A deep energy-saving process for tubular heating furnace

A tubular heating furnace and process technology, which is applied to the field of deep energy-saving technology of tubular heating furnaces, can solve the problems of no fuel gas, thermal efficiency is difficult to reach the design expected level, and high exhaust gas temperature, so as to save fuel gas and reduce the acidity of flue gas. The effect of dew point corrosion and high burning intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

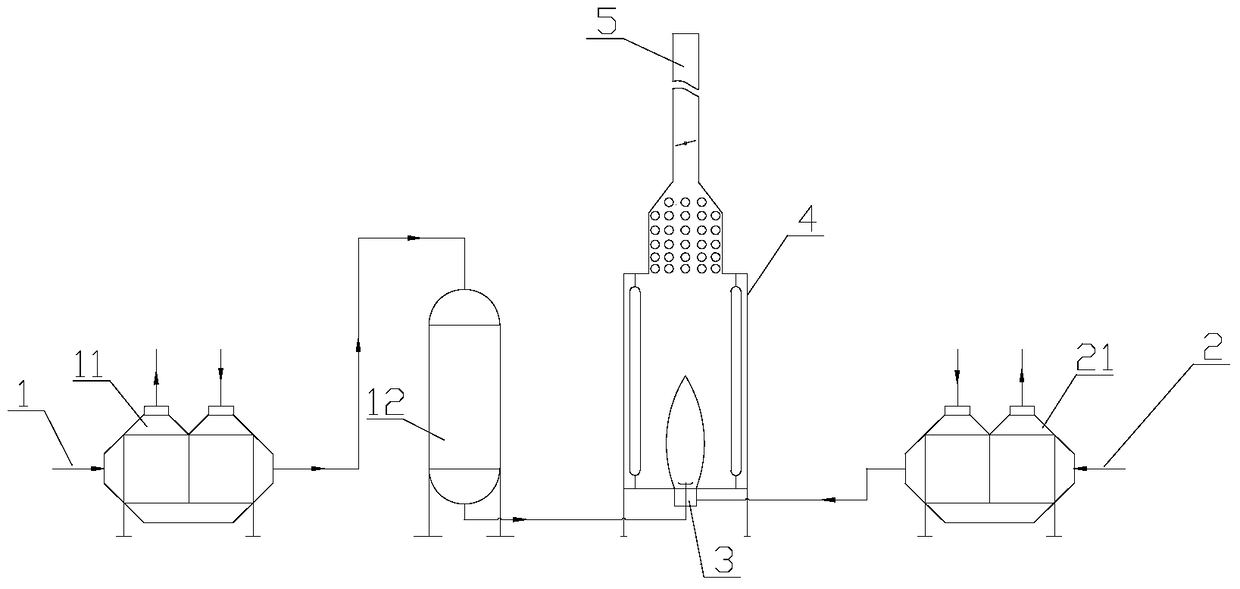

[0032] A deep energy-saving process for a tubular heating furnace, the process of which is as follows figure 1 As shown, the tubular heating furnace combustion system is mainly composed of fuel gas and air. In the method of the present invention, the fuel gas passes through the fuel gas preheater 11 and the gas desulfurization reactor 12, and the air passes through the air preheater 21. Enter the double preheating burner 3, and then burn in the tube heating furnace 4.

[0033] Fuel gas is generally refinery gas, natural gas or liquefied petroleum gas, in which the sulfur content is generally 100-300 μL / L, and the temperature is generally room temperature. The fuel gas first enters the fuel gas preheater 11 through the fuel gas pipeline 1, and is preheated to 100°C by the high-temperature flue gas. Subsequently, the fuel gas passes through the gas desulfurization reactor 12, and a desulfurization reaction occurs in the gas desulfurization reactor 12, reducing the sulfur conten...

Embodiment 2

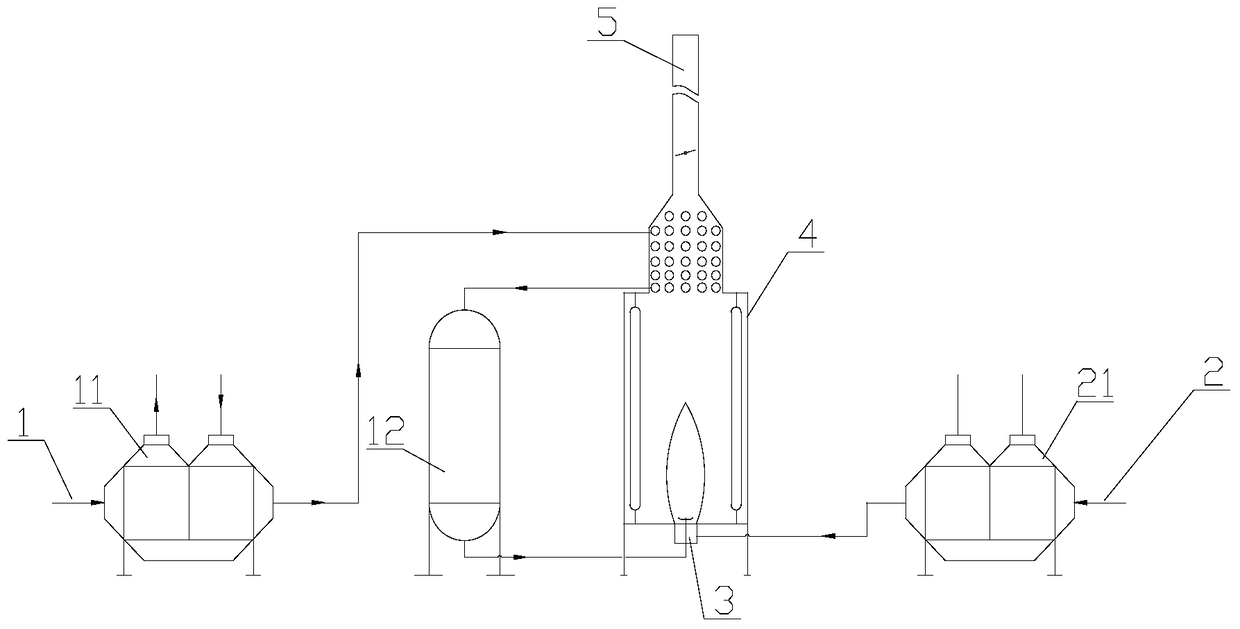

[0039] A deep energy-saving process for a tubular heating furnace, the process of which is as follows figure 2 As shown, it is generally the same as in Example 1, the difference is that since the fuel gas still cannot reach the reaction temperature required by the gas desulfurization reactor 12 after being preheated by the fuel gas preheater 11, it needs to pass through the tubular heating furnace 3 Auxiliary heating to 500 ° C, and then into the gas desulfurization reactor 12 for deep desulfurization treatment. The air is combustion-supporting air, generally at room temperature. The air first enters the air preheater 21 through the air pipeline 2, and is preheated to 500°C by the high-temperature flue gas.

Embodiment 3

[0041] The deep energy-saving process of the tubular heating furnace can also use the fuel gas without preheating, and directly desulfurize it at a working condition of about 40°C before entering the fuel burner of the heating furnace. A conventional low-nitrogen oxide burner can be used, and the internal gas desulfurization reactor can be appropriately increased. The catalyst prolongs the desulfurization time and improves the efficiency of the desulfurization reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com