Wide load denitration system suitable for subcritical thermal power units and control method

A thermal power unit and subcritical technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as excessive environmental protection parameters, dust blocking of air preheaters, and low denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

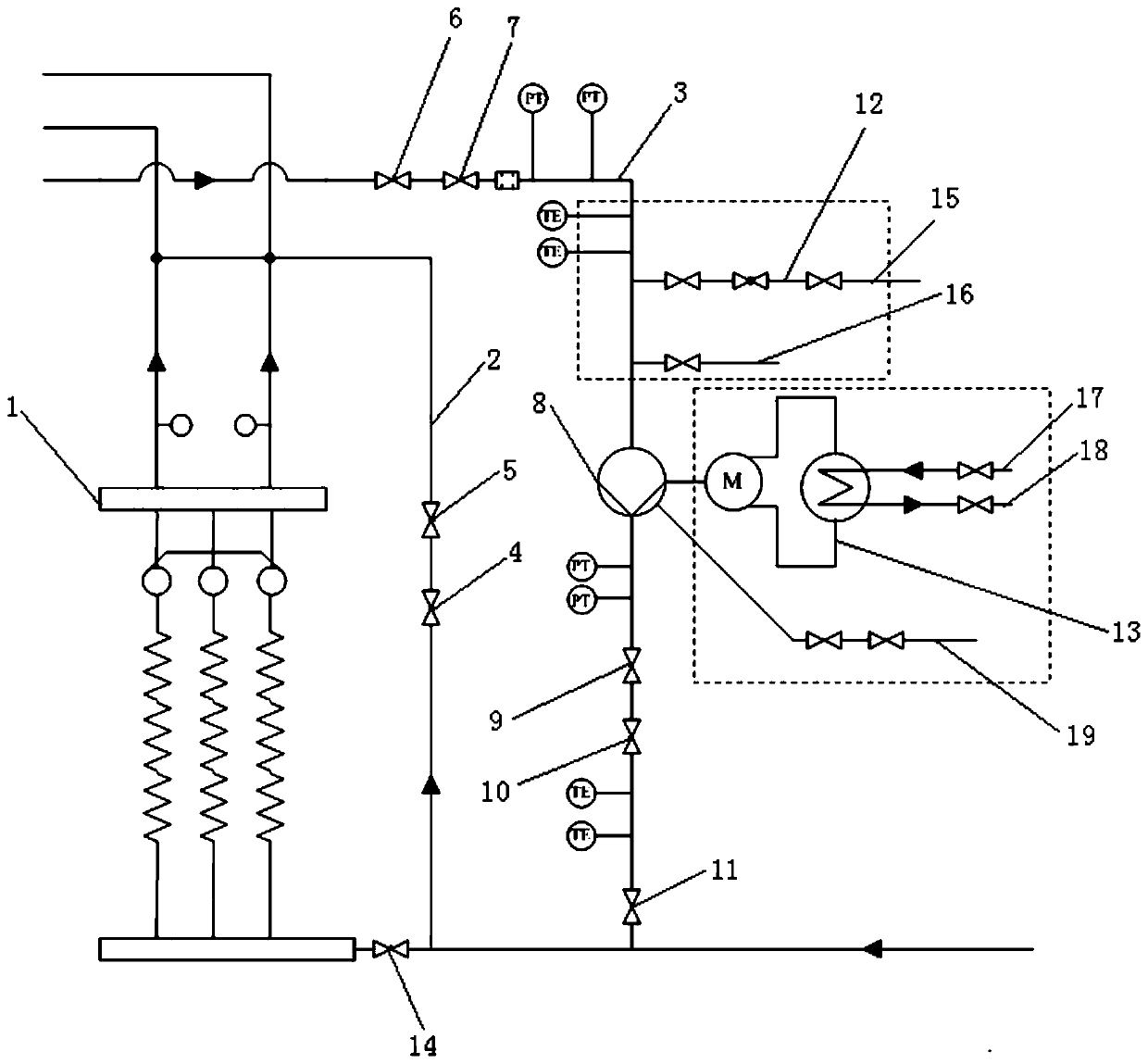

[0046] As shown in the figure, a wide-load denitrification system suitable for subcritical thermal power units includes SCR selective catalytic reduction denitrification device 1, economizer water bypass 2 and feedwater flow recirculation device 3,

[0047] One end of the economizer water bypass 2 is fixedly connected to the economizer outlet of the SCR selective catalytic reduction method denitrification device 1, and the other end of the economizer water bypass 2 is connected to the outlet of the SCR selective catalytic reduction method denitrification device 1. The inlet of the economizer is fixedly connected, and the water bypass 2 of the economizer is equipped with an electric gate valve I4 and an electric regulating valve I5;

[0048] The feed water flow recirculation device 3 includes a manual cut-off valve I6, an electric gate valve II7, a circulating pump 8, an electric regulating valve II9, an electric gate valve III10, a check valve I11, a warm pump pipeline 12 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com