Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve steam parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

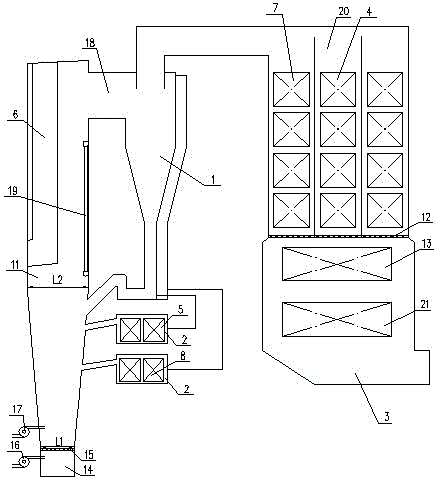

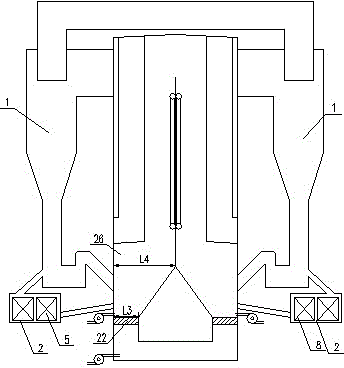

Sintered power generation by waste heat system with by-product gas afterburning

InactiveCN101509729AIncrease flue gas temperatureImprove steam parametersIncreasing energy efficiencySteam engine plantsSuperheaterEvaporator

The invention relates to a residual heat power generation system which is a power generation system with by-product gas supplemental combustion by sintering residual heat. The power generation system comprises a cooling machine, a waste heat boiler, a steam drum, a steam turbine, a boiler feed pump, an induced draft fan, an air blower and a chimney. A combustion hearth, a high-temperature superheater, a low-temperature superheater, an evaporator and an economizer are sequentially arranged on the waste heat boiler from top to bottom; the outlet of the high-temperature superheater and the steam inlet of the steam turbine are connected with each other by a pipeline; the waste heat boiler is provided with a sintering waste gas inlet and a by-product gas inlet; and the upper part of the cooling machine is provided with a high-temperature waste gas outlet, a middle-temperature waste gas outlet and a low-temperature waste gas outlet. The residual heat power generation system can greatly increase the temperature of the smoke and the temperature and the pressure of the overheated steam at the inlet of the steam turbine, and can improve the power generation capability.

Owner:江苏东能环保能源科技有限公司

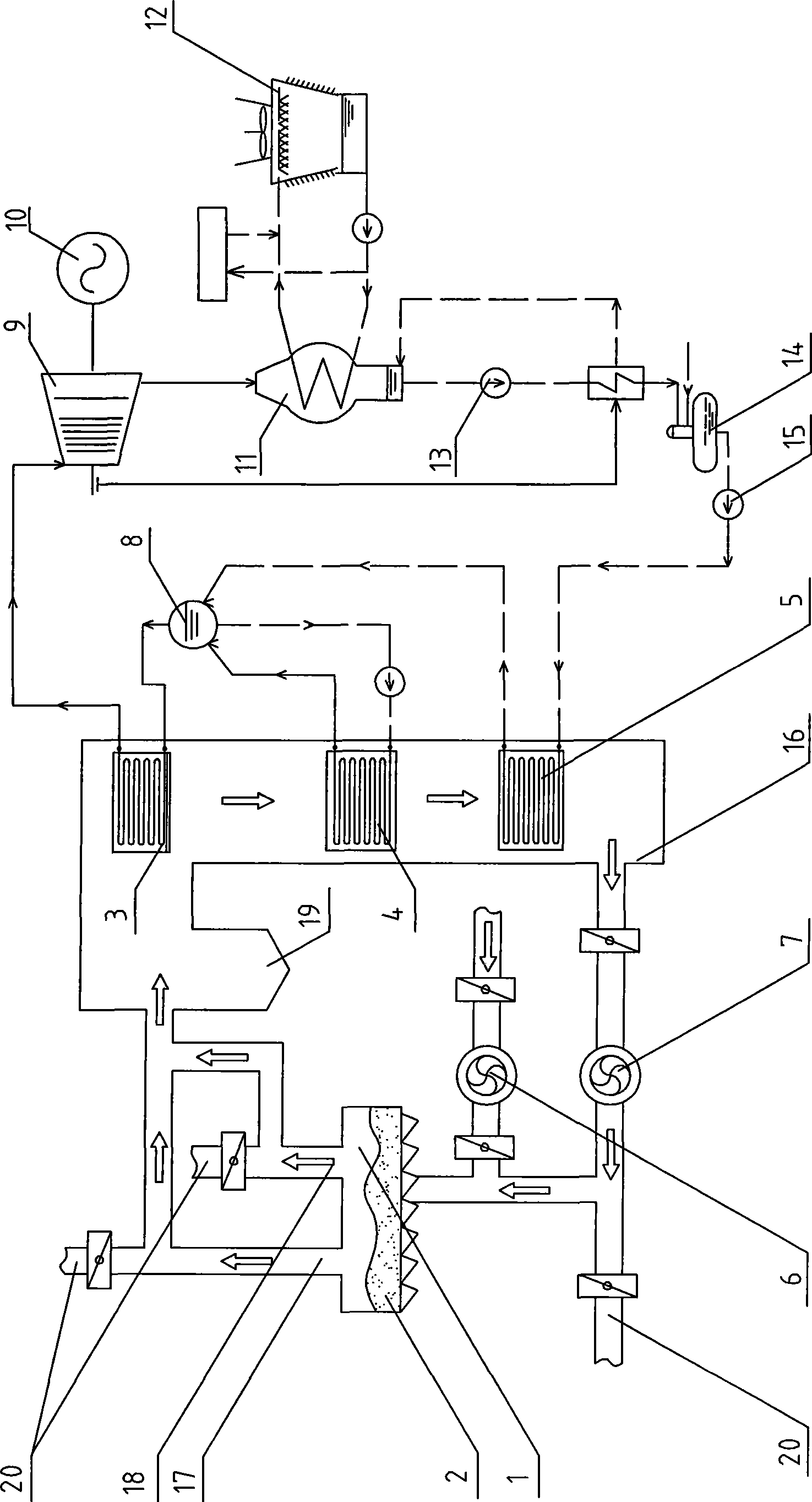

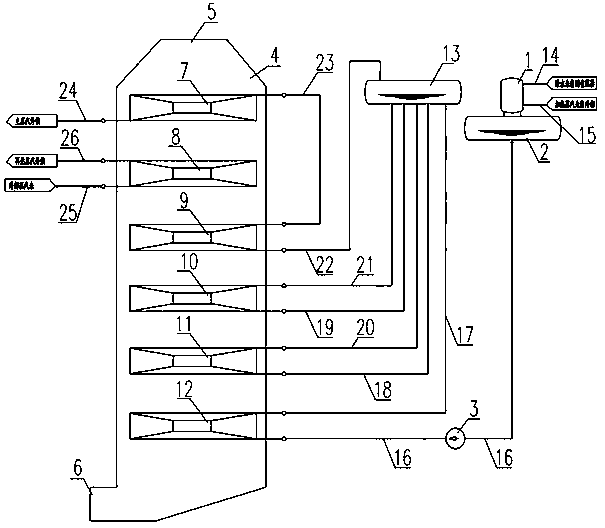

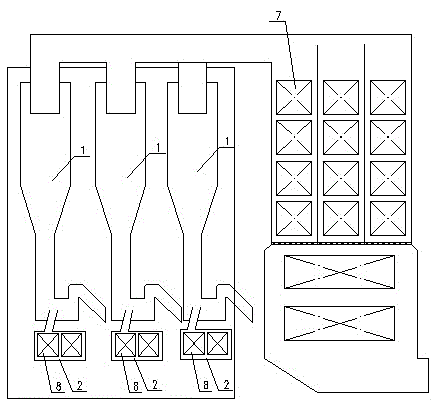

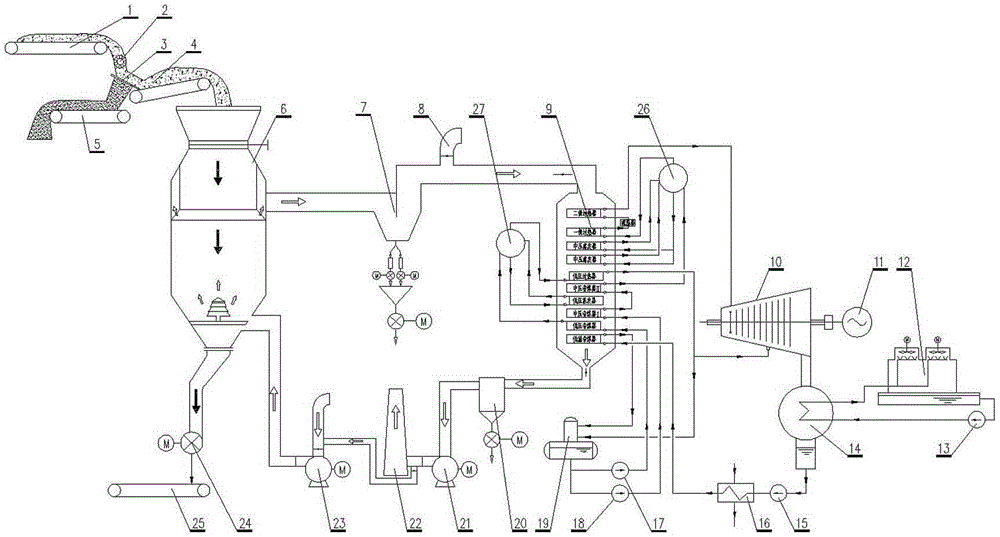

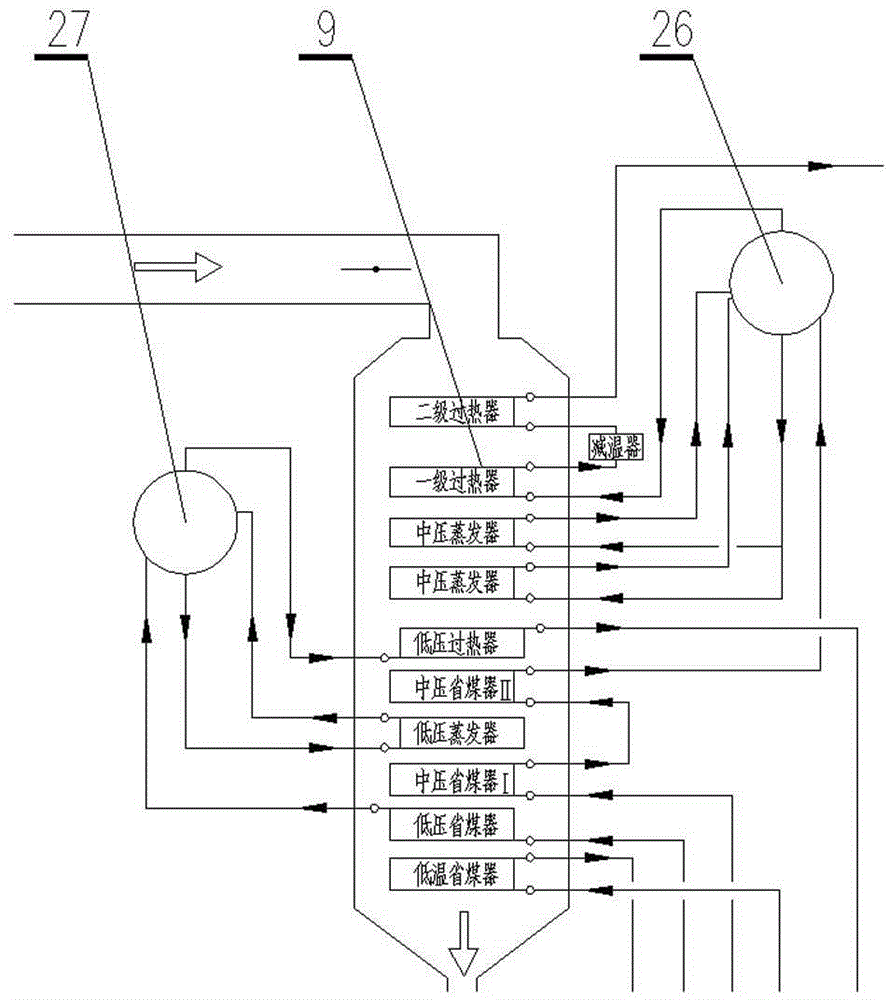

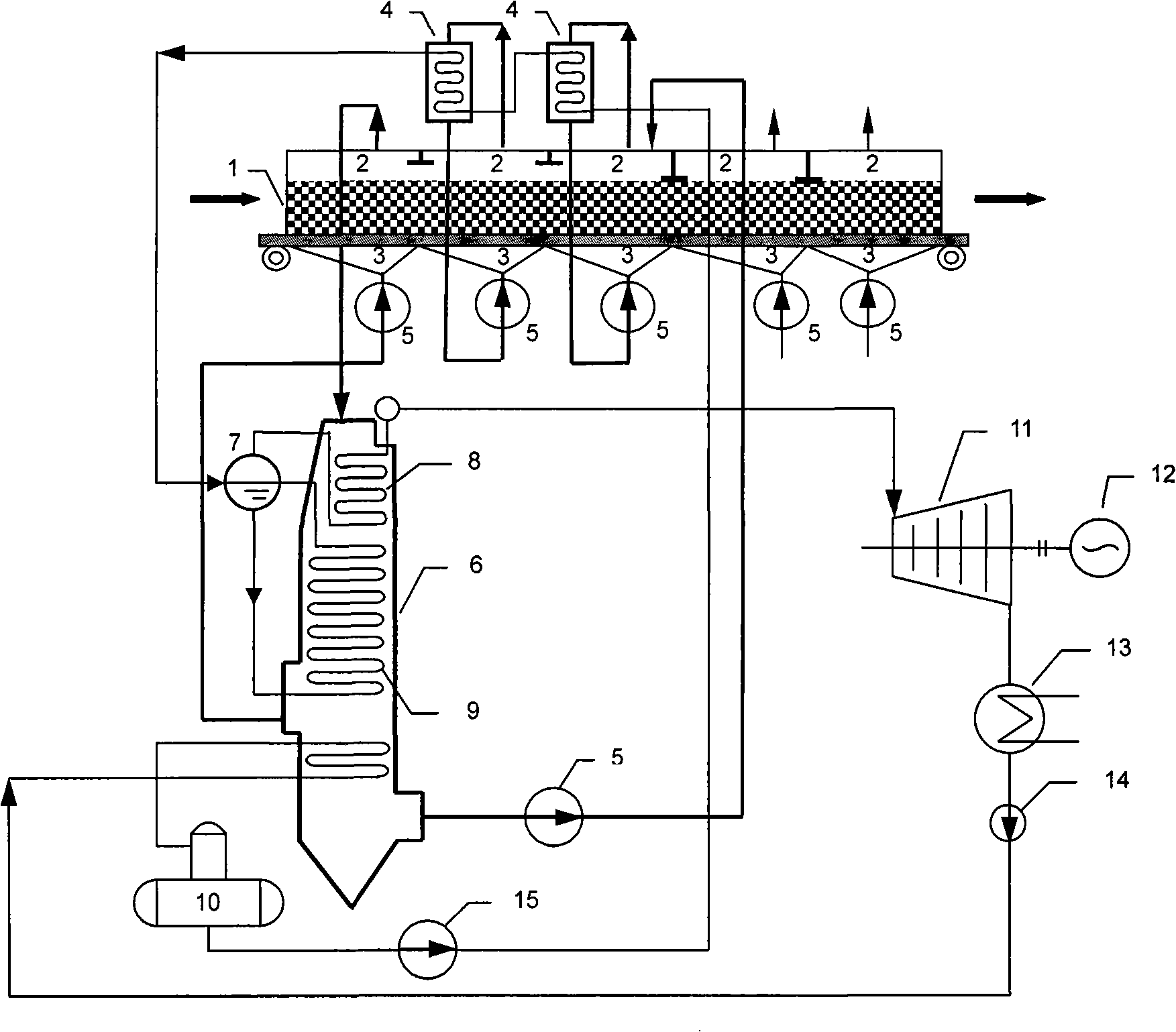

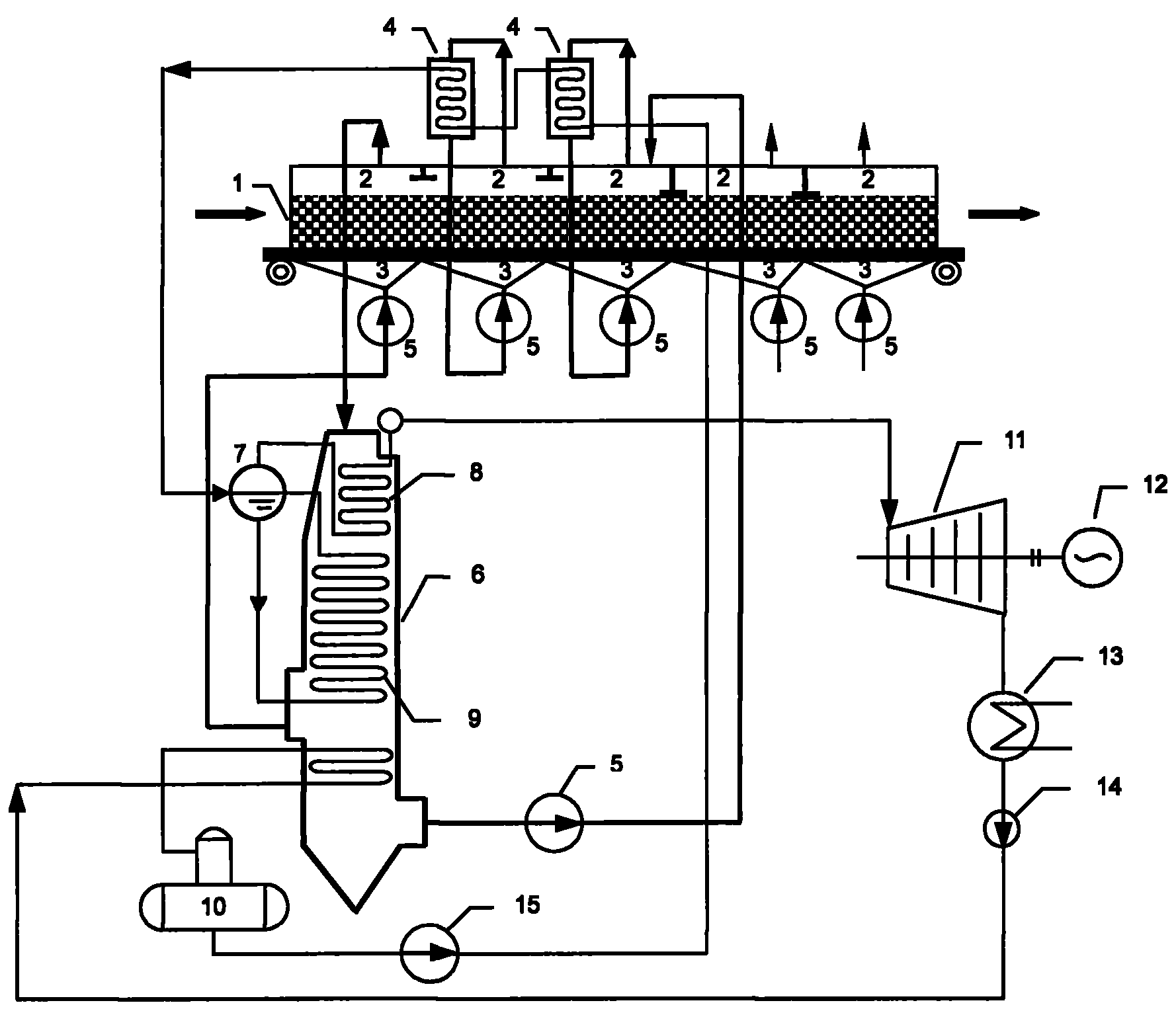

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359AGuaranteed cycleImprove parametersFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recovering the sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

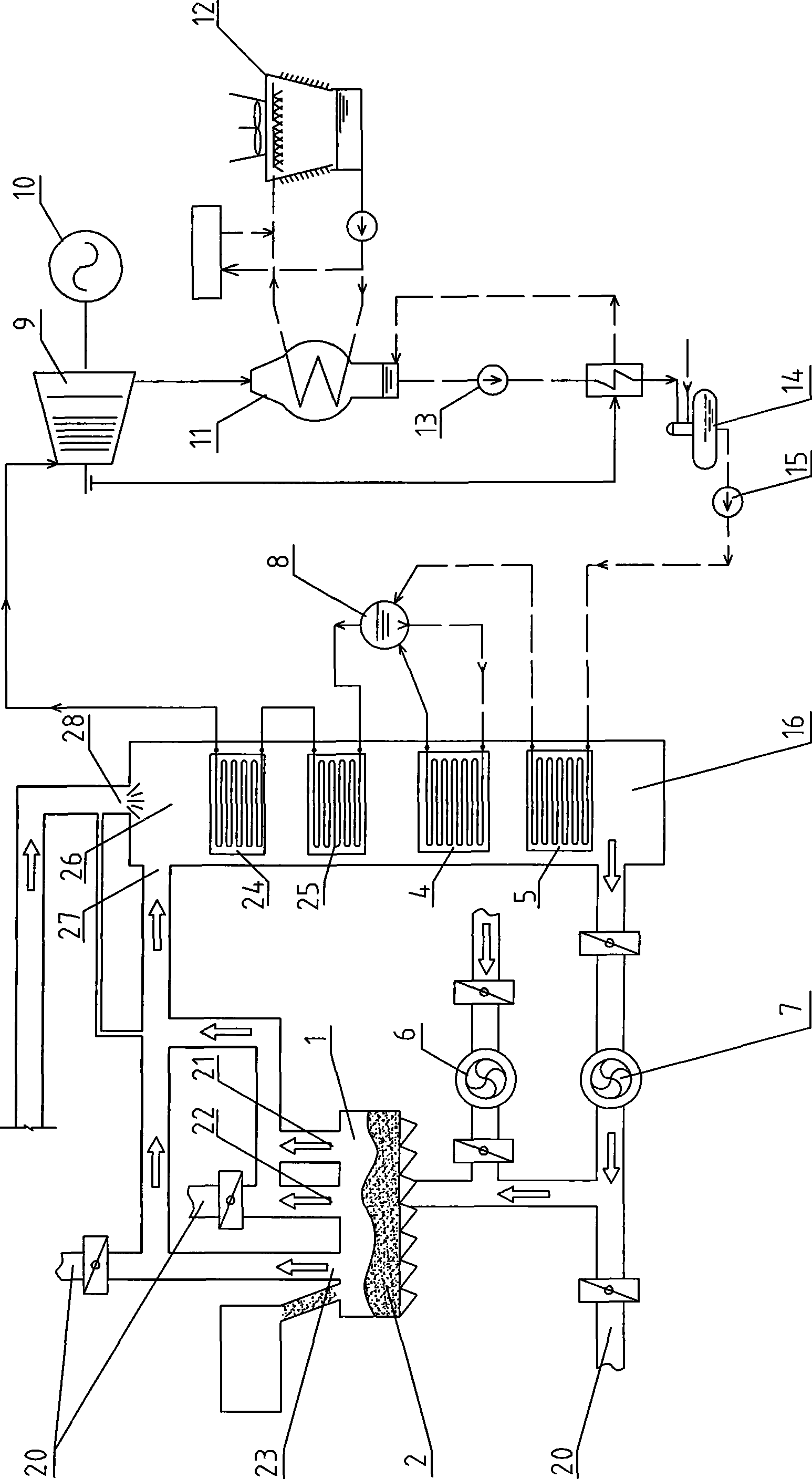

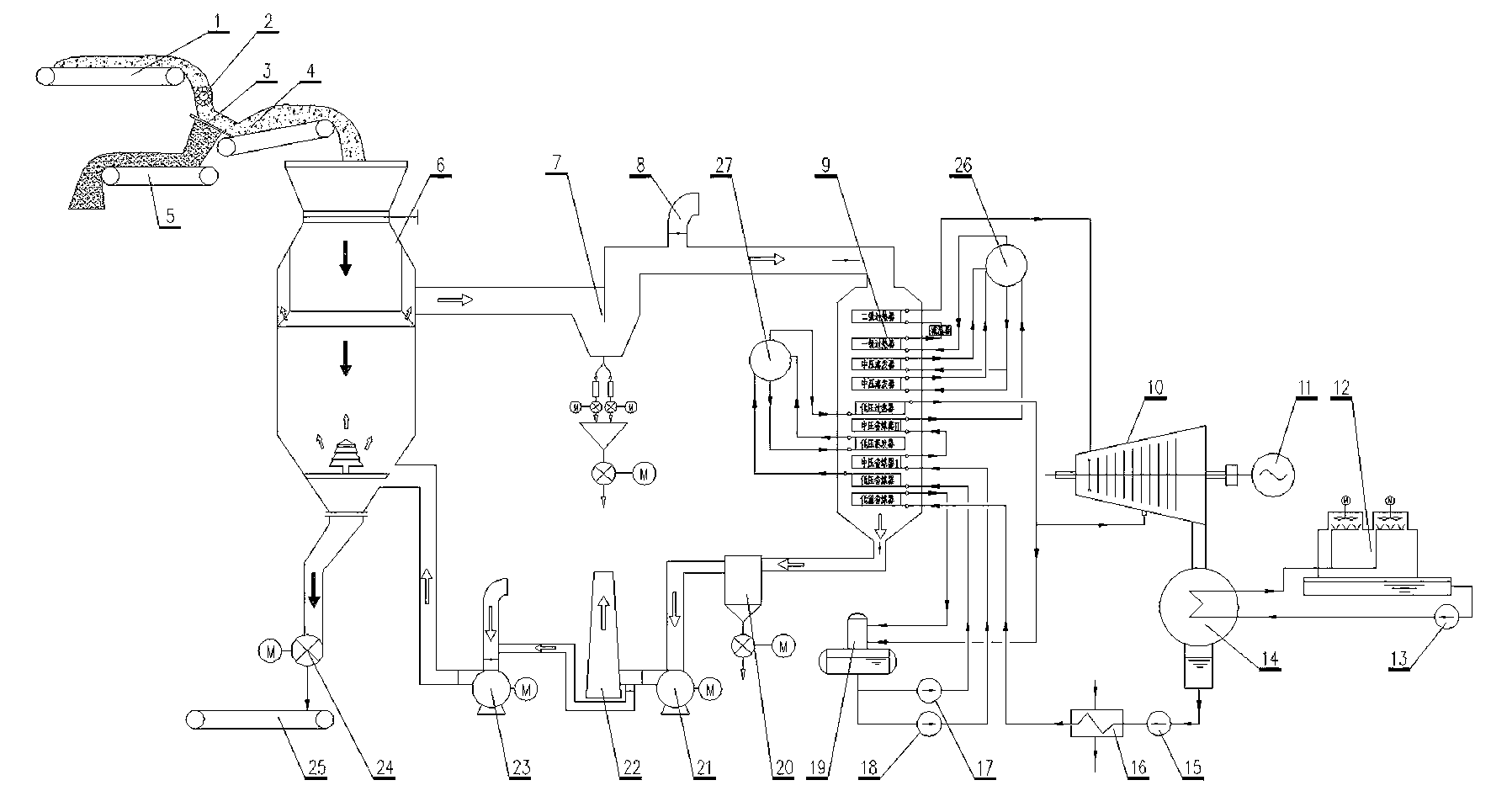

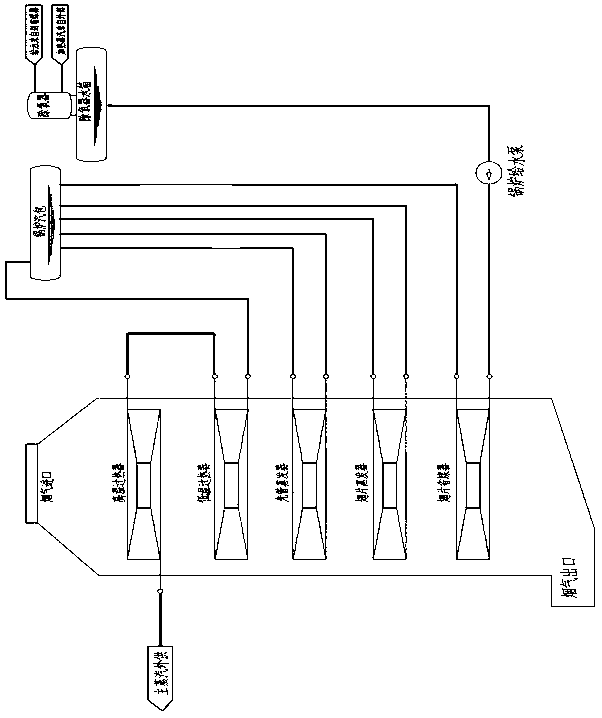

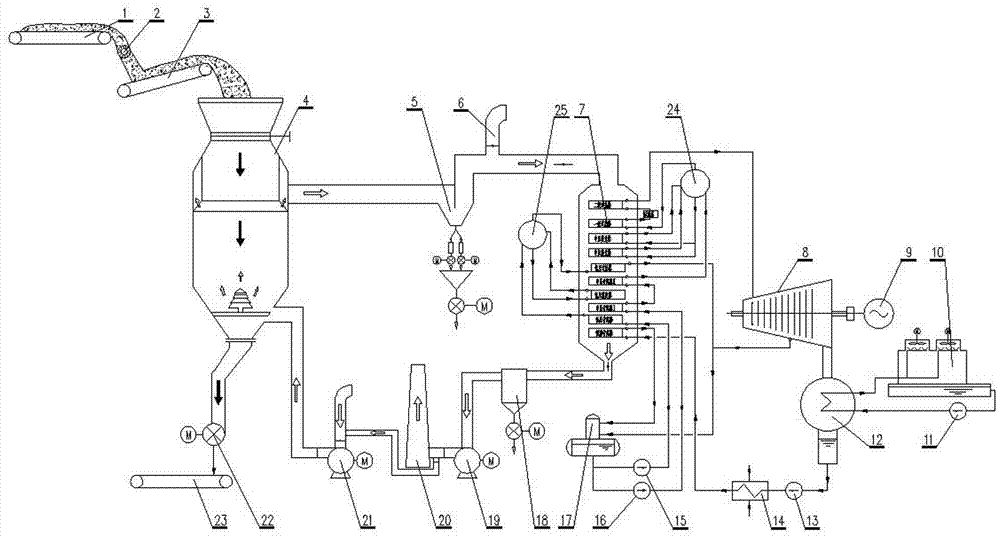

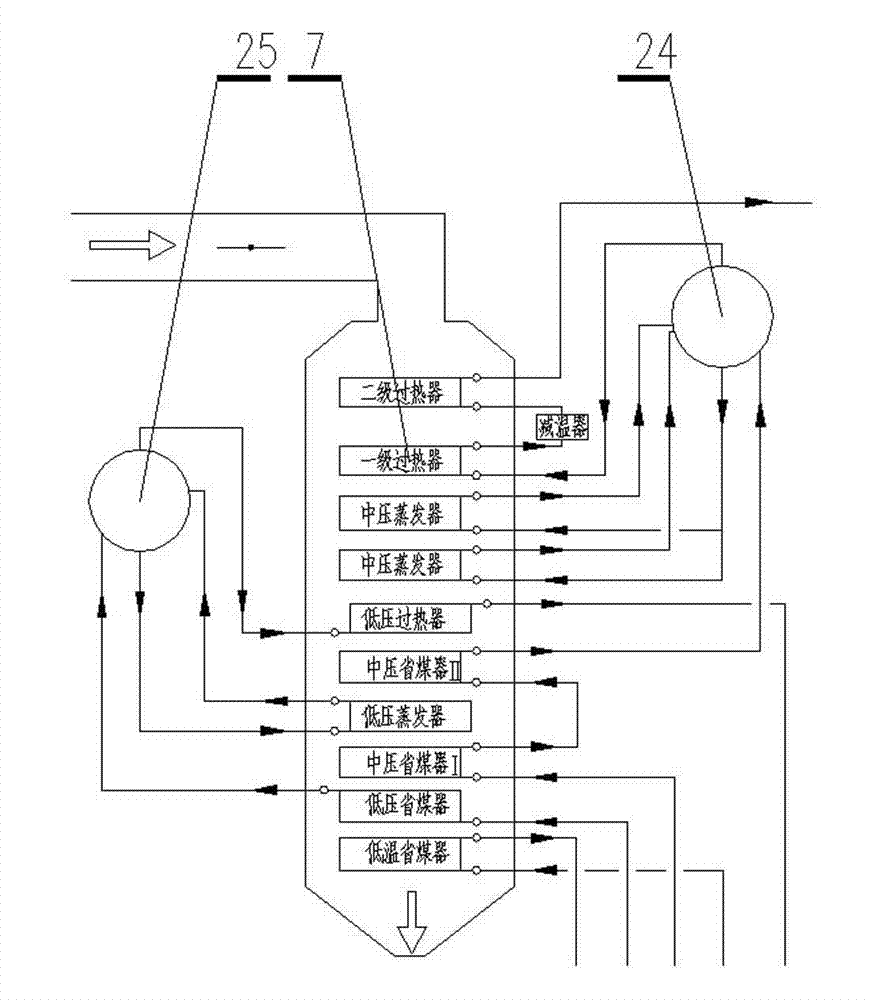

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

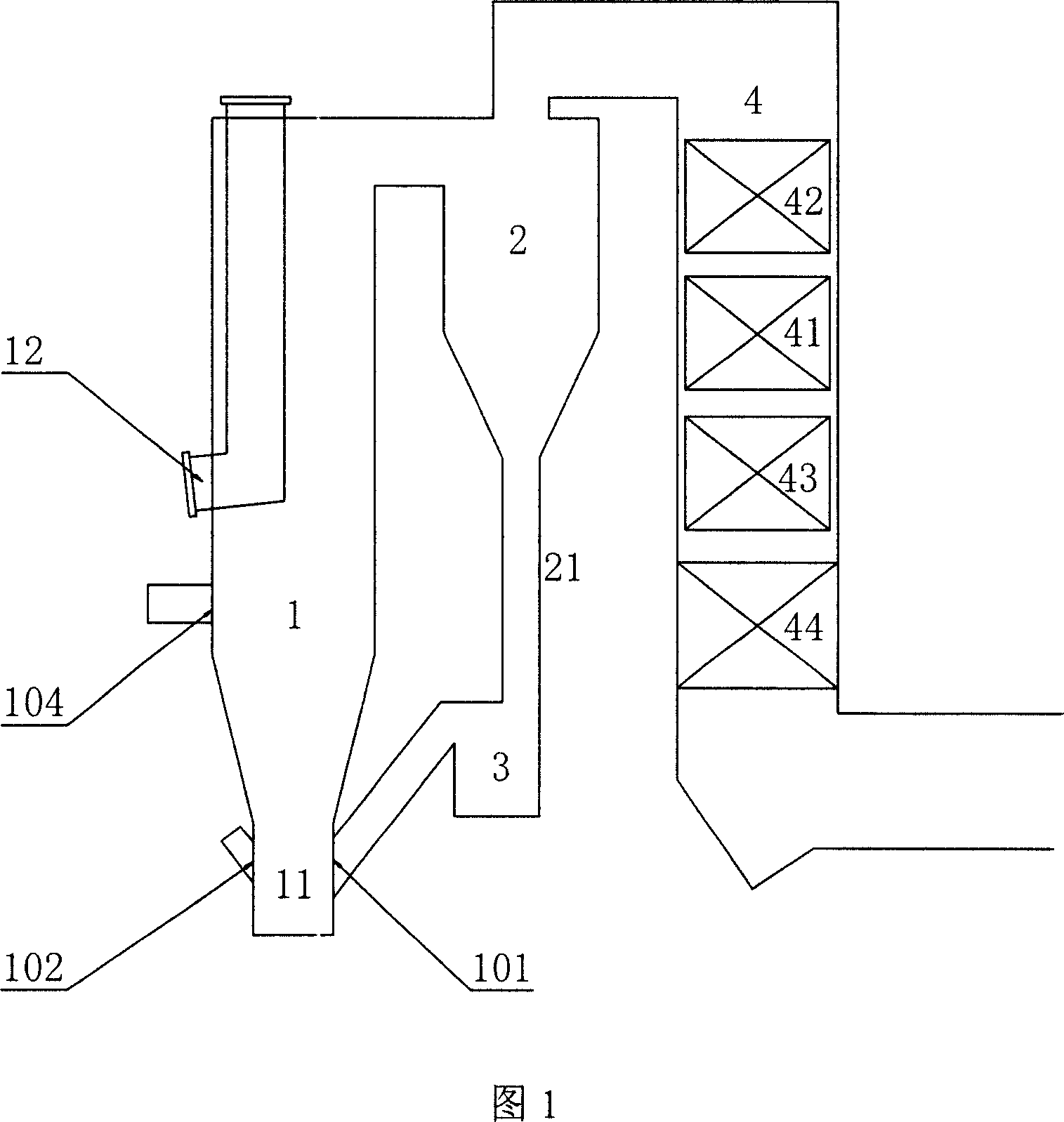

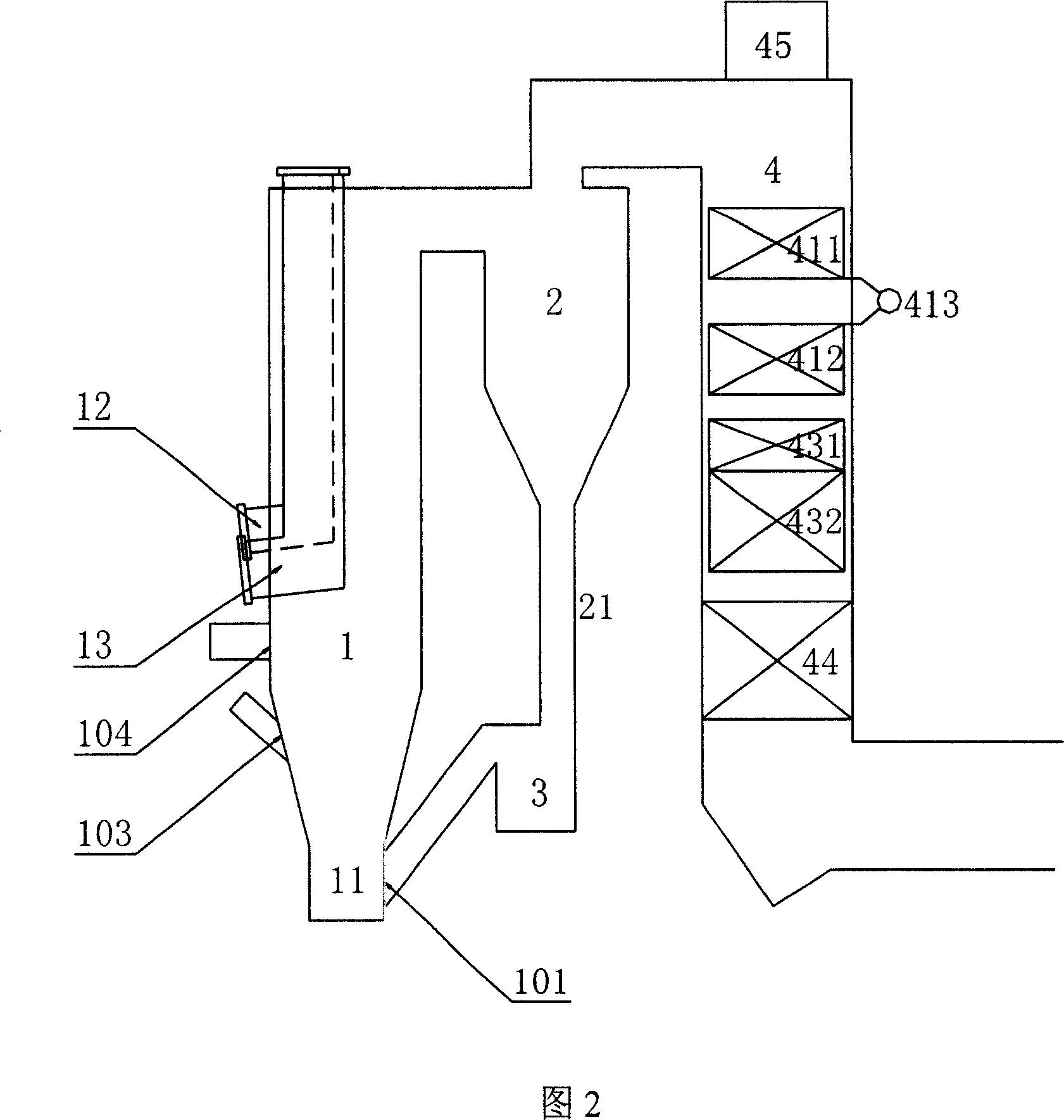

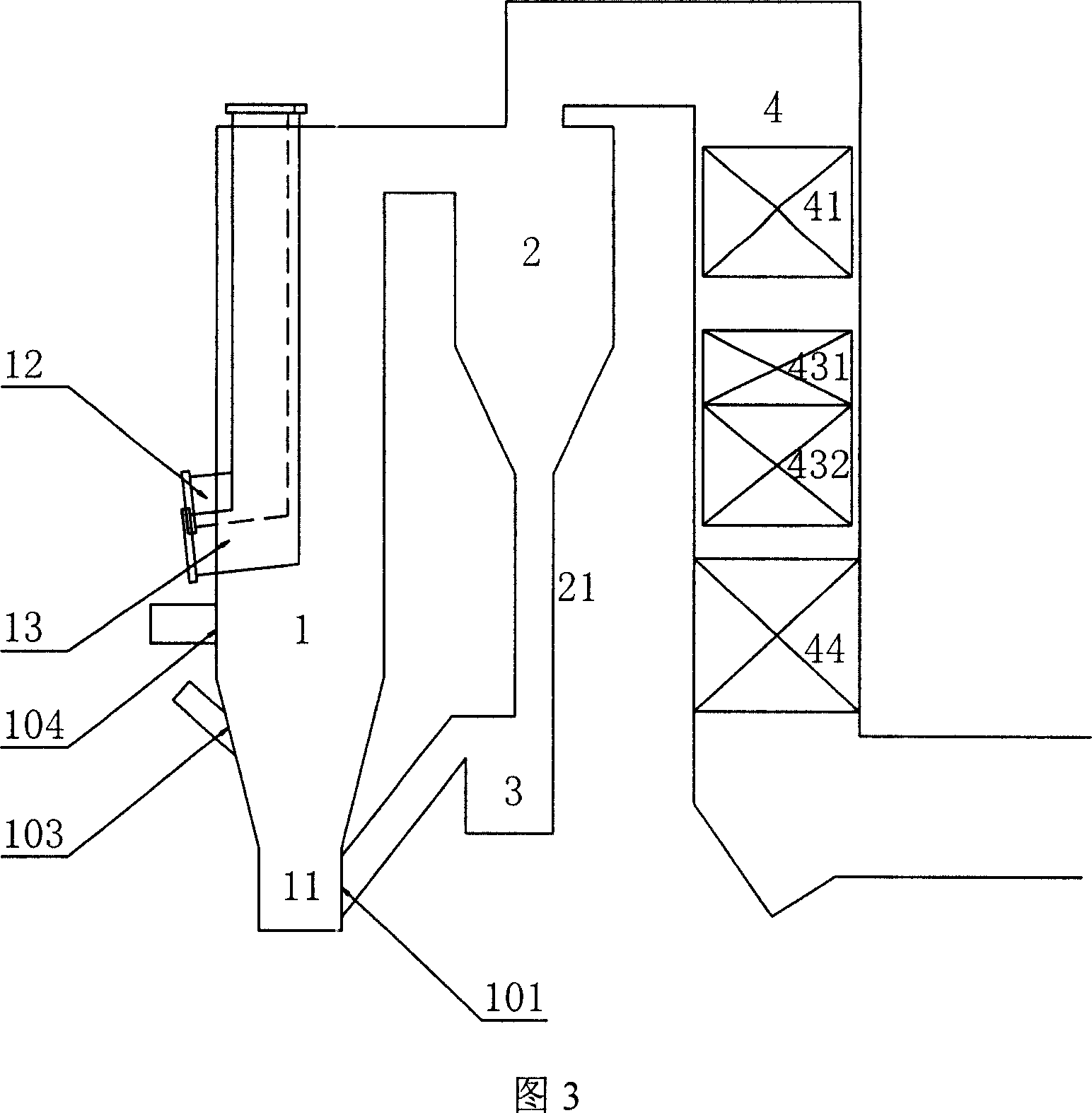

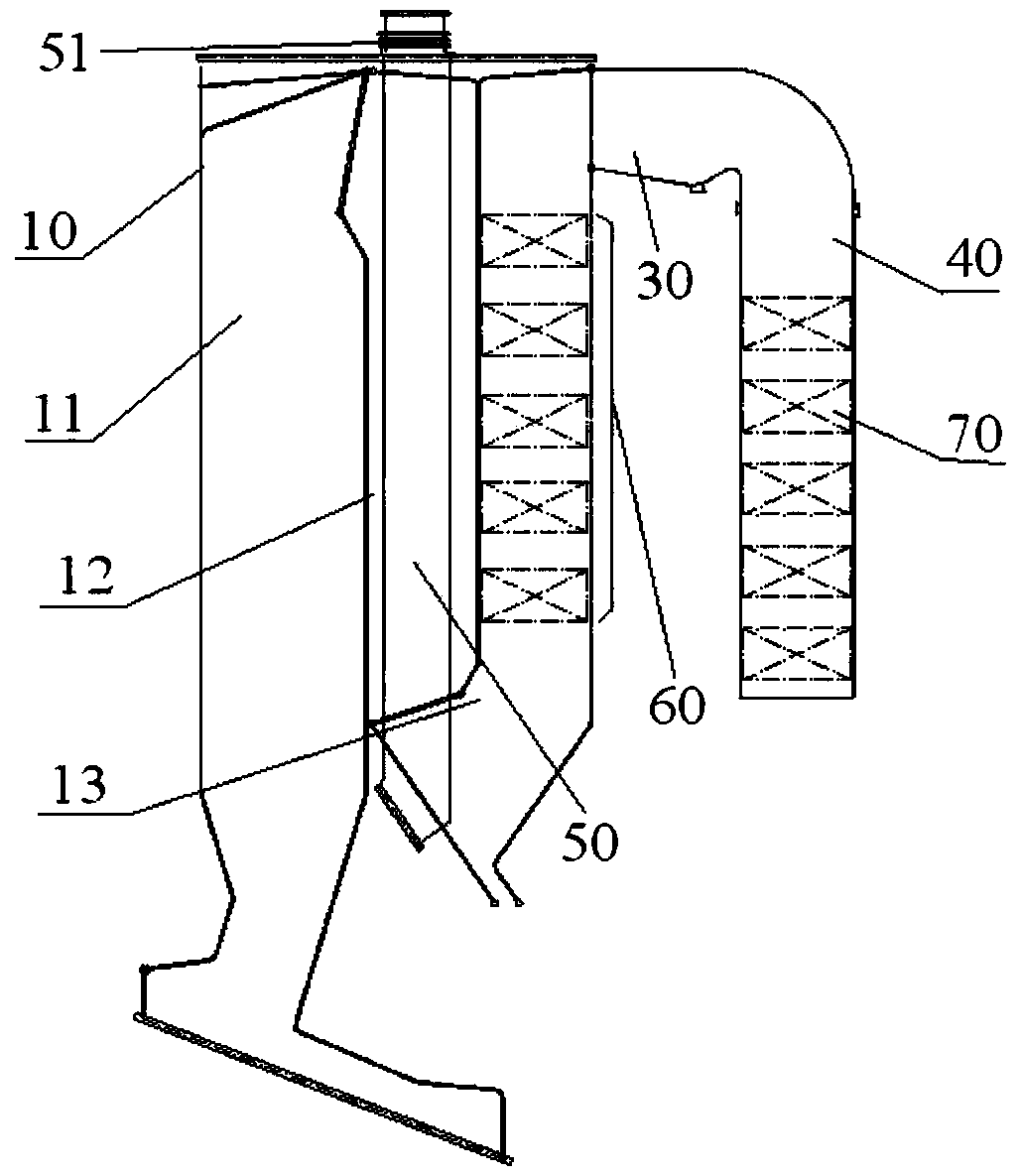

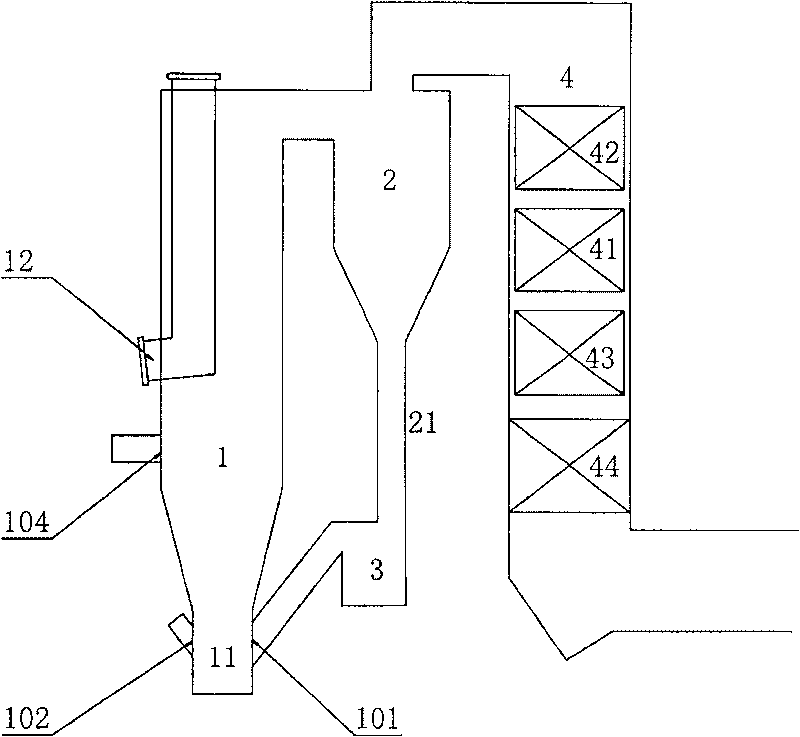

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

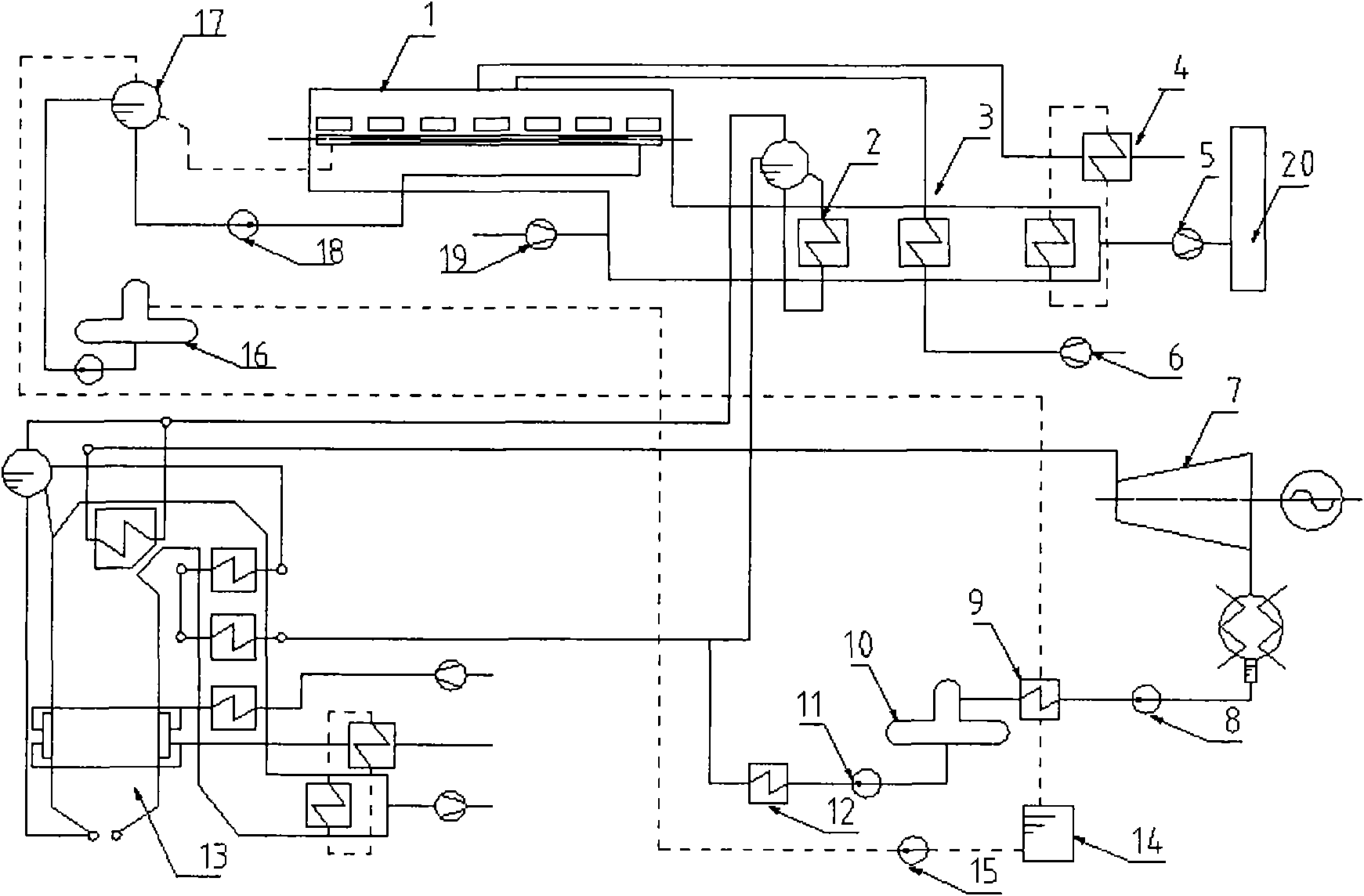

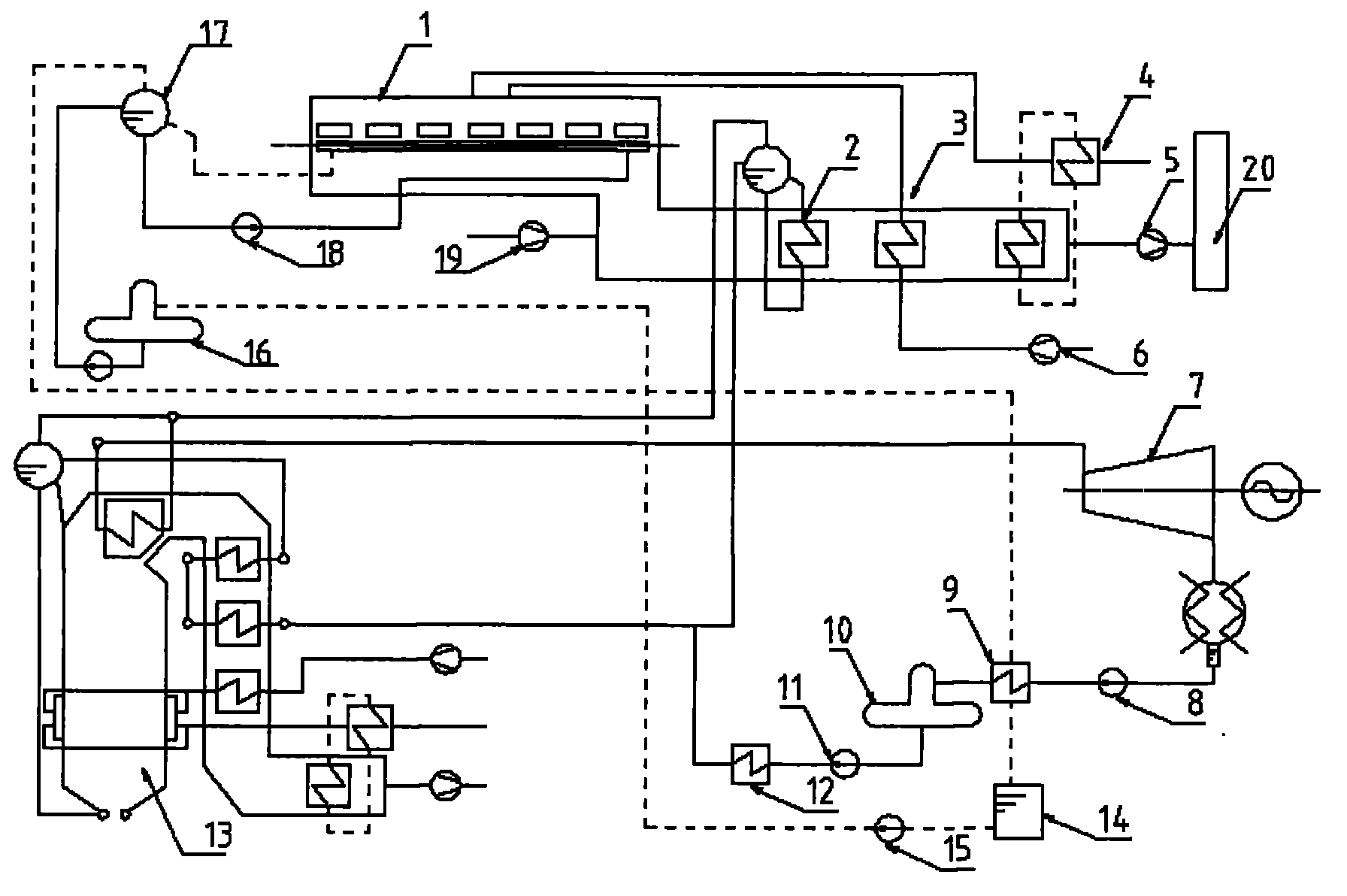

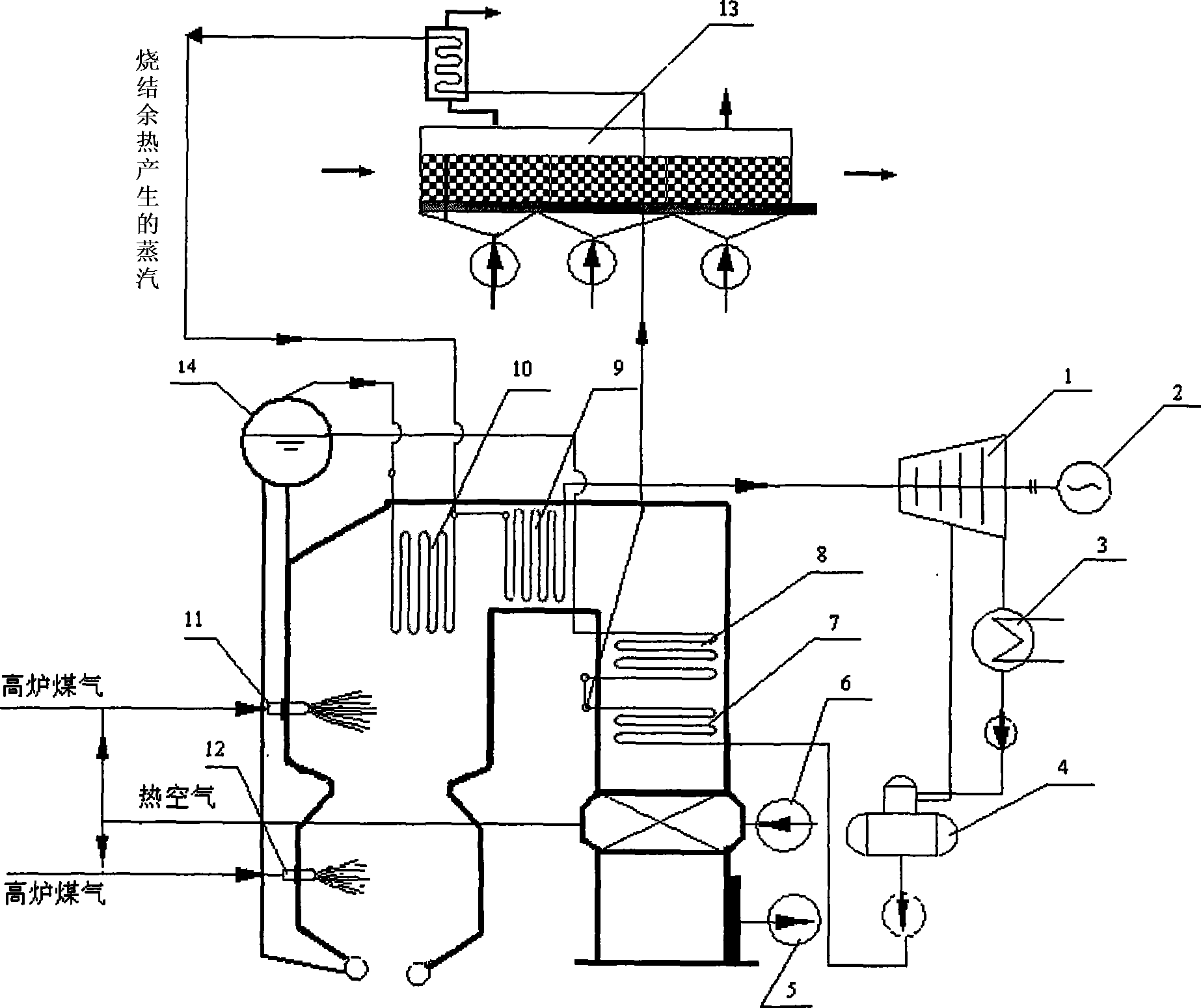

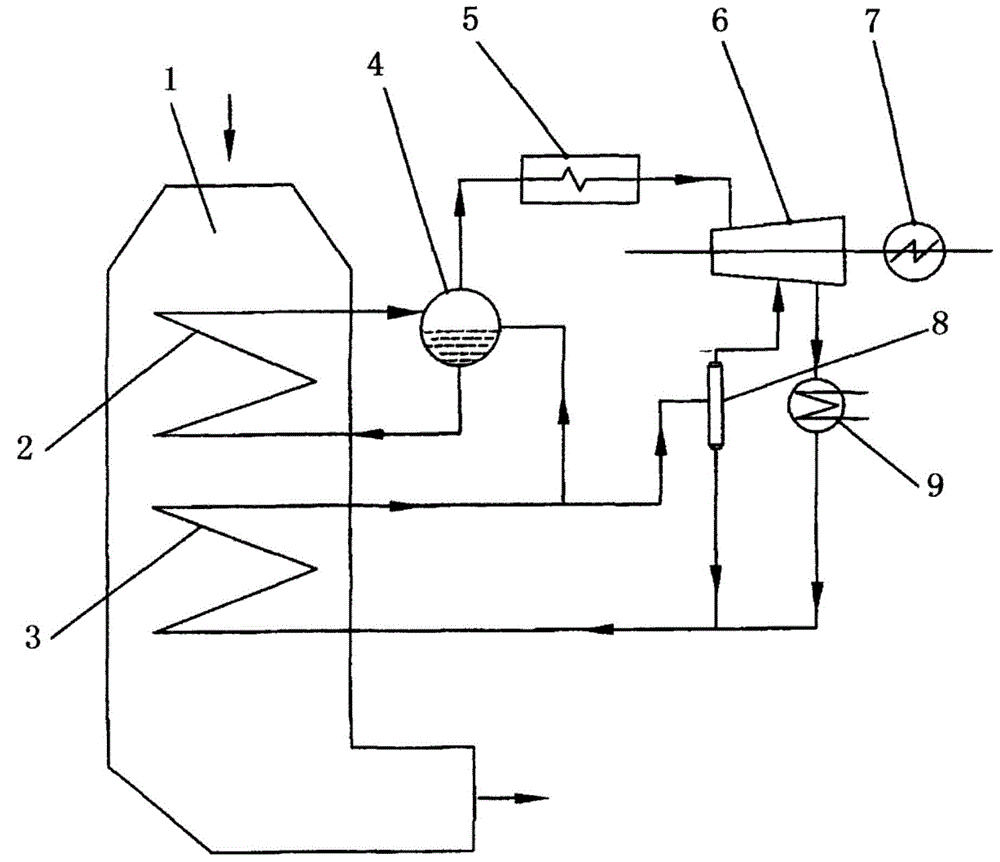

Heating-furnace cogeneration system and method thereof

ActiveCN101788233AImprove steam parametersImprove power generation efficiencySteam useEnergy industryAir preheaterElectricity

The invention relates to a heating-furnace cogeneration system and a method thereof, and belongs to the field of waste energy and heat recovery. The cogeneration system comprises a heating furnace, a heating-furnace waste heat boiler, a heating-furnace air preheater, a heating-furnace heat-pipe coal gas preheater, a heating-furnace tail suction fan, a superheated steam boiler, a turbogenerator set and a chemical water system, wherein the heating-furnace tail is orderly provided with the heating-furnace waste heat boiler, the heating-furnace air preheater, the heating-furnace heat-pipe coal gas preheater and the heating-furnace tail suction fan along the fume flow direction, and used for recovering the fume waste heat of the heating furnace; the heating-furnace waste heat boiler is used for generating electricity; and the chemical water system is used for providing supplementary water for the heating-furnace waste heat boiler and the superheated steam boiler. The invention enables the superheated steam boiler to still ensure the low-load stable operation of the cogeneration system when heating furnace is to be rolled, increases the steam parameter of the heating-furnace waste heat generating equipment by utilizing the superheated steam boiler, and enhances the generating efficiency. The invention maximally recovers the waste heat of the heating furnace, thereby having favorable economic and environmental benefits and high values for application and popularization.

Owner:SHOUGANG CORPORATION

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

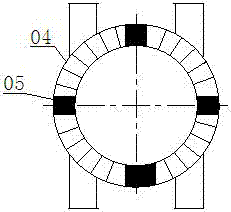

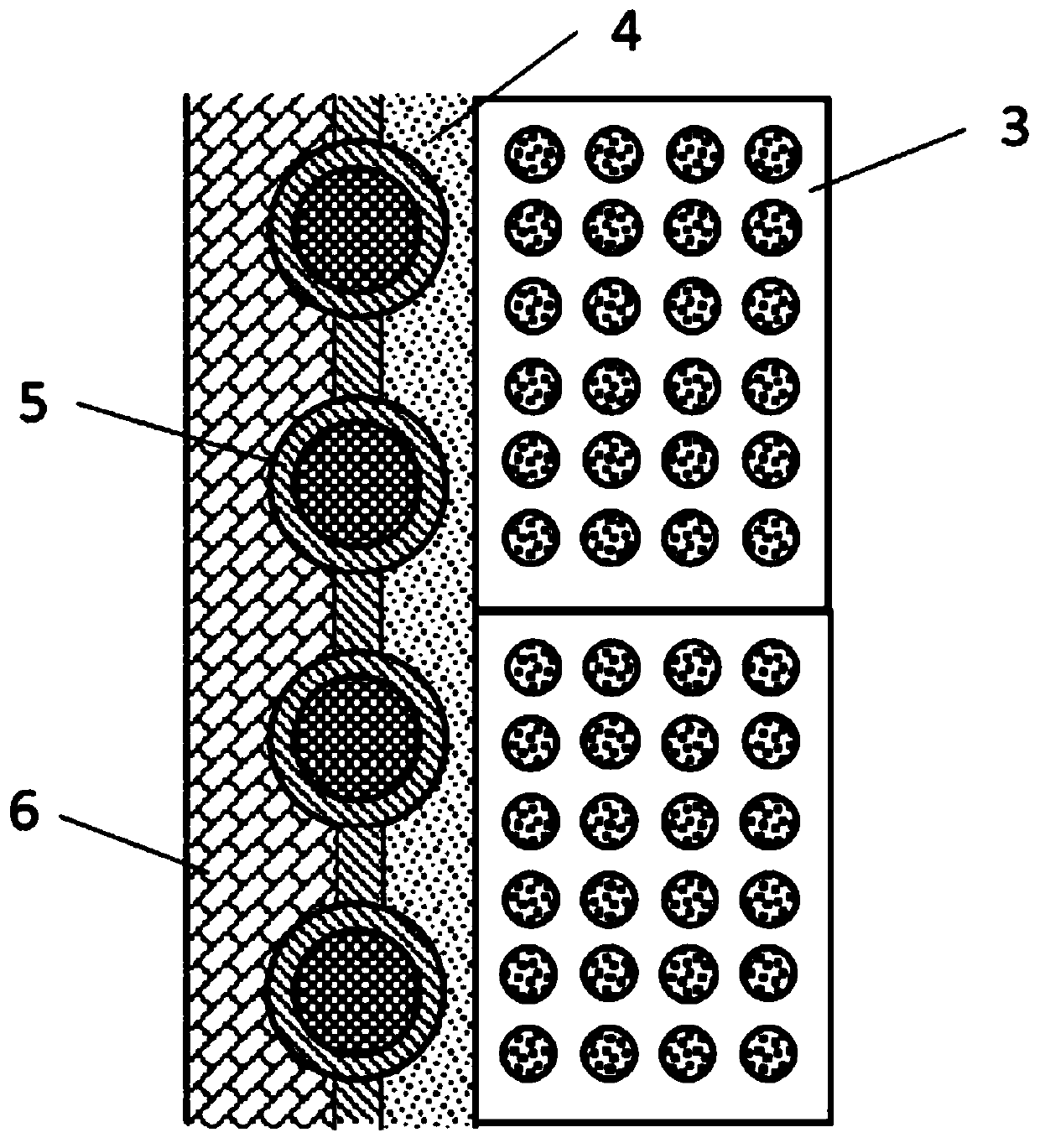

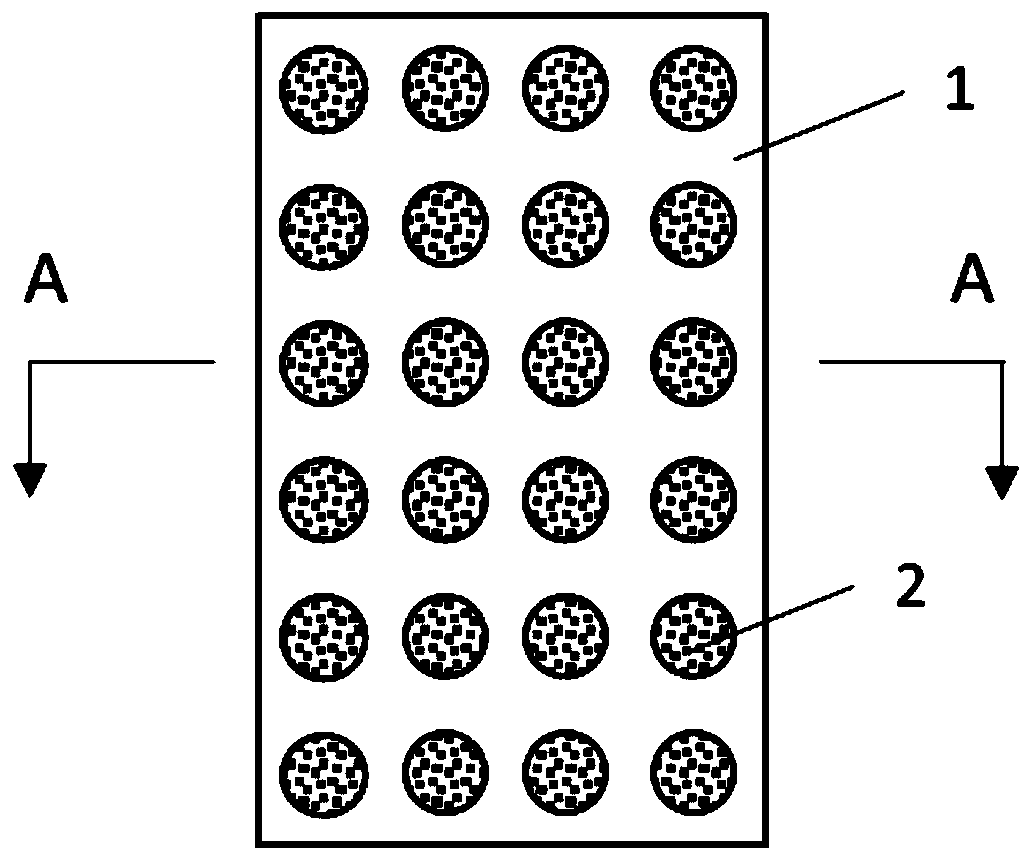

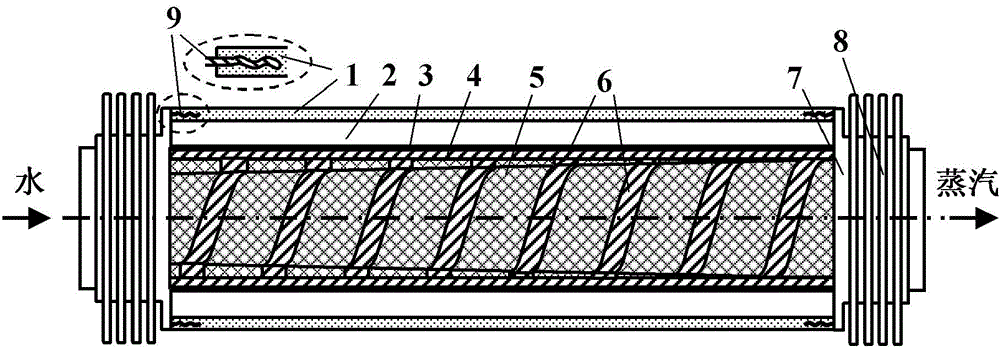

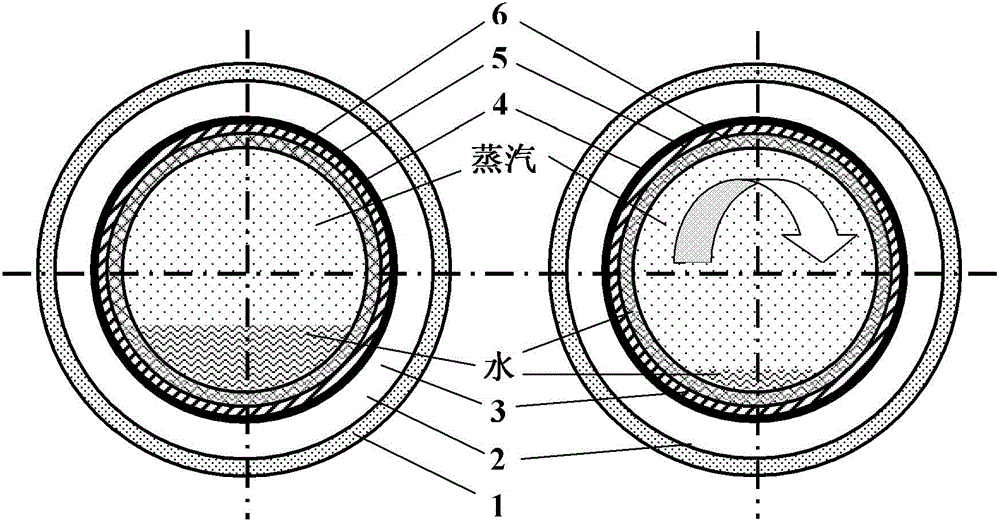

Groove type solar direct steam heat collecting pipe

ActiveCN103335427AEnhanced boiling heat transferImprove reliabilitySolar heating energySolar heat devicesEngineeringHeat stress

The invention discloses a groove type solar direct stream heat collecting pipe which is used for a solar thermal power generation system. The heat collecting pipe can directly receive solar focusing radiation to heat working medium water in the pipe so as to generate steam and comprises an absorption pipe, a glass casing pipe and connection devices at the two ends of the heat collecting pipe. A heat absorption pipe is composed of a stainless steel pipe, a selective absorption coating on the surface of the outer wall of the heat absorption pipe and a filling structure in the heat absorption pipe. The filling structure is an annular metal foam layer with an axial spiral groove, and the thickness of the layer gradually reduces in the flowing direction of a work medium. A vacuum layer is arranged between the absorption pipe and the glass casing pipe. The connection devices at the two ends of the heat collecting pipe are made of flanges and corrugate pipes. A glass-metal sealing connecting opening is processed in a crumpling mode. According to the groove type solar direct stream heat collecting pipe, on one hand, radial gas-liquid two-phase flow type reconstruction with gas inside and liquid outside in the absorption pipe is achieved, the fact that circumferential heat stress distribution of the absorption pipe is uneven is changed, and the problem of induction invalidation of heat stress is solved; on the other hand, local residual stress in the heat sealed technology can be reduced, and the problem of invalidation of end portion sealing connecting of the glass casing pipe is solved. The groove type solar direct stream heat collecting pipe can obviously improve the reliability and stability of the solar direct stream heat collecting pipe.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

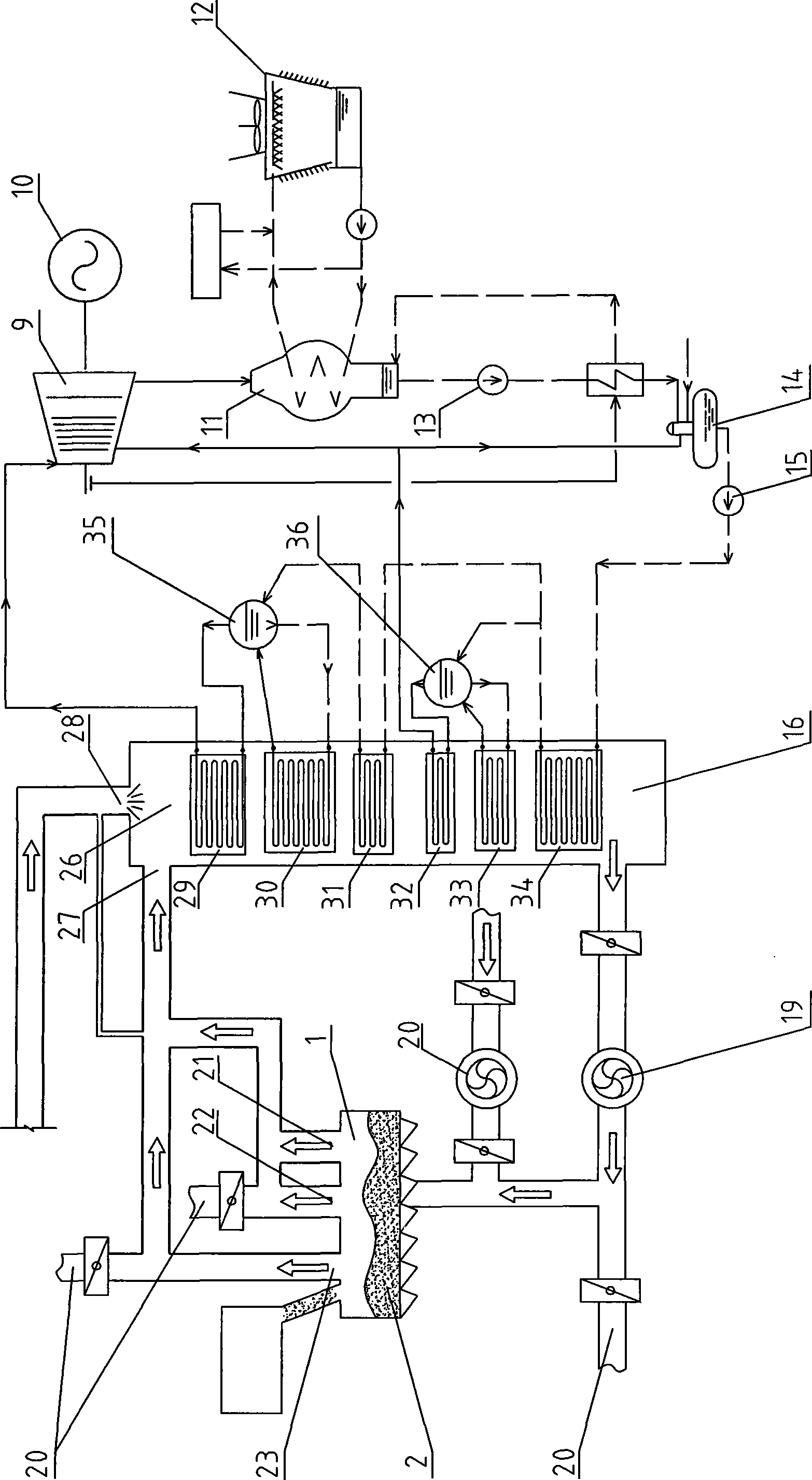

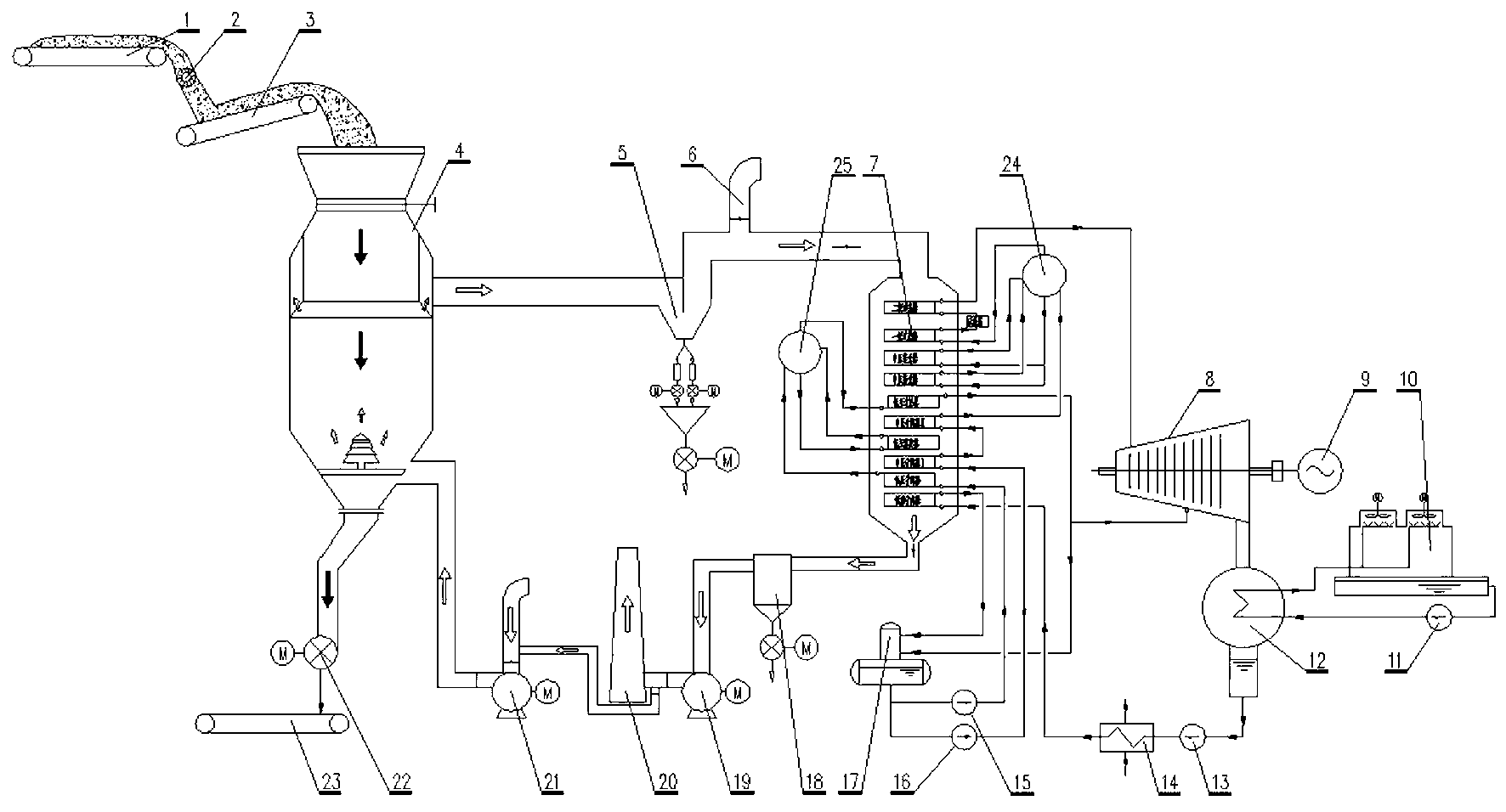

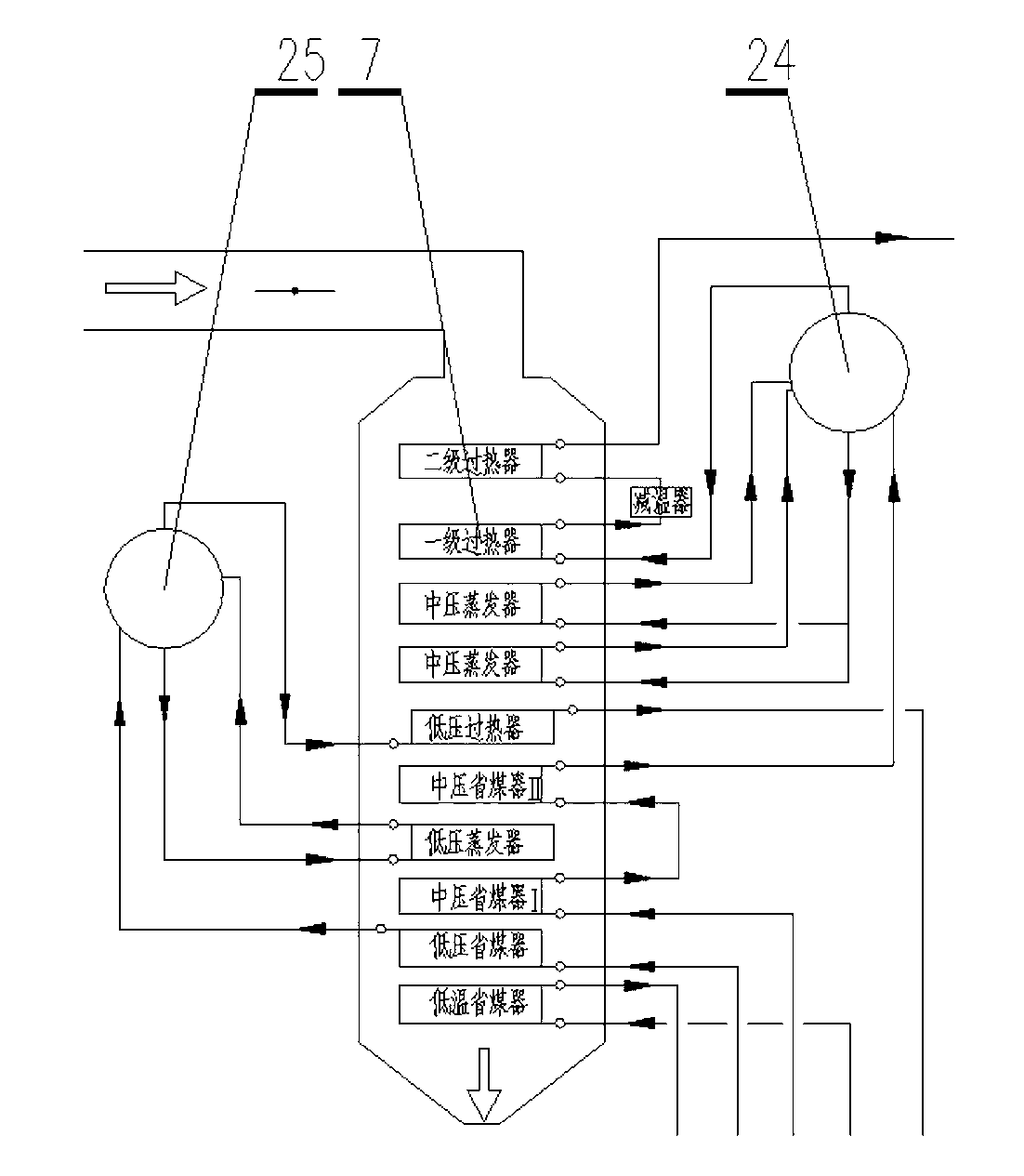

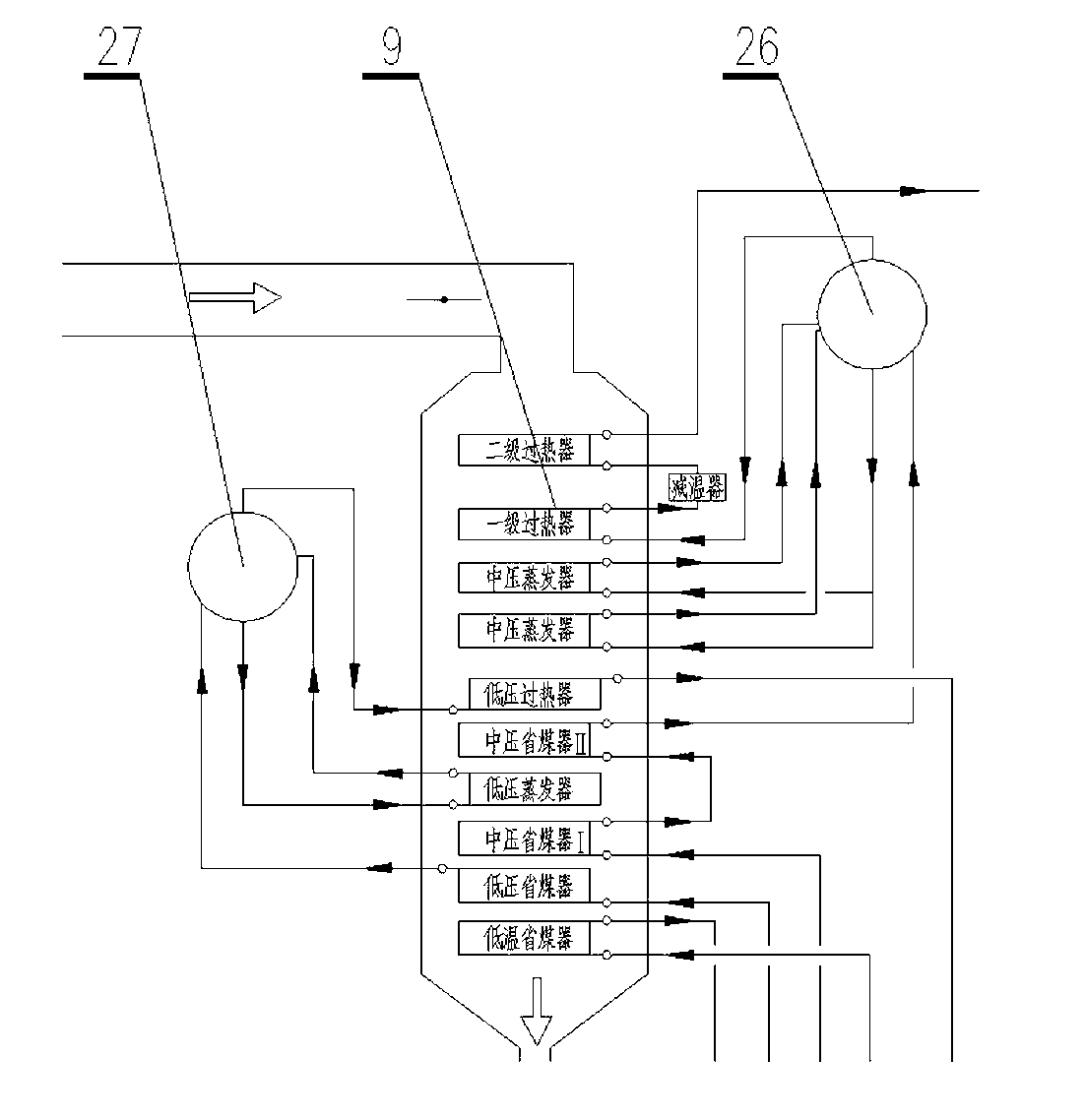

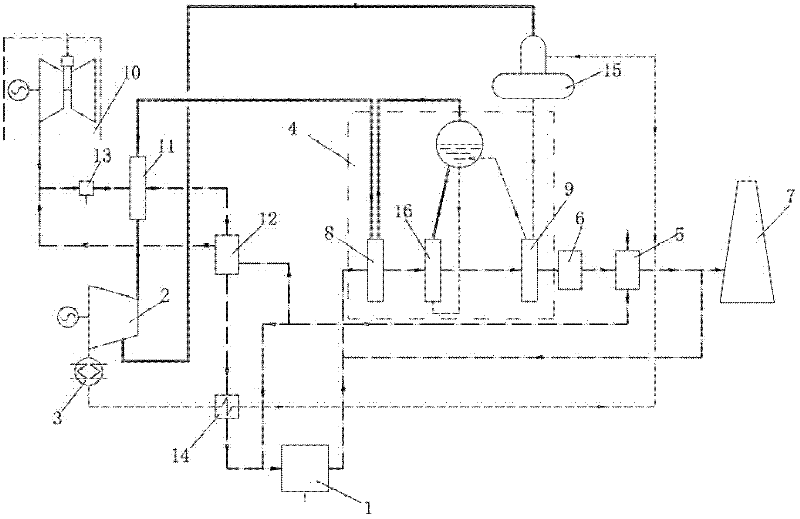

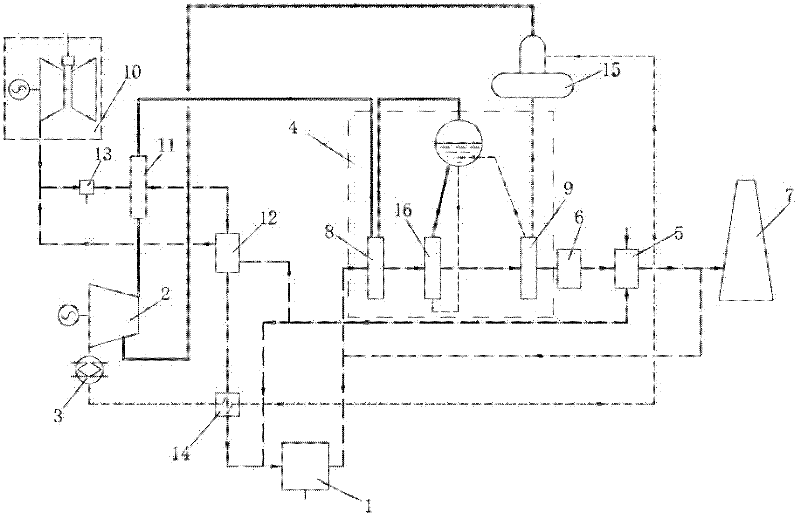

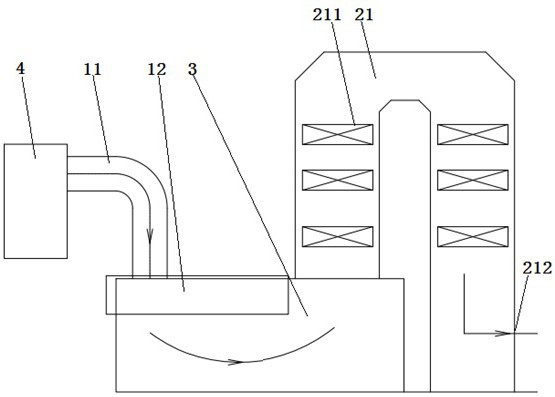

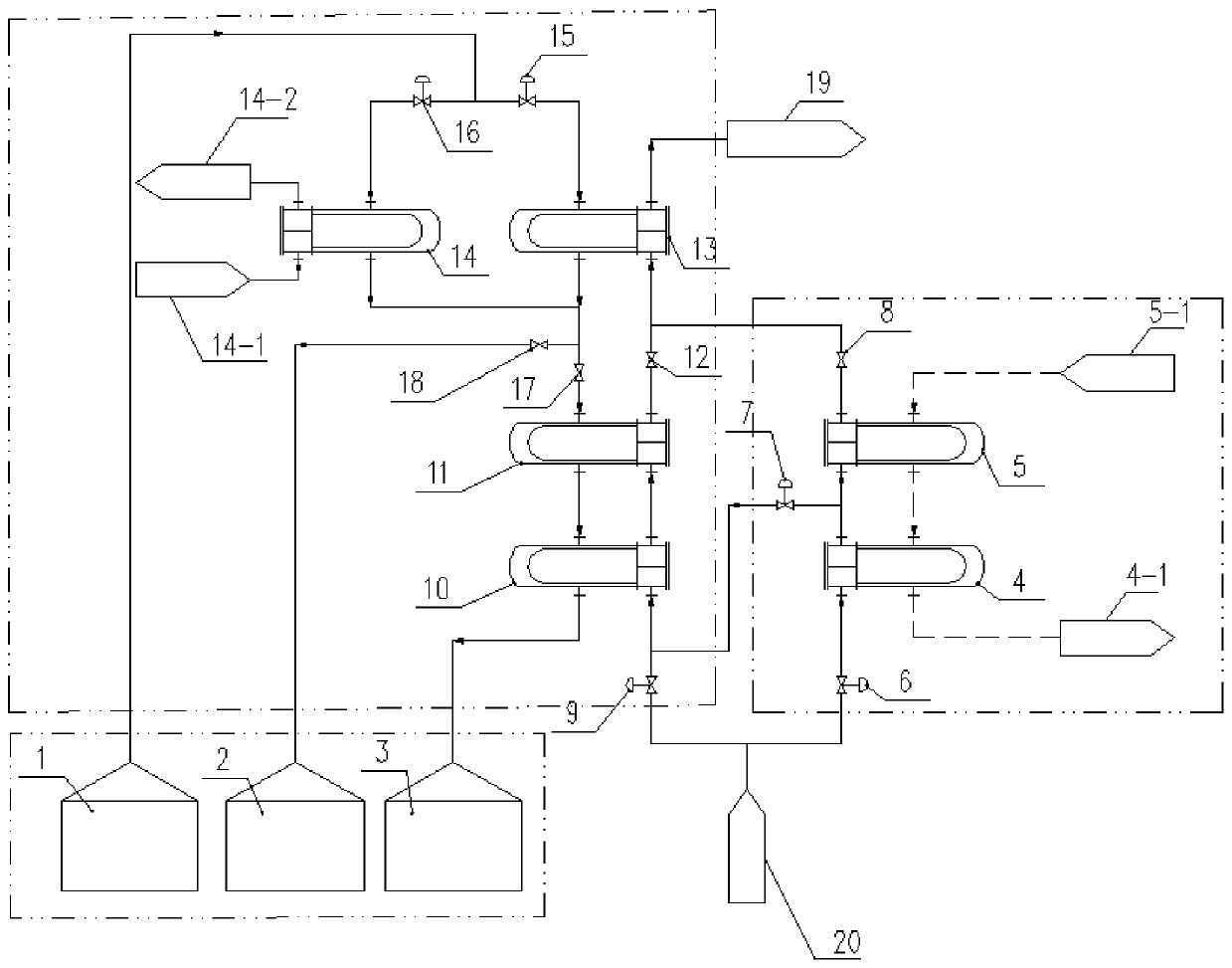

Sintering waste heat and pure burning blast-furnace gas combined generating system

InactiveCN101545726AImprove steam parametersImprove power generation efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringSuperheater

The invention relates to a sintering waste heat and pure burning blast-furnace gas combined generating system, and belongs to the technical field of steel metallurgy waste heat utilization. The combined generating system comprises a sintering waste heat reclaiming system, a pure burning blast-furnace gas boiler, a steam turbine and a generator; the pure burning blast-furnace gas boiler is divided into an upper combustion system and a lower combustion system and adopts a cyclone burner, and the boiler is ensured to operate safely and stably by using an arrangement mode of front and back walls or tangential four corners; the low temperature and pressure or medium temperature and pressure vapor generated by the sintering waste heat replaces desuperheating water to enter an overheater of the pure burning blast-furnace gas boiler or directly enter a boiler barrel to generate the medium temperature and pressure or high temperature and pressure vapor for generating; and water for the sintering waste heat reclaiming system is supplied by a secondary coal economizer of the boiler. When the supply of the sintering waste heat system and the blast-furnace gas is enough, the lower combustion system is put into operation, and the system operates under higher load working conditions. The combined generating system has the advantages that the system can greatly improve the utilization efficiency of the reclaimed sintering waste heat, ensures the stable operation of the system, reduces the diffusion of the blast-furnace gas, and has good economic benefit and popularization and application values.

Owner:SHOUGANG CORPORATION +1

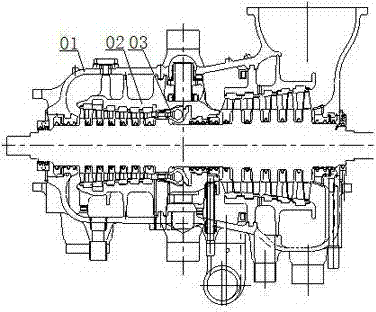

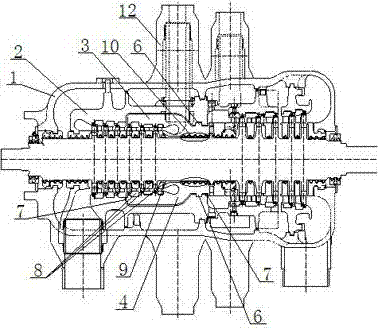

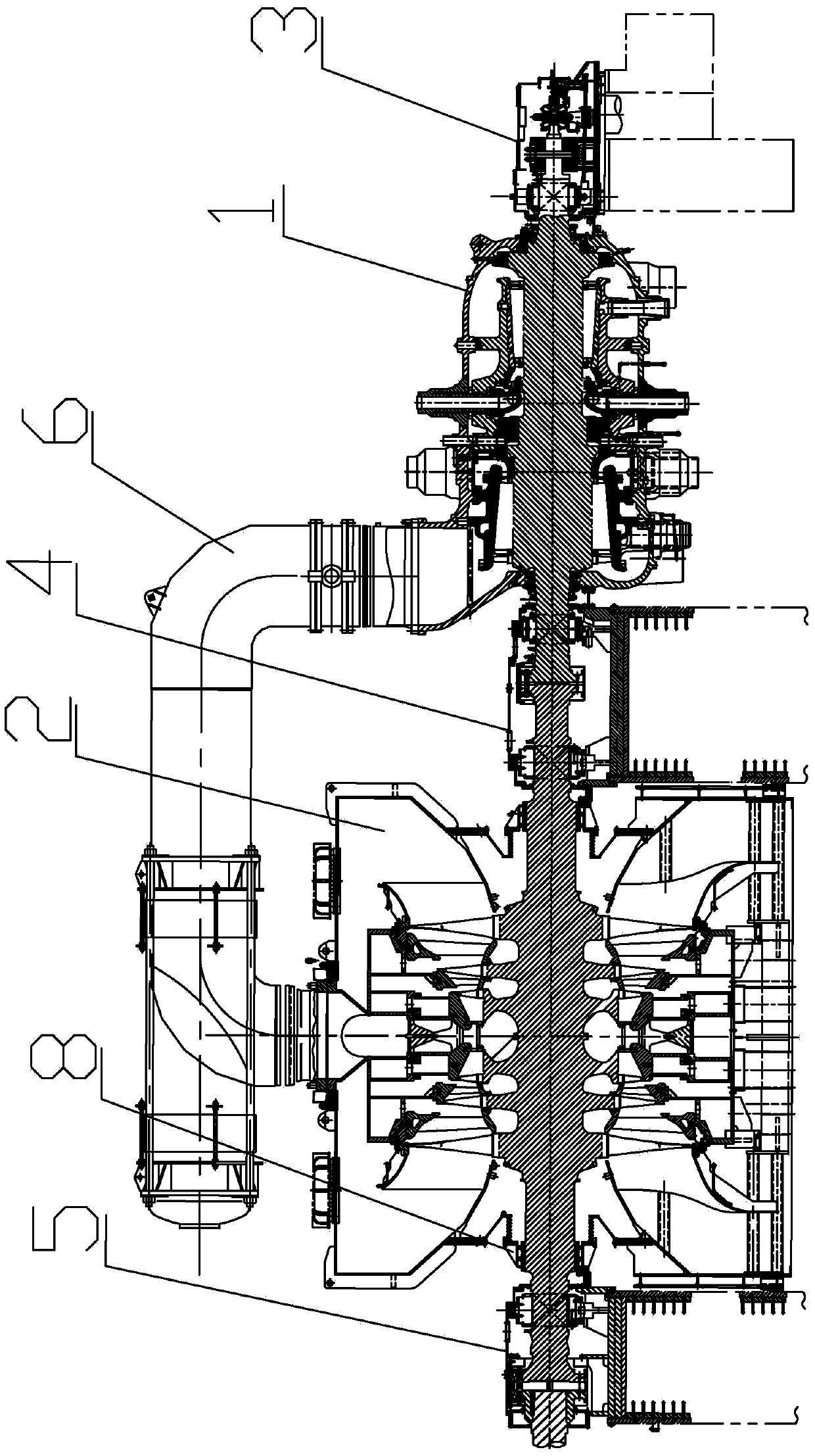

High-pressure cylinder of ultra-supercritical steam turbine set

InactiveCN103046974AReliable airtightnessLow manufacturing costMachines/enginesEngine componentsClapboardEngineering

The invention discloses a high-pressure cylinder of an ultra-supercritical steam turbine set. The high-pressure cylinder of the ultra-supercritical steam turbine set comprises an outer cylinder and an inner cylinder, wherein the inner cylinder is arranged inside the outer cylinder; the inner cylinder is internally provided with an intake air chamber; the intake air chamber is internally provided with clapboards at multiple levels and a first steam seal; the clapboard at each level is used for bearing a pressure difference and a temperature difference of the steam; the first steam seal is used for sealing a gap between the intake air chamber and a rotor; the intake air chamber is provided with an intake air pipe in a connecting manner; the intake air pipe penetrates through the inner cylinder and the outer cylinder to extend outwards; the intake air pipe is used for bringing steam into the intake air chamber; the steam after acting in the intake air chamber enters into the inner cylinder to act; a part of the steam penetrates through the inner cylinder to flow into the outer cylinder, so that gradient pressure difference as well as temperature difference is formed in the intake air chamber, the inner cylinder and the outer cylinder. As a nozzle chamber is replaced by the intake air chamber, and a third cylinder is formed in the inner cylinder of the high-pressure cylinder, the high-pressure cylinder of the ultra-supercritical steam turbine set not only can improve the efficiency of the steam turbine set through the intake air chamber without greatly improving the manufacturing cost of the high-pressure cylinder, but also can prevent steam flow shock excitation danger caused by uneven pressure of the steam, obtains high safety, and is reliable and practical.

Owner:DONGFANG TURBINE CO LTD

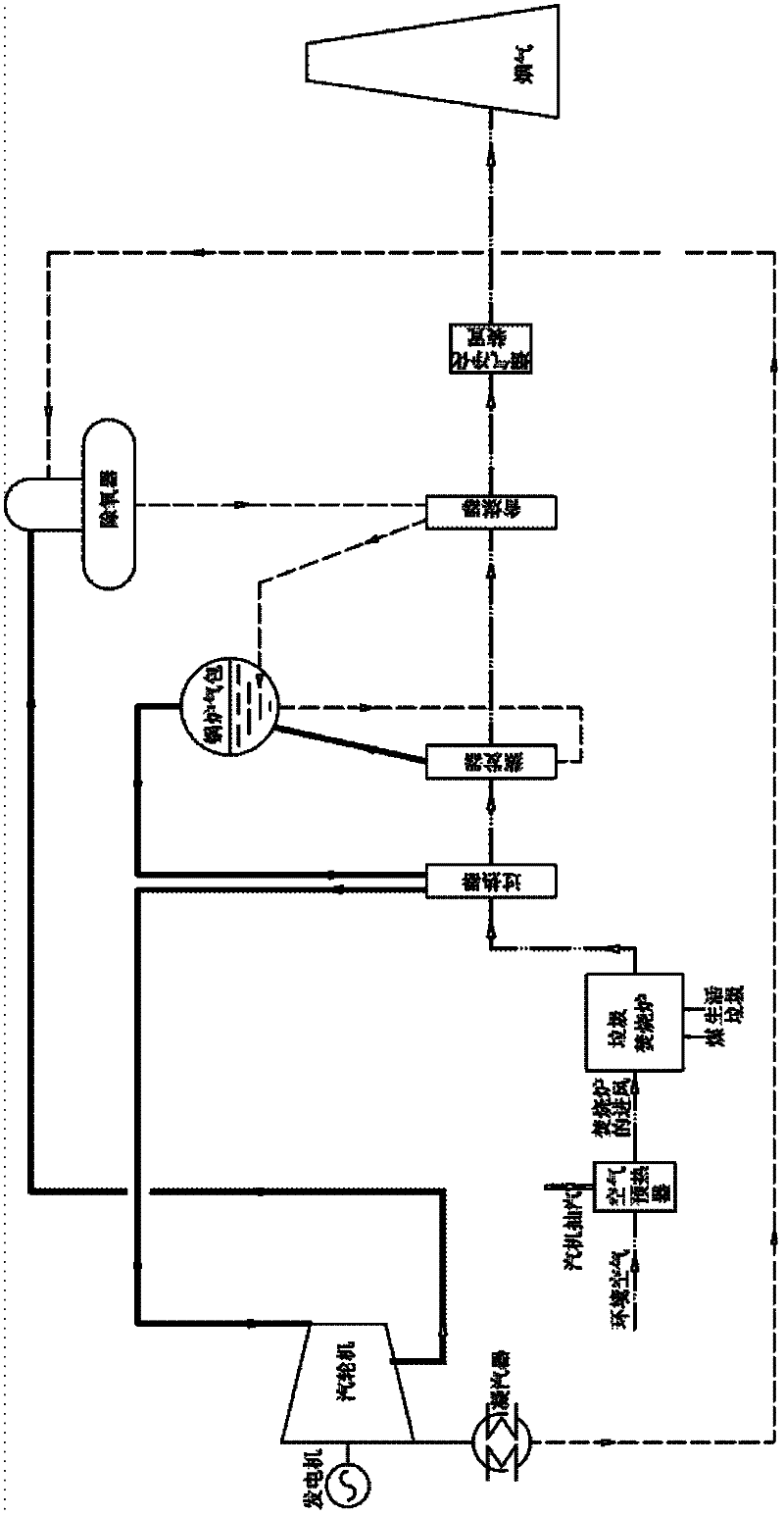

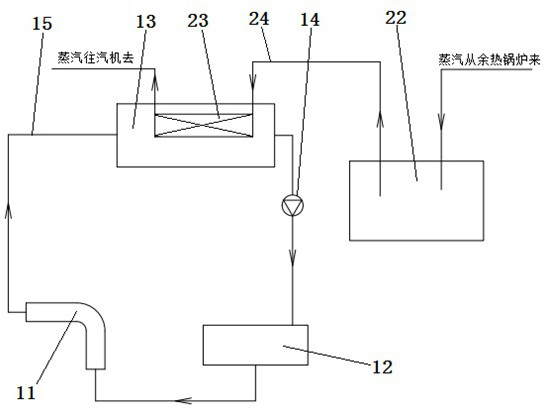

Garbage-incinerating circulated power-generating system

InactiveCN102374538AIncrease profitImprove steam parametersGas turbine plantsSteam engine plantsSuperheaterCoal

The invention discloses a garbage-incinerating circulated power-generating system, which relates to the technical filed of garbage-incinerating power generation and comprises a garbage incinerator, a steam turbine, a steam condenser, a surplus-heat boiler, a first air preheater, a smoke-gas purifying device and a chimney, wherein the garbage incinerator is communicated with a superheater in the surplus-heat boiler, a coal economizer in the surplus-heat boiler is communicated with the smoke-gas purifying device, the smoke-gas purifying device is communicated with the first air preheater, and the first air preheater is also communicated with the chimney and the superheater in the surplus-heat boiler; and the steam condenser is communicated with the coal economizer in the surplus-heat boiler, and the steam turbine is communicated with the superheater in the surplus-heat boiler. Through adopting the garbage-incinerating circulated power-generating system, the heat utilization ratio in the garbage-incinerating power-generating process can be improved, thereby the power-generating efficiency is improved, high-temperature corrosion caused by high-temperature smoke gas can be reduced, and the service life of equipment is prolonged.

Owner:FUJIAN FENGQUAN ENVIRONMENTAL PROTECTION GRP CO LTD

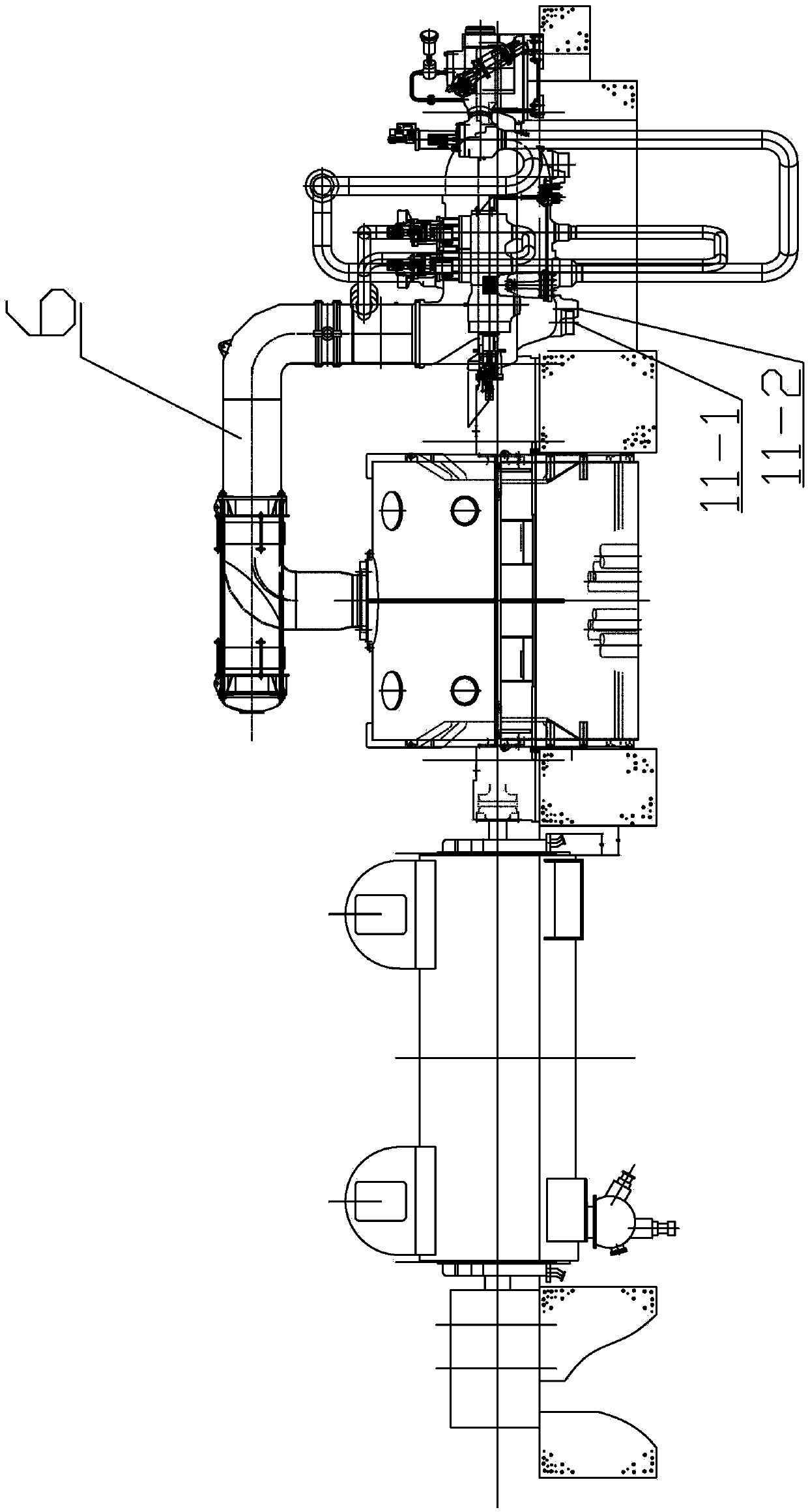

660MW-grade primary intermediate reheat extraction steam turbine unit

InactiveCN105370330AImprove steam parametersIncrease vitalitySteam useLeakage preventionSteam condensationCogeneration

The invention discloses a 660MW-grade primary intermediate reheat extraction steam turbine unit relating to an extraction steam turbine unit and aims at solving the problems of high net coal consumption rate, low energy utilization rate and pollutant discharge increment of the existing thermal power generating unit equipment. A front bearing box, a high-medium-pressure cylinder, a 2 # bearing box, a low-pressure cylinder and a 3# bearing box are sequentially arranged; two high-pressure main steam regulating valves and two medium-pressure reheat regulating combined valves are respectively located at the left and right sides of the high-medium-pressure cylinder; and middle-row steam is introduced to the low-pressure cylinder through a communicating pipe. Due to the adoption of a communicating pipe structure with a hydraulic control butterfly valve, double steam extraction openings are formed in the lower part of the middle row of the high-medium-pressure cylinder, so that the steam extraction capacity can be regulated to be high enough, and furthermore heating demands in winter can be met. The 660MW-grade primary intermediate reheat extraction steam turbine unit is ultra-supercritical and has the advantages of primary intermediate reheat, single shaft, two-cylinder and two-row steam, double extraction, eight-stage back-heating steam extraction and steam condensation. The 660MW-grade primary intermediate reheat extraction steam turbine unit is suitable for pure-condensation power generation in a non-heating period and combined heat and power generation in a heating period.

Owner:HARBIN TURBINE

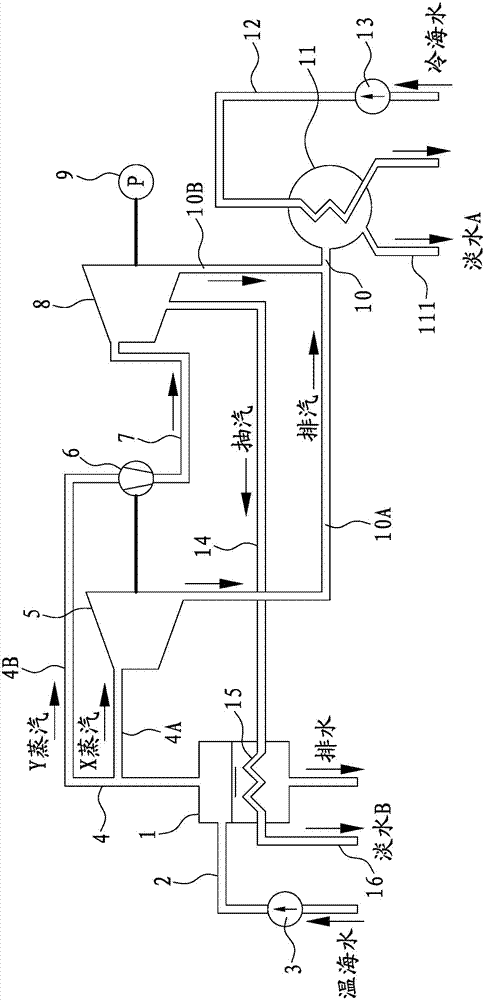

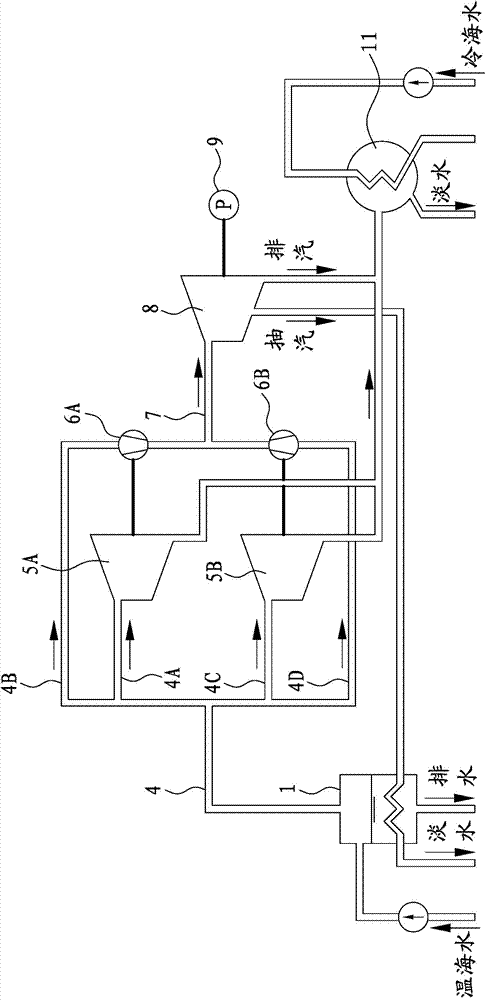

Ocean heat energy open circulation power generation system

InactiveCN103790793AReduce volumeBreak through the problem of limited capacityMachines/enginesMechanical power devicesExhaust pipeSeawater

The invention discloses an ocean heat energy open circulation power generation system which comprises a flash evaporator, a warm seawater pipe, a warm seawater pump, a low-pressure steam pipe, a front-arranged small steam turbine, a steam compressor, a high-pressure steam pipe, a main steam turbine, a power generator, a steam exhaust pipe, a surface type condenser, a cold seawater pipe, a cold seawater pump, a steam pumping pipe and a heat exchange pipe bundle. Low-pressure steam is divided into two channels, one channel of low-pressure steam enters the front-arranged small steam turbine to do work to drive the steam compressor to work, the other channel of low-pressure steam is compressed by the steam compressor to become high-temperature high-pressure steam, the high-temperature high-pressure steam then enters the main steam turbine to do work to drive the power generator to generate power, part of steam is pumped from the main steam turbine to be used for heating seawater in the flash evaporator, and the amount of the steam generated by the flash evaporator is increased. According to the ocean heat energy open circulation power generation system, the size of the steam turbine in existing open circulation is effectively reduced, and the problem that the unit capacity is limited is solved; the ocean heat energy open circulation power generation system has the advantages of being high in system heat efficiency, high in water power utilizing rate, high in net power generated power and the like.

Owner:JIMEI UNIV

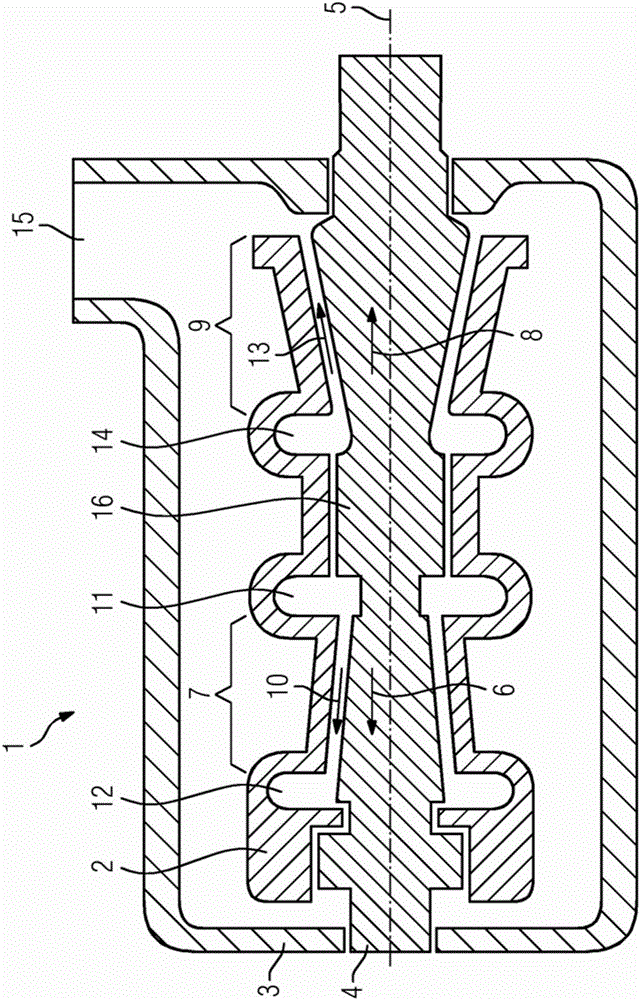

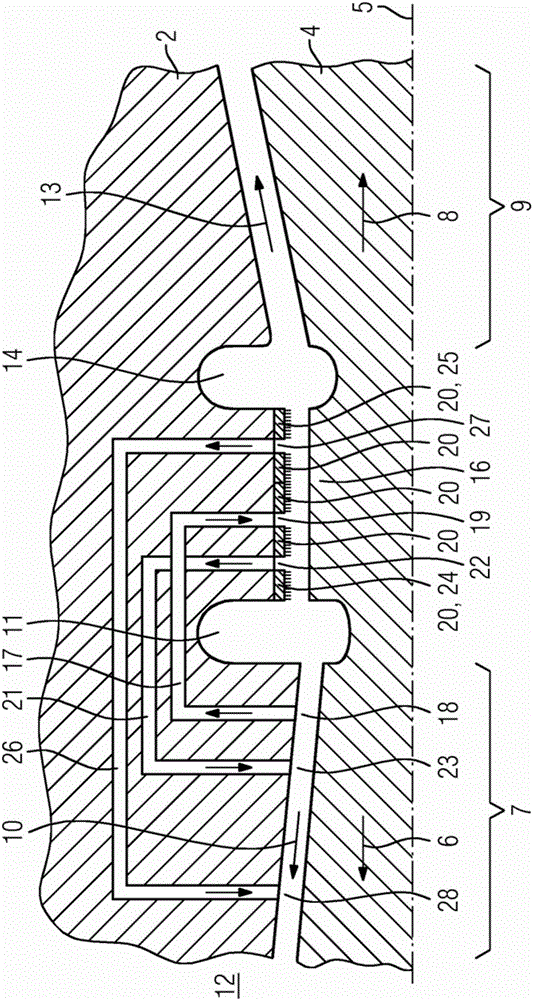

Steam turbine, and method for operating a steam turbine

InactiveCN106574502AImprove steam parametersExtract clearEngine fuctionsMachines/enginesEngineeringSteam turbine

The invention relates to a steam turbine (1) having a cooling option, in which steam is taken from the flow channel, said steam cooling the thrust-compensating intermediate floor (16), being mixed with a small amount of live steam and being returned to the flow channel.

Owner:SIEMENS AG

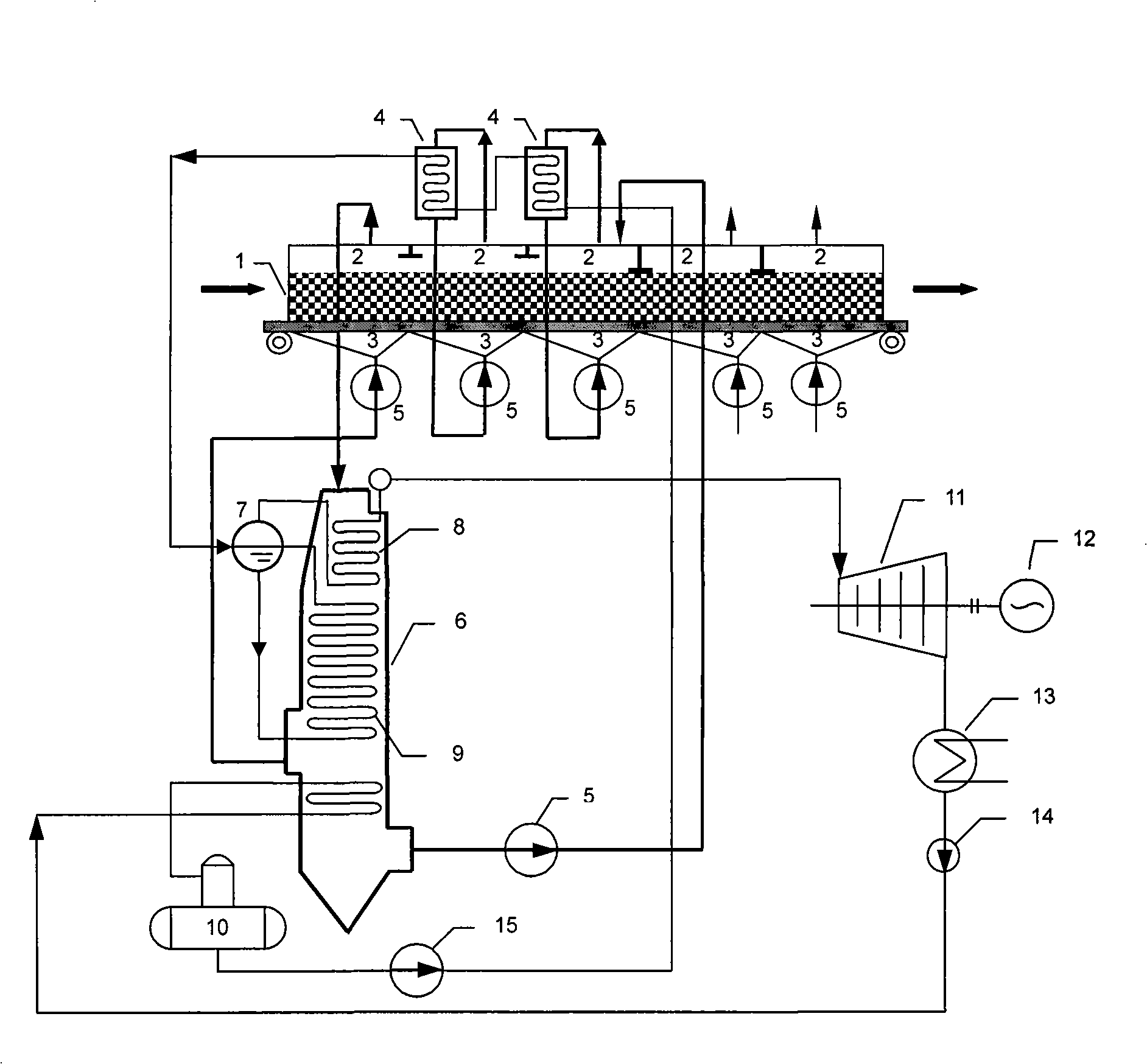

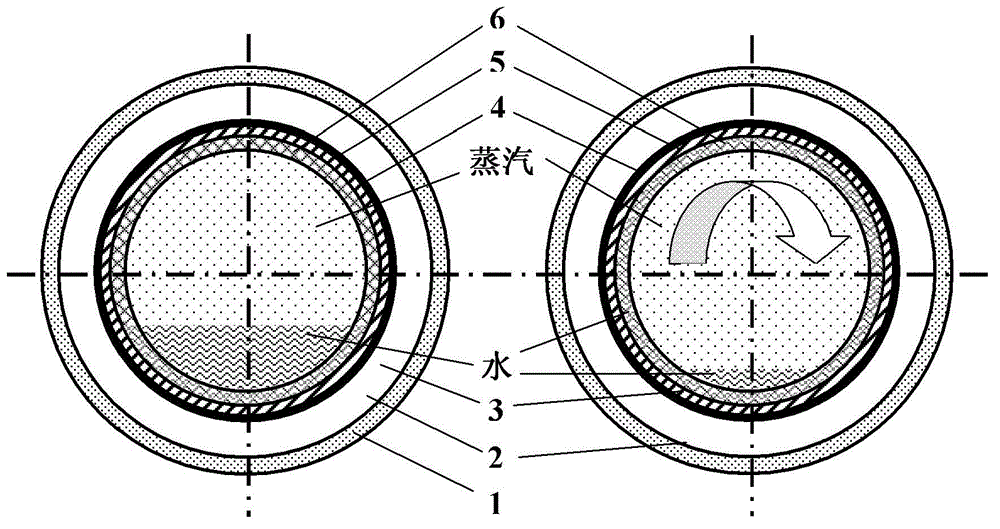

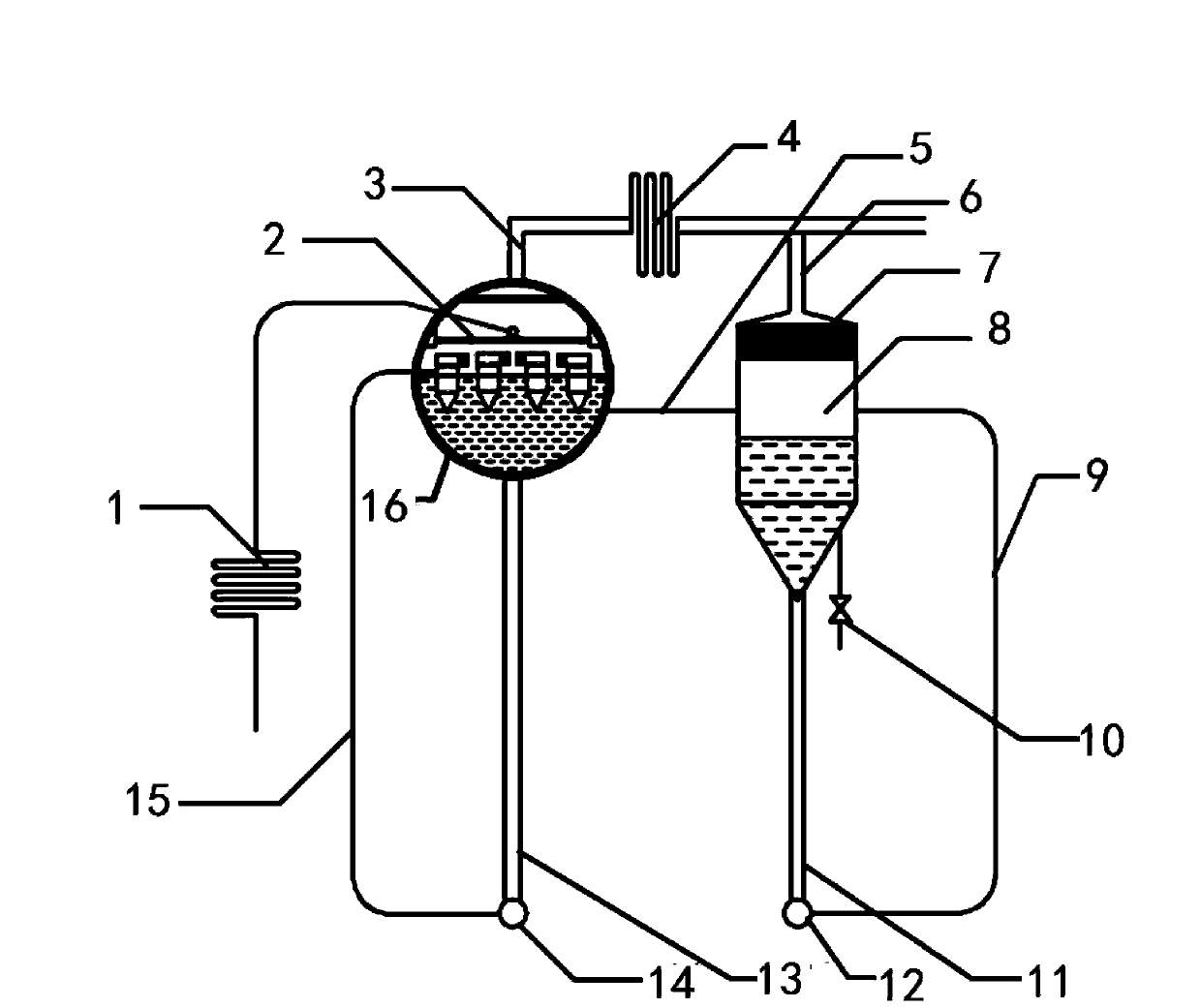

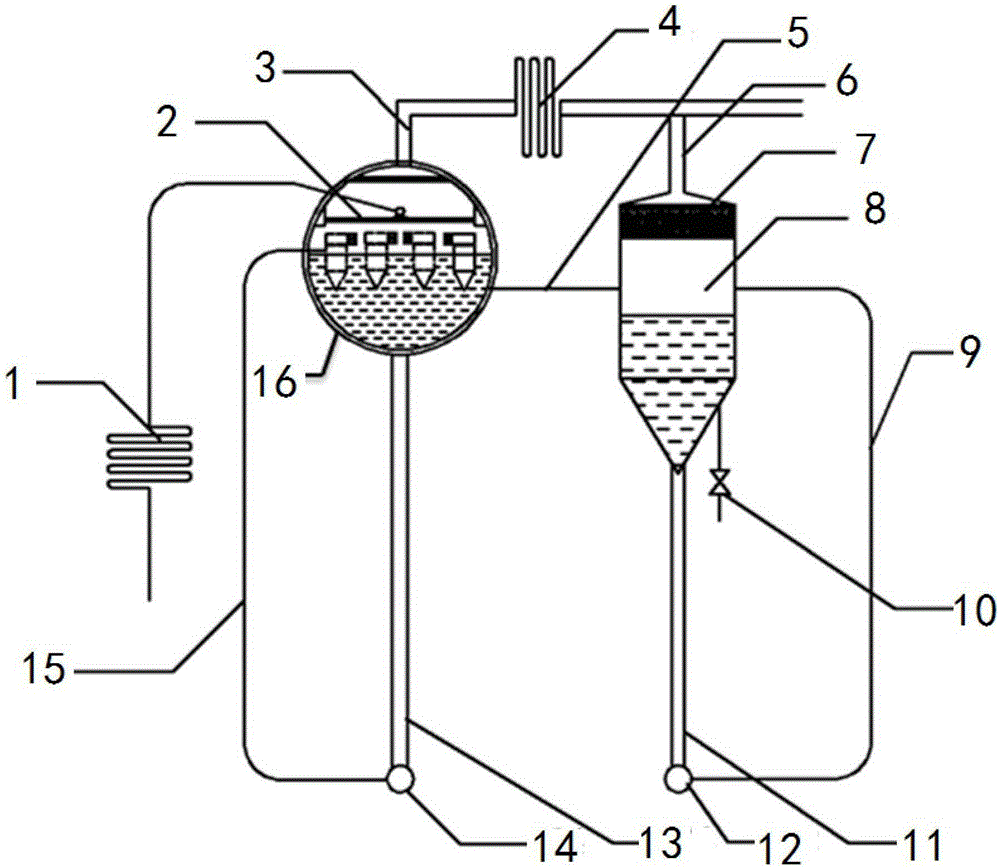

Method and device for generating superheated steam from high-salt boiler feed water through stage evaporation

ActiveCN103968365AEfficient separationImprove mining efficiencySteam separation arrangementsSteam superheatersCycloneSalt content

The invention discloses a method and a device, which are used for generating superheated steam from high-salt boiler feed water through stage evaporation, and belongs to the technical field of boiler equipment. According to the method, a boiler drum is divided into a net section and a salt section; the lower part of a salt-section cyclone is connected with the salt section to achieve discharging; the bottom end of the salt-section cyclone is connected with a salt-section down pipe, the salt-section down pipe is connected with a salt-section distribution header, the other end of a salt-section riser pipe is connected with the middle of the salt-section cyclone, a cavity body in the upper part of the salt-section cyclone is connected with a corrugated plate, the top of the salt-section cyclone is connected with a salt-section steam outlet, and the salt-section steam outlet is connected with a pipeline at one end of a super heater; the net-section distribution header is connected with a net-section riser pipe; a salt-section communication pipe is used for communicating a net-section steam drum with the salt-section cyclone. The method has the benefits that the requirement on the salt content of boiler water in a heavy oil thermal recovery boiler is greatly lowered on the premise of guaranteeing the steam quality, moderately treated heavy oil recovery water can be reused, heavy oil development water can be recycled, the clear water consumption and the sewage discharge are reduced, the environment is protected, and the heavy oil thermal recovery cost is reduced.

Owner:PETROCHINA CO LTD

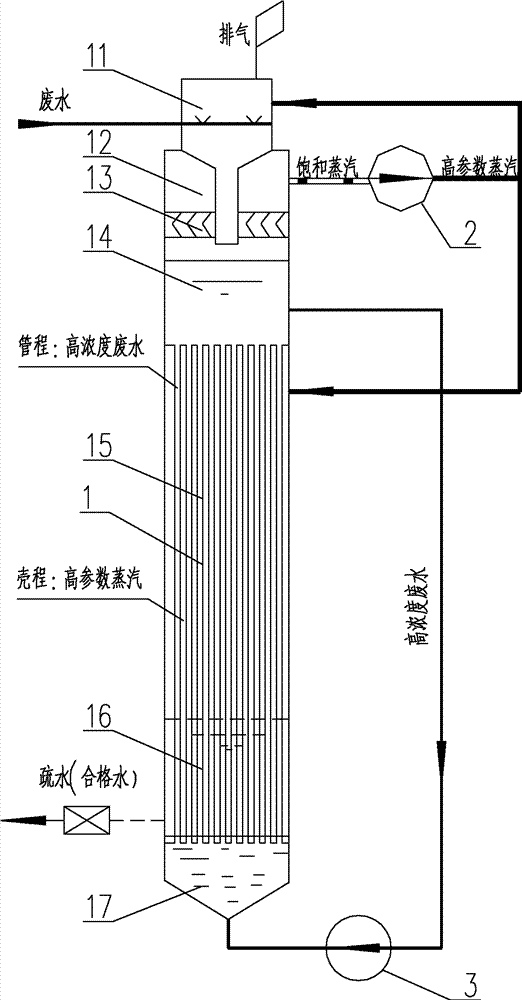

Thermal waste water treatment apparatus and method employing heat pump

ActiveCN102372331BReduce energy consumptionImprove steam parametersWater/sewage treatment by degassingHigh concentrationWater vapor

Owner:SHANGHAI HANZHUO ENERGY TECH

High-parameter waste heat boiler suitable for garbage incinerator grate

PendingCN109630998ASolve the problem of high temperature corrosionImprove power generation efficiencySteam superheatersIncinerator apparatusSuperheaterHigh-temperature corrosion

The invention discloses a high-parameter waste heat boiler suitable for a garbage incinerator grate. The high-parameter waste heat boiler suitable for the garbage incinerator grate comprises a water cooling flue, a tail flue and a horizontal flue or a connecting flue located between the water cooling flue and the tail flue, and a heating surface of a high-temperature superheater is arranged in thewater cooling flue, so that the temperature of a superheated steam outlet of the high-parameter waste heat boiler reaches 450-540 DEG C and the pressure reaches above 6.4MPa. According to the high-parameter waste heat boiler suitable for the garbage incinerator grate, by reasonably designing the arrangement positions of the heating surfaces of the boiler high-temperature stage superheater and reheater, effective anti-corrosion measurements are adopted in the surfaces of the heating surfaces, high-temperature corrosion of the heating surfaces is effectively prevented and the steam parameter ofthe boiler is improved, and the steam parameter of the waste heat boiler can be improved to high-temperature and high-pressure and ultrahigh pressure parameter is even further improved to efficient ultrahigh pressure. Further, a reheater system is arranged in the boiler to heat steam which is from a turbine high-pressure cylinder and has relatively low outlet temperature to 540 DEG C again, and higher power generation efficiency is obtained.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

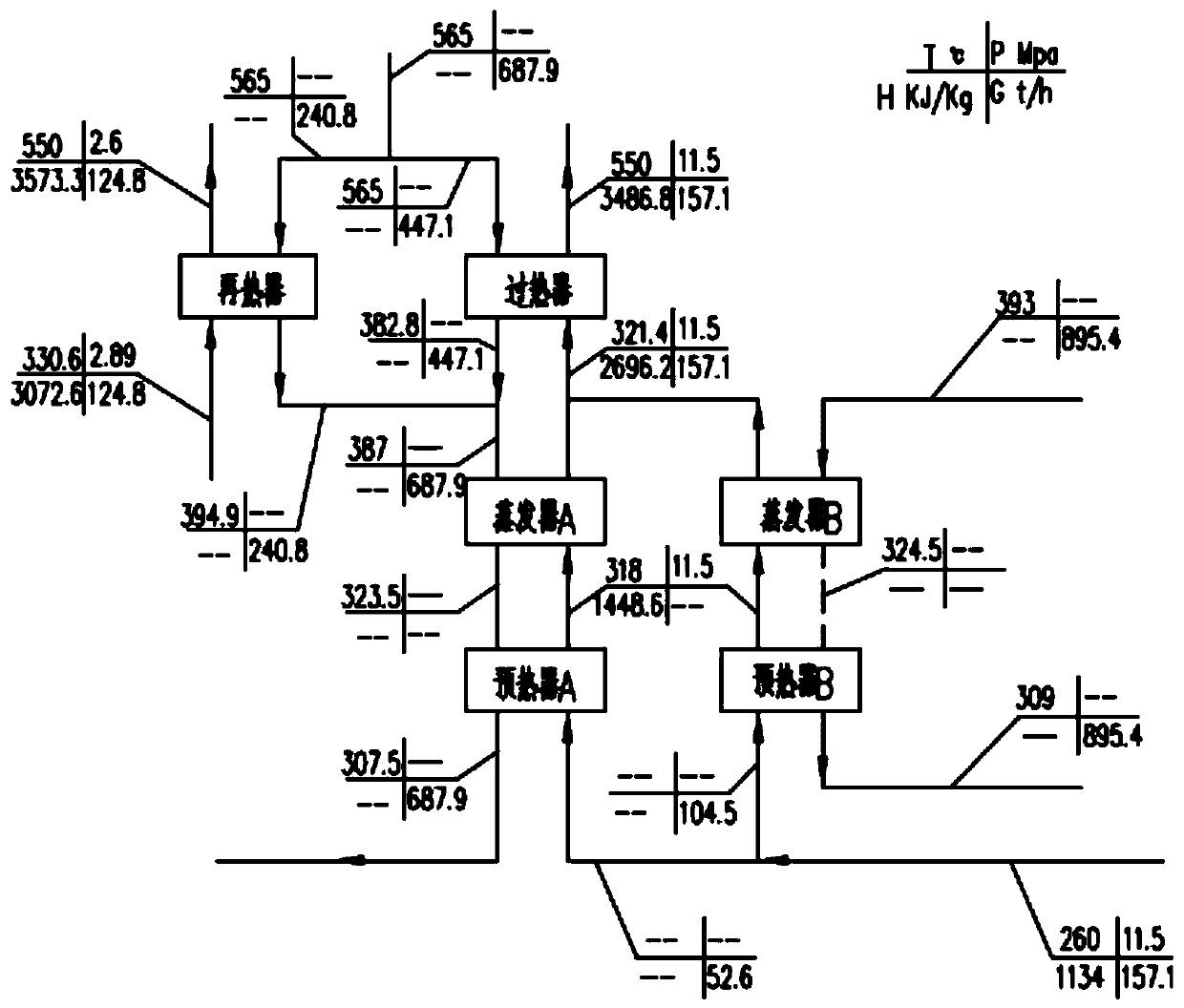

Dry quenching subcritical ultrahigh temperature reheating boiler thermal system

PendingCN110207081ARaise the water temperatureHigh thermal efficiencyCoke quenchingLiquid degasificationLight pipeSuperheater

The invention relates to waste heat recycling in the technical field of coking and metallurgical engineering, in particular to a dry quenching subcritical ultrahigh temperature reheating boiler thermal system. The dry quenching subcritical ultrahigh temperature reheating boiler thermal system is characterized by at least comprising a deaerator, a deaerator water tank, a boiler feed pump, a dry quenching boiler and a boiler steam drum; a high-temperature superheater, a low-temperature superheater, a light pipe evaporator, a fin evaporator and a fin economizer are distributed between a smoke inlet and a smoke outlet of the dry quenching boiler at intervals from top to bottom; and a steam reheater is arranged between the high-temperature superheater and the low-temperature superheater, and the high-temperature superheater is close to the lower end of the smoke inlet and at least comprises two external pipelines. The dry quenching subcritical ultrahigh temperature reheating boiler thermalsystem can bring higher economic benefits so that main steam generating subcritical ultrahigh temperature parameters of the dry quenching boiler can generate reheat steam, and the power generation efficiency can be improved by 10% or higher.

Owner:XIAN HUAJIANG ENVIRONMENTAL TECH

Combustion chamber and waste incineration boiler for burning waste and working method thereof

ActiveCN109812813BImprove efficiencyAvoid corrosionFeed water supplyCasings/liningsCombustion chamberFlue gas

The invention discloses a combustion chamber used for garbage incineration, a garbage incineration boiler and a working method of the garbage incineration boiler, belongs to a garbage incineration device and a working method thereof, and provides a combustion chamber capable of preventing superheater corrosion, high in reliability and high in incineration efficiency, a garbage incineration boilerand a working method of the garbage incineration boiler. The combustion chamber is formed by bonding phase-change energy storage refractory bricks, mortar and an outer wall from inside to outside; heat exchange pipes are arranged at the combined position of the outer wall of the mortar; the combustion chamber is divided into an upper part and a lower part, a hearth evaporation heated face is located on the upper part of the combustion chamber, a second-stage superheater is located on the lower part of the combustion chamber, and a first evaporation heated face, a first-stage superheater, a second evaporation heated face and a coal economizer are arranged in a flue gas channel from top to bottom; and a boiler barrel is connected with the hearth evaporation heated face, the first evaporationheated face, the second evaporation heated face, the first-stage superheater, the second-stage superheater, a steam turbine, a condenser, a degassing device and the coal economizer. The combustion chamber is mainly used for garbage incineration.

Owner:广东省特种设备检测研究院惠州检测院

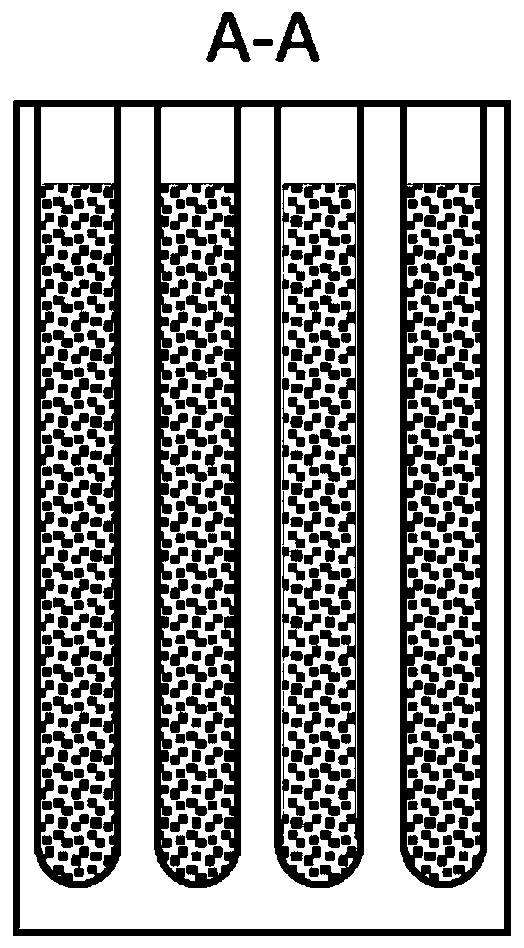

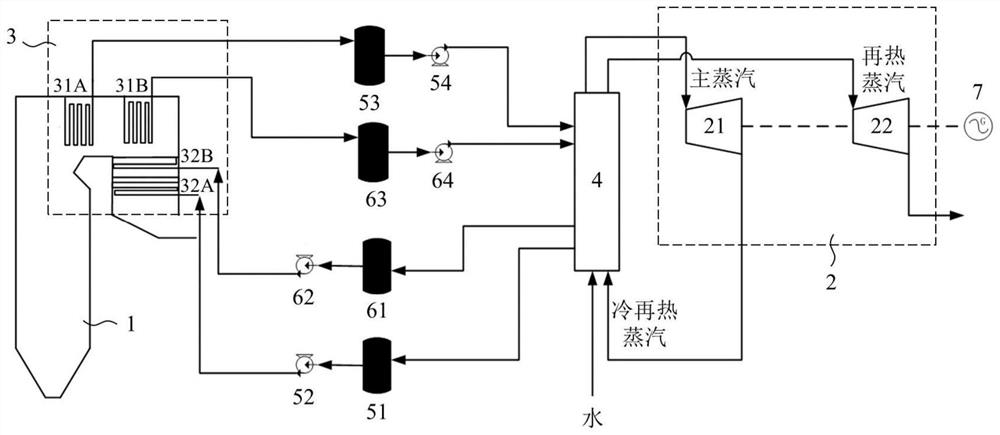

Energy storage power generation system

PendingCN113847836AReduce the impact of operational flexibilityImprove FM capabilityHeat storage plantsSteam engine plantsProcess engineeringTurbine

The invention provides an energy storage power generation system. The energy storage power generation system comprises a boiler comprising a first heat exchange jig, a steam turbine comprising a turbine proper and a second heat exchange rig, and a plurality of fused salt circulating systems, wherein the fused salt circulating systems are arranged between the boiler and the turbine proper and are configured to transfer heat generated by the boiler to an acting working medium of the turbine proper so that the working medium can drive the turbine proper to rotate, and different fused salt circulating systems adopt fused salt of different components as heat exchange media; and the fused salt circulating systems are thermally coupled with the boiler through the first heat exchange jig, the fused salt absorbs heat from the boiler through the first heat exchange jig, the fused salt circulating systems are thermally coupled with the turbine proper through the second heat exchange jig, and the fused salt releases heat to the acting working medium of the turbine proper through the second heat exchange jig. According to the energy storage power generation system, flexible operation of a thermal power generating unit under different loads can be realized.

Owner:YANTAI LONGYUAN POWER TECH

Method and device for generating superheated steam from high-salt boiler feed water by stage evaporation

ActiveCN103968365BReduce salt contentHigh salt contentSteam separation arrangementsSteam superheatersCyclonePipeflow

The invention discloses a method and a device, which are used for generating superheated steam from high-salt boiler feed water through stage evaporation, and belongs to the technical field of boiler equipment. According to the method, a boiler drum is divided into a net section and a salt section; the lower part of a salt-section cyclone is connected with the salt section to achieve discharging; the bottom end of the salt-section cyclone is connected with a salt-section down pipe, the salt-section down pipe is connected with a salt-section distribution header, the other end of a salt-section riser pipe is connected with the middle of the salt-section cyclone, a cavity body in the upper part of the salt-section cyclone is connected with a corrugated plate, the top of the salt-section cyclone is connected with a salt-section steam outlet, and the salt-section steam outlet is connected with a pipeline at one end of a super heater; the net-section distribution header is connected with a net-section riser pipe; a salt-section communication pipe is used for communicating a net-section steam drum with the salt-section cyclone. The method has the benefits that the requirement on the salt content of boiler water in a heavy oil thermal recovery boiler is greatly lowered on the premise of guaranteeing the steam quality, moderately treated heavy oil recovery water can be reused, heavy oil development water can be recycled, the clear water consumption and the sewage discharge are reduced, the environment is protected, and the heavy oil thermal recovery cost is reduced.

Owner:PETROCHINA CO LTD

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362BIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialThermodynamicsCogeneration

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

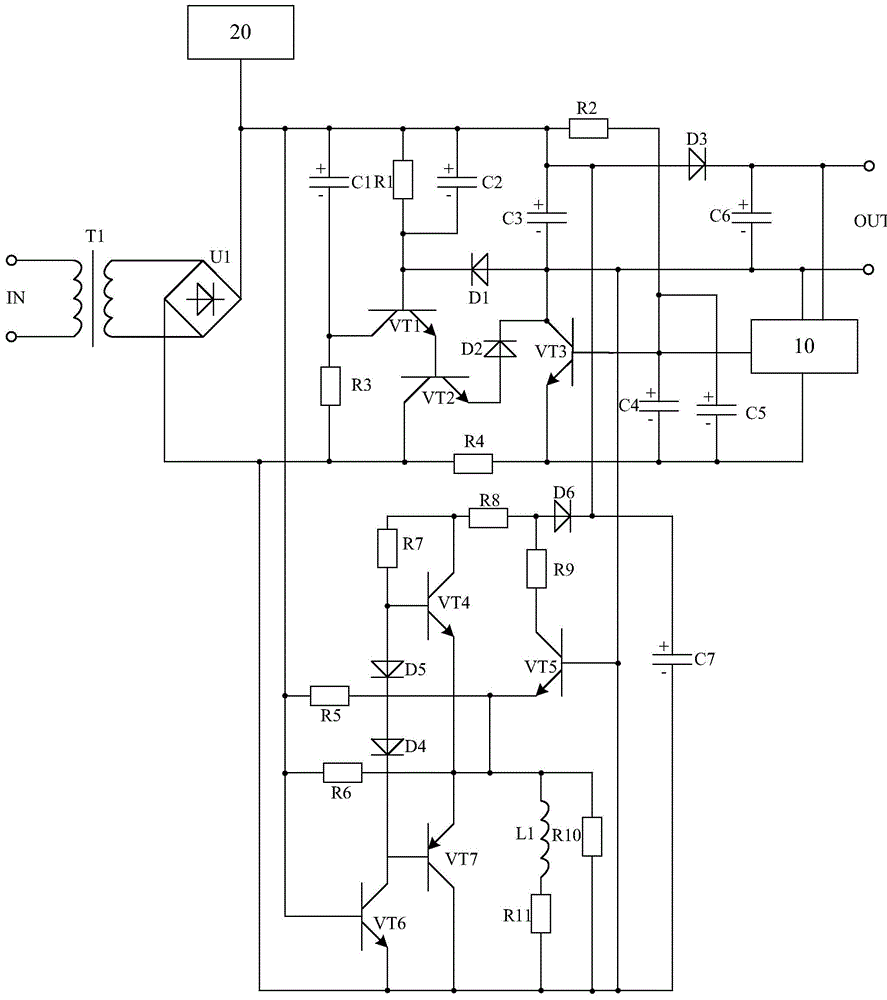

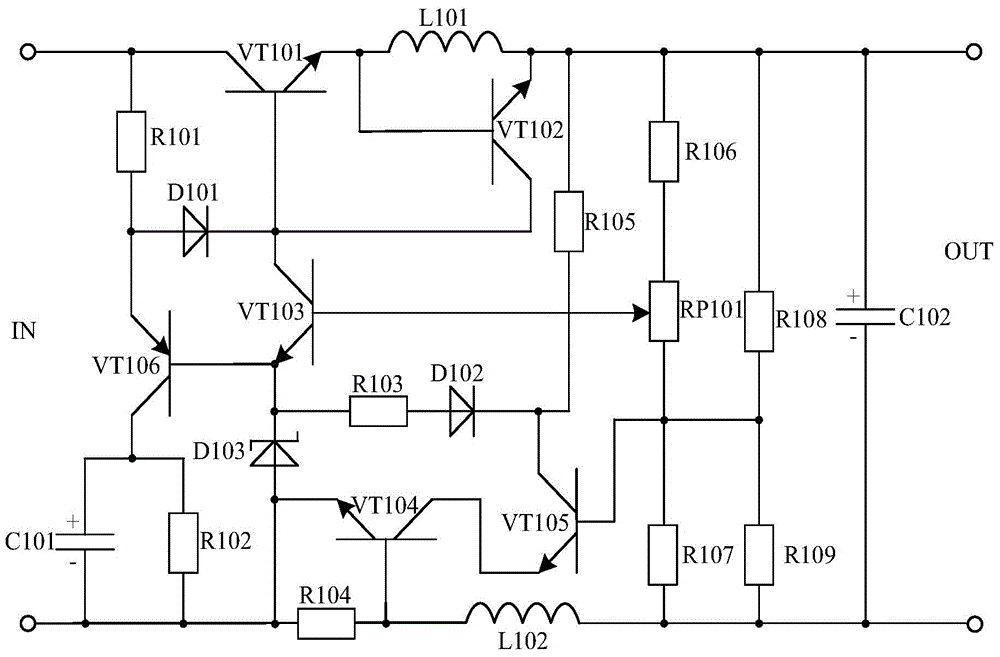

Alarm current-limiting type waste-heat power generation system based on submerged-arc furnace

InactiveCN104930863ASimple structureImprove steam parametersDc-dc conversionEnergy industrySuperheaterCurrent limiting

The invention discloses an alarm current-limiting type waste-heat power generation system based on a submerged-arc furnace. The alarm current-limiting type waste-heat power generation system based on the submerged-arc furnace comprises a waste heat boiler, an evaporation heating surface, a coal economizer, a steam pocket, a steam superheater, a steam turbine, a power generator, a flash evaporator and a condenser. A waste heat power generation control system is arranged inside the power generator 7. The waste heat power generation control system is composed of a transformer T1, a diode bridge rectifier U1 connected with a secondary side coil of the transformer T1 in series, a power circuit and a power amplification circuit connected between the positive output end and negative output end of the diode bridge rectifier U1 in series, a temperature alarm circuit connected with the positive output end of the diode bridge rectifier U1, and a current-limiting circuit connected to the power circuit in series. The two ends of a primary side coil of the transformer T1 form the input ends. The waste-heat power generation system capable of recovering waste heat can recover and process waste heat sufficiently, thereby increasing the utilization rate of energy and further relieving burdens of enterprises.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

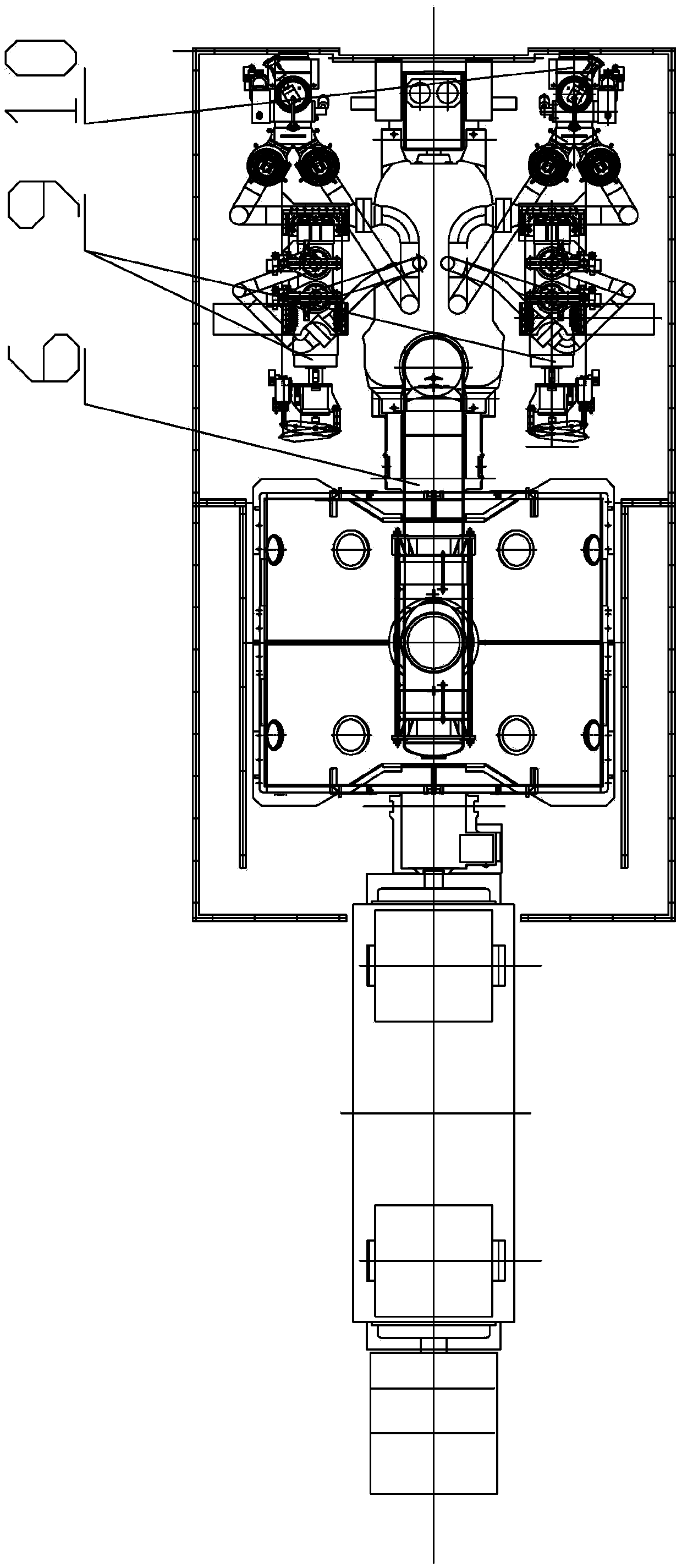

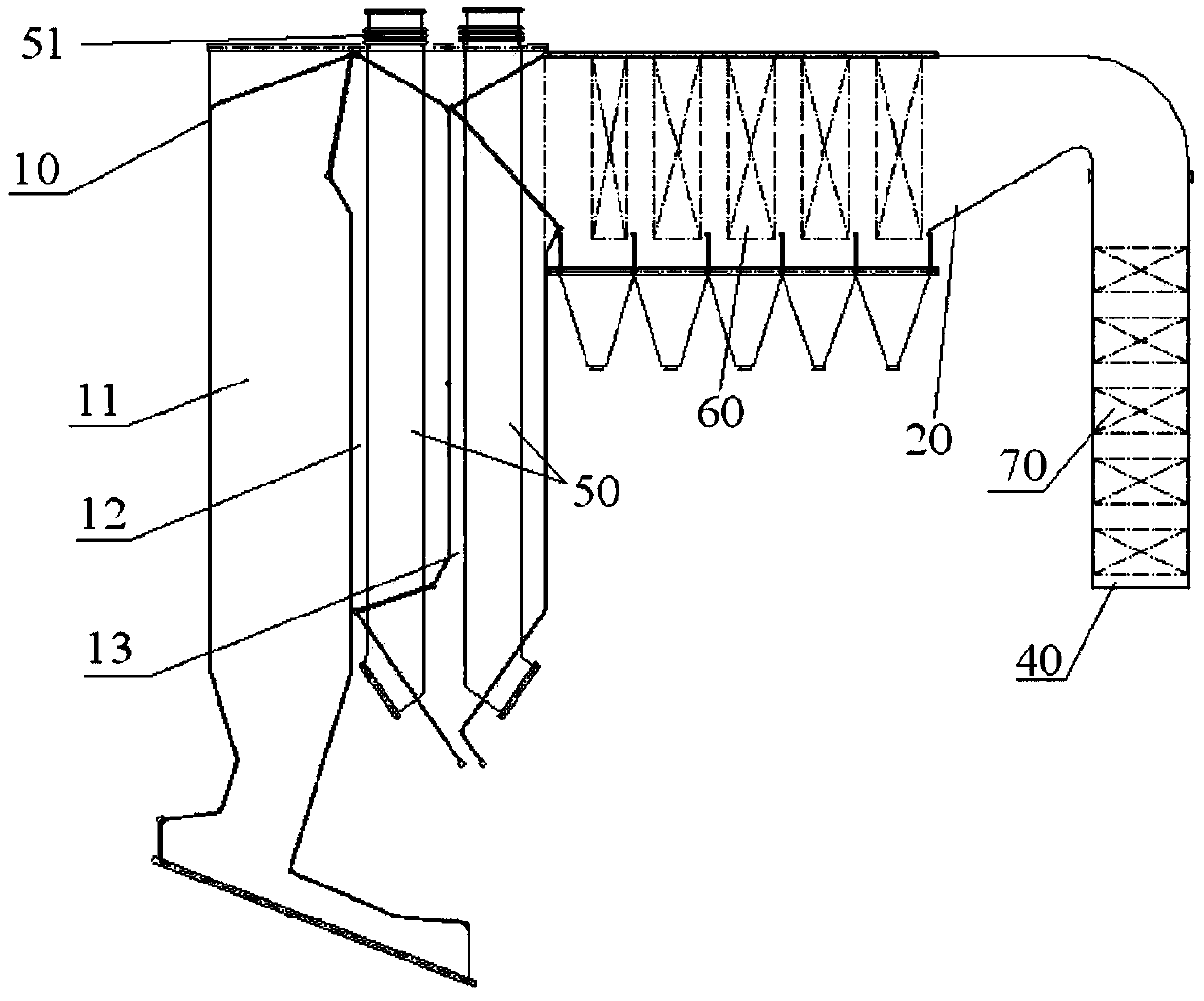

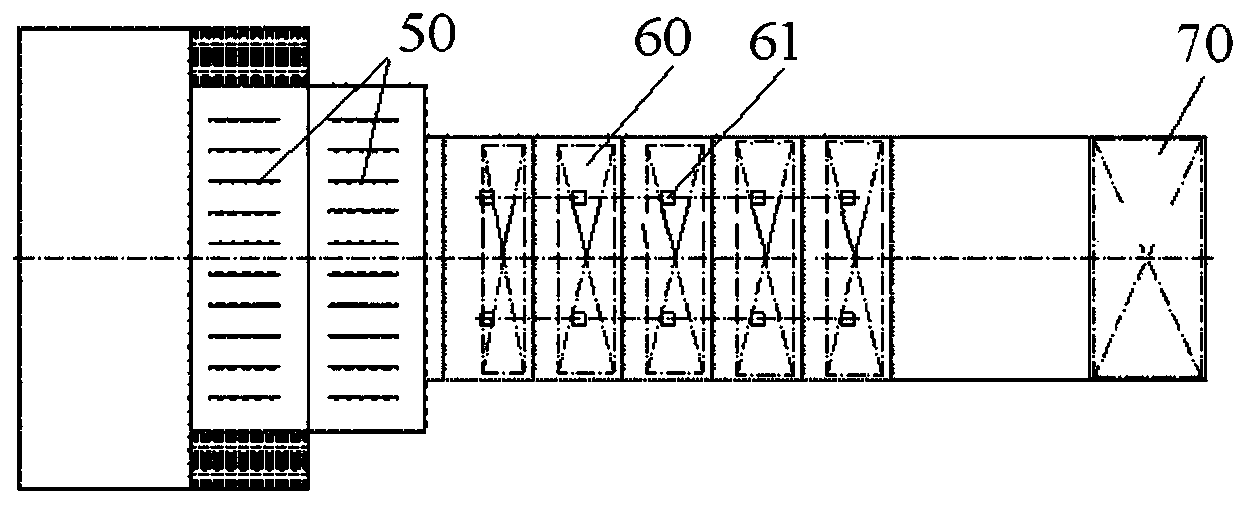

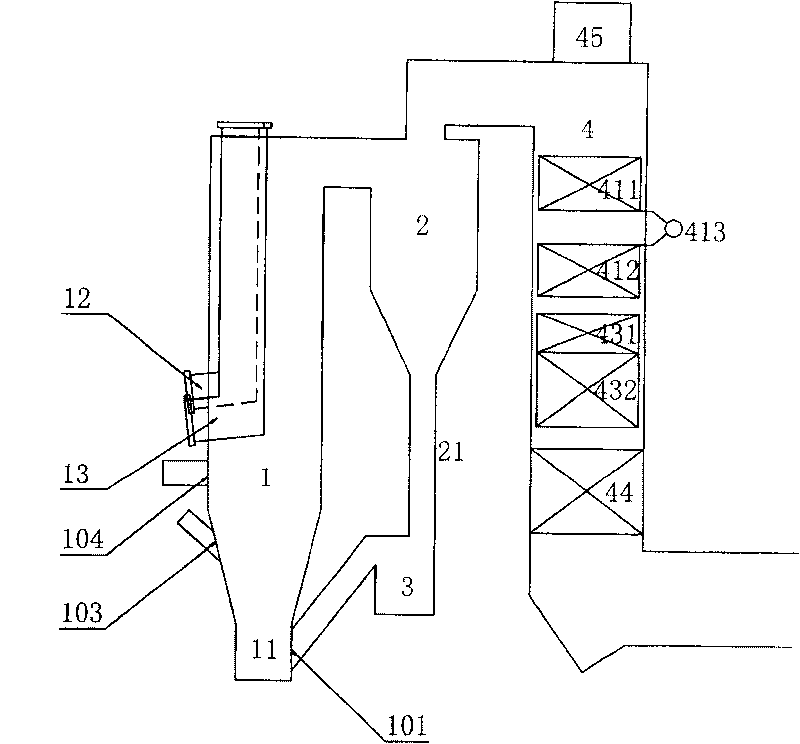

A high bed temperature circulating fluidized bed boiler with steam parameters of 700°C and above

ActiveCN103363517BEffective combinationImprove unit efficiencyFluidized bed combustionSteam boilersCombustion chamberSuperheater

The invention discloses a circulating fluidized bed boiler with a high bed temperature and with a steam parameter of 700 DEG C and above. The boiler comprises an air compartment, an air distributor, a combustion chamber, a primary air system, a second air system, a horizontal flue, a plurality of cyclone separators, a plurality of external heat exchangers and a rear flue. The contraction ratio of the lower part of the combustion chamber along the depth direction is 0.22-0.48. A flue gas damper is arranged in the rear flue. The rear flue contains at least two parallel flues. A low-temperature superheater is arranged in one parallel flue. A low-temperature reheater is arranged in the other parallel flue. A medium-temperature superheater is arranged in one external heat exchanger. A high-temperature reheater is arranged in one external heat exchanger. A high-temperature superheater is arranged in the combustion chamber. The boiler can effectively raise the heat-transfer intensity inside the combustion chamber, the bed temperature can reach 950 DEG C and above, the steam parameter can reach 700 DEG C and above, and therefore the aims of raising power generating efficiency of coal power units and reducing pollutant discharge are achieved, and long and high-efficient running of the device can be guaranteed.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

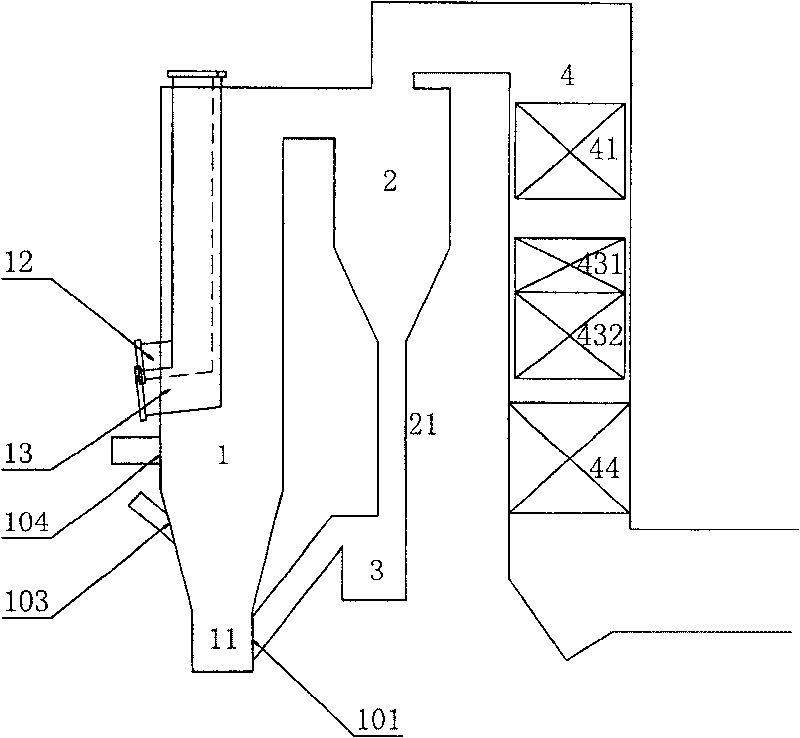

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816BGuaranteed normal outputStable combustionFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch,a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, andthe material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption ofbiological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364BIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialThermodynamicsProcess engineering

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Groove type solar direct steam heat collecting pipe

ActiveCN103335427BEnhanced boiling heat transferImprove reliabilitySolar heating energySolar heat devicesEngineeringHeat stress

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Double-process electric furnace waste heat utilization system with stable steam parameters

PendingCN113513923AStable outputImprove securityIncreasing energy efficiencySteam superheatersExternal energySuperheater

The invention discloses a double-process electric furnace waste heat utilization system with stable steam parameters. The double-process electric furnace waste heat utilization system comprises a heat conduction oil working medium process and a steam working medium process; the heat conduction oil working medium process comprises a heat conduction oil flue, a heat conduction oil furnace top and a heat conduction oil storage tank arranged at the upper parts of the heat conduction oil flue and the heat conduction oil furnace top, and the heat conduction oil flue, the heat conduction oil furnace top and the heat conduction oil storage tank are sequentially connected through heat conduction oil pipes to realize circulation of heat conduction oil in the three structures; the steam working medium process comprises a waste heat boiler, a heat accumulator and a superheater which are sequentially connected through a steam pipeline, and the superheater is arranged in the heat conduction oil storage tank; the heat conduction oil flue and the heat conduction oil furnace top of the heat conduction oil working medium process and the waste heat boiler of the steam working medium process are sequentially connected to form a high-temperature smoke circulation channel for waste heat recovery. The invention relates to the double-process electric furnace waste heat utilization system which has the stable steam parameters and can realizing entering of a steam turbine without the assistance of external energy.

Owner:上海四方无锡锅炉工程有限公司

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359BImprove steam parametersImprove waste heat power generation capacityFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recoveringthe sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

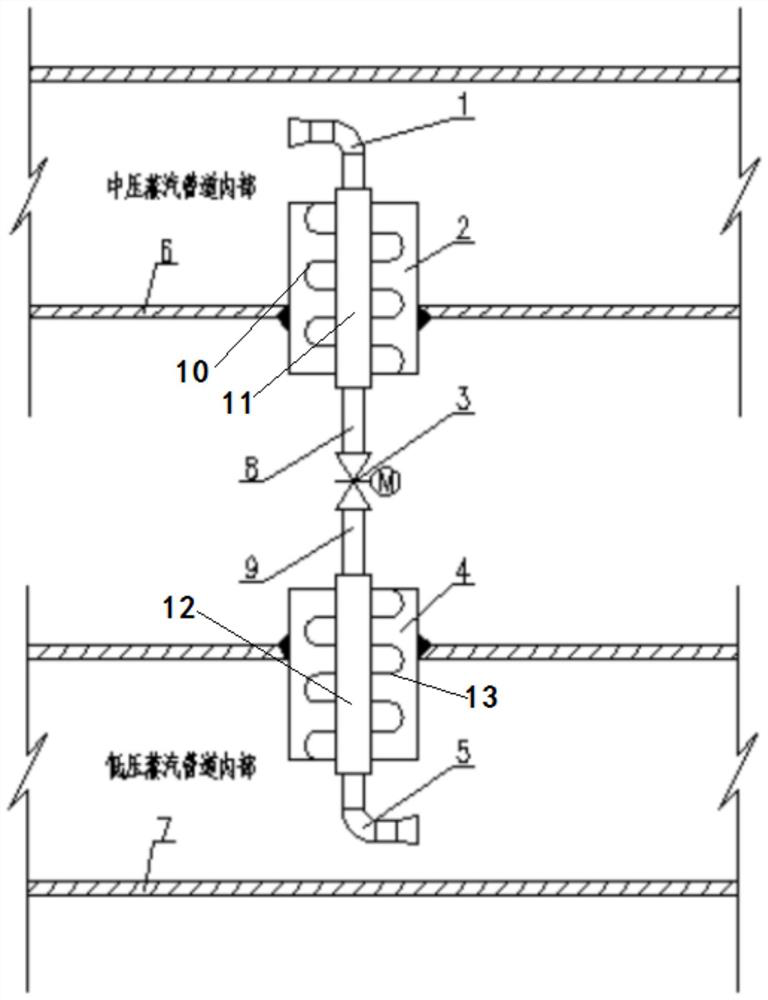

Medium-pressure introduction device and method capable of improving parameters of tail end of low-pressure steam pipe network

PendingCN113217975AImprove terminal parametersBuilt less hydrophobicLighting and heating apparatusSpace heating and ventilation detailsSocial benefitsThermodynamics

The invention discloses a medium-pressure introduction device and method capable of improving parameters of the tail end of a low-pressure steam pipe network. The medium-pressure introduction device comprises an inlet introduction pipe and an outlet introduction pipe, wherein an outlet of the inlet introduction pipe is connected with a first steam flow guide pipeline, the first steam flow guide pipeline is connected with a second steam flow guide pipeline through a regulating valve, the second steam flow guide pipeline is connected with an inlet of the outlet introduction pipe, an inlet of the inlet introduction pipe is located in a first steam pipeline, an outlet of the outlet introduction pipe is located in a second steam pipeline, and parameters of steam in the first steam pipeline are larger than those of steam in the second steam pipeline. According to the medium-pressure introduction device and method, the steam parameters of the whole low-pressure steam pipe network or the tail end of the low-pressure steam pipe network are improved to meet user requirements; and meanwhile, the supersaturation degree of low-pressure steam is improved to reduce dewatering and reduce the pipe loss, so that the economic benefit and the social benefit are increased.

Owner:华能(广东)能源开发有限公司海门电厂 +1

Trough-tower combined steam generation system

InactiveCN110566920AImprove photoelectric conversion efficiencyNo accidents of molten salt solidification and freezingFrom solar energyStorage heatersHeat conductingMolten salt

The invention relates to steam generation systems and provides a trough-tower combined steam generation system in order to improve the photoelectric conversion efficiency of a trough type solar-thermal power station. The trough-tower combined steam generation system comprises an energy storage system, a trough type heat conducting oil steam generation system, a tower type molten salt steam generation system and a water supply system. The energy storage system is connected with the tower type molten salt steam generation system. The tower type molten salt steam generation system and the troughtype heat conducting oil steam generation system are both connected with the water supply system. The tower type molten salt steam generation system is connected with the trough type heat conducting oil steam generation system. The invention belongs to the field of the solar thermal technology. The trough-tower combined steam generation system integrates two kinds of solar-thermal power generationforms, enables steam of the trough type heat conducting oil solar-thermal system to get into the tower type molten salt steam generation system to be further heated and improves the solar-thermal conversion efficiency of the trough-tower combined comprehensive solar-thermal power station.

Owner:HARBIN BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com