Desulfurized wastewater spray evaporation treatment device with bypath system

A desulfurization wastewater and sub-system technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as blockage of the shell-and-tube heat exchanger, to achieve the effect of simple structure, no heat exchange loss, and no local resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

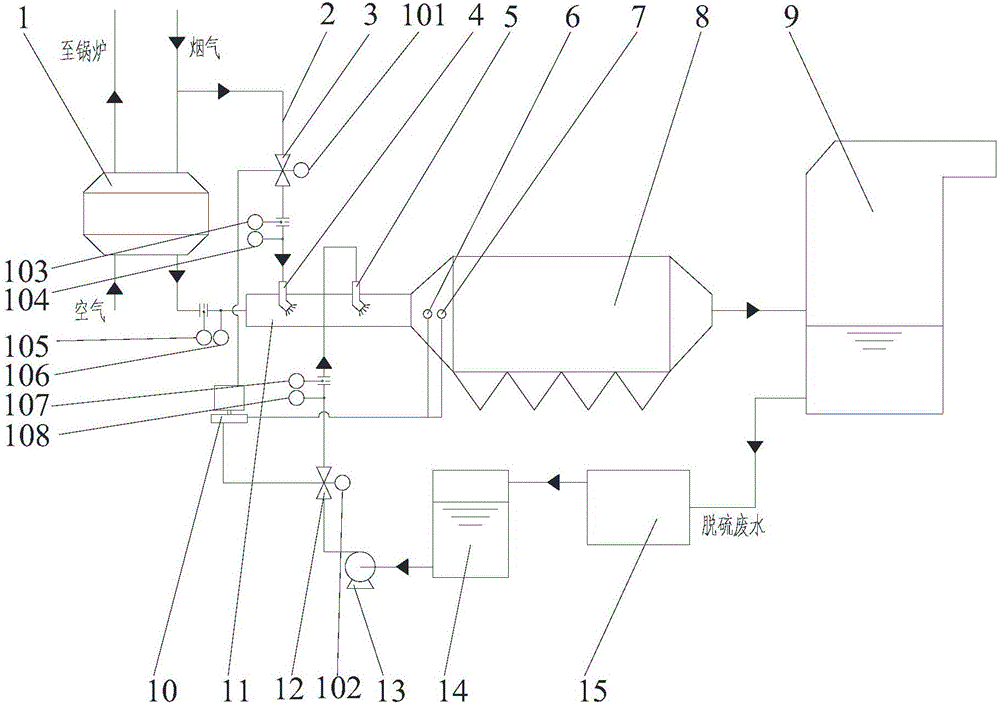

[0022] see figure 1 , the embodiment of the present invention is provided with a bypass flue subsystem, a desulfurization wastewater spray subsystem, and a control unit; the bypass flue subsystem is provided with a bypass flue 2, a bypass flue regulating valve 3, a high-temperature flue gas Nozzle 4; the desulfurization wastewater spray subsystem is provided with a spray device 5, a desulfurization wastewater pipeline regulating valve 12, and a water pump 13; the control unit is provided with a control processor 10, a bypass flue electric actuator 101, and a desulfurization wastewater pipeline electric Executing agency 102, bypass flue flow transmitter 103, bypass flue temperature transmitter 104, air preheater outlet flue flow transmitter 105, air preheater outlet flue temperature transmitter 106, Desulfurization wastewater pipeline flow transmitter 107, desulfurization wastewater pipeline temperature transmitter 108.

[0023] The bypass flue 2 draws flue gas from the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com