Plate type air preheating device with adjusting function

An air preheating and adjusting plate technology, applied in the direction of cleaning heat transfer devices, waste heat treatment, heat exchanger shells, etc., can solve problems such as high price, dew point corrosion, heat exchanger damage, etc. The effect of reducing smoke temperature and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

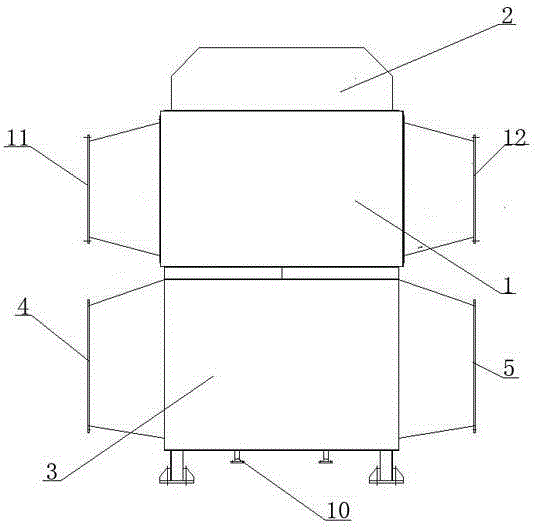

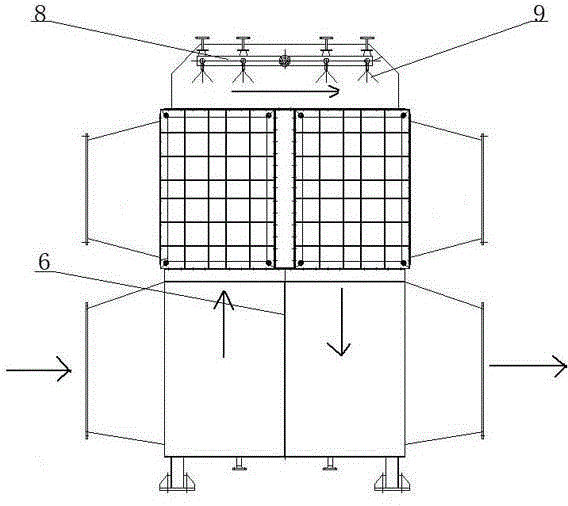

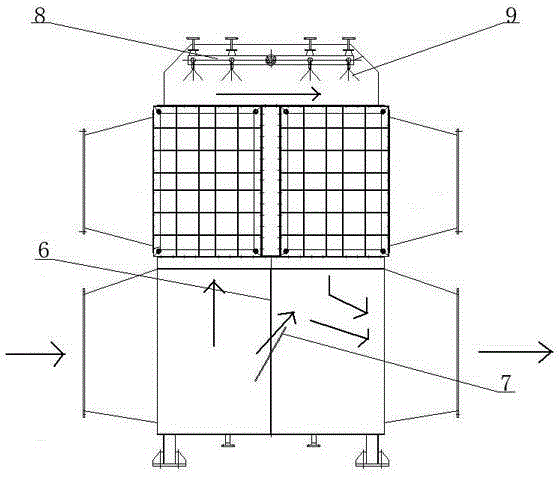

[0021] As shown in the figure: a plate-type air preheating device with regulating function, including a plate-type heat exchange assembly 1, a shroud 2 and an adjustment cylinder 3, the plate-type heat exchange assembly 1 has a preheated air flow channel and flue gas The flow channel, the guide cover 2 and the regulating cylinder 3 are respectively arranged at both ends of the flue flow channel of the plate heat exchange assembly 1. The guide cover 2 is a cover body with one end open, and the guide cover 2 passes through its open end cover. Set at one end of the flue gas flow channel of the plate heat exchange assembly 1, the two ends of the regulating cylinder 3 are the flue gas inlet 4 and the flue gas outlet 5 respectively, and the inside of the regulating cylinder 3 is separated by a fixed baffle 6 for the flue gas inlet. The air chamber and the flue gas outlet chamber, and the cylinder walls of the two chambers are respectively provided with through holes communicating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com