Wet-process deacidification flue gas white smoke removing system applied to hazardous waste incineration and application method of wet-process deacidification flue gas white smoke removing system

A flue gas and deacidification technology, applied in the field of incineration flue gas purification and treatment, can solve the problems of corrosion of steam heaters and subsequent equipment, large steam consumption, short service life, etc., to avoid corrosion of equipment, reduce steam consumption, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

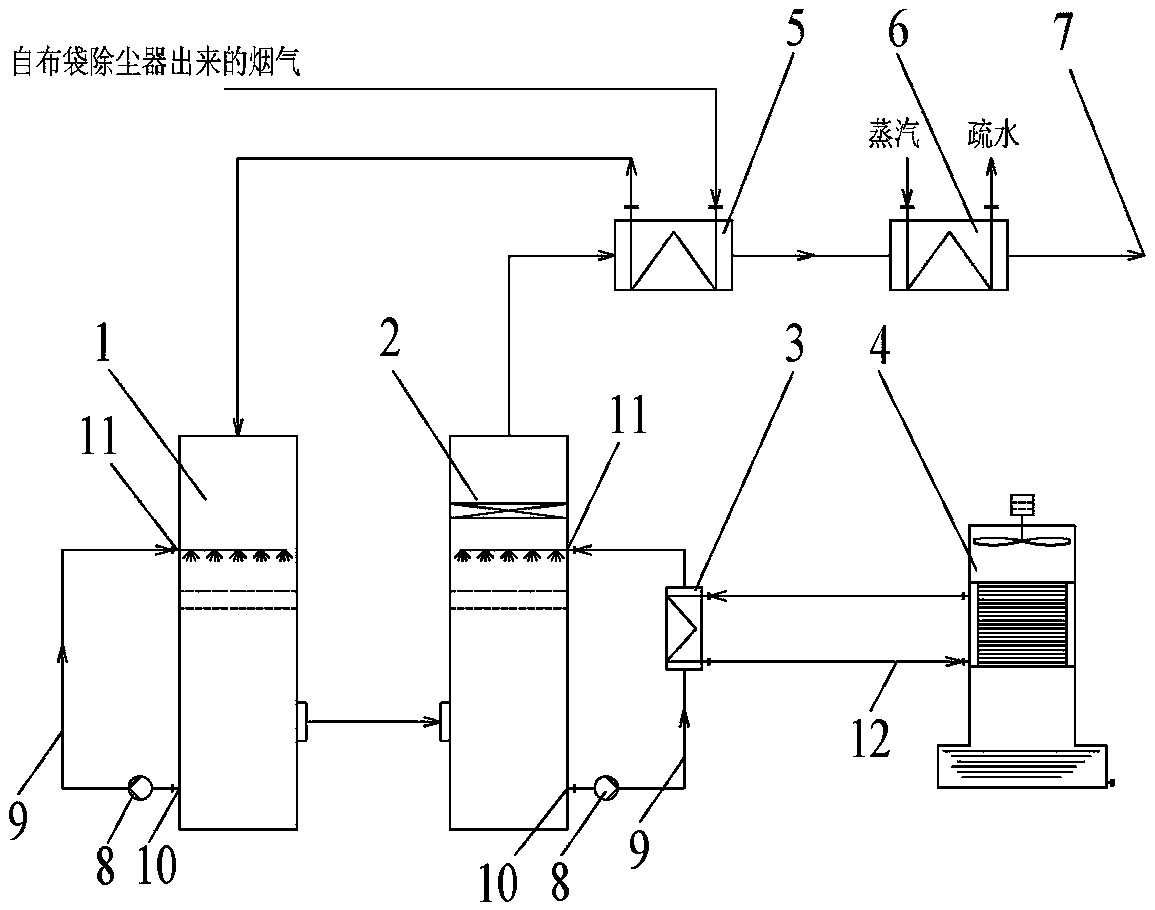

[0018] Such as figure 1 As shown, a hazardous waste incineration wet deacidification flue gas dewhitening system of the present invention includes a washing tower, a steam heater 6, and the steam heater 6 is connected to the chimney 7, and it also includes the flue gas connected to the bag filter. The fume-smoke heat exchanger 5 is connected with the steam heater 6 after being circulated with the washing tower; specifically, the fume-smoke heat exchanger 5 is a GGH fume-smoke heat exchanger, and its heat exchange The pipe material is PTFE fluoroplastic; the steam heater 6 is a SGH steam heater.

[0019] The scrubber includes a primary scrubber 1 and a secondary scrubber 2. The smoke heat exchanger 5 is connected to the steam heater 6 after sequentially circulating with the primary scrubber 1 and the secondary scrubber 2. The primary scrubber 1. The secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com