High-efficiency sulfur recovery method of waste gas containing hydrogen sulfide

A hydrogen sulfide and sulfur recovery technology, applied in the direction of sulfur preparation/purification, energy input, etc., can solve the problems of not considering the properties, unable to ensure that the acid mist in the condensation stage meets the standard, and unable to apply to industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Taking the waste gas from the purification section of a coal chemical plant as an example to illustrate the method for efficient sulfur recovery from hydrogen sulfide waste gas according to the present invention.

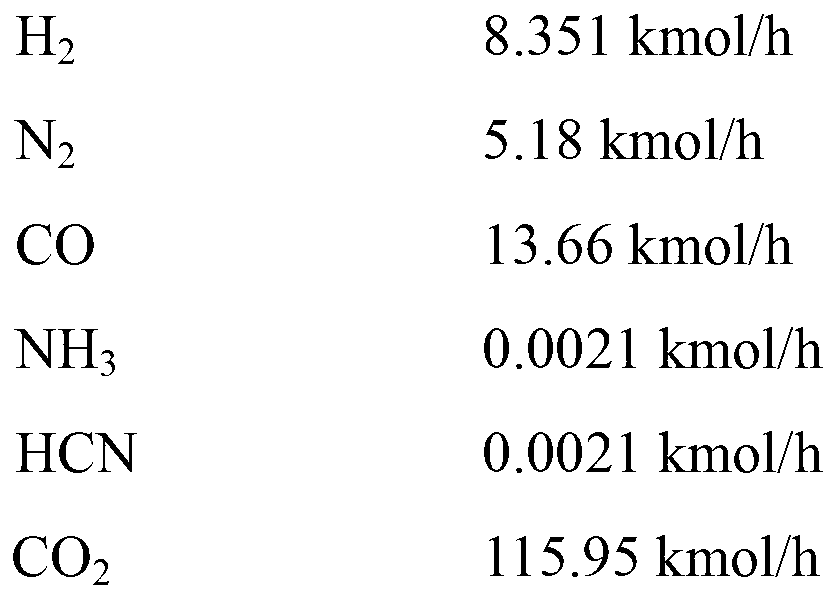

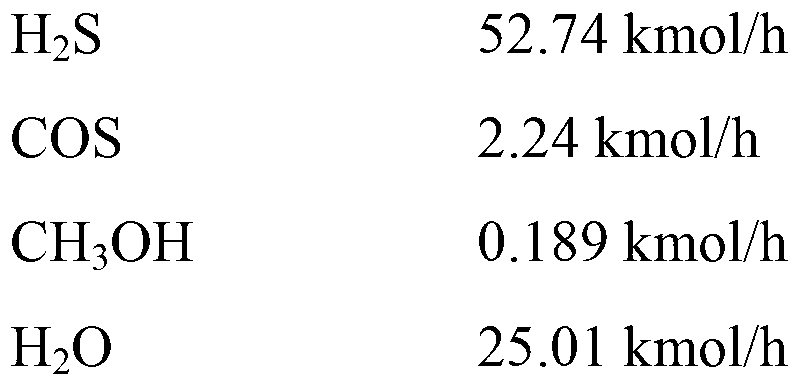

[0036] Exhaust gas conditions: temperature 33°C, pressure 2.2bar, gas composition as follows:

[0037]

[0038]

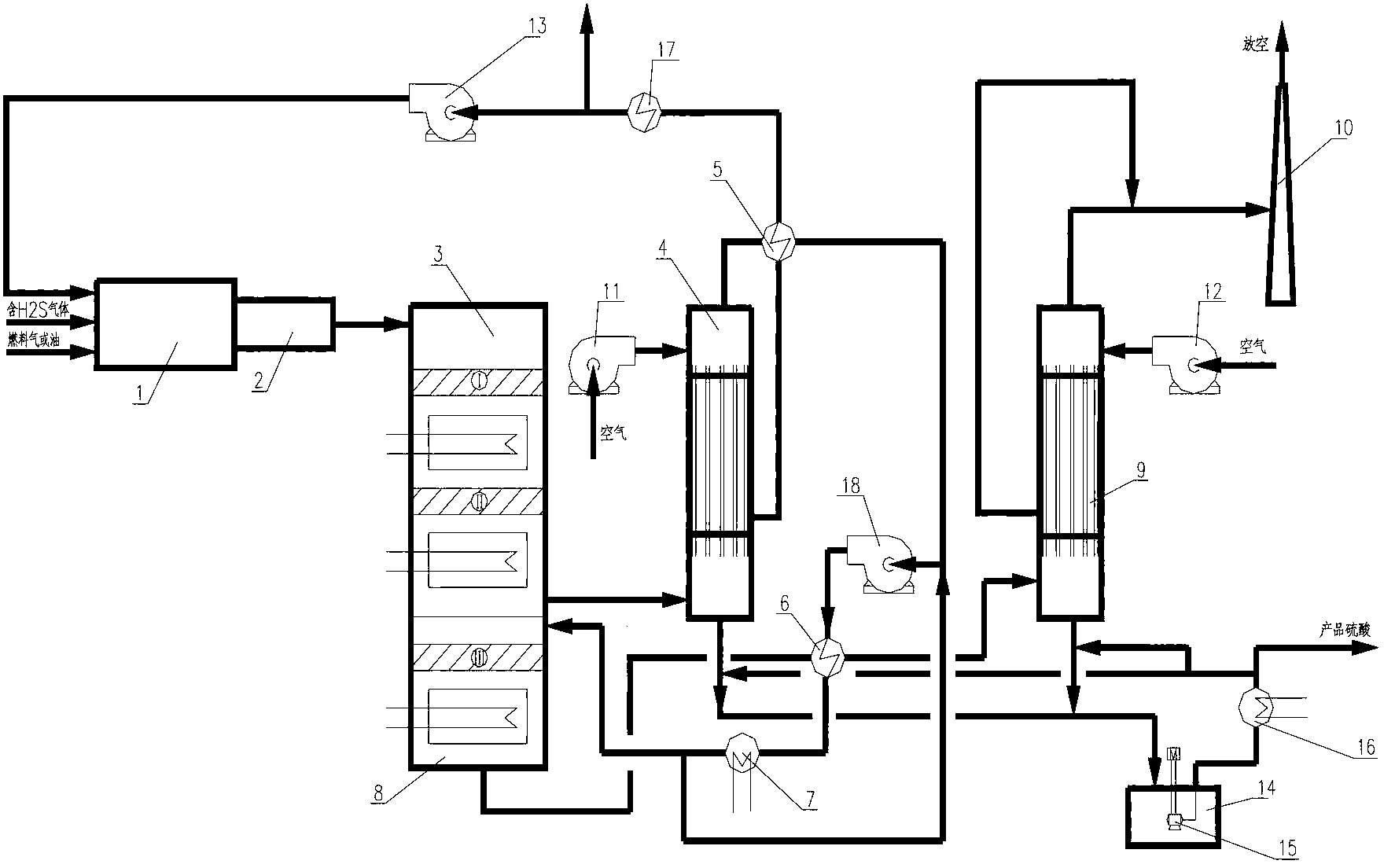

[0039] The above-mentioned waste gas from the purification section enters the incinerator 1 together with the hot air from the first-stage heater 5 with a shell side outlet temperature of ~180°C for combustion, and the sulfur components such as hydrogen sulfide in the gas are completely burned to produce water and SO 2 , CO, NH in gas 3 , HCN and other components burn to produce CO 2 , N 2 and water, and the temperature of the incinerator 1 is controlled at about 1100-1250° C. by adjusting the amount of air. The high-temperature process gas exiting the combustion furnace 1 recovers heat through the waste heat boiler 2 to pro...

Embodiment 2

[0040] Embodiment 2: Taking the sulfur-containing waste gas of an oil refinery as an example to illustrate the high-efficiency method for hydrogen sulfide waste gas of the present invention. There are three streams of waste gas in the plant, namely acid water stripping acid gas, a set of 1.8 million tons / year ARGG device acid gas, and a set of 1 million tons / year ARGG device acid gas. The composition of the three acid gases is as follows:

[0041] 1. Sour water stripping acid gas

[0042] Temperature: 70°C, Pressure: 70kPag

[0043]

[0044] 2. 1.8 million tons / year acid gas of ARGG unit

[0045] Temperature: 74°C, Pressure: 70kPag

[0046]

[0047] 3. 1 million tons / year ARGG plant acid gas

[0048] Temperature: 74°C, Pressure: 70kPag

[0049]

[0050] The plant decided to convert the above-mentioned sulfur-containing waste gas into sulfuric acid to meet the sulfuric acid required by other devices in the plant, and at the same time generate steam for production. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com