A manufacturing process of an integrated water jacket heating plate for a large plate hot press

A water jacket heating and manufacturing process technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of blockage of circulation channels, increase of operating costs, scrapping of water jacket heating plates, etc., and achieve the effect of avoiding scrapping and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

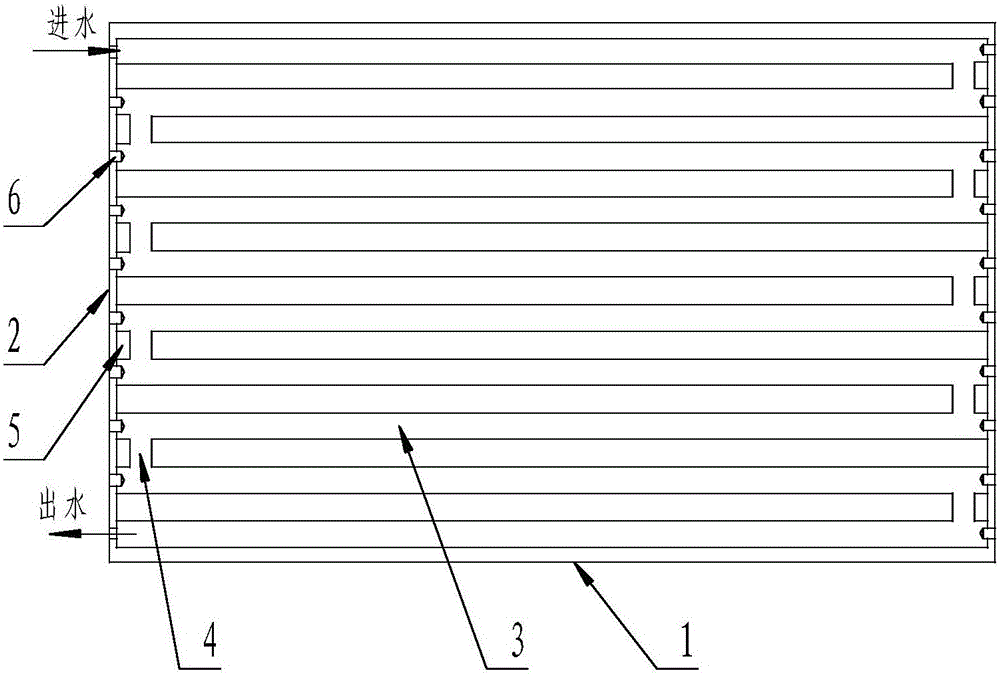

[0026] At least six horizontal circulation channels 3 parallel to each other are set between the two ends of the whole steel plate 1, a corner channel 4 is vertically set at one end between two adjacent horizontal circulation channels 3, and a corner channel 4 is vertically set at one end between two adjacent horizontal circulation channels 3 and two adjacent horizontal circulation channels 3. A corner channel 4 constitutes an S-shaped circulation channel;

[0027] A stopper 5 is arranged in the corner passage 4, and the horizontal width of the stopper 5 is less than one-third of the horizontal width of the corner passage 4;

[0028] The longitudinal height of the stopper 5 is equal to the longitudinal height of the corner channel 4, and one end of the stopper 5 is flush with the end face of the whole steel plate 1;

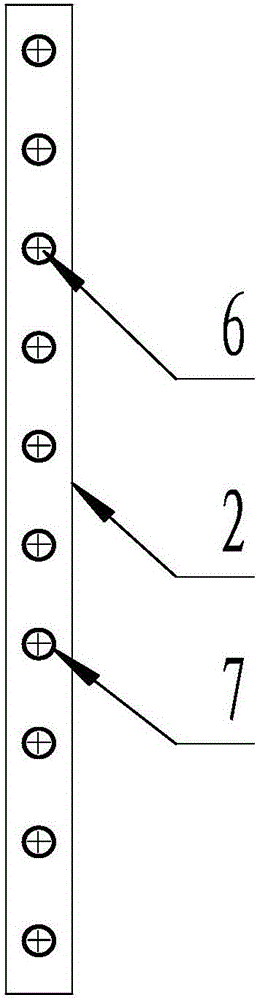

[0029] Both ends of the whole steel plate 1 are provided with a head plate 2, and an observation and cleaning hole 7 is arranged on the head plate 2 correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com