Feedwater replacement type economizer system for whole commissioning of denitration device

An economizer and equipment technology, applied in the field of boilers, can solve problems such as failure to work normally, and achieve the effects of reducing heat absorption, simple system and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

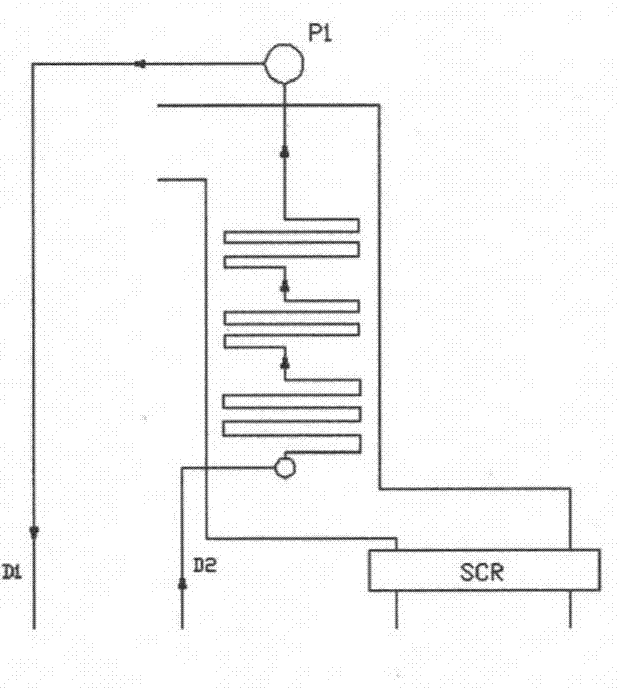

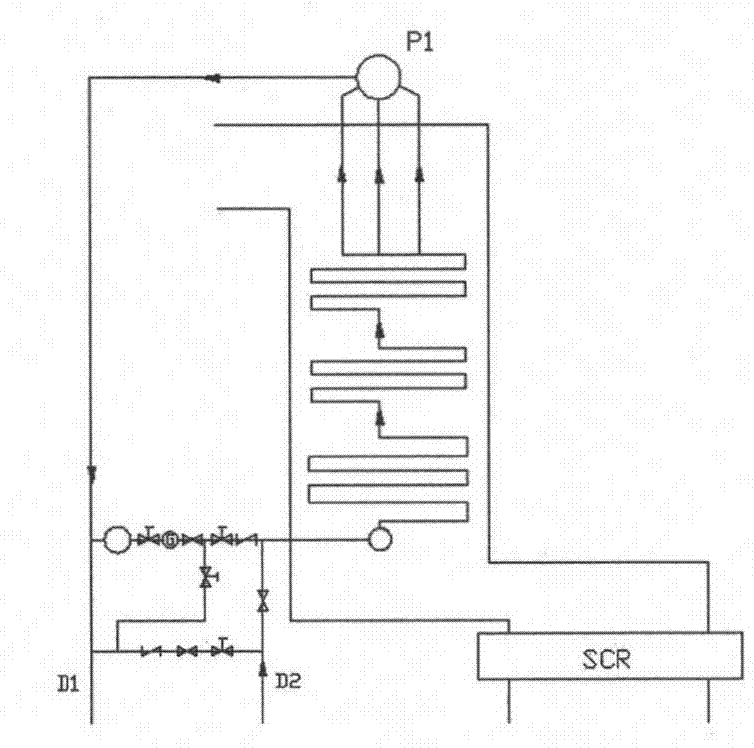

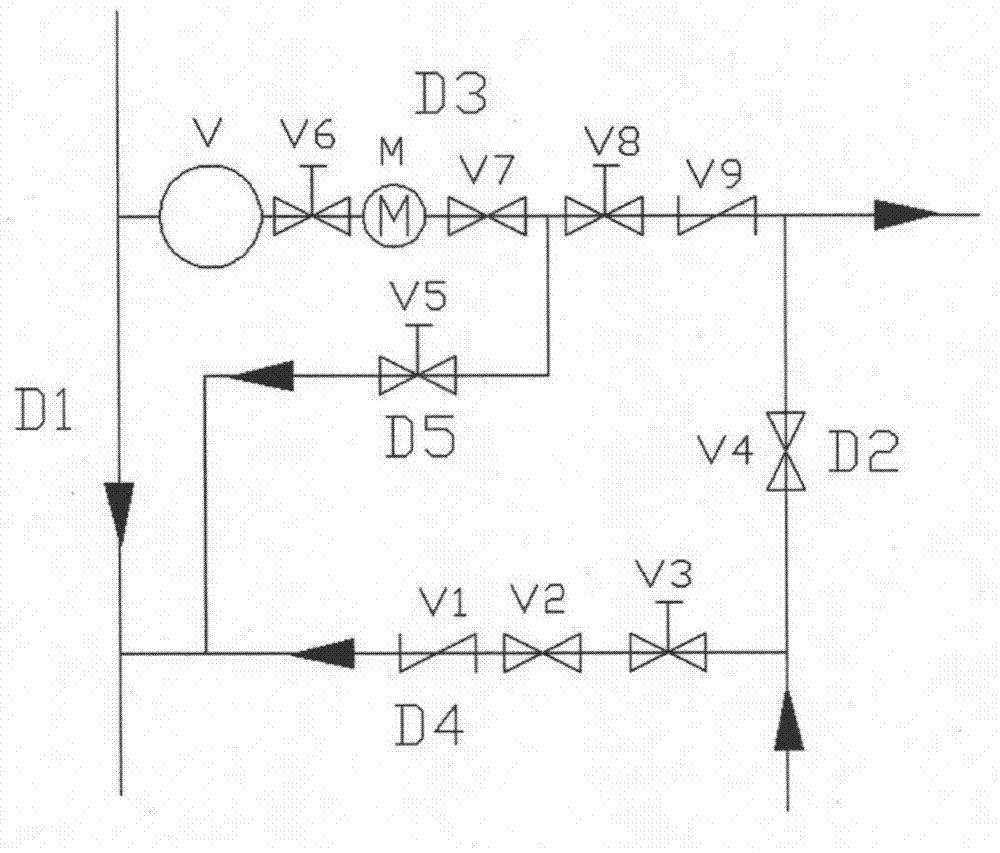

[0021] Taking a 600MW supercritical boiler of a power plant produced by Shanghai Boiler Factory as an object, this embodiment provides a feedwater replacement economizer system for the whole process of denitrification equipment to be put into operation, such as figure 2 As shown, it includes the first bypass D3 for making the water in the downcomer D1 flow into the water supply pipe D2, the second bypass D4 for making the water in the water supply pipe D2 flow into the downcomer D1, and the first Three bypasses S3, the first bypass D3 and the second bypass D4 are set between the downpipe D1 and the water supply pipeline D2, according to the order of the interface with the water supply pipeline D2, the first bypass D3 is at the After two bypasses D4. Such as image 3 As shown, the first bypass D3 is provided with a container tank V, a fourth shut-off valve V6, a circulating pump M, a first flow regulating valve V7, and a first shut-off valve V8 along the direction from the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com