Waste heat boiler used for waste sulfuric acid cracking regeneration device and flue gas treatment method

A technology of waste heat boiler and regeneration device, which is applied in the field of waste heat boiler and flue gas treatment, and can solve the problems of inconvenient operation, large floor area and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

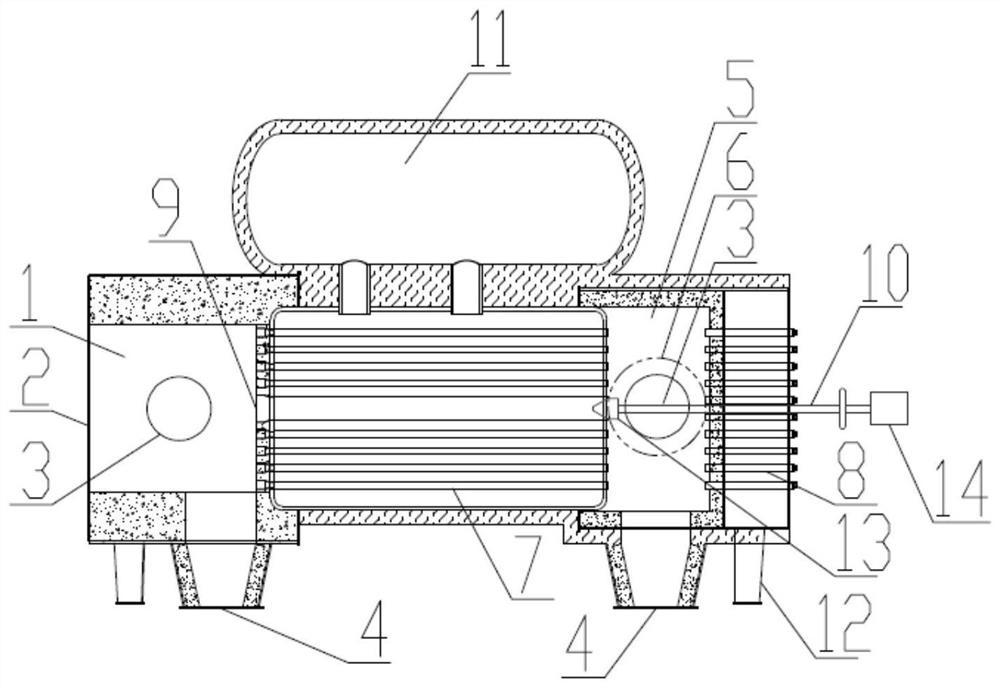

[0053] A waste heat boiler used for waste sulfuric acid cracking regeneration unit, such as figure 1 As shown, it includes the front smoke box, the boiler body and the rear smoke box connected in sequence. Among them, the front end of the front smoke box is provided with a flue gas inlet, the side is provided with a manhole, and the lower part is provided with a lower ash port; 50 heat exchange tubes are arranged inside the boiler body. , the material of the heat exchange tubes is No. 20 steel, the diameter of each heat exchange tube is DN50, and the sum of the cross-sectional areas of the heat exchange tubes is 0.1m 2 , and the inner center of the boiler body is provided with a center tube, the diameter of the center tube is DN150, and the cross-sectional area is 0.018m 2 , the central tube is made of No. 20 steel, and the outlet of the central tube is provided with a conical regulating valve. The conical regulating valve includes a conical spool and an actuator. The materia...

Embodiment 2

[0056] A waste heat boiler used for waste sulfuric acid cracking and regeneration equipment, comprising a front smoke box, a boiler body and a rear smoke box connected in sequence, wherein the front end of the front smoke box is provided with a flue gas inlet, the side is provided with a manhole, and the lower part is provided with a lower ash port ; There are 50 heat exchange tubes inside the boiler body, the material of the heat exchange tubes is No. 20 steel, the diameter of each heat exchange tube is DN65, and the sum of the cross-sectional areas of the heat exchange tubes is 0.166m 2 , and the inner center of the boiler body is provided with a central tube with a diameter of DN200 and a cross-sectional area of 0.031m 2 , the central tube is made of No. 20 steel, and the outlet of the central tube is provided with a conical regulating valve. The conical regulating valve includes a conical spool and an actuator. The material is ALLOY20 alloy steel, the actuator is manuall...

Embodiment 3

[0059] A waste heat boiler used for waste sulfuric acid cracking and regeneration equipment, comprising a front smoke box, a boiler body and a rear smoke box connected in sequence, wherein the front end of the front smoke box is provided with a flue gas inlet, the side is provided with a manhole, and the lower part is provided with a lower ash port ; There are 60 heat exchange tubes inside the boiler body, the material of the heat exchange tubes is alloy steel, the diameter of each heat exchange tube is DN50, and the sum of the cross-sectional areas of the heat exchange tubes is 0.12m 2 , and the inner center of the boiler body is provided with a center tube, the diameter of the center tube is DN150, and the cross-sectional area is 0.018m 2 , the central tube is made of alloy steel, and the outlet of the central tube is provided with a conical regulating valve, which includes a conical spool and an actuator, wherein the conical spool corresponds to the exit of the central tube,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com