Liquid-phase dechlorinating method for chlorine-contained alkylate oil

A technology for chloroalkylation and dechlorination alkylation, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., to achieve the effect of reducing heat exchange equipment, avoiding dew point corrosion and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

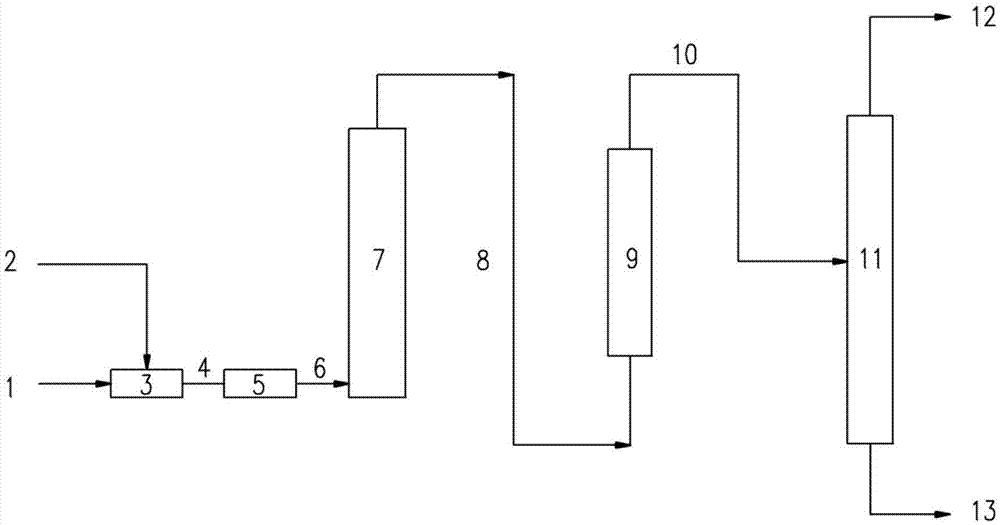

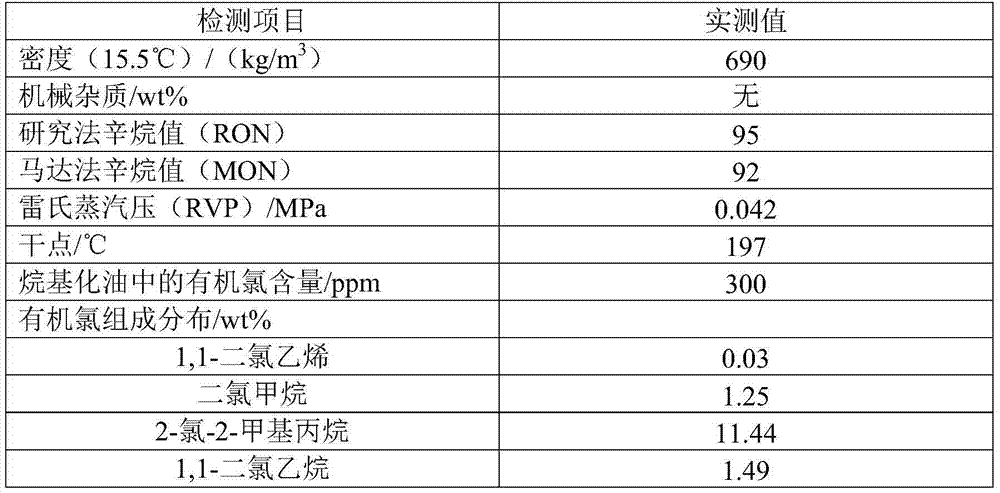

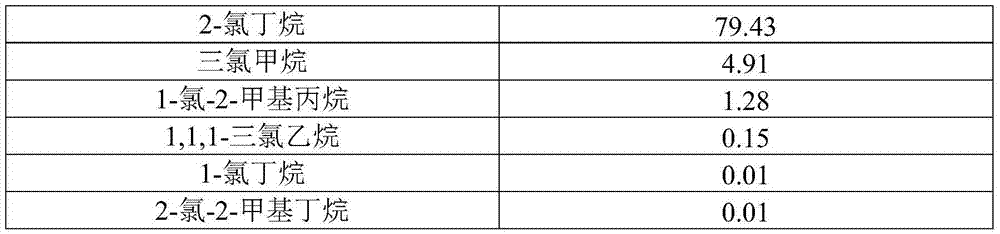

[0038] The chlorinated alkylate oil 1 enters the hydrogenation feed heater / heat exchanger 5 under the injection of the new hydrogen 2 gas stream, and is heated to the temperature required for the hydrogenation reaction at 150°C under the action of the heat source. Then it enters the liquid phase hydrogenation unit 7 to react the organic chloride and hydrogen to generate a hydrogenation stream 8 containing HCl, and the hydrogenation catalyst is a Pt-Pd-containing catalyst. The HCl-containing hydrogenation stream 8 enters the liquid phase adsorption unit 9 from the bottom, and the HCl contained in the HCl-containing hydrogenation stream 8 is removed by the adsorption of the adsorbent, that is, the dechlorination agent KT405. The hydrogenated product 10 from which HCl is removed then enters the oil-gas separation unit 11 to separate the dechlorinated alkylate oil 13 and the hydrogen-containing hydrocarbons 12. The dechlorinated alkylated oil 13 can be used as a product delivery de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com