Application of gas buffered heat pipe for preventing dew-point corrosion

A gas-filled heat pipe and dew point corrosion technology, which is applied in the direction of damage protection, heat exchange equipment, indirect heat exchangers, etc., can solve the problems that have not been seen in the application, and achieve the effect of avoiding dew point corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

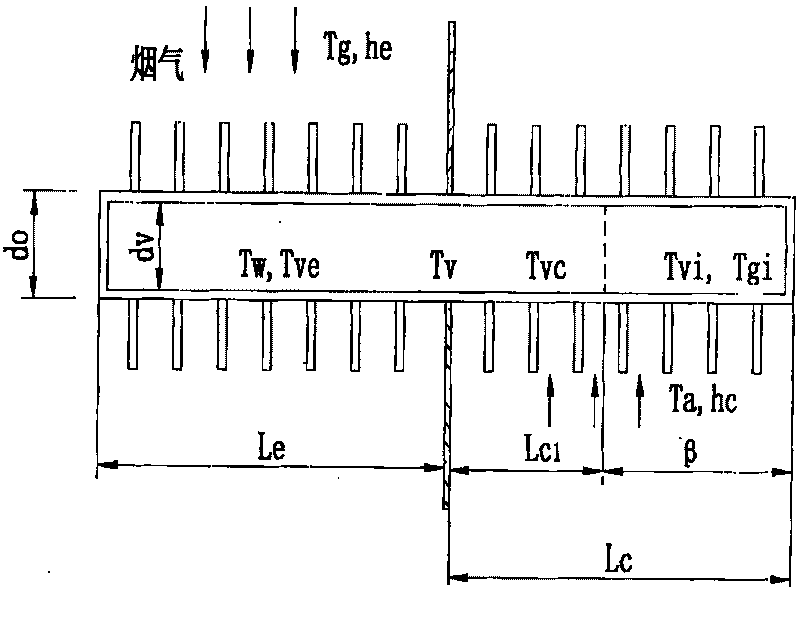

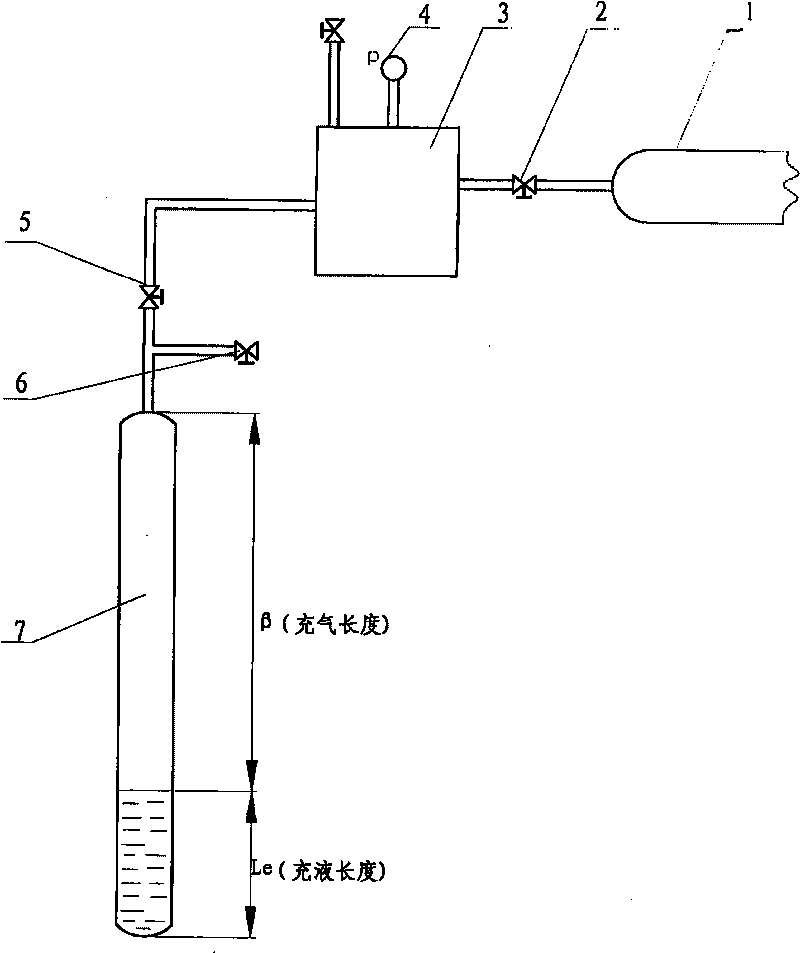

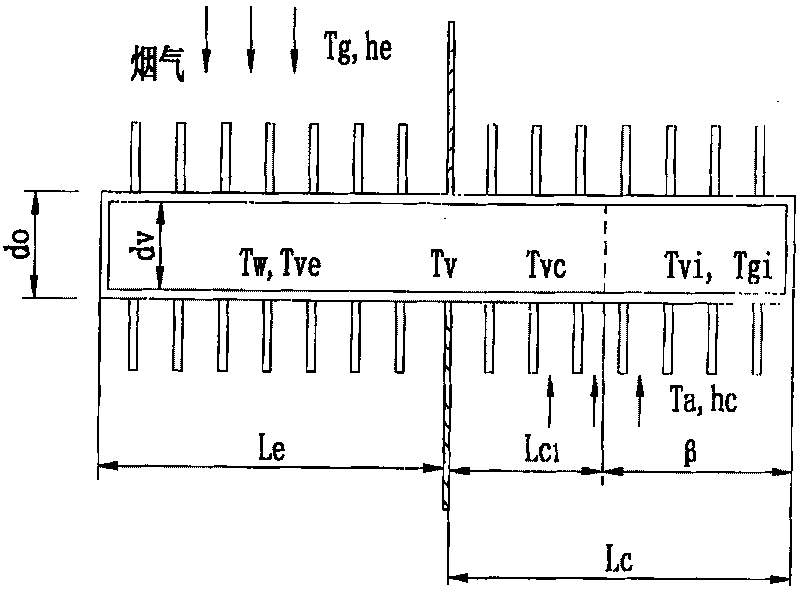

[0069] A heat pipe air preheater is used to recover the exhaust heat of a certain boiler. After design, the geometric characteristics of the selected carbon steel-water heat pipe elements are as follows:

[0070] The outer diameter of the base tube: 38mm, the inner diameter of the base tube is 32mm, the wall thickness is 3mm, the length of the evaporation section Le=2.0m, the length of the cooling section Lc=1.5m, there are high-frequency welded spiral circular fins on the outside of the base tube, and the fin spacing Both are 8mm, and the fin height is 16mm;

[0071] The flue gas inlet temperature is 220°C and the outlet temperature is 150°C; the air inlet temperature is 20°C and the outlet temperature is 100°C.

[0072] After calculation, the acid dew point of the smoke exhaust is 120°C. In order to prevent dew point corrosion, it is planned to use air-filled heat pipes. It is hoped that the wall temperature of all heat pipes will be above 130°C. Try to calculate the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com