Method for Preventing Dew Point Corrosion of Maleic Anhydride Cycle Tail Gas

A dew point corrosion and tail gas technology, applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of reduced production capacity of the device, explosive mixture, and reduced conversion rate of n-butane, so as to ensure the intrinsic safety of the process and avoid Dew point corrosion, the effect of ensuring the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

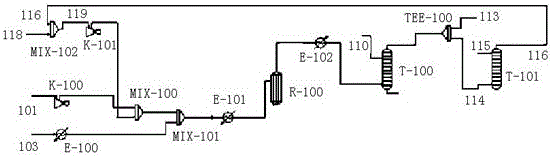

Image

Examples

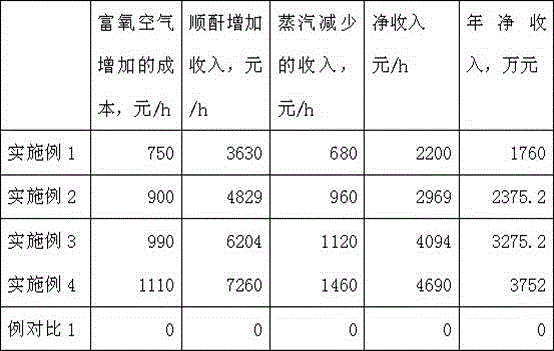

Embodiment 1

[0042] Embodiment 1: With 98%wt n-butane 6892kg / h as raw material, the air addition is 143700kg / h, 2500kg / h of oxygen-enriched air with 95% oxygen content, through 36000kg / h di-n-butyl phthalate Solvent absorption and analysis produce 6835kg / h of maleic anhydride, the first part of gas stream 113 can recover 4.0MPa after incineration, and 17.1t / h of superheated steam at 400°C.

Embodiment 2

[0043] Embodiment 2: With 98%wt n-butane 6892kg / h as raw material, the air addition is 132500kg / h, 3000kg / h of oxygen-enriched air with 95% oxygen content, through 36000kg / h di-n-butyl phthalate The solvent is absorbed and decomposed to produce 6944kg / h of maleic anhydride, the first part of the gas stream 113 can be recovered after incineration at 4.0MPa, and the superheated steam at 400°C is 15.7t / h.

Embodiment 3

[0044] Embodiment 3: With 98%wt n-butane 6892kg / h as raw material, the air addition is 95050kg / h, 3300kg / h of oxygen-enriched air with 95% oxygen content, through 36000kg / h di-n-butyl phthalate Solvent absorption and analysis produce maleic anhydride 7069kg / h, the first part of gas stream 113 can recover 4.0MPa after incineration, 400℃ superheated steam 14.9t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com