversely-buckled cylindrical inwards-concave horn shape so that fuel in the combustion room can be diffused, and inner combustion and temperature field distribution can be more uniform. According to the miniature heat regeneration diffusion type uniform combustion device, smoke waste heat is utilized, meanwhile, a porous material is adopted for multi-face air feeding, combustion is strengthened, a temperature field is more uniform, and therefore the power of the device is improved.

Owner:CHONGQING UNIV

A wet and dry combined flue gas desulfurization system and desulfurization method

ActiveCN107899408BIncrease flue gas temperatureImprove adaptabilityGas treatmentDispersed particle separationMulti pollutantProcess engineering

Owner:NANJING NORMAL UNIVERSITY

Flue gas sampling device

ActiveCN102004047BNo cloggingWork reliablyWithdrawing sample devicesPreparing sample for investigationAtmospheric airFlue gas

The invention relates to the technical field of sampling, detection and analysis of gas and discloses a flue gas sampling device. For solving the problems of short service life and the like of a sampling pump, the invention provides the following technical scheme. The flue gas sampling device is characterized in that a driving mechanism comprises a gas source machine (104) for providing a gas source and a jet injector (105) for driving flue gas to flow in a drainage manner, wherein air current provided by the gas source machine (104) enters a spray nozzle (105b) from top to bottom and is sprayed out at the lower retracted part of the spray nozzle (105b) so as to form a vacuum trend, thereby attracting sampling gas to enter from the second gas inlet end of the jet injector (105); and two strands of air current is mixed in a hollow-out cavity and is exhausted to the atmosphere through the gas outlet end of the jet injector (105). The invention has the benefits that the jet injector is provided with a movable component without the maintenance, repair and replacement and can work reliably for a long term; the pressure and the flow speed of the sampling gas are stable; the phenomenon that fine particles are blocked can be avoided; and the jet injector made of all metal can bear high temperature of the flue gas.

Owner:上海北分科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com