Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Avoid Dew Point Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

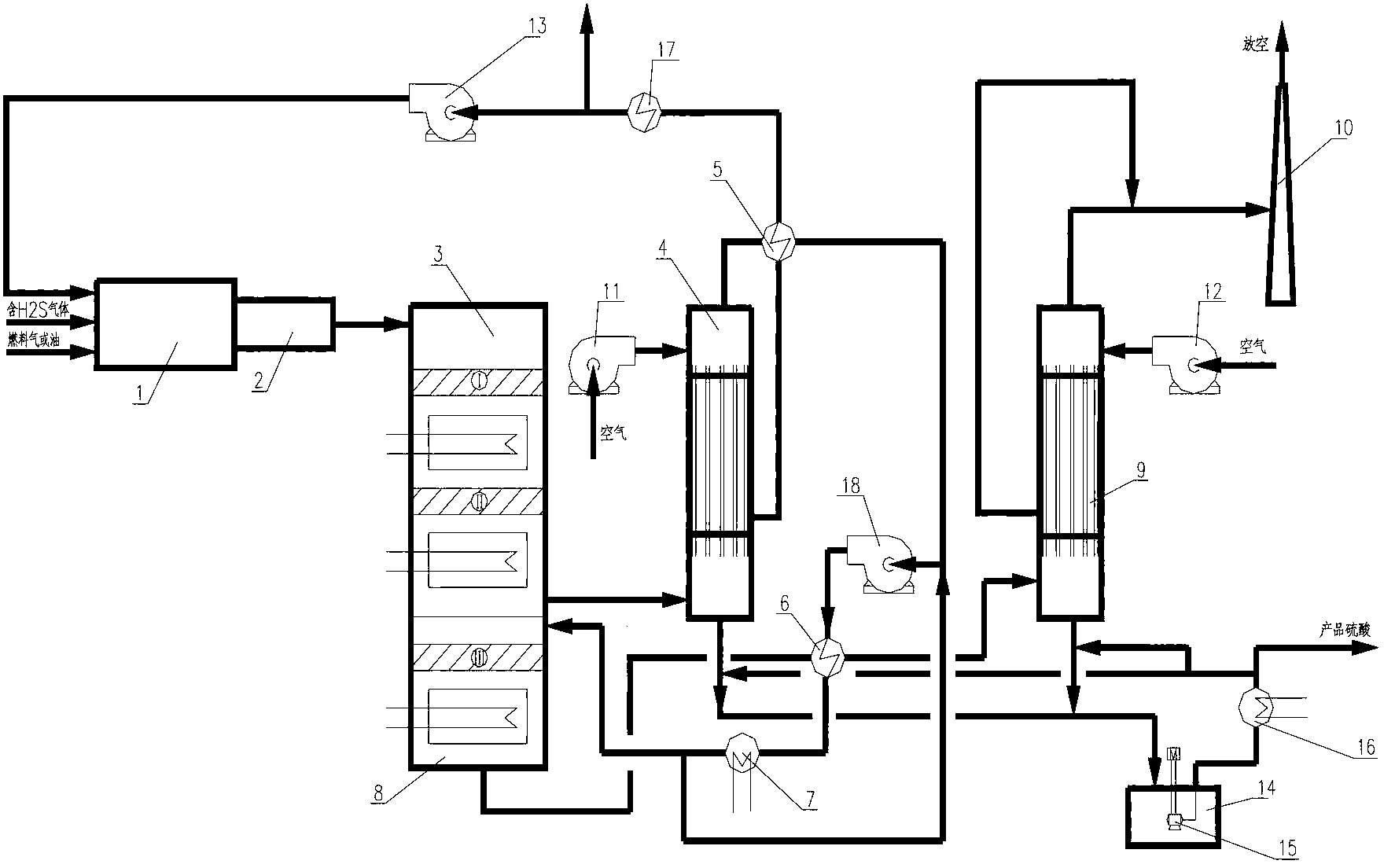

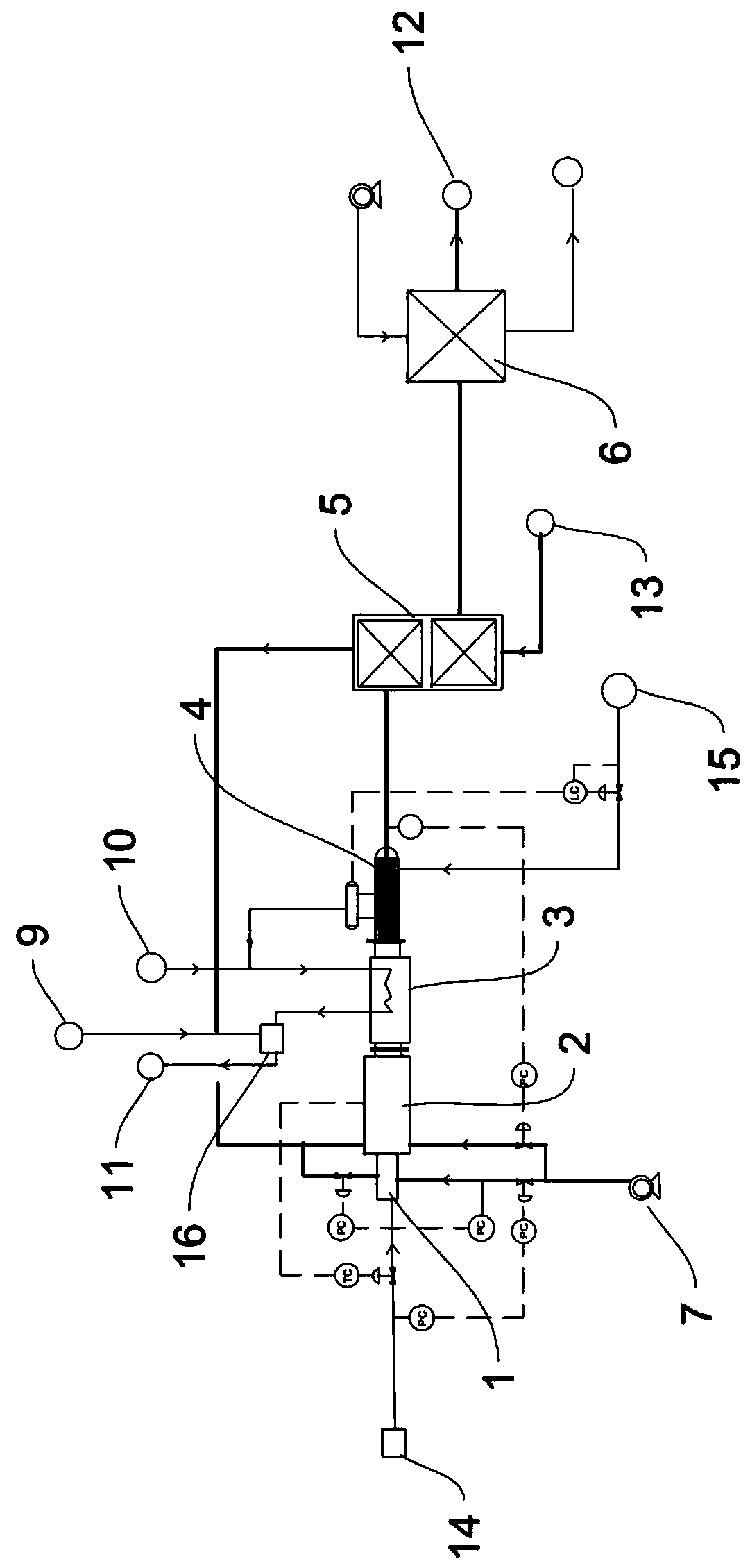

Wet method used for preparing sulfuric acid from exhaust gas containing hydrogen sulfide

InactiveCN103626136AAvoid Dew Point CorrosionAvoid corrosionSulfur compoundsEnergy inputWater vaporWaste treatment

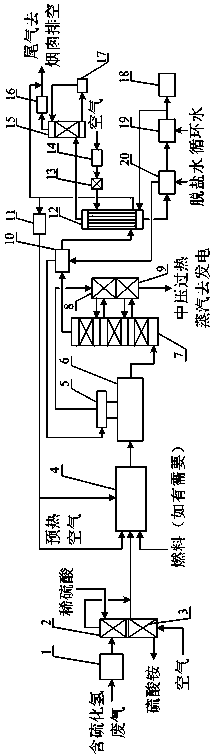

The invention discloses a wet method used for preparing sulfuric acid from exhaust gas containing hydrogen sulfide, and belongs to the technical field of waste gas treatment in environmental protection industry and chemical production. The wet method comprises following steps: removal of nitrogen compounds of the exhaust gas containing hydrogen sulfide is realized using dilute sulphuric acid with a mass fraction of 30 to 50%; the treated exhaust gas containing hydrogen sulfide is delivered into an incinerator, preheated air is added so as to maintain a combustion temperature of 700 to 1000 DEG C and a reducing / oxidizing atmosphere, so that sufficient burning of hydrogen sulfide and other combustible components is realized, and generation amount of nitrogen oxide is reduced; high temperature gas at an incinerator outlet is delivered into a medium pressure waste heat boiler so as to recycle heat energy and byproduct saturated vapour; flue gas containing sulfur dioxide at a waste heat boiler outlet is delivered directly into a converter, and flue gas containing sulfur trioxide and vapour is obtained via primary conversion; reaction heat in the converter is removed in time using heat-exchange equipment; flue gas at a converter outlet is delivered into at least primary-stage condenser tube pass, and an appropriate amount of air is delivered into condenser shell pass to be used as a cooling medium; heat energy of high temperature concentrated sulfuric acid flows out from the bottom of the condenser is recycled via a desalting water preheater and an acid cooler; and exhaust gas at a condenser outlet is delivered into a desulfurization tower so as to remove sulfur dioxide and nitrogen oxides.

Owner:CHINA PETROLEUM & CHEM CORP +1

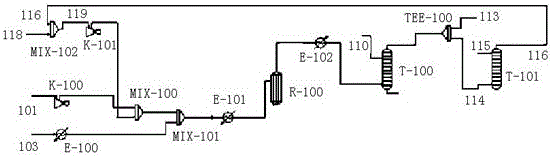

Liquid-phase dechlorinating method for chlorine-contained alkylate oil

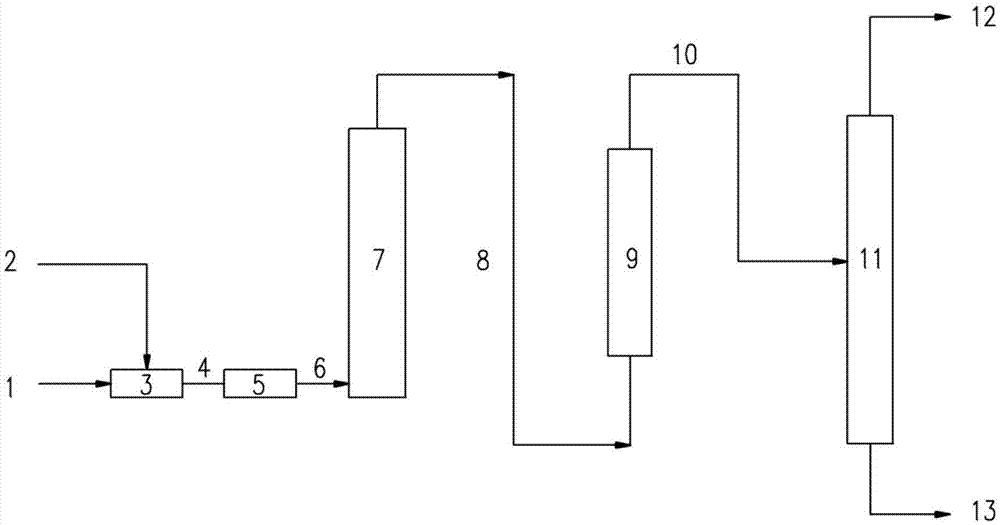

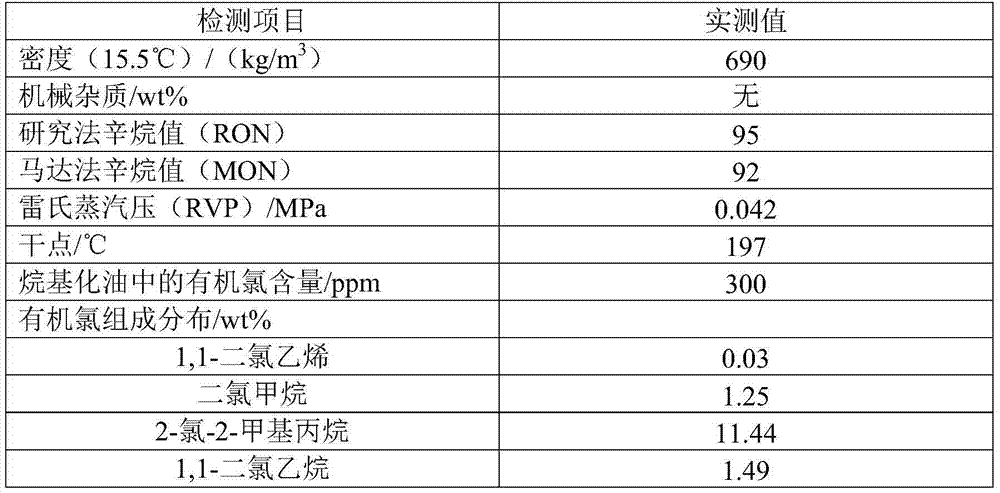

InactiveCN106995720AMild reaction conditionsReduce hydrogen oil ratioTreatment with hydrotreatment processesHydrogenSorbent

The invention provides a liquid-phase dechlorinating method for chlorine-contained alkalate oil. The method comprises the following steps: (1) liquid phase hydrogenation: under hydrogenation condition, enabling chlorine-contained alkalate oil in a liquid phase state to react with hydrogen and a hydrogenation catalyst to generate a hydrogenated product containing HCl; (2) liquid phase adsorption: contacting the hydrogenated product containing the HCl in a liquid phase state with an adsorbent and obtaining the hydrogenated product with the HCl removed after the HCl is adsorbed; (3) oil and gas separation: separating the hydrogenated product with the HCl removed from hydrogen and obtaining the dechlorinated alkalate oil. The synthesizing method utilizes liquid-phase hydrogenation, has moderate operation conditions and low hydrogen-oil ratio, avoids arranging equipment of hydrogenating furnaces, feeding furnaces, heating furnaces and the like, reduces investment and operation cost of devices and can achieve complete conversion of organic chloride.

Owner:SINOPEC ENG +1

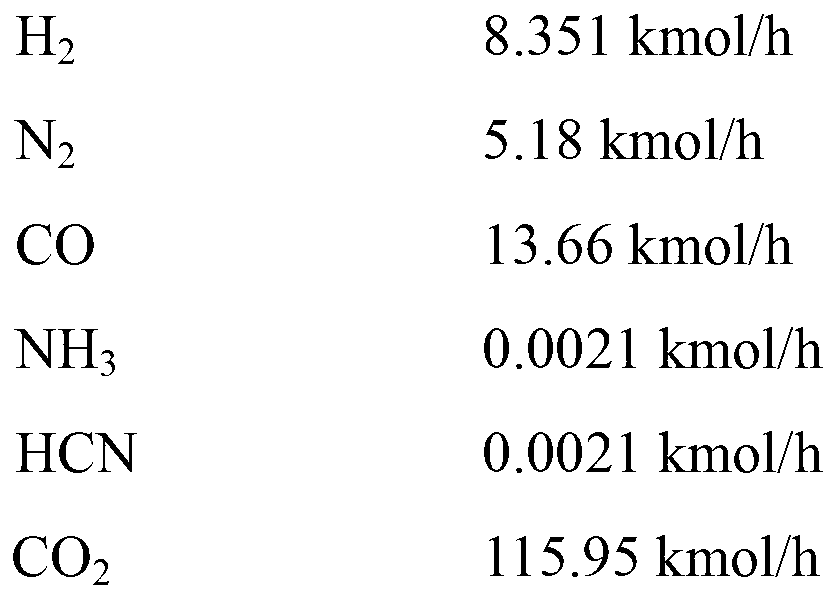

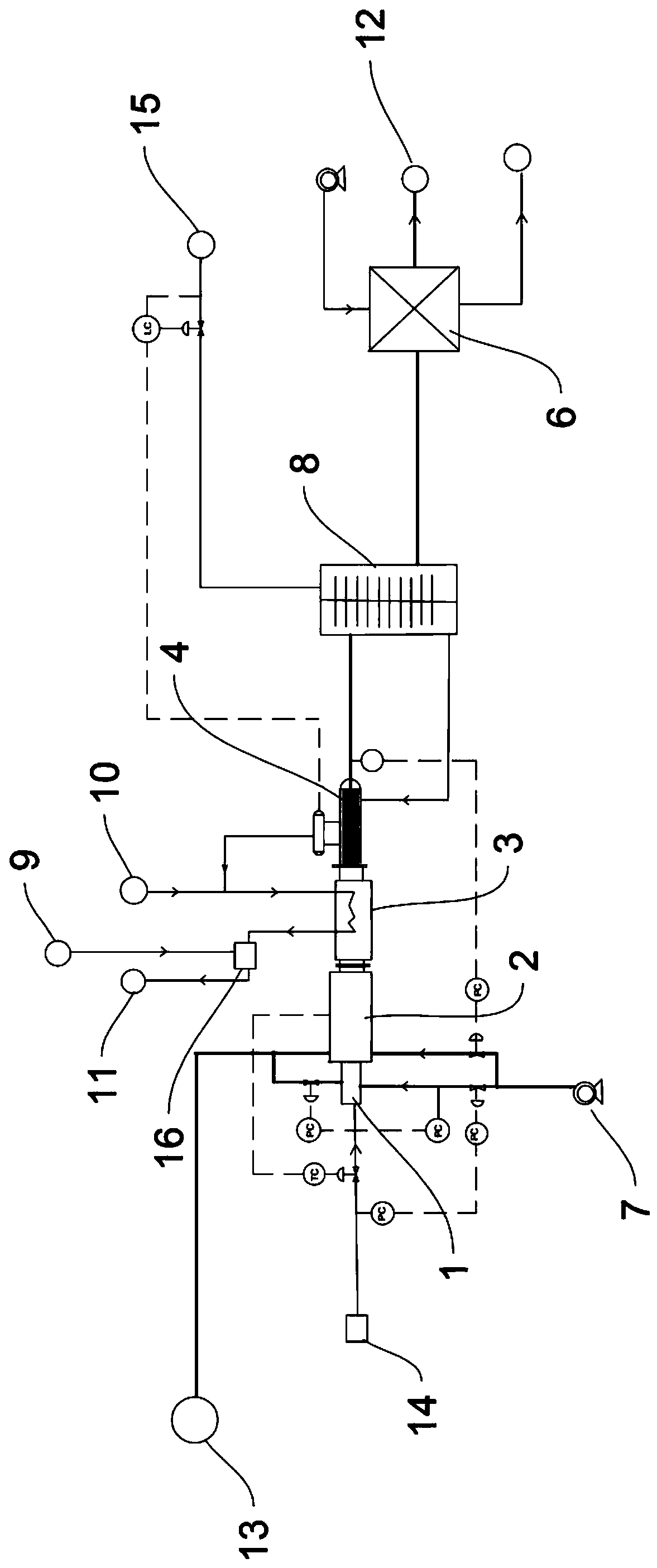

High-efficiency sulfur recovery method of waste gas containing hydrogen sulfide

ActiveCN103318847AGuaranteed separation effectAvoid Dew Point CorrosionEnergy inputSulfur preparation/purificationRecovery methodWater vapor

The invention discloses a high-efficiency sulfur recovery method of hydrogen sulfide containing waste gas. The high-efficiency sulfur recovery method is characterized in that the H2S containing waste gas is completely burned in an incinerator to generate SO2 gas and water vapor, then the SO2 gas and the water vapor are cooled through a waste heat boiler to generate process gas with the temperature of 300 DEG C-500 DEG C, and simultaneously, the 7.0-7.5 MPa high-pressure gas is generated; the process gas enters an oxidation reactor with a reaction section and a cooling section and is catalyzed and oxidized in the oxidation reactor to generate SO3 which is converted into sulfuric acid vapor; the sulfuric acid vapor enters a cooler and is cooled by air when the temperature of the sulfuric acid vapor is above 250 DEG C, so that sulfuric acid liquid and non-condensable gas are generated; the non-condensable gas is subjected to multistage heating, and then is subjected to secondary catalytic oxidation and secondary cooling separation, the non-condensable gas reaching the emission standards is discharged, and the sulfuric acid liquid separated out is collected. The high-efficiency sulfur recovery method has the advantages that the corrosion on production equipment can be avoided, the technology practicability is ensured, the heat is stepwise used according to the difference of liquid levels, and the utilization rate of heat is high.

Owner:SINOPEC NANJING ENG & CONSTR +1

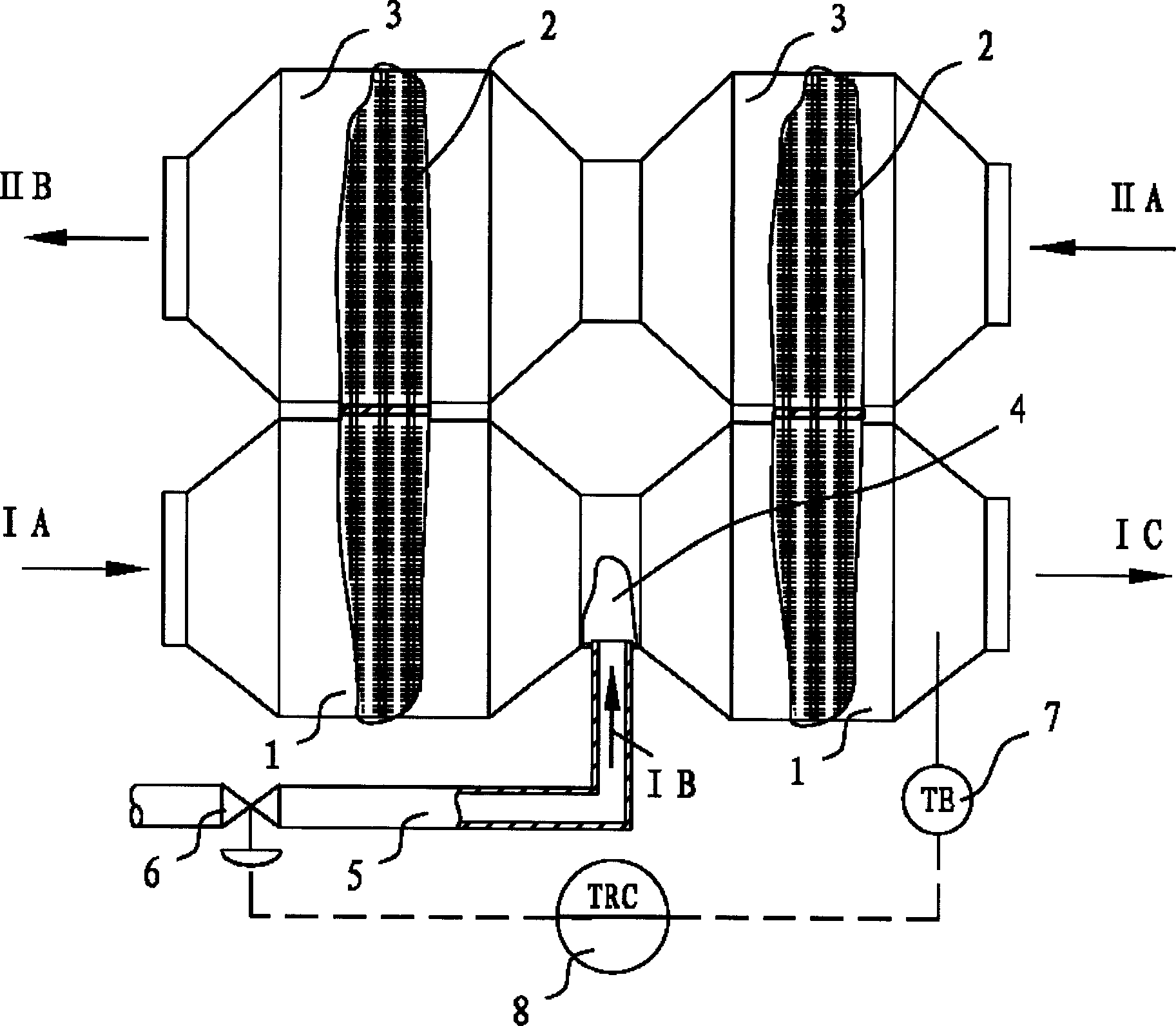

Double-preheating environmental protection combustor for tube heating furnace and applications thereof

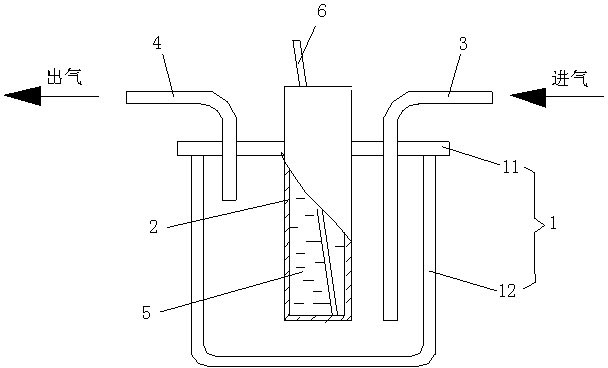

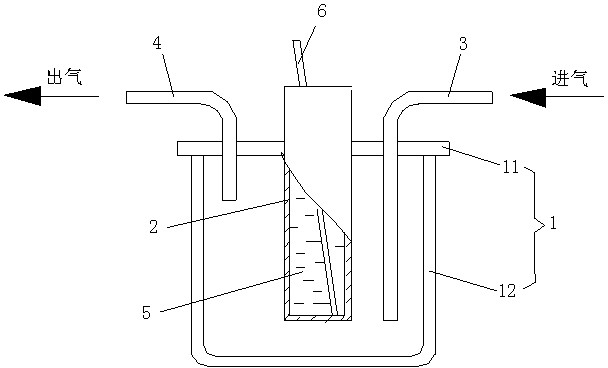

InactiveCN104964282AIncrease temperatureReduce the temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFlue gas

The invention relates to a double-preheating environmental protection combustor for a tube heating furnace and applications thereof. The combustor is disposed in a hearth (16) of the tube heating furnace, and comprises a cylinder (2), a firebrick (6), outer spray guns (4), and inner spray guns (5). The firebrick (6) is arranged at the upper portion of the cylinder (2). A flue (15) concentric with the cylinder (2) is formed inside the firebrick (6). The height of an outer spray gun nozzle (8) of each outer spray gun (4) is larger than the height of an inner spray gun nozzle (7) of each inner spray gun (5), and the portions, between the outer spray gun nozzles (8) and the inner spray gun nozzles (7), of the firebrick (6) are provided with firebrick inclined holes (12), so that combustion gas passing through the outer spray guns (4) and the inner spray guns (5) can burn in stages. According to the invention, a problem that a conventional combustor cannot be used for dual-preheating gas is solved, and fuel staging and flue gas multistage circulation technologies are employed, so that flame combustion high-temperature regions can be reduced, and the combustion can be stabilized.

Owner:上海浩用工业炉有限公司 +1

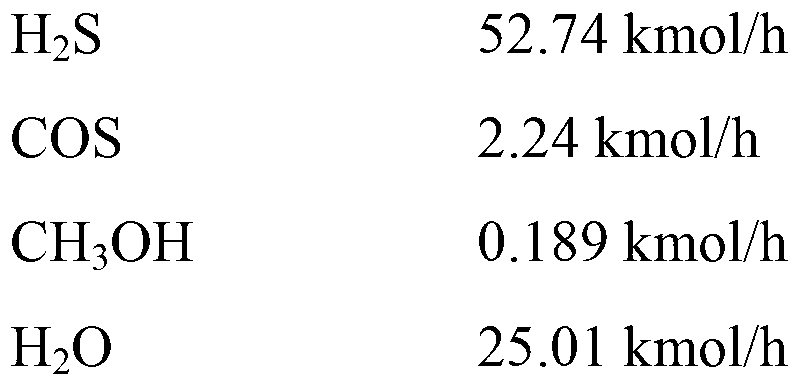

Tail gas treatment system for waste salt recycling treatment and application of tail gas treatment system

PendingCN110201514ASimple structural connectionEasy to useCombination devicesIncinerator apparatusCombustion chamberEmission standard

The invention relates to a tail gas treatment system for waste salt recycling treatment. The tail gas treatment system comprises a two-time combustion chamber, a waste heat boiler, a quench tower, a bag dust collector, a precooler, a two-stage washing tower, a white flue gas elimination device, a chimney and a circulating water tank, wherein the two-time combustion chamber comprises an input end and a flue gas output end, the input end of the two-time combustion chamber comprises a natural gas input end, a pyrolysis gas input end and an ammonium hydroxide input end, the natural gas input end is connected with natural gas, the natural gas can be input into the two-time combustion chamber through the natural gas input end, the pyrolysis gas input end of the two-time combustion chamber is connected with pyrolysis waste gas of a pyrolyzing furnace, the ammonium hydroxide input end is connected with ammonium hydroxide, and the ammonium hydroxide can be input into the two-time combustion chamber through the ammonium hydroxide input end. The tail gas treatment system for the waste salt recycling treatment has the advantages that the connection of the structure is simple, the use is convenient, after the pyrolysis waste gas in the pyrolyzing furnace is treated, pollutants in flue gas can completely meet emission standards, the cost is low, the effect is good, and the system can be applied in the waste salt recycling treatment.

Owner:北京航天环境工程有限公司

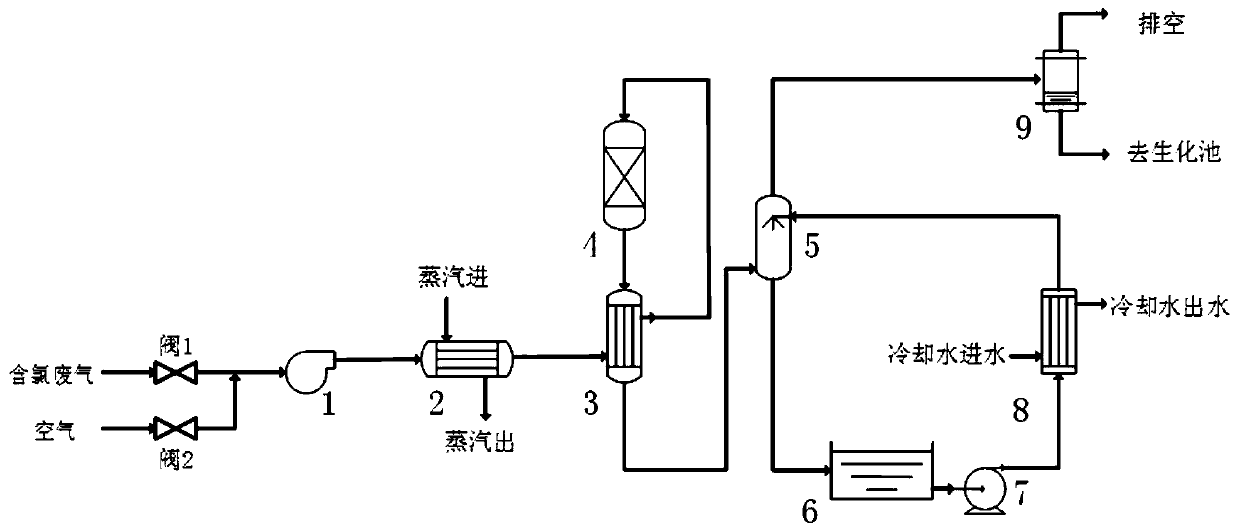

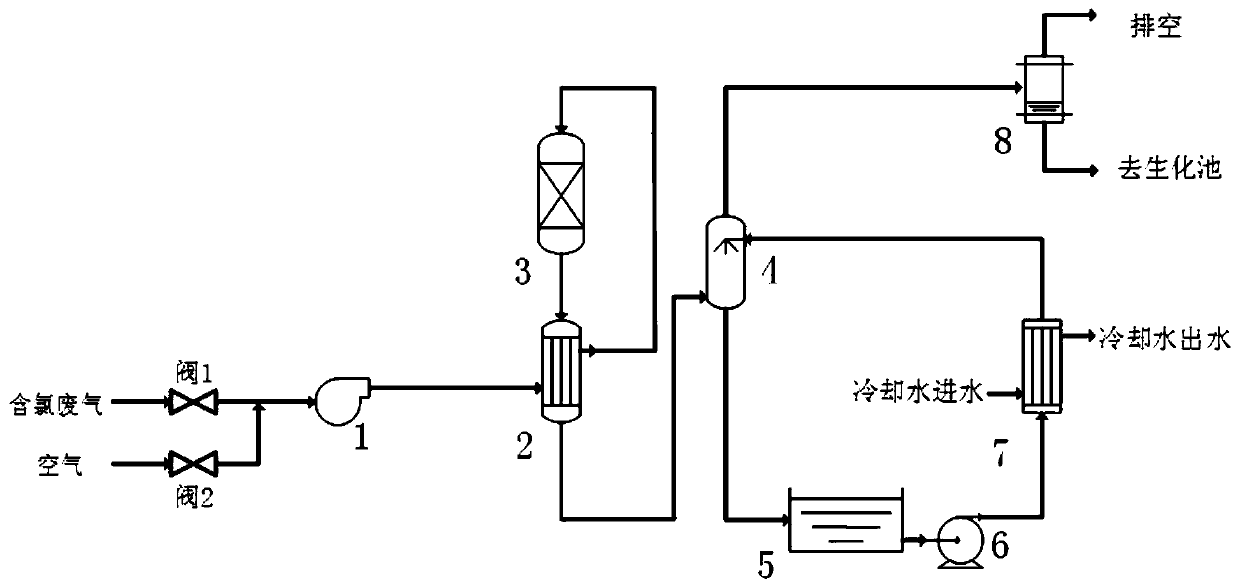

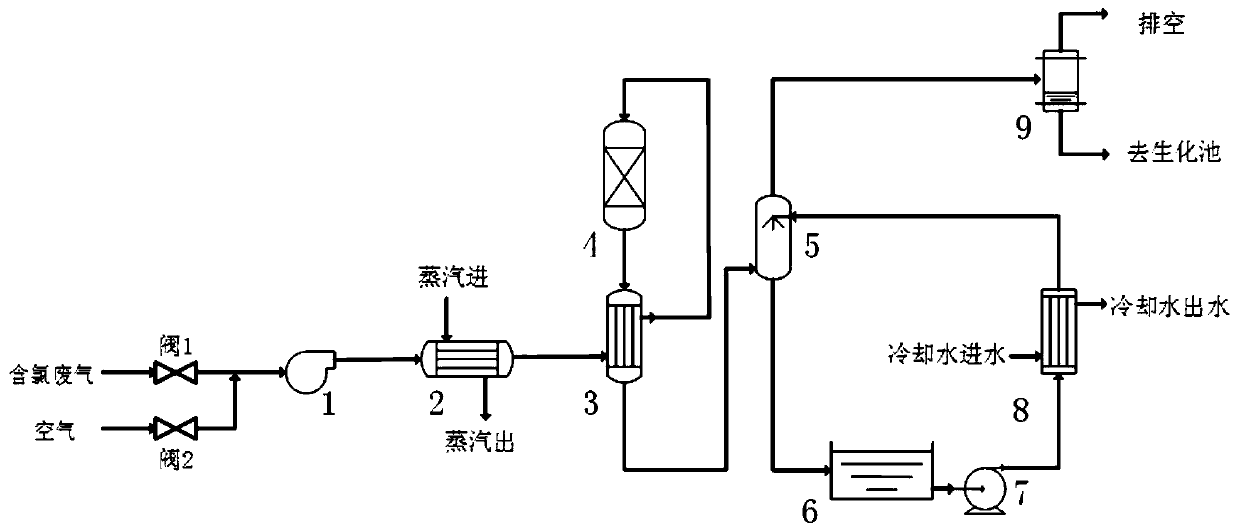

Method and system for purifying exhaust gas containing hydrogen chloride gas and organic chlorine compound gas

InactiveCN110038407AAvoid Dew Point CorrosionExtended service lifeGas treatmentDispersed particle separationFixed bedCatalytic oxidation

The invention discloses a method for purifying an exhaust gas containing a hydrogen chloride gas and an organic chlorine compound gas. The method comprises the following steps: introducing a mixed gasof exhaust gas and air into a graphite preheater for preheating; exchanging heat and rising temperature by introducing a high-temperature gas from a shell side of a heat exchanger A and a fixed bed reactor; introducing the mixed gas into the fixed bed reactor for catalytic oxidation reaction; introducing high-temperature gas after reaction into a tube pass of the heat exchanger A, exchanging heatand cooling; introducing the cooled gas into a spraying washer for absorbing an acidic gas, and then introducing into a gas-liquid separator and directly discharging the gas. According to the invention, the method for catalytic oxidation by using the fixed bed reactor is adopted for efficiently low-cost treating the exhaust gas containing the hydrogen chloride gas and the organic chlorine compound gas; the graphite preheater is adopted for preheating the mixed gas, so that the dew point corrosion of HCl gas to the pipeline and the heat exchanger can be reduced; the high-temperature exhaust gas after catalytic oxidation exchanges heat with the to-be-treated exhaust gas through the heat exchanger, so that reaction heat can be fully utilized; the method has higher economic benefits.

Owner:NANJING UNIV OF TECH +1

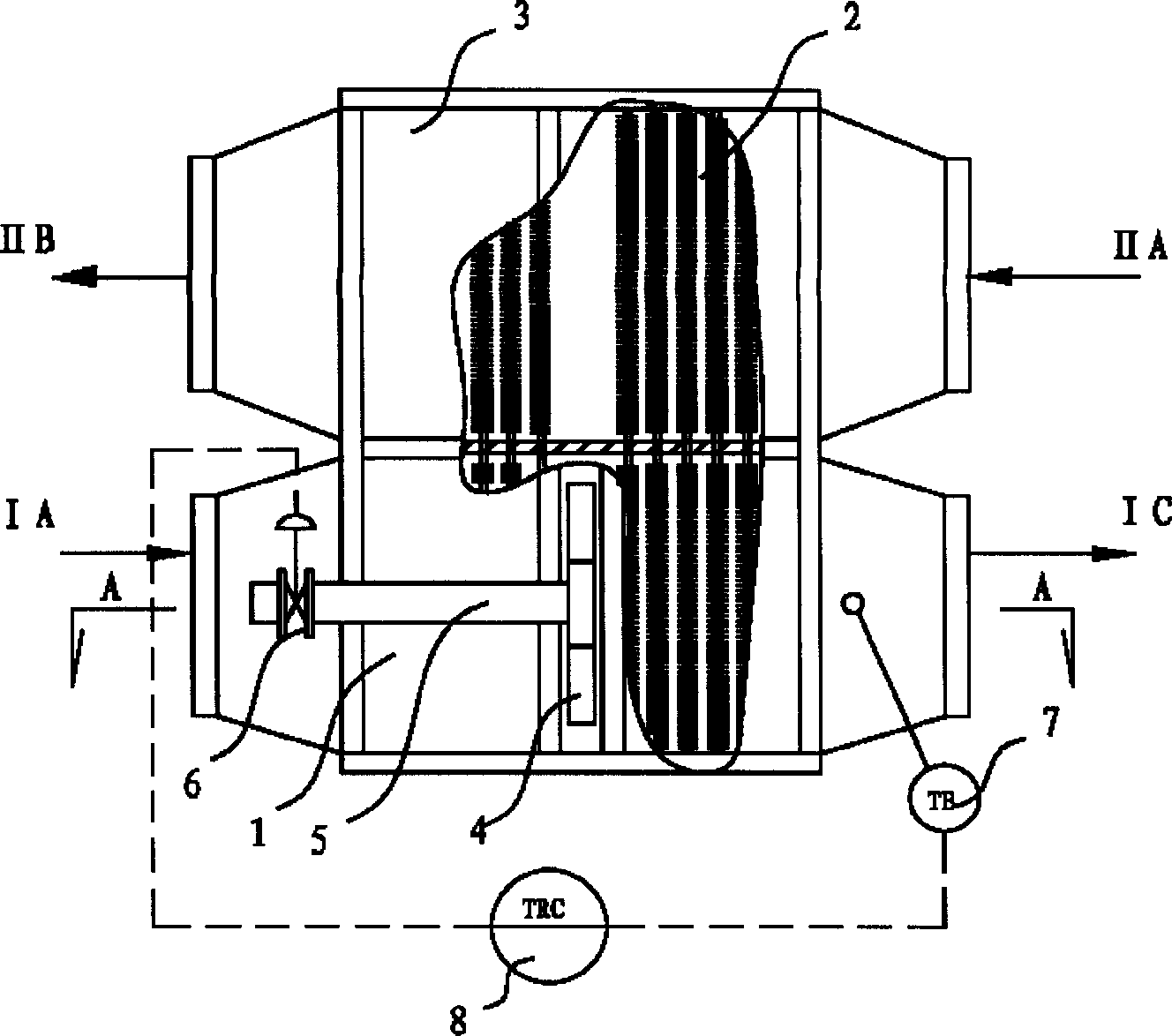

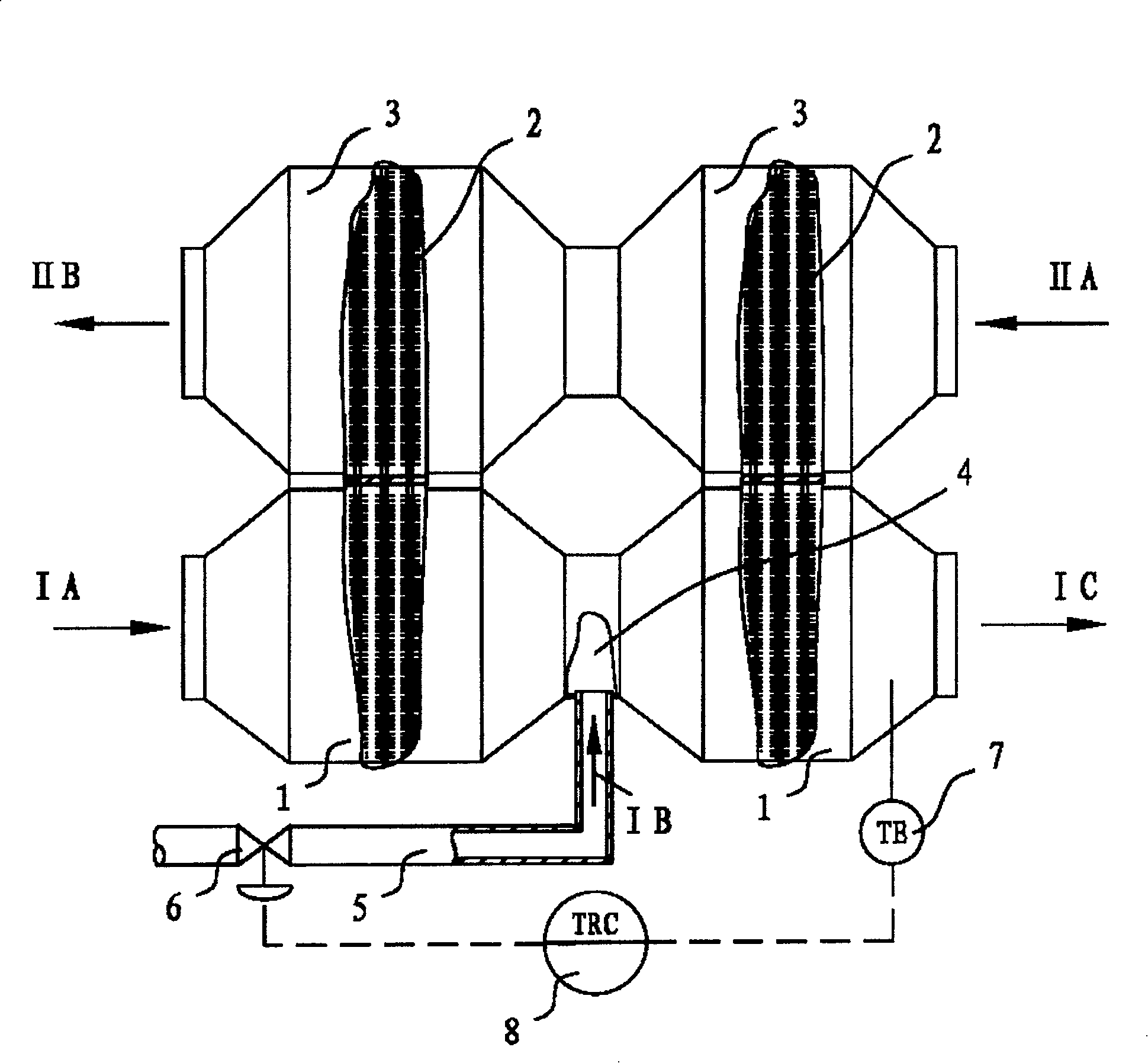

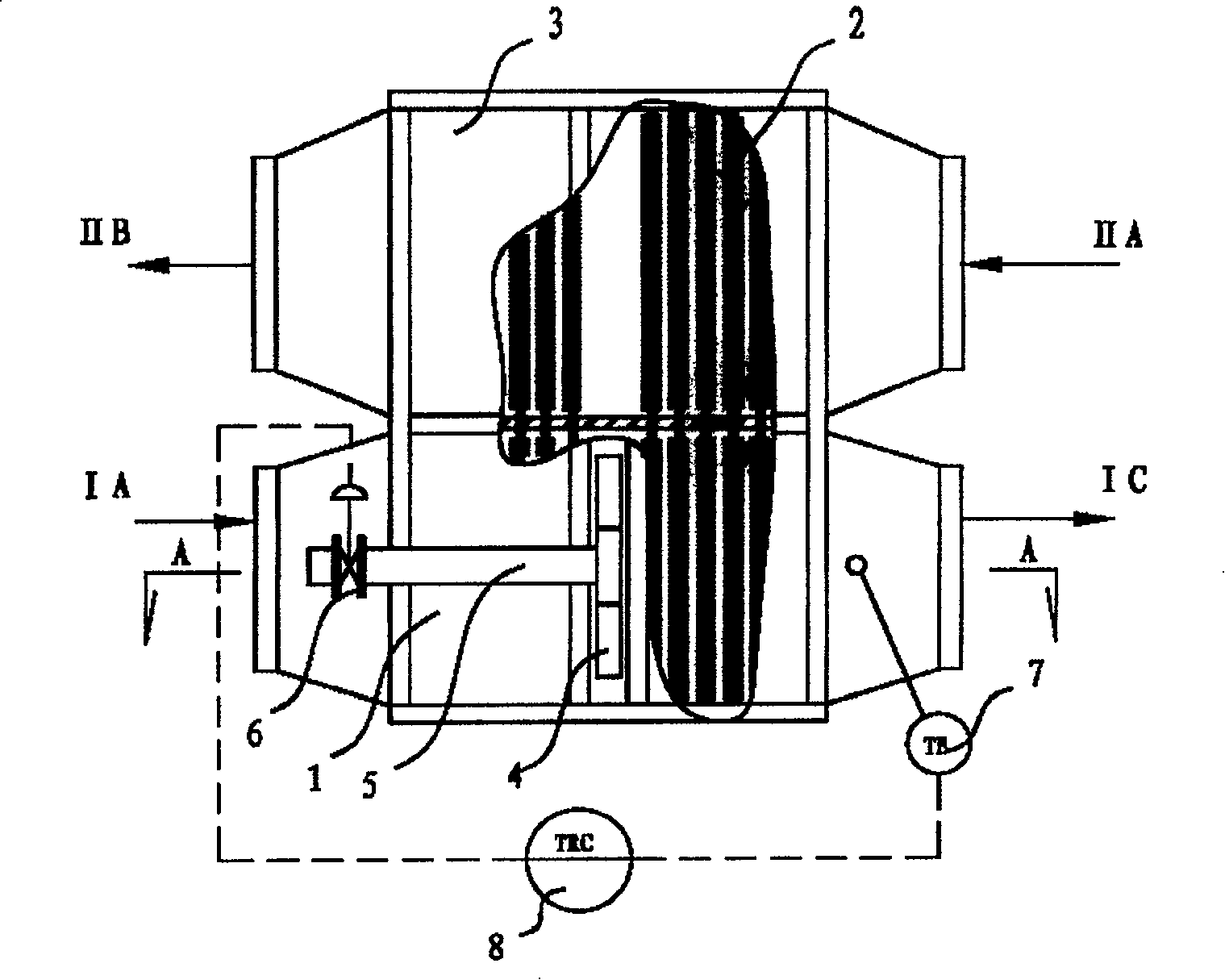

Method for avoiding dew point corrosion of heat pipe heat exchanger and a heat pipe heat exchanger

InactiveCN1789873ANo special requirements for manufacturing materialsSolve the problem of dew point corrosionIndirect carbon-dioxide mitigationWaste heat treatmentTemperature controlMechanics

This invention relates to heat pipe exchanger method to avoid exposed point erosion and to one exchanger device, wherein, The exchanger comprises smoke channel, heat pipe set and heated air channel, wherein, the channel and the heated air channel are parallel to each other; the heat pipe set is located to the smoke channel and the dissipation section is located on the heated air channel; The smoke and the heated air are inversed through smoke channel and heated air channel with near exit section to one high temperature for heating.

Owner:杨署生

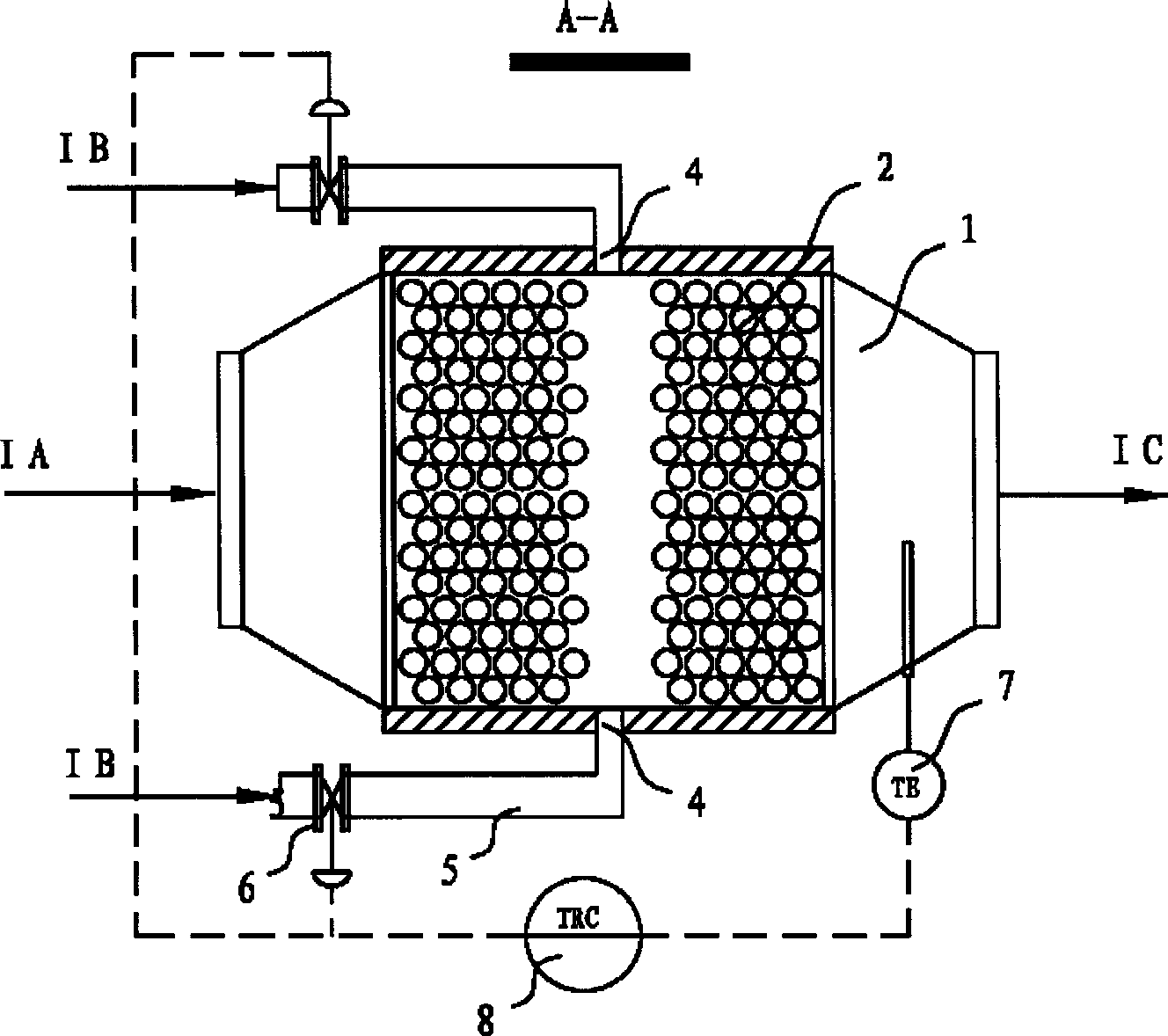

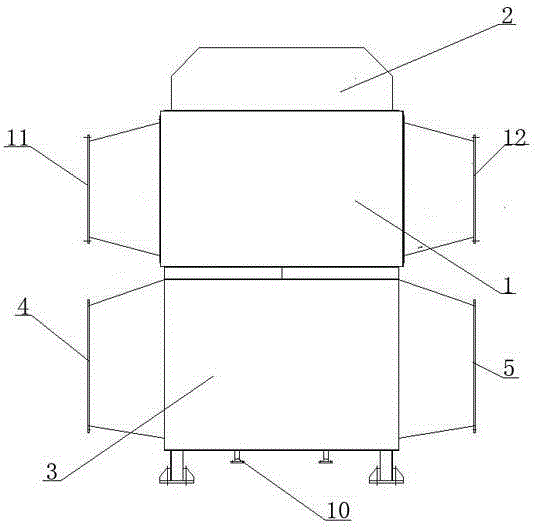

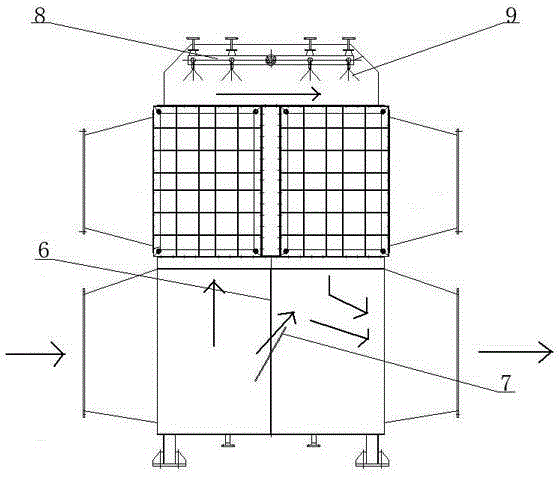

Plate type air preheating device with adjusting function

ActiveCN104567476AEnsure exhaust gas temperatureGuaranteed uptimeHeat exchanger casingsStationary tubular conduit assembliesThermodynamicsEngineering

The invention relates to a plate type air preheating device with the adjusting function. The device comprises a plate type heat exchange assembly, a guide cover and an adjusting barrel body; the plate type heat exchange assembly is equipped with a preheating air runner and a smoke runner; the guide cover and the adjusting barrel body are respectively arranged at two ends of the smoke runner of the plate type heat exchange assembly; the guide cover is a cover body of which one end is opened, and the guide cover covers one end of the smoke runner of the plate type heat exchange assembly through the opening end; a smoke inlet and a smoke outlet are respectively formed in two ends of the adjusting barrel body; the inner part of the adjusting barrel body is divided into a smoke inlet chamber and a smoke outlet chamber through a fixed baffle plate; through holes which communicate with the smoke runner of the plate type heat exchange assembly are respectively formed in the barrel walls of the two chambers. According to the air preheating device, movable baffles can be adjusted when the operation condition is less than the design condition, and then part of the smoke is directly exhausted into the smoke outlet without flowing through a heat exchange module, so that the exhaust temperature can be kept within a stable range, and as a result, dew point corrosion can be avoided, and long-term stable running is achieved.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

Hydrogenation corrosion inhibitor

InactiveCN109504438ANeutralizeFunctionalTreatment apparatus corrosion/fouling inhibitionNitrogenWater soluble

The invention discloses a hydrogenation corrosion inhibitor. The hydrogenation corrosion inhibitor is prepared from the following components by mass: 8-12 percent of water-soluble quaternary ammoniumsalt, 1-5 percent of dispersant, 2-5 percent of monoethanolamine, 4-10 percent of water-soluble imidazoline compound, 1-5 percent of alkynol compound, 4-15 percent of nitrogen-containing adsorption corrosion inhibitor, and the balance of water. The synergistic effect of all the components of the hydrogenation corrosion inhibitor disclosed by the invention can significantly reduce acidic corrosioninhibition, and simultaneously reduce the amount of the hydrogenation corrosion inhibitor. Moreover, the hydrogenation corrosion inhibitor does not contain metals that are harmful to a catalyst, a pHvalue is 9-11, and a mechanical impurity is less than or equal to 0.08 percent.

Owner:JIANGSU KECHUANG PETROCHEM

United acid manufacturing method by utilizing sulfuretted hydrogen and sulphur

ActiveCN103030115AImprove efficiencyAvoid Dew Point CorrosionSulfur compoundsHydrogenProcess equipment

The invention relates to a united acid manufacturing method by utilizing sulfuretted hydrogen and sulphur. The method is characterized in that in a united acid manufacturing production process by utilizing the sulfuretted hydrogen and the sulphur, a fire-tube boiler is adopted at a third section of outlet of a converter and behind an intermediate temperate superheater; the evaporating pressure of the boiler is controlled to be 5.1-5.6Mpa, and the saturation temperature is 265-271 DEG C, the inner wall temperature of a fire tube is improved, and the temperature of the fire tube wall is 265.5-271.4 DEG C, so that the condition that the temperature of the fire tube wall is higher than the dew point temperature of sulfuric acid in the gas is guaranteed, and the dew point temperature in a whole sulfuretted hydrogen working condition is 263 DEG C, so that the dew point corrosion is avoided; meanwhile, two acid manufacturing working conditions of a wet method and a dry method are considered, two fire tube boilers are adopted to be connected in series for operation; when the acid is manufactured by the wet method, the pressure of the two boilers is controlled to be 5.1-5.6Mpa; when the acid is manufactured by a dry method, the dew point of the sulfuric acid in the gas is about 155 DEG C according to the test of the dew point of the sulfuric acid in gas; the two boilers are separated to operate; the pressure of the first boiler is controlled to be 4.0-4.8Mpa; the pressure of the second boiler is controlled to be 1.0-1.8Mpa; and low-pressure steam is directly produced, and the heat is further recovered. With the adoption of the method provided by the invention, the dew point corrosion is avoided, and the use efficiency of process equipment is greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

Method for avoiding dew point corrosion of heat pipe heat exchanger and a heat pipe heat exchanger

InactiveCN100402964CNo special requirements for manufacturing materialsSolve the problem of dew point corrosionCombustion processIndirect heat exchangersTemperature controlEngineering

This invention relates to heat pipe exchanger method to avoid exposed point erosion and to one exchanger device, wherein, The exchanger comprises smoke channel, heat pipe set and heated air channel, wherein, the channel and the heated air channel are parallel to each other; the heat pipe set is located to the smoke channel and the dissipation section is located on the heated air channel; The smoke and the heated air are inversed through smoke channel and heated air channel with near exit section to one high temperature for heating.

Owner:杨署生

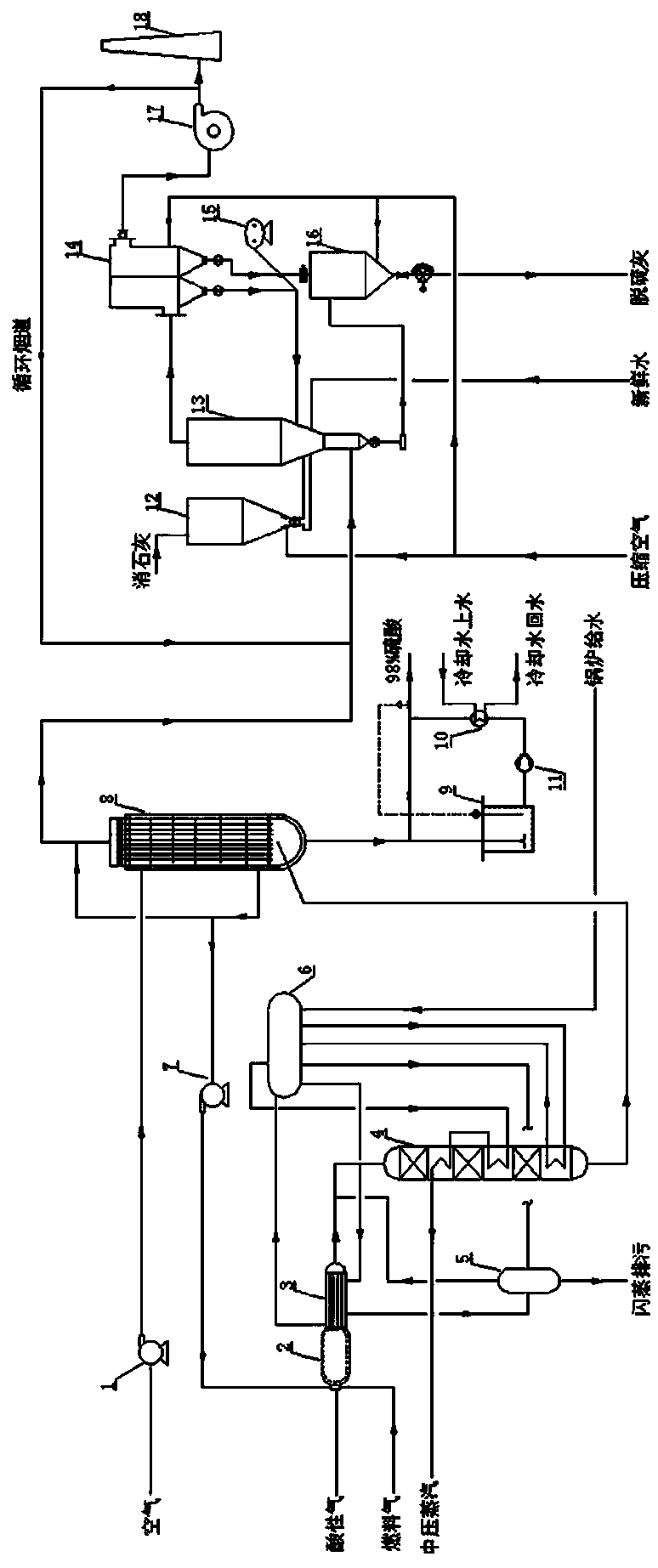

Acid gas wet method acid making technology combined with semidry method tail gas desulfurization

InactiveCN108862207AAchieve emission standardsImprove economyDispersed particle filtrationSulfur compoundsComing outFluidized bed

The invention relates to an acid gas wet method acid making technology combined with semidry method tail gas desulfurization. Acid gas and fuel gas enter an acid gas combustion furnace, the burnt technological gas enters a sulfur dioxide converter after subjected to heat exchanging through an acid gas waste heat boiler, the technological gas coming out from the sulfur dioxide converter enters a sulfuric acid condenser, sulfur acid flowing out from the bottom of the sulfur acid condenser enters a sulfur acid mixing slot after being mixed with recycling cool acid, and then cooled by a sulfur acid water cooler to serve as a sulfur acid product to be sent out of boundary, the tail gas coming out from the top of the sulfur acid condenser is mixed with part of hot air coming out from the sulfuracid condenser to form acid making tail gas which enters a venturi section on the lower part of a circulating fluidized bed desulfurizing tower, the acid making tail gas is in sufficient contact withslaked lime in the tower, the tail gas containing the slaked lime powder enters a bag filter, and the purified tail gas is exhausted into a chimney through a desulfurization induced draft fan. The method firstly combines the semidry method desulfurization with a wet method acid making technology, achieves 97-100% removal rate of SO3 (sulfuric acid mist) while removing SO2 in the tail gas, and up-to-standard emission of the tail gas is achieved.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

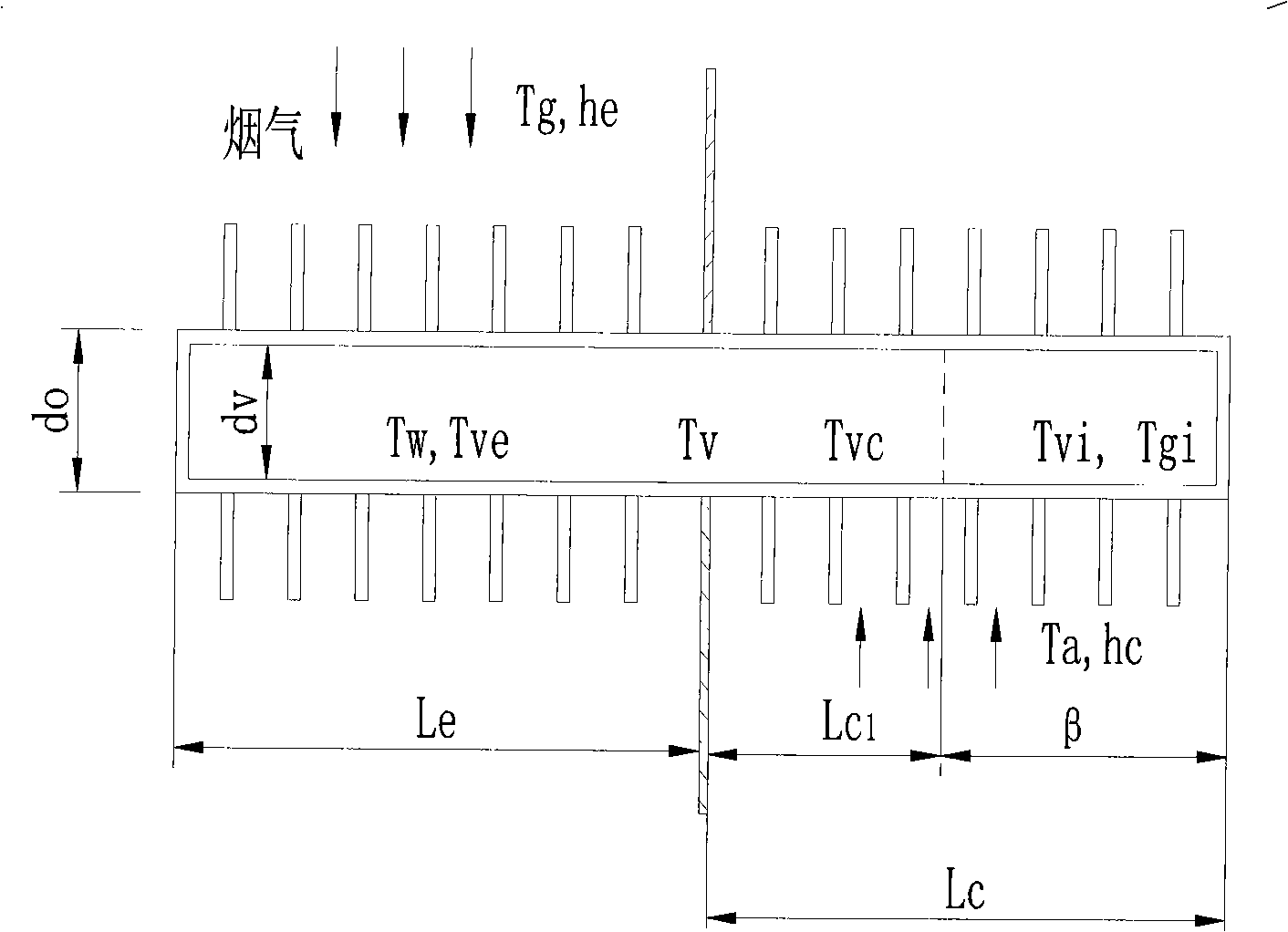

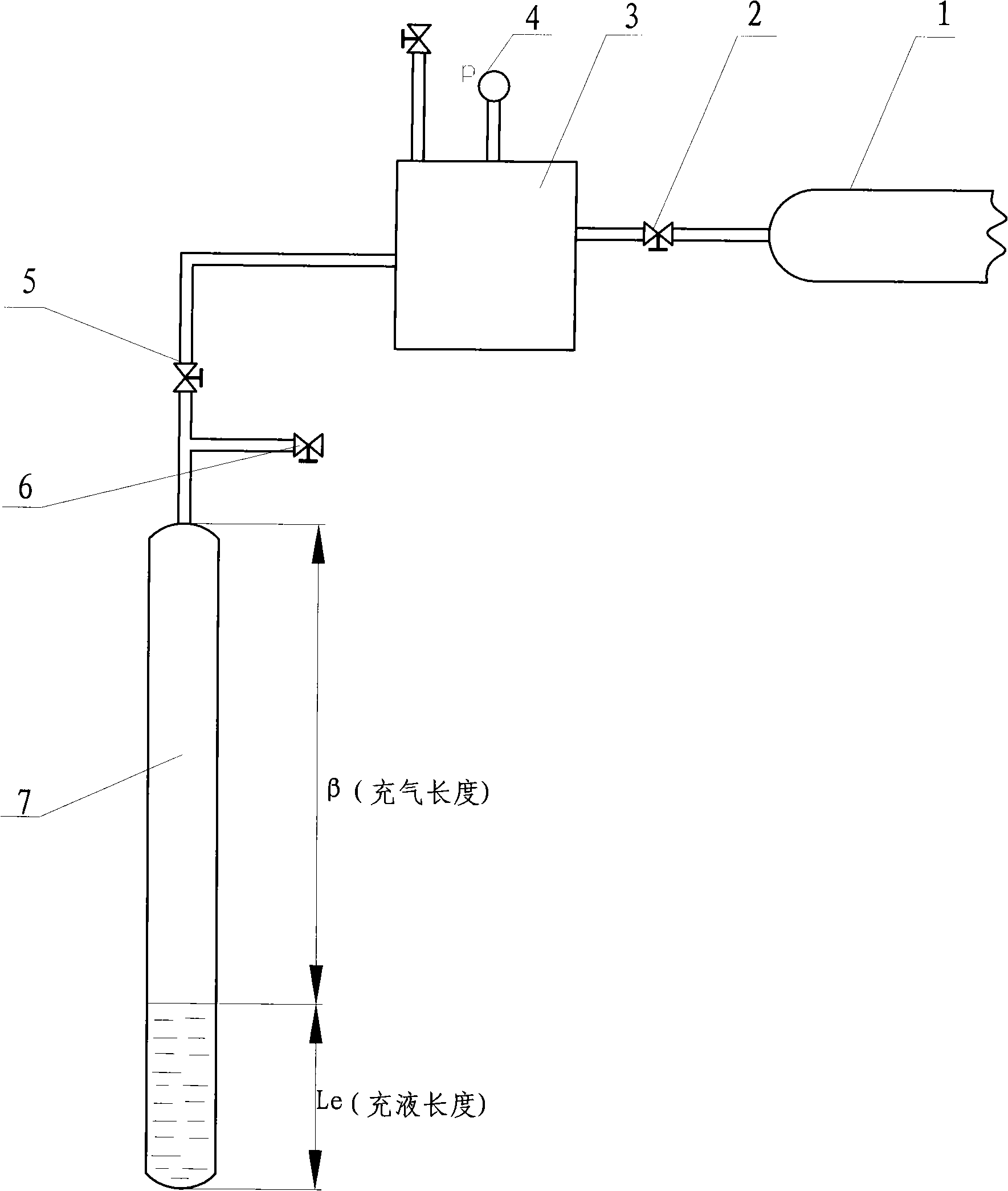

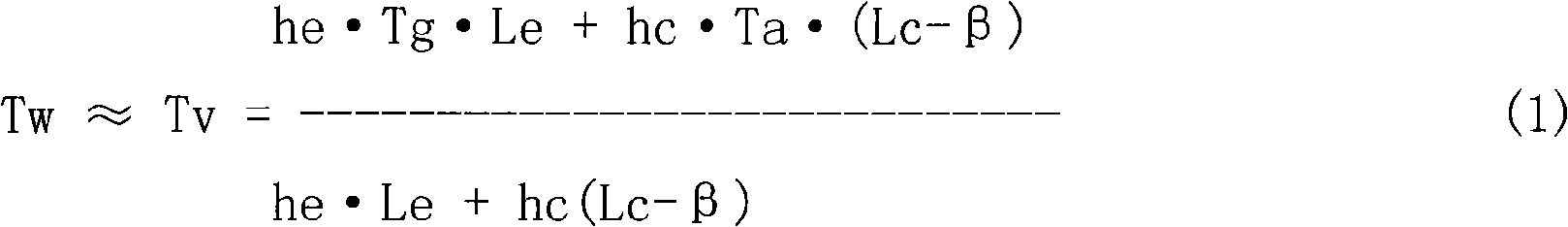

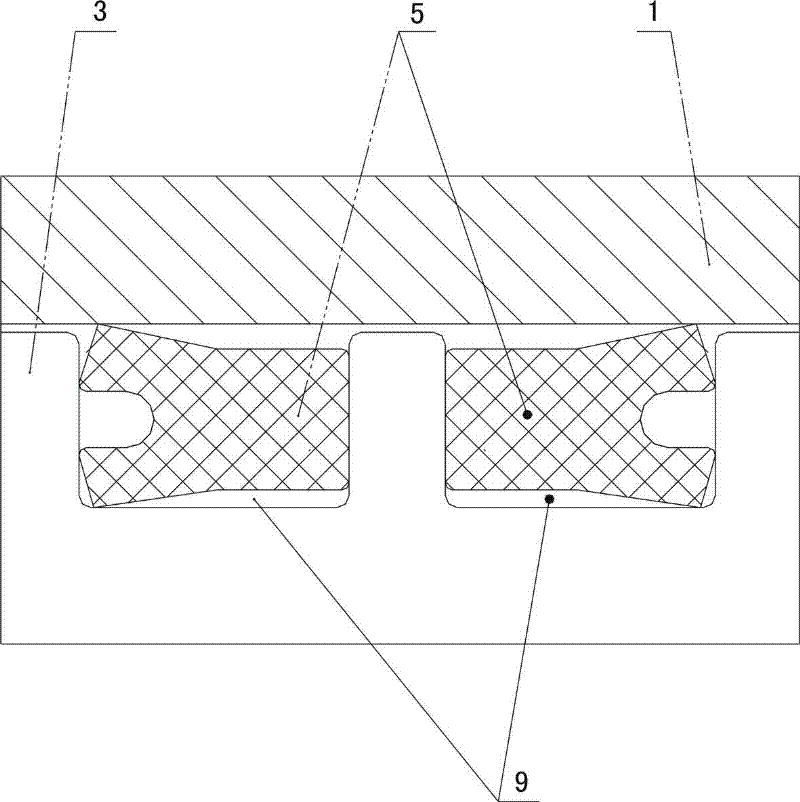

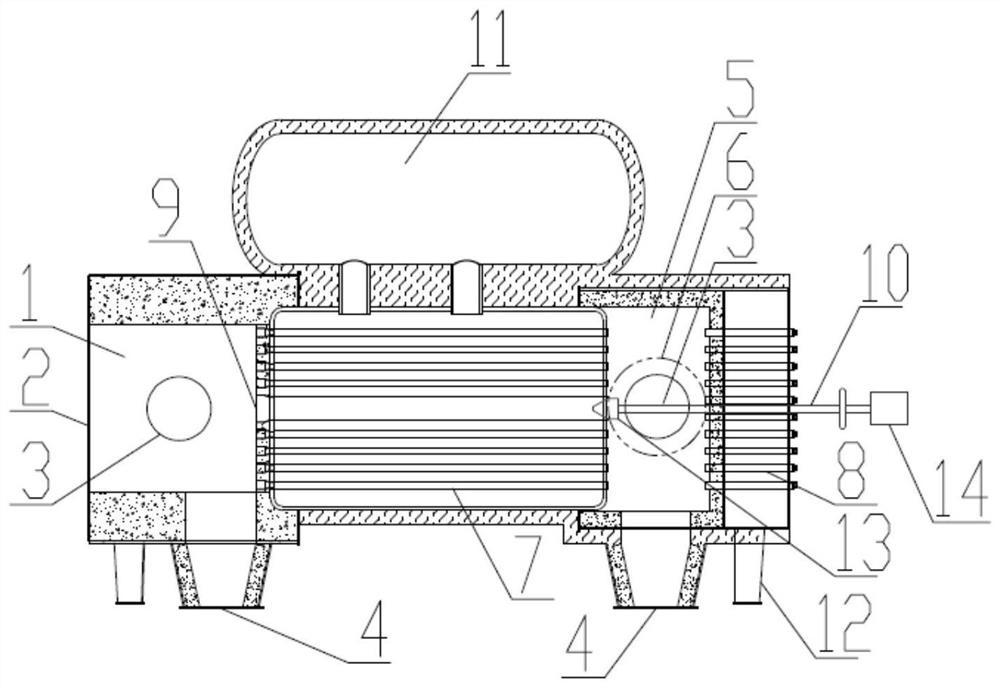

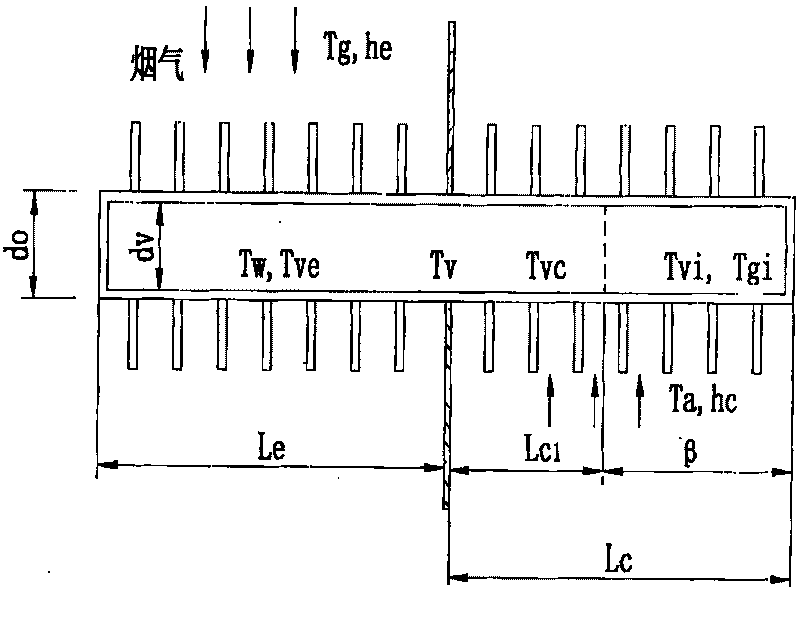

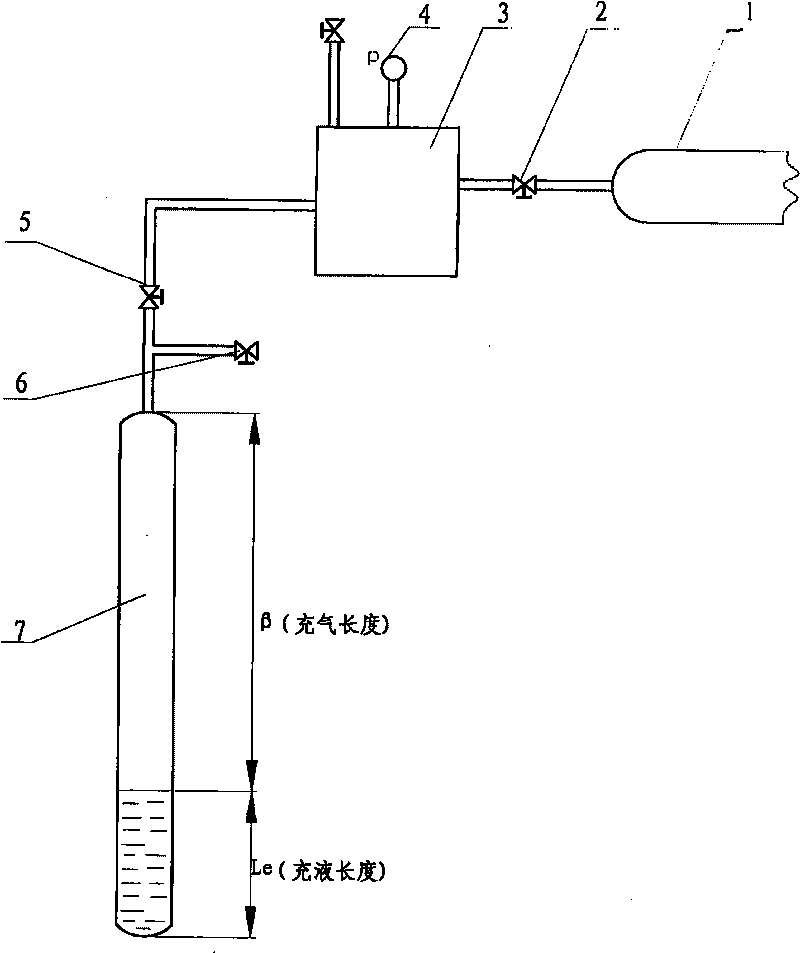

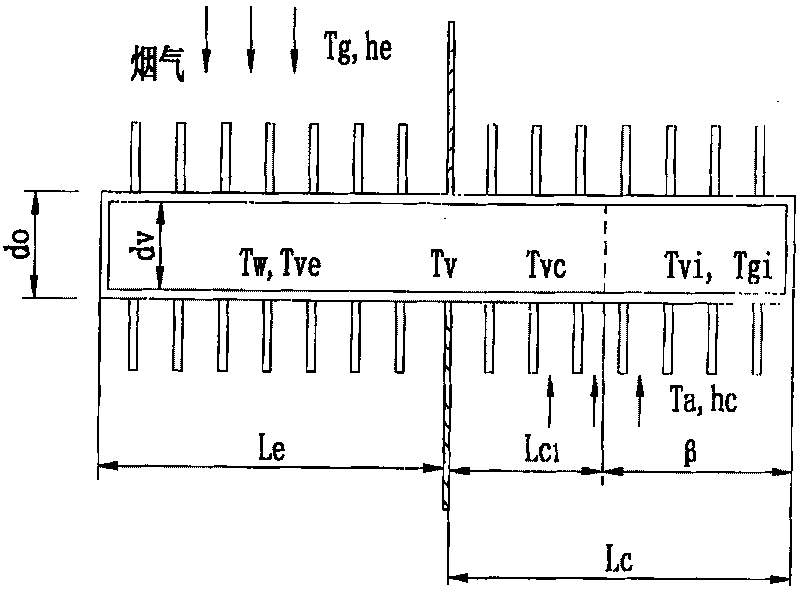

Application of gas buffered heat pipe for preventing dew-point corrosion

InactiveCN101303205AChange and adjust temperatureAvoid Dew Point CorrosionCorrosion preventionIndirect heat exchangersEvaporationProduct gas

The invention discloses an application of a gas-filled heat pipe in avoiding the dew point corrosion of a heat pipe exchanger. The gas-filled heat pipe comprises an evaporation segment and a condensation segment filled with a work substance. The application is characterized in that the condensation segment is also simultaneously filled with inert gases or nitrogen gas according to specified length and specified quantity of filled gases and can be filled with a mixture combined by gas molecules and the steam molecule of the work substance. The filled inert gases can automatically change occupied volume and filled gas length so as to change and adjust the temperature in the pipe and wall surface temperature, thus achieving the purpose of avoiding the dew point corrosion of the heat pipe.

Owner:余传林 +1

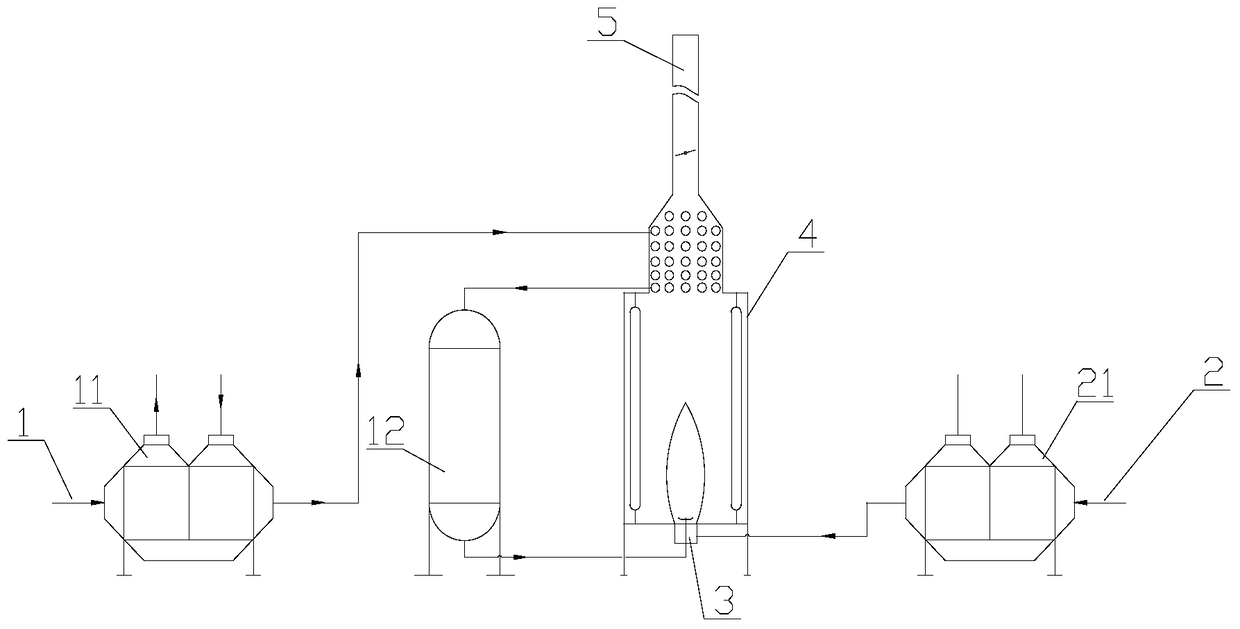

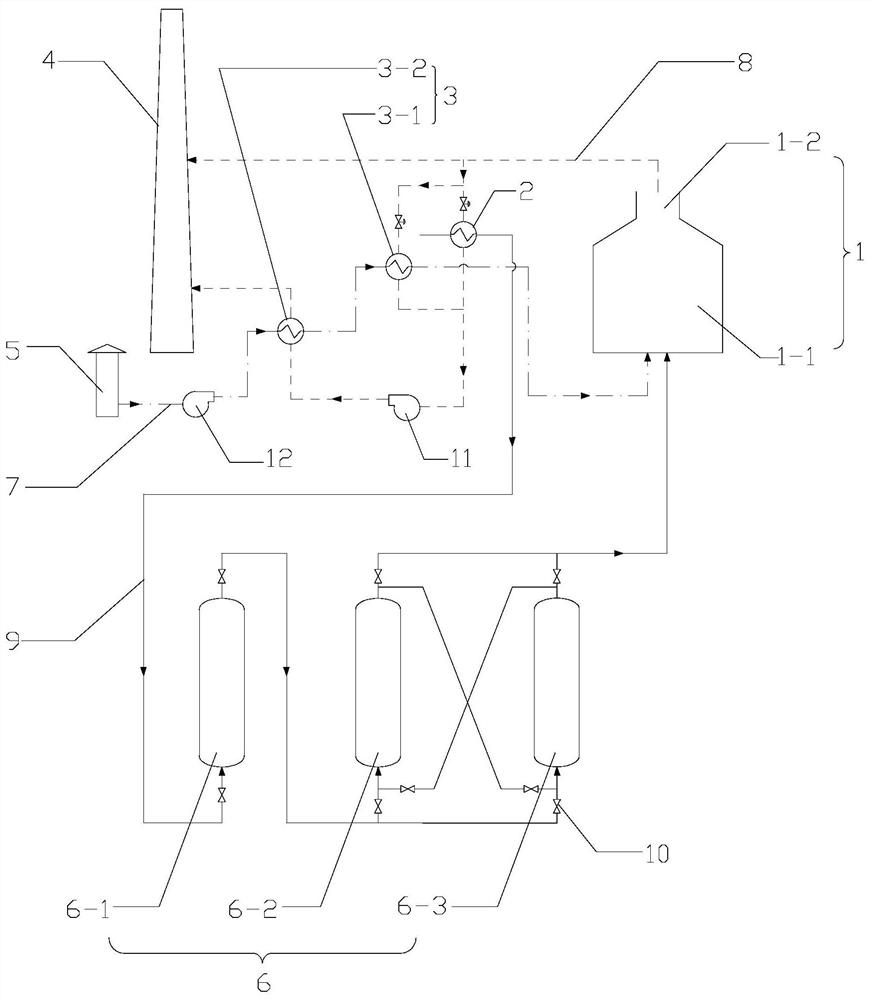

High-sulfur tail gas treatment system and technology

PendingCN110056890ARaise the furnace temperatureIncrease temperatureIndirect carbon-dioxide mitigationIncinerator apparatusAir preheaterSuperheater

The invention provides a high-sulfur tail gas treatment system and technology. The high-sulfur tail gas treatment system comprises a tail gas incineration unit and a flue gas waste heat recovery unit.The tail gas incineration unit comprises a combustor and an incinerator. The combustor and the incinerator are connected through a flange or in a welding mode. The mixed gas of high-sulfur tail gas,fuel gas and combustion air is burnt in the incinerator, and then high-temperature flue gas is discharged and enters the flue gas waste heat recovery unit. The flue gas waste heat recovery unit is setas multi-stage waste heat recovery facilities, and comprises a medium-pressure steam superheater, a steam generator, an energy-saving heat exchange facility and an air preheater. The steam superheater is connected with the incinerator, the steam generator is connected with the medium-pressure steam superheater, and the air preheater is connected with the tail end of the energy-saving heat exchange facility. According to the high-sulfur tail gas treatment system and technology, due to the design of multi-stage air distribution and tail gas flow separation of the incinerator, the emission indexrequirement can be met. Meanwhile, the equipment structure and materials of the waste heat recovery unit are optimized, and therefore the low-temperature acid dew point corrosion is avoided, and thelong-period stable operation is guaranteed.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

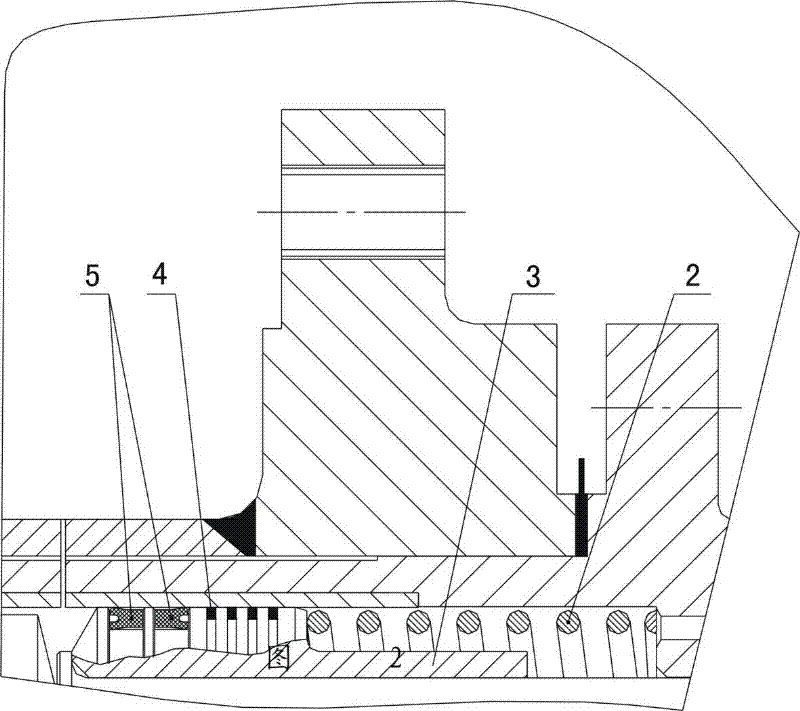

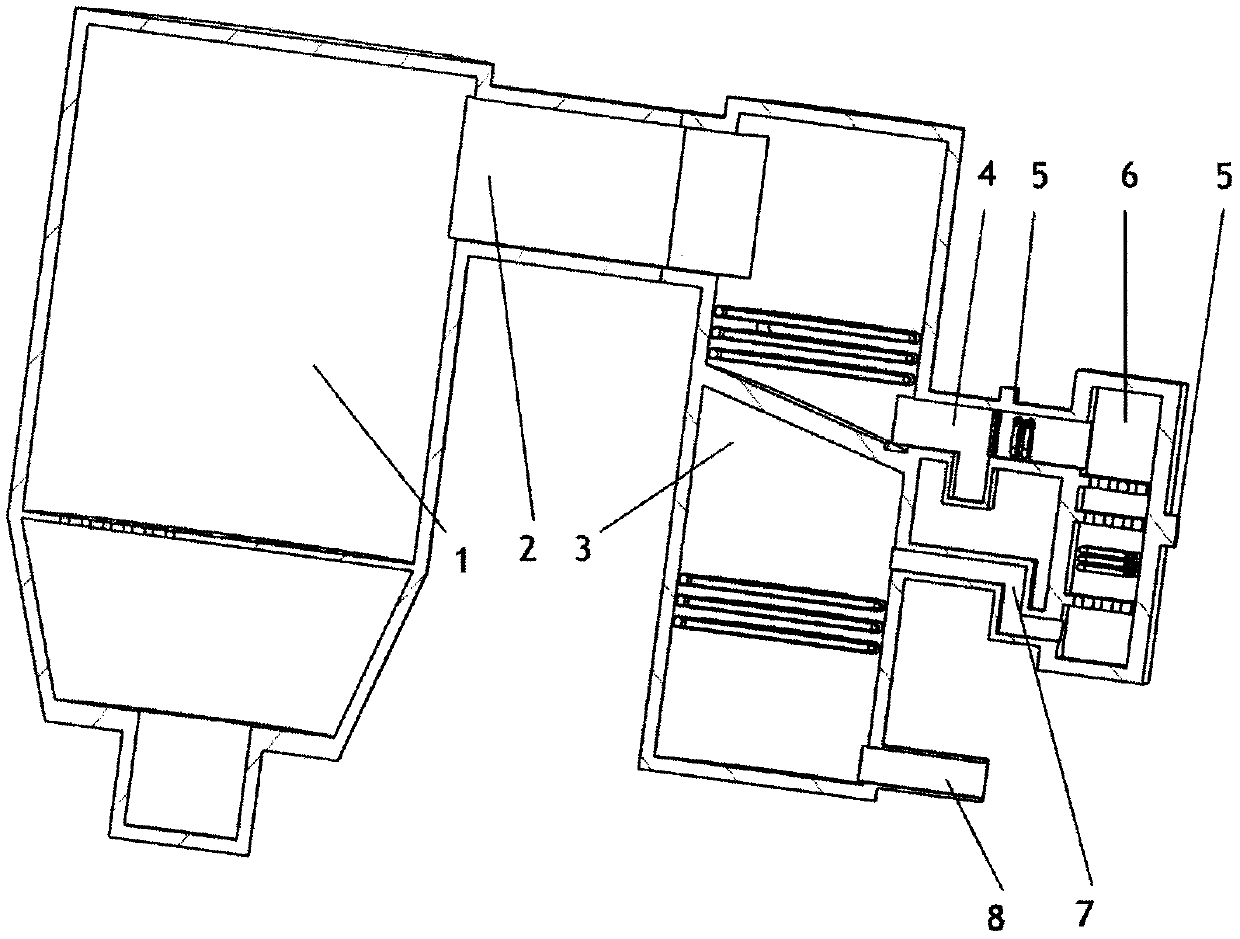

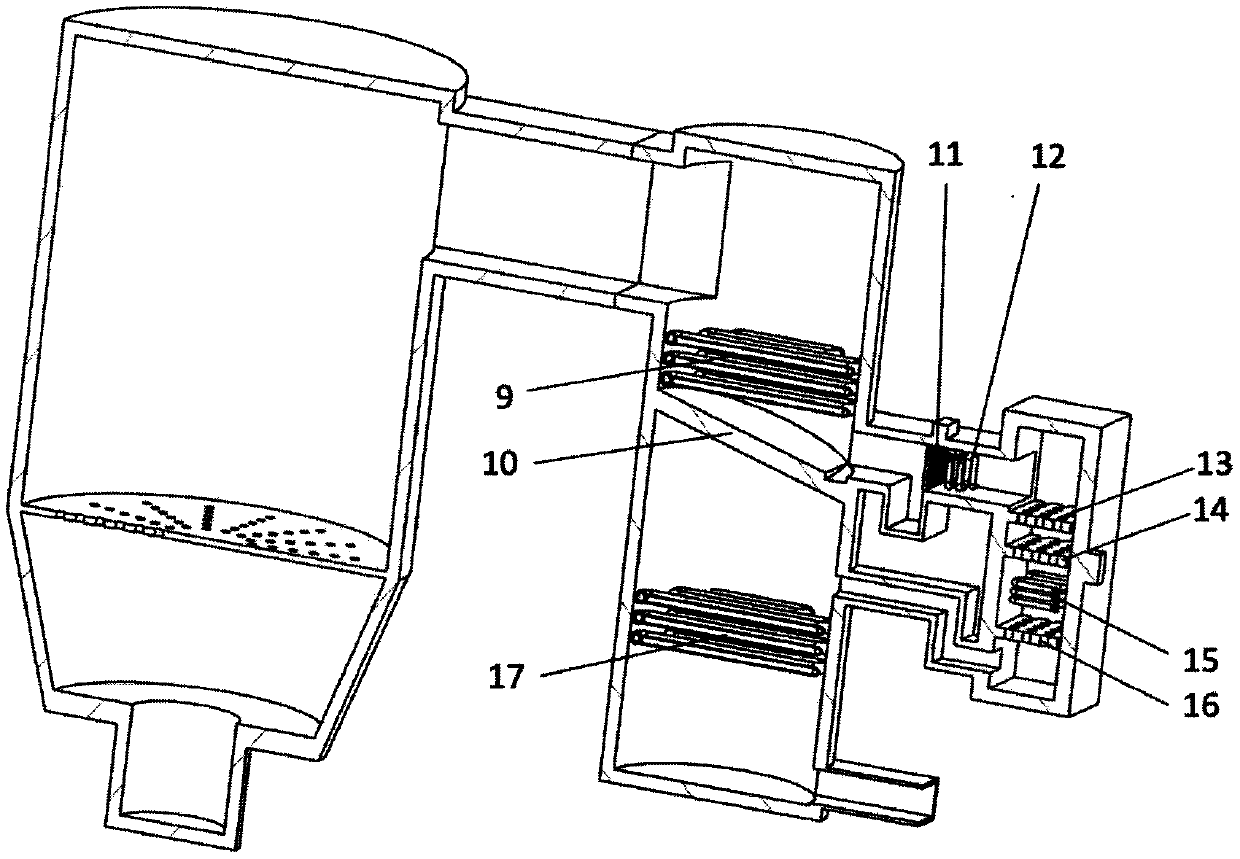

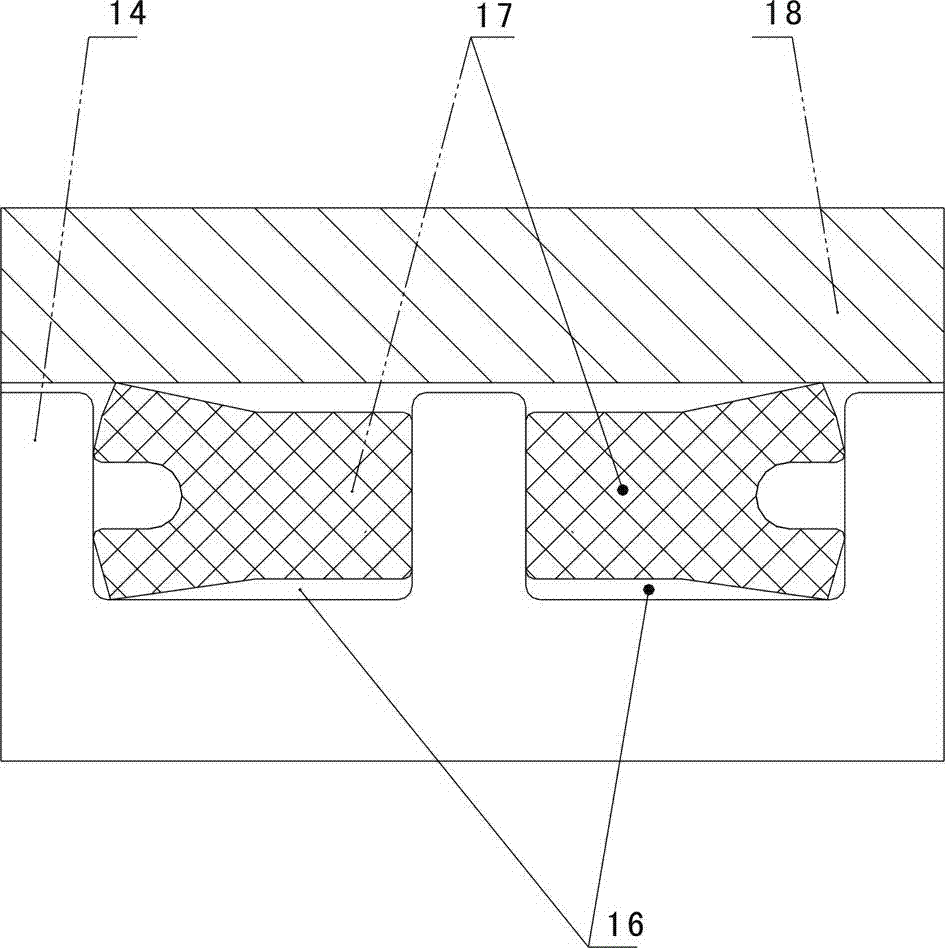

Bidirectional internal sealing structure of mechanical vibrator

InactiveCN102364168AAchieve sealingAvoid direct contactEngine sealsPiston ringsPiston ringMechanical engineering

The invention relates to a bidirectional internal sealing structure of a mechanical vibrator. The bidirectional internal sealing structure of the mechanical vibrator comprises a spring, a piston and a Y-shaped sealing ring, wherein the piston is arranged on one side of the spring and is in tight contact connection with the spring; an annular groove and a rectangular groove are formed on the piston; the Y-shaped sealing ring is arranged in the rectangular groove of the piston; the Y-shaped sealing ring is a bidirectional Y-shaped sealing ring consisting of two Y-shaped sealing rings; directions of lips of the two Y-shaped sealing rings are opposite; and the bidirectional Y-shaped sealing ring is sealed at the piston to achieve a bidirectional self-sealing effect, so as to improve a sealing effect of the bidirectional Y-shaped sealing ring between the piston and a piston sleeve. The bidirectional internal sealing structure of the mechanical vibrator has the main advantages that: the bidirectional Y-shaped sealing ring, a piston ring, the spring and other components act together to form a high-efficiency internal sealing system, so that the internal sealing performance of the mechanical vibrator is effectively improved and the service life of the mechanical vibrator is prolonged.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

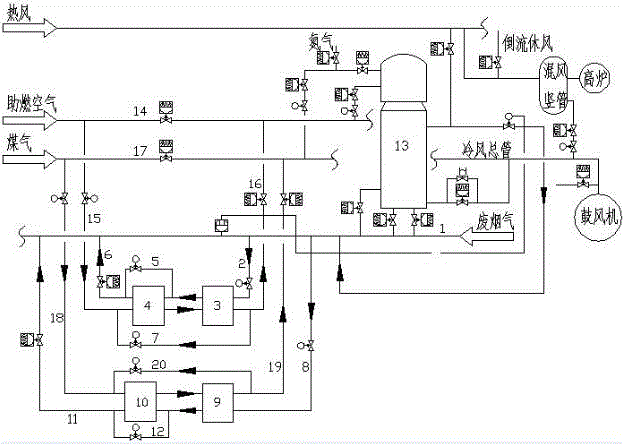

Device and process for utilizing waste heat of waste flue gas of hot-blast stove

InactiveCN105403058ARaise the inlet gas temperatureIncrease temperatureWaste heat treatmentFlue gasGas passing

The invention relates to a device and process for utilizing waste heat of waste flue gas of a hot-blast stove. The process is characterized by comprising the steps that during normal operation, the waste flue gas sequentially enters secondary heat exchangers and primary heat exchangers through flue gas pipelines, and gas passing through the heat exchangers is preheated; when the temperature of the flue gas is higher than a design value, the amount of the flue gas entering the heat exchangers is controlled by adjusting regulating valves of the flue gas pipelines and inlets of the heat exchangers; and when the temperature of the flue gas is lower than the design value, the procedure includes the following steps that a, the valves arranged on the flue gas pipelines at the front ends of the heat exchangers are adjusted, and the amount of the flue gas entering the secondary heat exchangers is controlled; b, valves on bypass pipelines of the primary heat exchangers are opened, and the flue gas passing through the secondary heat exchangers are made to directly enter the flue gas pipelines at the rear ends of the primary heat exchangers by bypassing the primary heat exchangers; and c, the gas to be preheated sequentially enters the primary heat exchangers and the secondary heat exchangers and then enters bypass channels enabling outlets of the secondary heat exchangers and the inlets of the primary heat exchangers to be communicated, and therefore the temperature of the gas at the inlets of the primary heat exchangers is increased.

Owner:SHANDONG DAIRONG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

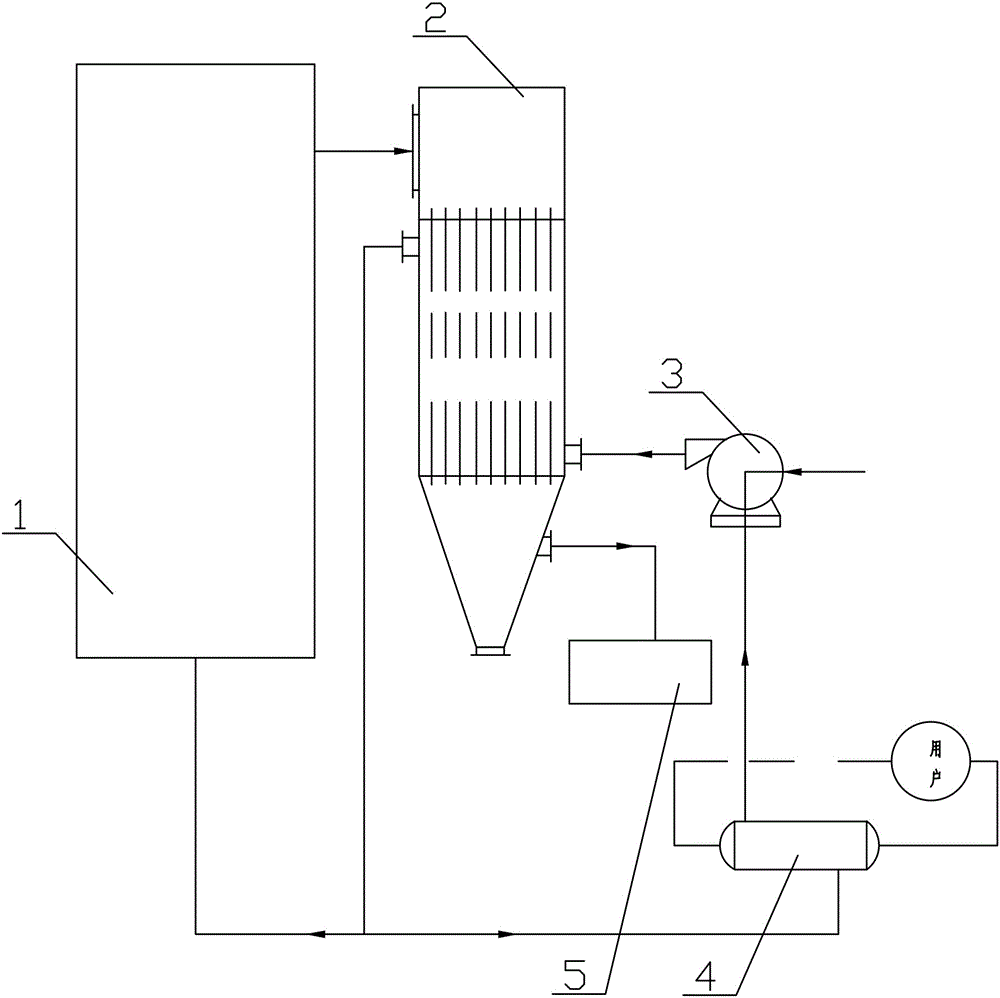

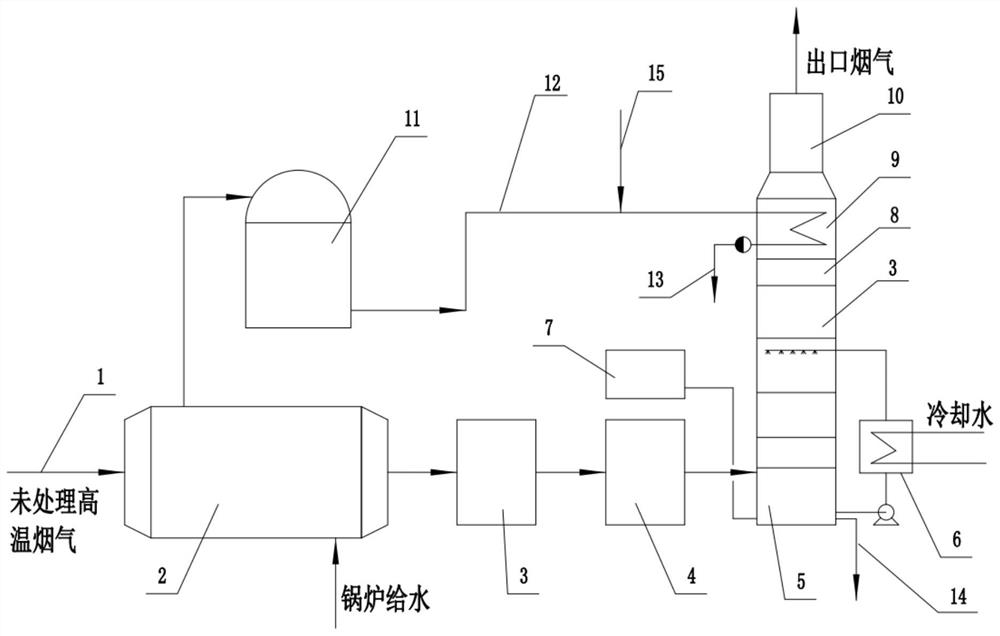

Waste heat utilizing system and method of waste acid cracking furnace using organic waste sulfuric acid as raw material

InactiveCN106765202AReduce consumptionEfficient use ofIndirect carbon-dioxide mitigationIncinerator apparatusChemical industryComing out

The invention belongs to the technical field of chemical industry production and is suitable for waste heat utilization of a waste sulfuric acid cracking treatment device using organic waste sulfuric acid as a raw material. The waste sulfuric acid cracking treatment device comprises a waste heat cracking furnace, a furnace gas cooler, an air fan, heat exchange equipment and a SO2 treatment system. High-temperature flue gas enters the furnace gas cooler after coming out from the waste heat cracking furnace and enters the SO2 treatment system after being cooled by cold air, the cold air is divided into two streams after being heated in the furnace gas cooler, one stream enters the waste heat cracking furnace to support combustion of fuel, and the other stream heats a cold medium for a user to use. Waste heat utilization of the waste heat cracking furnace is realized, and safety and stability in running of the device are greatly improved.

Owner:扬州嘉明环保科技有限公司

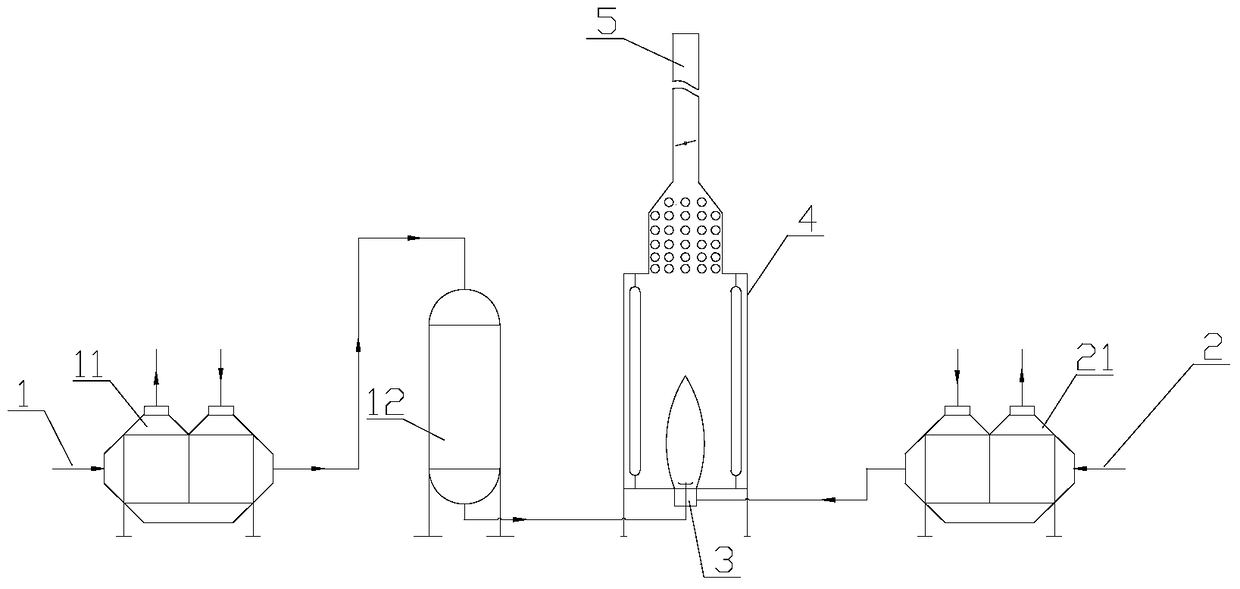

A deep energy-saving process for tubular heating furnace

ActiveCN104964304BReduce contentAvoid Dew Point CorrosionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to a tube heating furnace deep energy-saving technology. The technology employs an energy-saving concept of fuel gas deep desulfurization, and functions of dual pre-heating combustors are improved through the addition of a fuel gas pre-heater and a gas desulfurization reactor, so that the dew-point temperature in the flue gas can be reduced, the exhaust gas temperature of the flue gas can be decreased, the thermal efficiency of a system can be improved, high-intensity combustion can be performed, the energy utilization rate is high, the fuel is saved, a process flow is simple, a good environmental protection function is achieved, and the reliability and security during an operation process are high. Compared with the prior art, the method can be widely applied, an operation period is long, the reliability and the security are high, the engineering investment is saved, and an improved method is provided for energy conservation for a tube heating furnace.

Owner:上海浩用工业炉有限公司

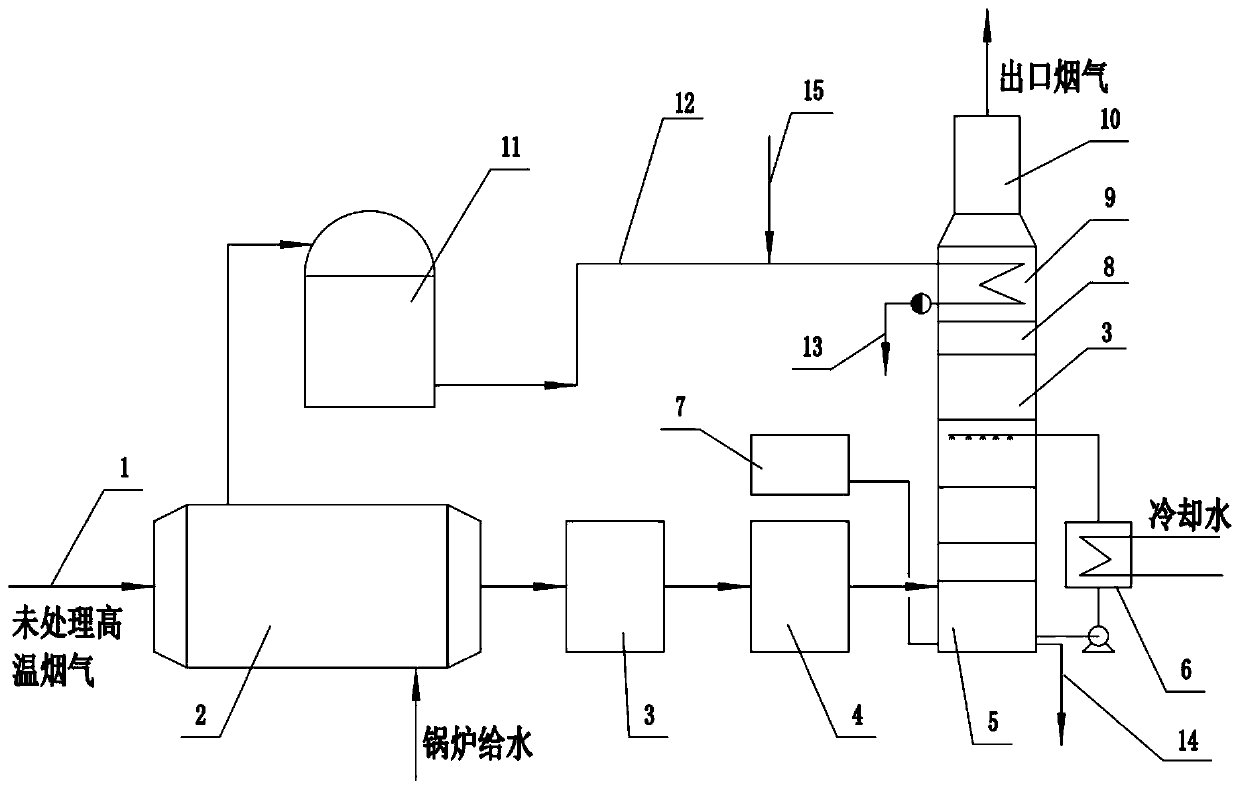

Coal-fired boiler flue gas whiteness-removing system with low energy consumption

ActiveCN109806751AReduce heat transfer areaIncrease tube wall temperatureDispersed particle separationCombustion technology mitigationFlue gasLower grade

The invention discloses a coal-fired boiler flue gas whiteness-removing system with low energy consumption. The flue gas whiteness-removing system comprises a boiler water-supply preheater, a sprayingand condensing system, a duster, a desulfurization tower, a flue gas heater and a chimney. The spraying and condensing system comprises a spraying tower, a spraying water cooler, a dosing device, theduster, and a defogger; a spraying device is arranged in the middle of the spraying tower; the spraying device is communicated with the bottom of the spraying tower through the spraying water cooler;the dosing device is communicated with the bottom of the spraying tower; the top of the spraying tower is sequentially provided with the duster and the defogger. Condensed flue gas is heated throughsteam saved or produced to remove whiteness from the flue gas, and a heating source of the flue gas heater is transferred into steam, so that the heat exchanging area of the flue gas heater is reduced, and the temperature of the wall of the flue gas heater is increased to prevent dew point corrosion from appearing on the flue gas heater. Ordinary materials can be used to ensure the long service life of the equipment, used steel materials are reduced, project construction price is lowered, and after heat resources is transferred from low grade to high grade to be utilized.

Owner:周岩

A kind of pulsating heat pipe heat exchanger and its processing method

ActiveCN105066754BNo mixingGood safety and reliabilityIndirect heat exchangersHigh volume manufacturingEngineering

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

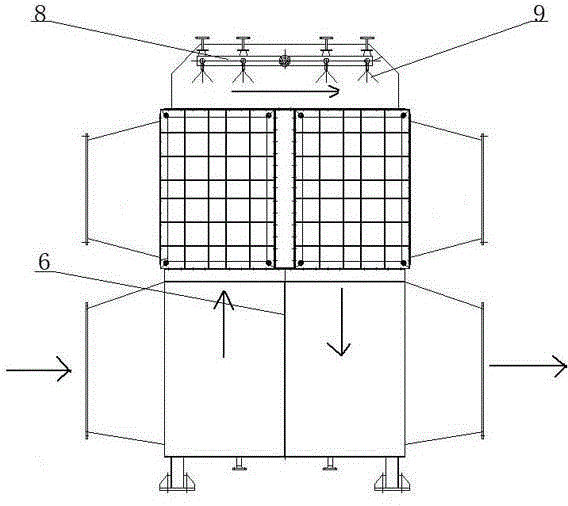

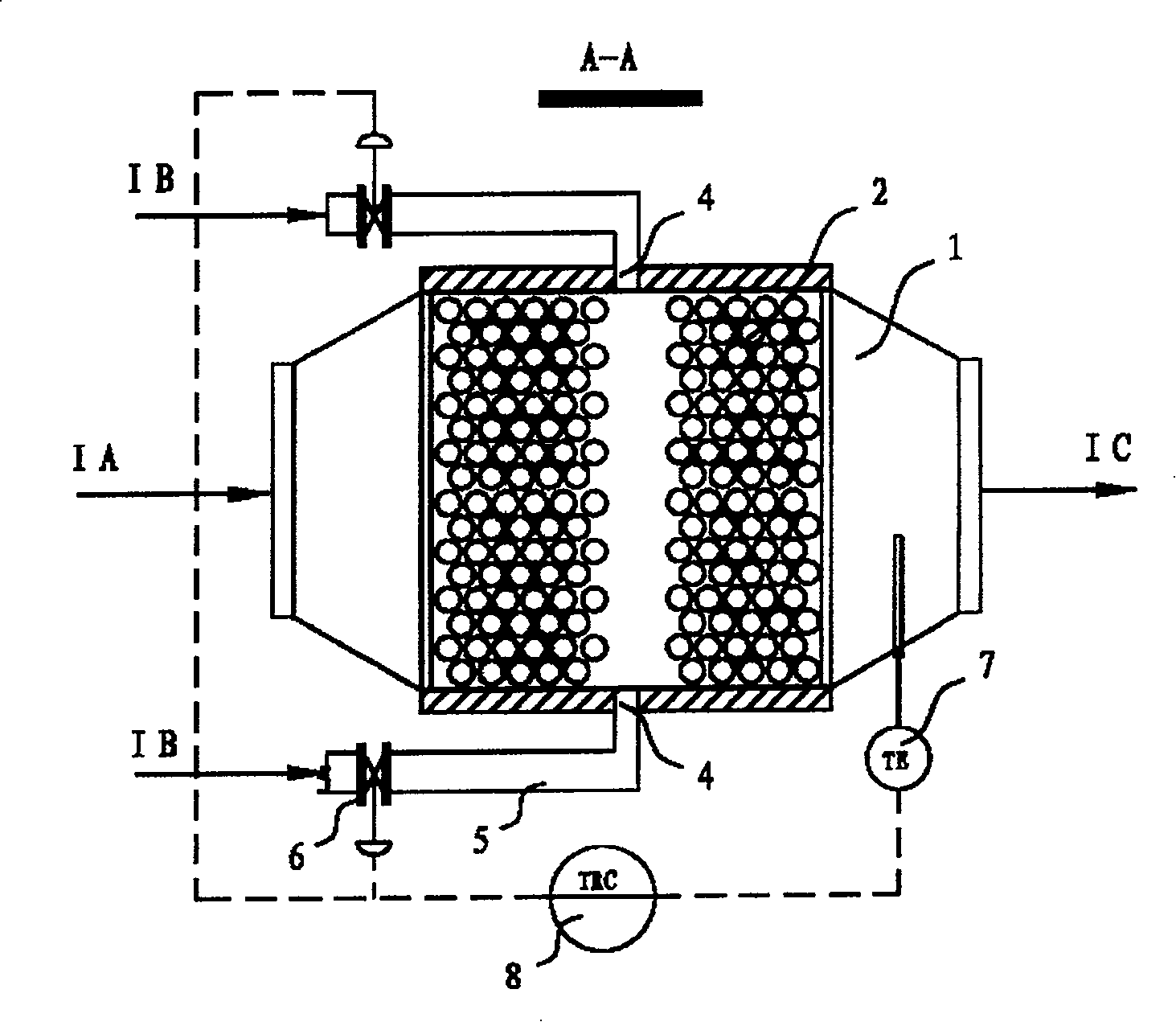

Hot gas comprehensive purification device for preventing dew point corrosion at boiler tail

PendingCN109821337AReduce contentAvoid Dew Point CorrosionCombination devicesCombustion processAir preheaterNitrogen oxides

The invention discloses a hot gas comprehensive purification device for preventing the dew point corrosion at a boiler tail, which comprises a purification device body and an inclined partition plate.The tail heating surface is divided by the inclined partition plate into an upper chamber and a lower chamber which are independent from each other. The purification device body is internally and sequentially provided with an SCR denitration layer, a soda lime desulfurization layer, a secondary air preheater and a super absorbent resin layer from top to bottom. The purification device body is communicated with the upper chamber through an air inlet pipeline and is communicated with the lower chamber through an air outlet pipeline. A dust collecting groove, a dust removing net and a primary air preheater are arranged in the air inlet pipeline, and ultrasonic dust removers are arranged on the outer walls of the air inlet pipeline and the purification device body.According to the hot gas comprehensive purification device, the dust removal net and the three purification layers are used for reducing the contents of large-particle dust, nitrogen oxide compounds, sulfur oxide compounds and water vapor in the hot gas at the boiler tail, so that the occurrence of the dew point corrosion of a low-temperature heating surface at the boilertail is avoided, and the abrasion of dust particles onthe outer wall of an air preheater pipeline and dust deposition are slowed down.

Owner:NANJING NORMAL UNIVERSITY

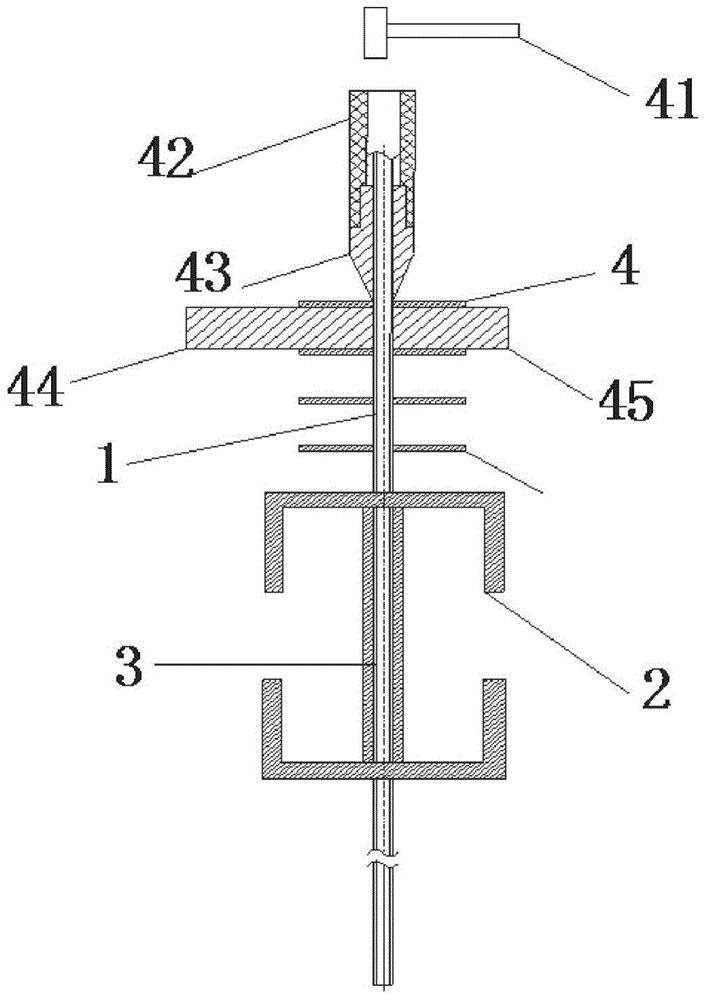

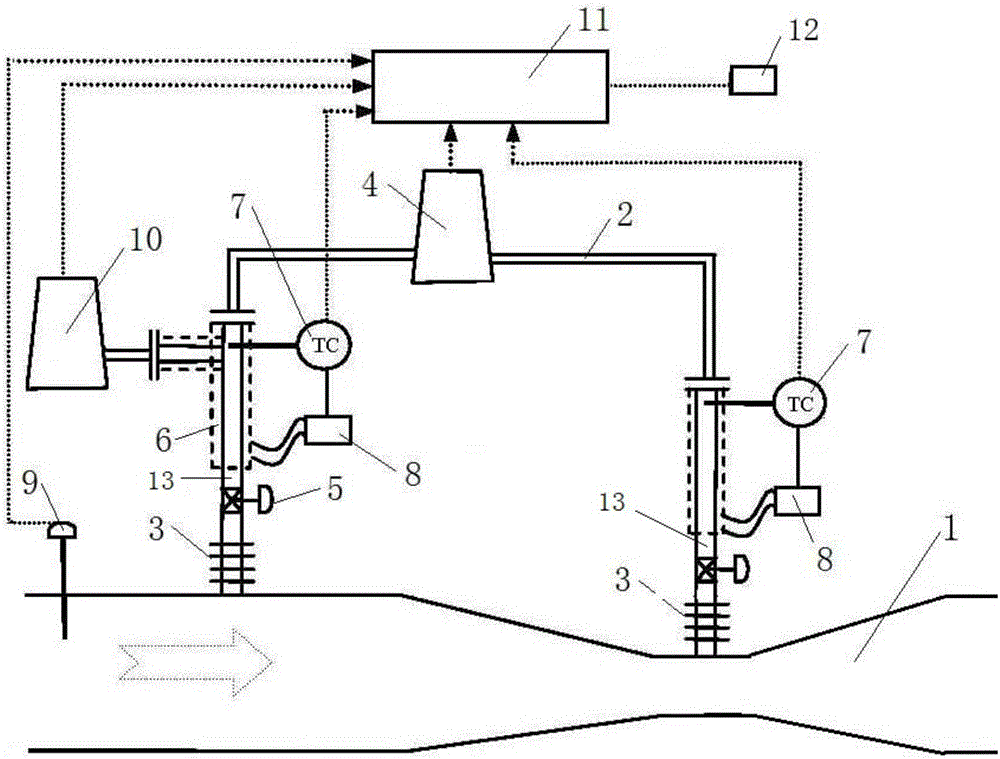

Automatic rapping dust removing system

ActiveCN102492480BAchieve sealingAvoid direct contactGranular/pulverulent flues gasificationCommunications systemDistributed control system

The invention relates to an automatic rapping dust removing system comprising an electrical control cabinet and a PLC programmable programme control cabinet, wherein the PLC programmable programme control cabinet is accessed into a DCS (data communication system) and is connected with the electrical control cabinet; the electrical control cabinet is connected with cylinders on a plurality of mechanical rapping machines through air pipes; the mechanical rapping devices are mounted on the water wall of a gasification furnace at different parts; nitrogen is led to the air inlets of the mechanical rapping machines through sealed nitrogen hoses; compressed air is set into a power gas source and a control gas source after being accessed into the electrical control cabinet; the power gas source is connected to the power gas source interfaces of the cylinders of the mechanical rapping machines through power gas source hoses; and the control gas source is connected to the control gas source interfaces of the cylinders of the mechanical rapping machines through control gas source hoses. The technology of the invention is advanced in that the structure is more compact; gas in gasification equipment can be prevented from escaping effectively; rapping force, rapping frequency and rapping sequence can be controlled more effectively; and the distributed control system is centralized in management and dispersed in control.

Owner:WUHAN JEHOO HIGH TECH

Method for measuring flow of high-temperature highly corrosive flue gas

ActiveCN106525164AAvoid Dew Point CorrosionPrevent high temperature gasification cycleVolume/mass flow by differential pressureThermal insulationFlue gas

The invention provides a method for measuring the flow of high-temperature highly corrosive flue gas. The method includes the following steps: 1), installing a Venturi flowmeter on a high temperature flue gas pipeline firstly, introducing the high-temperature flue gas into the Venturi flowmeter, and regulating the temperature of the high-temperature flue gas in a pressure measuring tube on the Venturi flowmeter to 100-180 DEG C; 2) measuring the temperature T and the pressure intensity P of the high-temperature flue gas entering the Venturi flowmeter, and measuring the differential pressure delta P of the Venturi flowmeter; 3) based on the temperature T, the pressure intensity P and the differential pressure delta P of the Venturi flowmeter, obtaining the actual flow Q1of the flue gas (please see the formula defined in the specification), and converting the Q1 into a flow value Q0 in the standard condition, wherein K refers to the flow coefficient of the Venturi flowmeter. The method is based on the properties of high-temperature highly corrosive flue gas, a radiator is adopted for cooling or a ribbon heater is adopted for thermal insulation, it is guaranteed that the flue gas in the pressure measuring tube reaches an appropriate temperature, dew point corrosion caused by the flue gas is prevented, the condensation droplet high-temperature gasification cycle is prevented, pressure fluctuation is avoided, and it is ensured that the measurement process is reliable and stable and the measurement is accurate.

Owner:SHANDONG UNIV

Waste heat boiler used for waste sulfuric acid cracking regeneration device and flue gas treatment method

PendingCN112682809AIncrease flue gas temperatureIncrease temperatureCombustion technology mitigationCoatingsThermodynamicsFlue gas

The invention discloses a waste heat boiler used for a waste sulfuric acid cracking regeneration device and a flue gas treatment method. The waste heat boiler comprises a front smoke box, a boiler body and a rear smoke box which are in sequential communication, multiple heat exchange pipes are arranged in the boiler body, a center pipe is arranged in the center in the boiler body, an adjusting valve is arranged at an outlet of the center pipe, inlets of the heat exchange pipes and an inlet of the center pipe communicate with the front smoke box, and outlets of the heat exchange pipes and the outlet of the central pipe communicate with the rear smoke box. The waste heat boiler can effectively avoid dew point corrosion of pipelines and equipment, the service life of the boiler is prolonged, construction cost is low, operation is convenient, and the occupied area is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of gas buffered heat pipe for preventing dew-point corrosion

InactiveCN101303205BAvoid Dew Point CorrosionCorrosion preventionIndirect heat exchangersEvaporationProduct gas

The invention discloses an application of a gas-filled heat pipe in avoiding the dew point corrosion of a heat pipe exchanger. The gas-filled heat pipe comprises an evaporation segment and a condensation segment filled with a work substance. The application is characterized in that the condensation segment is also simultaneously filled with inert gases or nitrogen gas according to specified lengthand specified quantity of filled gases and can be filled with a mixture combined by gas molecules and the steam molecule of the work substance. The filled inert gases can automatically change occupied volume and filled gas length so as to change and adjust the temperature in the pipe and wall surface temperature, thus achieving the purpose of avoiding the dew point corrosion of the heat pipe.

Owner:余传林 +1

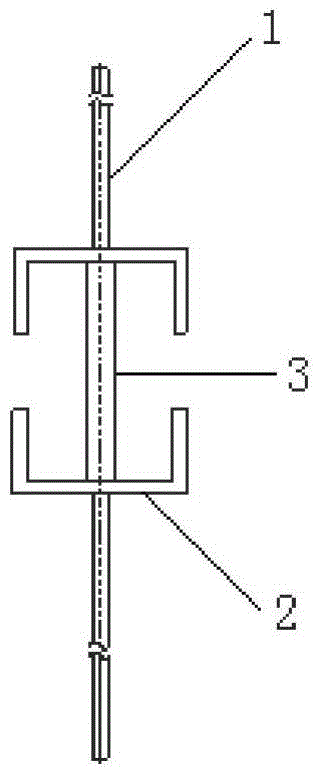

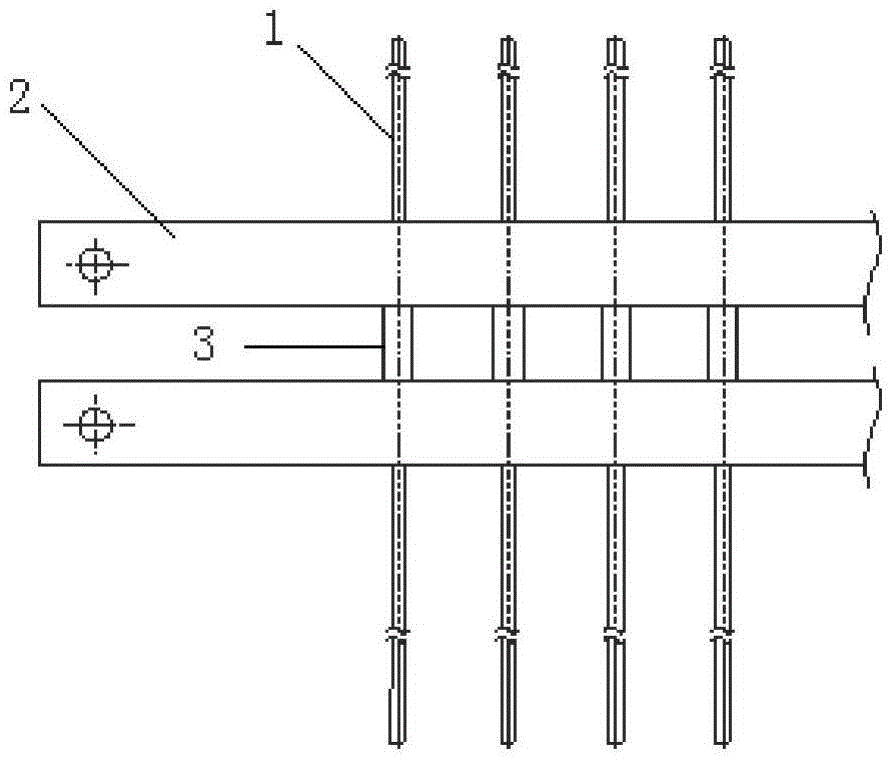

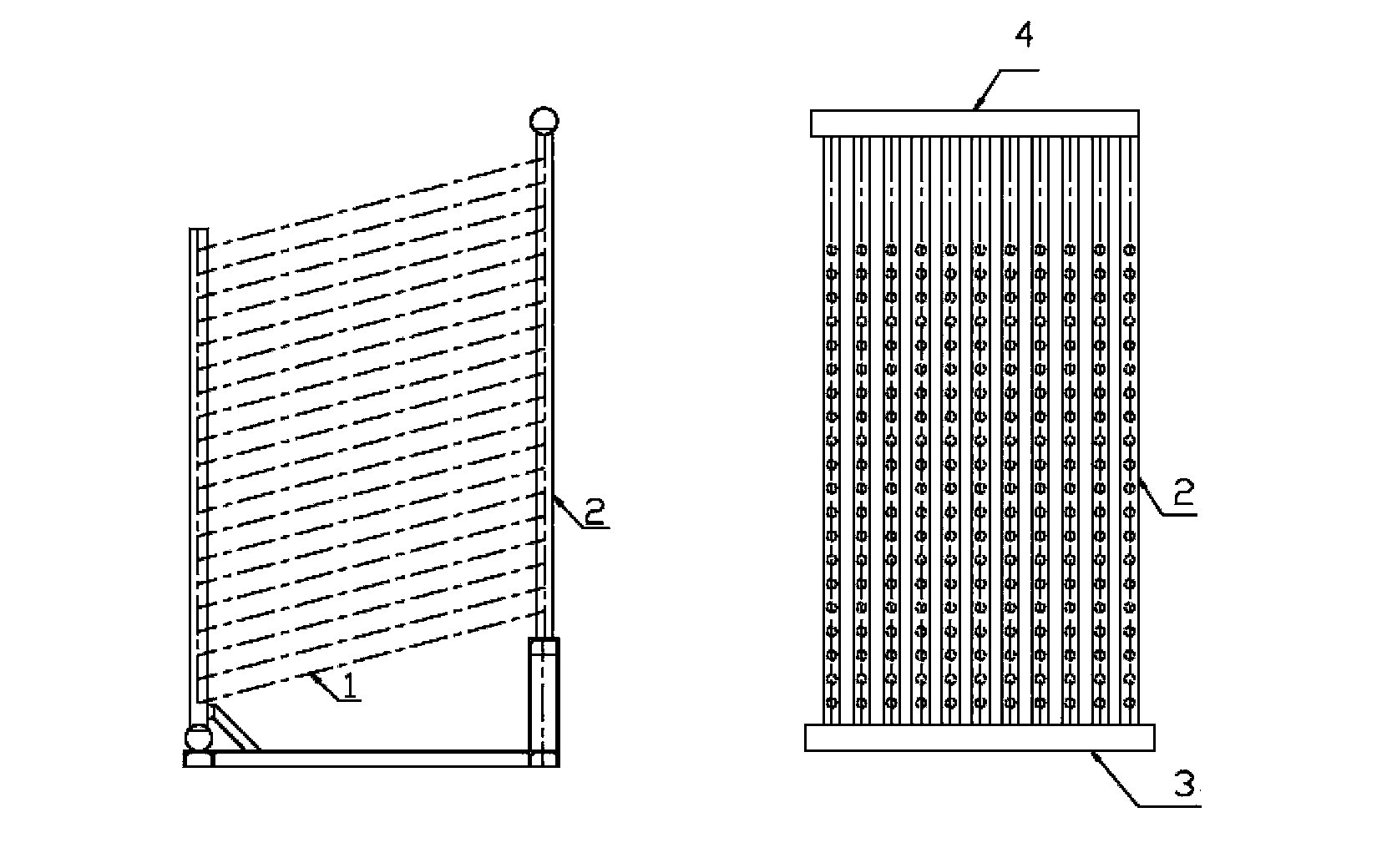

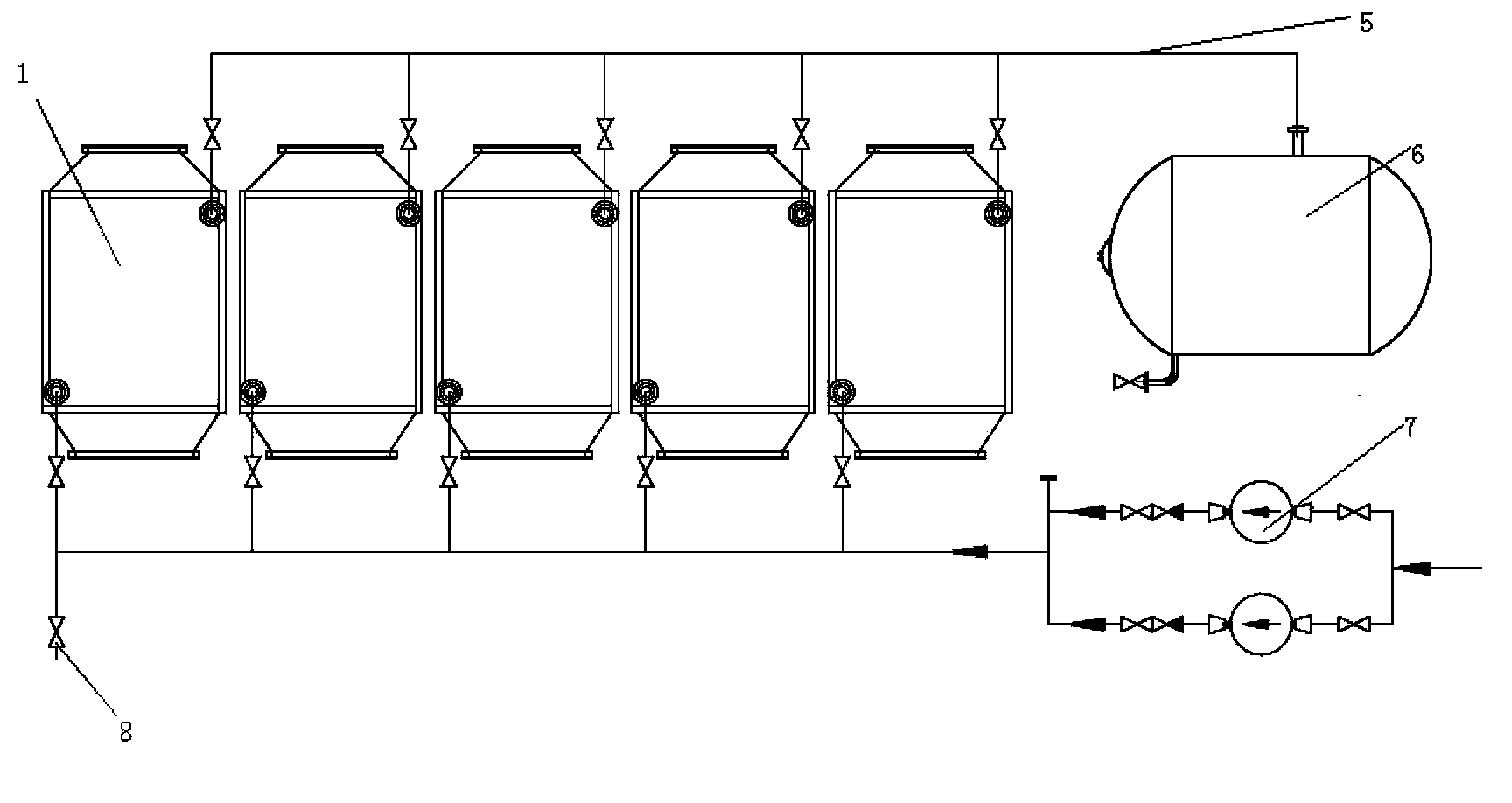

Flue gas recovery system of glass kiln heat preservation channel

InactiveCN103880269AEasy to control temperatureImprove heat transfer efficiencyGlass furnace apparatusFlue gasEngineering

Provided in the invention is a flue gas recovery system of a glass kiln heat preservation channel. The recovery system includes: a set of heat exchanger, a gas outlet pipe (5), a steam drum (6), a circulating water pump (7) and a drain valve (8). The heat exchanger, the gas outlet pipe and the steam drum are connected successively. The heat exchanger comprises: multiple sets of finned tubes (1) in parallel, a water header pipe (2), a water inlet pipe (3) and a vapor header box (4); the water inlet pipe, the water header pipe, the finned tubes and the vapor header box are connected successively to each other. The finned tubes are filled with working medium fluid and are vacummized. Cold water is fed into the water header pipe by the circulating water pump through the water inlet pipe, is fed into the finned tubes for being heated and vaporized, and is fed upwardly into the vapor header box. The vapor is fed into the steam drum through the gas outlet pipe and is supplied to the produce process.

Owner:上海蕲黄节能环保设备有限公司

A low energy consumption coal-fired boiler flue gas dewhitening system

ActiveCN109806751BReduce heat transfer areaIncrease tube wall temperatureDispersed particle separationCombustion technology mitigationSprayerDust collector

The invention discloses a low-energy consumption coal-fired boiler flue gas dewhitening system, which includes a boiler feed water preheater, a spray condensing system, a dust collector, a desulfurization tower, a flue gas heater and a chimney; the spray condensing system includes a spray tower, Spray water cooler, dosing device, dust collector and demister. There is a sprinkler in the middle of the spray tower. The sprayer communicates with the bottom of the spray tower through the spray water cooler. The dosing device and the spray tower The bottom is connected, and the top of the spray tower is provided with a dust collector and a mist eliminator in turn. The invention utilizes the saved or generated steam to heat the condensed flue gas to realize flue gas dewhitening. This process converts the heating source of the flue gas heater into steam, reduces the heat exchange area of the flue gas heater, and increases the temperature of the pipe wall of the flue gas heater. , to avoid dew point corrosion in the flue gas heater, the use of ordinary materials can also ensure the long-term service life of the equipment, reduce the use of steel, reduce the cost of the project, and realize the conversion and utilization of waste heat resources from low-grade to high-grade.

Owner:周岩

Method for Preventing Dew Point Corrosion of Maleic Anhydride Cycle Tail Gas

ActiveCN104177317BReduce contentAvoid condensationOrganic chemistryChemical industryFlue gasMaterial consumption

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Determination apparatus for dew point of gas

InactiveCN102495102AExtended service lifeAvoid Dew Point CorrosionMaterial moisture contentDry iceDew

The invention relates to a determination apparatus for the dew point of gas. The apparatus comprises an enclosed transparent cup and a copper cup inserted into the transparent cup; a gap is provided between the bottom of the copper cup and the bottom of the transparent cup, a gas inlet pipe and a gas outlet pipe are arranged on the transparent cup, the upper end of the copper cup is provided with an opening, and an acetone solution, dry ice and a mercury thermometer are provided in the copper cup. According to the invention, gas to be determined is blown into the transparent cup through the gas inlet pipe; dry ice is added into the acetone solution in the copper cup and is continuously stirred by using the mercury thermometer so as to allow temperature of the copper cup to decrease; when the temperature decreases to the dew point of the gas to be determined, condensable acid mist begins to coagulate and forms fine dew on the external surface of the copper cup, which enables the acid mist to lose its original luster, and temperature displayed by the mercury thermometer at the time is the dew point of the gas; through control of temperature of a heat exchanger, the service life of equipment can be prolonged, and dew point corrosion is prevented.

Owner:ANHUI HUAIHUA

High-efficiency recovery system for low-temperature waste heat of xylene heating furnace

ActiveCN113654362AHigh thermal efficiencyAvoid Dew Point CorrosionOther chemical processesCombustion processAir preheaterXylylene

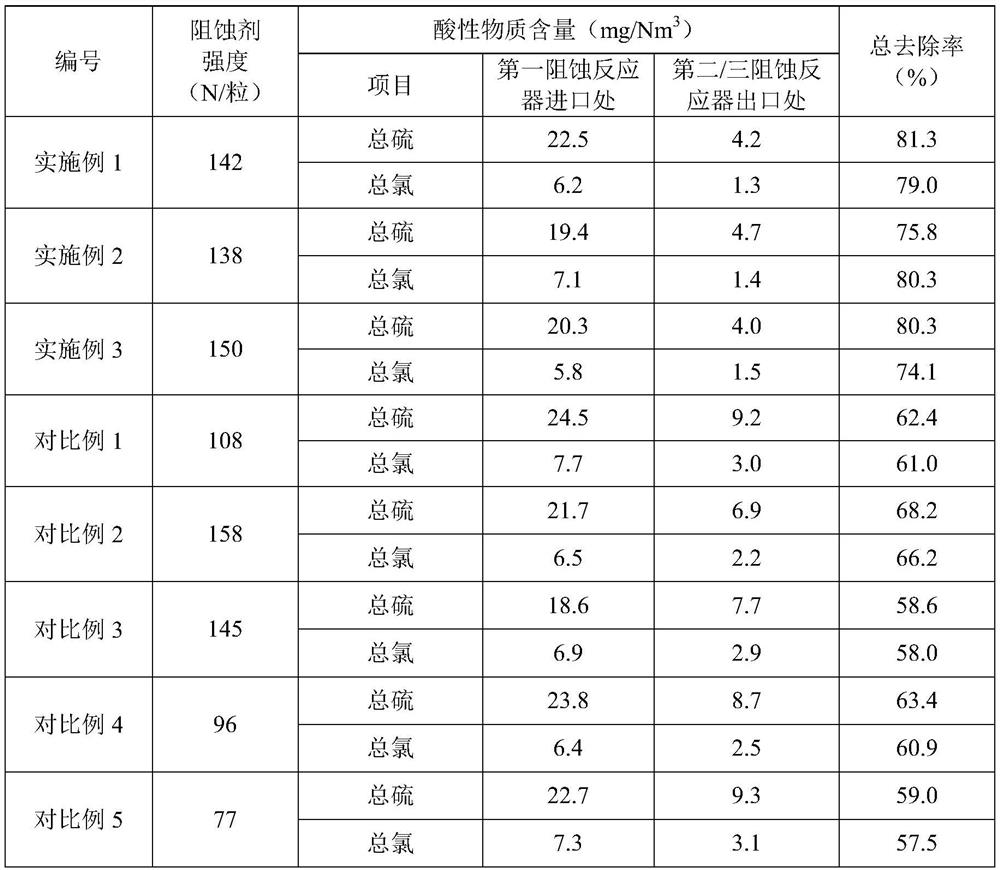

The invention discloses a high-efficiency recovery system for the low-temperature waste heat of a xylene heating furnace. The high-efficiency recovery system for the low-temperature waste heat of the xylene heating furnace comprises a heat exchange unit and a corrosion inhibition unit. The heat exchange unit comprises a heating furnace, a fuel gas-flue gas heat exchanger, an air preheater, a chimney and an exhaust inlet; the exhaust inlet is connected with the air preheater and a combustion chamber of the heating furnace through air pipelines; a flue gas outlet of the heating furnace is connected with inlets of the fuel gas-flue gas heat exchanger and the air preheater through flue gas pipelines; outlets of the fuel gas-flue gas heat exchanger and the air preheater are connected with the chimney through flue gas pipelines; a corrosion inhibition reactor is arranged in the corrosion inhibition unit; an inlet of the corrosion inhibition reactor is connected with the fuel gas-flue gas heat exchanger through a fuel gas pipeline; and an outlet of the corrosion inhibition reactor is connected with the combustion chamber of the heating furnace through a fuel gas pipeline. According to the high-efficiency recovery system for the low-temperature waste heat of the xylene heating furnace provided by the invention, the corrosion inhibition unit is arranged in the system, and acid gas in fuel gas is removed through a corrosion inhibitor, so that dew point corrosion at the low flue gas emission temperature is avoided, heat of flue gas can be efficiently recycled, and the heat efficiency of the heating furnace is remarkably improved.

Owner:NINGBO ZHONGJIN PETROCHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com