Heat conduction oil heat storage and boiler low temperature corrosion prevention device and working method

A technology of low temperature corrosion and oil heat storage, applied in combustion methods, circuit devices, heat storage heaters, etc., can solve the problems of low flue gas temperature and low temperature corrosion of air preheaters, so as to achieve short construction period and reduce factory use. Electricity rate, the effect of avoiding low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

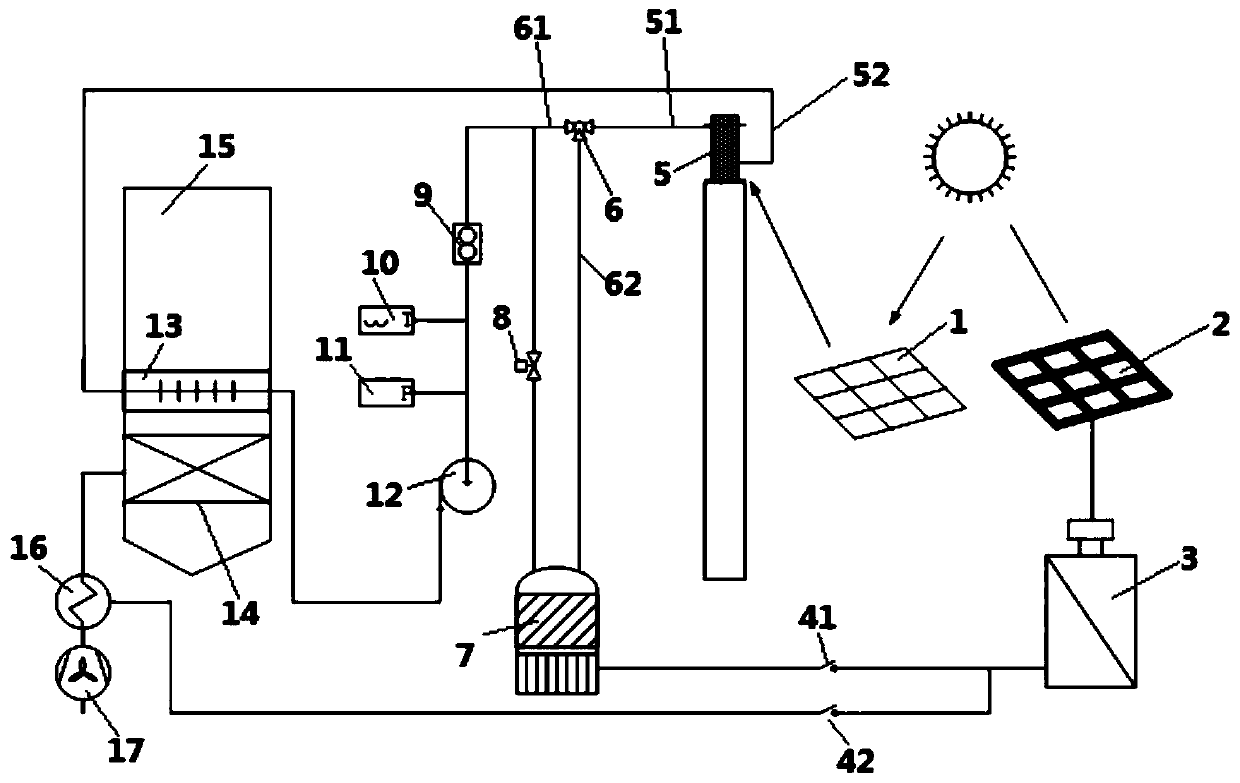

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0028] Such as figure 1 As shown, the present invention provides an anti-corrosion device for boilers with heat-conducting oil heat storage, comprising a photovoltaic cell panel 2, which is connected to the input end of a battery 3, and the output end of the battery 3 is connected to a heat-conducting oil tank 7. Electric heater, the heat conduction oil tank 7 is delivered by external equipment with heat conduction oil, the battery 3 is powered, the heat conduction oil tank 7 heats the heat conduction oil, and the heat is maintained when the temperature meets the actual requirements. The outlet of the heat conduction oil tank 7 is connected The heat transfer oil inlet of the oil-fume heat exchanger 13 (heat-conducting oil-flue gas heat exchanger), the oil-fume heat exchanger 13 penetrates the tail flue 15, and an air preheater 14 is also provided in the tail f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com