Method for measuring flow of high-temperature highly corrosive flue gas

A high-temperature flue gas and flow measurement technology, which is applied in the direction of volume/mass flow generated by mechanical effects, fluid flow detected by measuring pressure difference, etc. Problems such as inaccurate measurement data can prevent condensed water droplets from high-temperature gasification cycle, avoid pressure fluctuations, and achieve accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

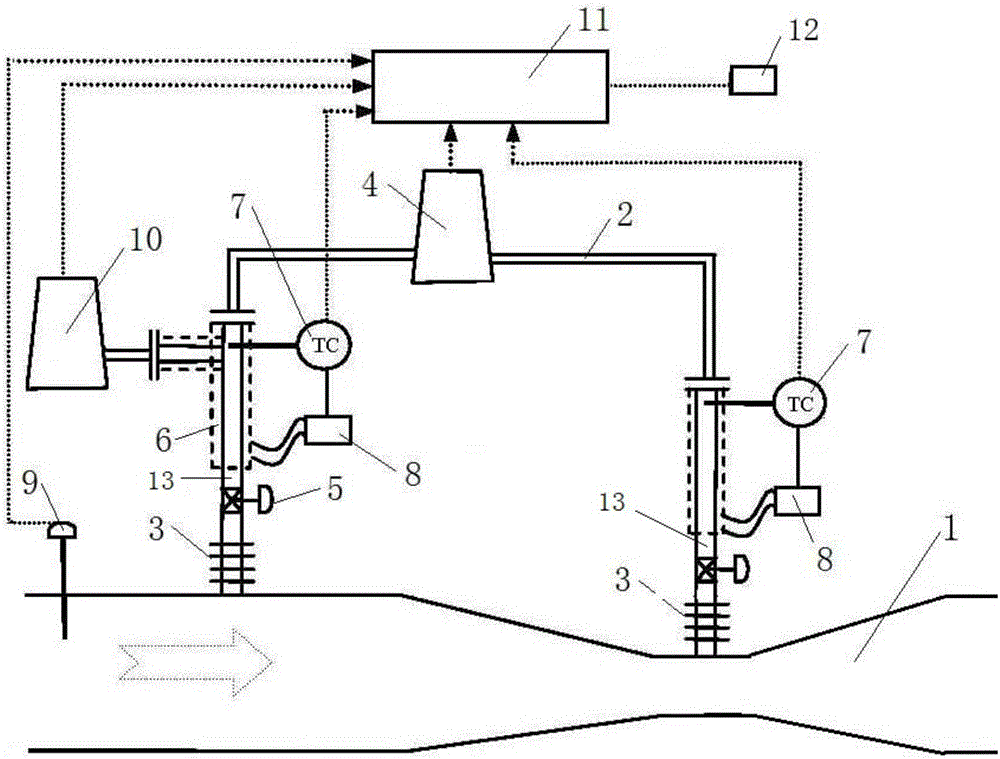

[0012] Based on the properties of high-temperature and highly corrosive flue gas, the present invention proposes to use a Venturi flowmeter to measure the pressure, temperature, and pressure difference of the flowmeter for high-temperature flue gas, and uses tube fin cooling and electric heating to keep warm, and the two pressure measuring ports are respectively The temperature controller is used for temperature control, combined with ensuring the appropriate temperature of the pressure measuring port, to prevent dew point corrosion of flue gas, to prevent high-temperature gasification cycle of condensed water droplets, and to avoid problems such as pressure fluctuations.

[0013] The present invention adopts the improved Venturi flowmeter to measure the flow rate of high temperature and strong corrosion flue gas, such as figure 1 As shown in the Venturi flowmeter, a pressure guide tube 2 is connected between the inlet section of the Venturi tube 1 (high-temperature flue gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com