A miniature regenerative diffused uniform combustion device with a tapered combustion chamber

A uniform combustion and combustion chamber technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of high-power burner flow rate and blowout, short residence time of reaction gas, insufficient local mixed combustion, etc. , to achieve the effects of prolonging the gas movement path, uniform flame and temperature distribution, and reducing the difficulty of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

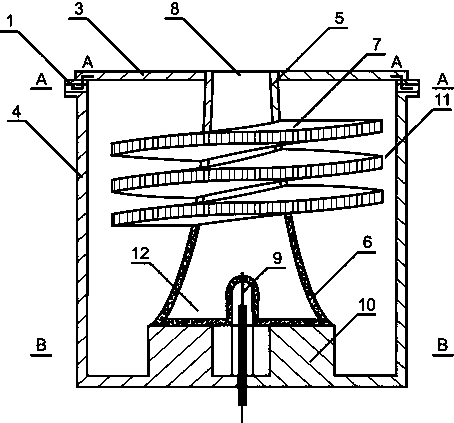

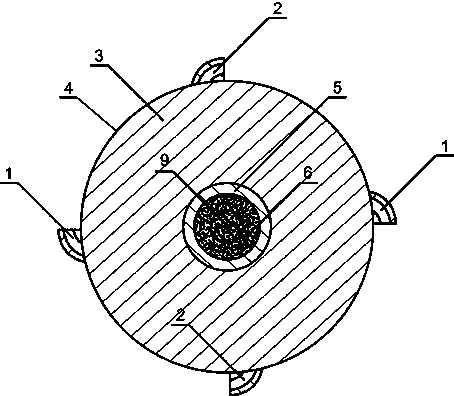

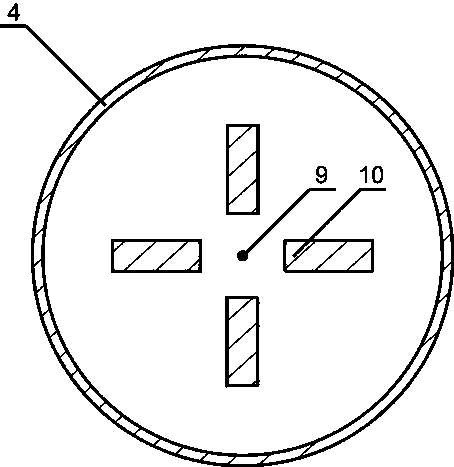

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as figure 1 , figure 2 with image 3 As shown, a miniature regenerative diffuse uniform combustion device with a tapered combustion chamber includes an ignition device 9 , an outer sleeve 4 , an inner sleeve 5 and an upper panel 3 . The inner sleeve 5 is located in the outer sleeve 4, and the inner sleeve 5 and the outer sleeve 4 are coaxially arranged. The outer wall of the inner sleeve 5 adopts a "three-stage" different structure, and the inner sleeve 5 is a combustion chamber 12. A preheating and premixing chamber 11 is formed between the inner sleeve 5 and the outer sleeve 4 to provide space for sufficient premixing and preheating of the gas. The bottom end of the outer sleeve 4 is provided with a sealing plate, and the upper panel 3 is arranged on the top end of the outer sleeve 4 and sealed with the outer sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com