660MW-grade primary intermediate reheat extraction steam turbine unit

A 660MW, steam turbine technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of high coal consumption for power supply, low energy utilization rate, and increased pollutant emissions, so as to save energy, strengthen vitality, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

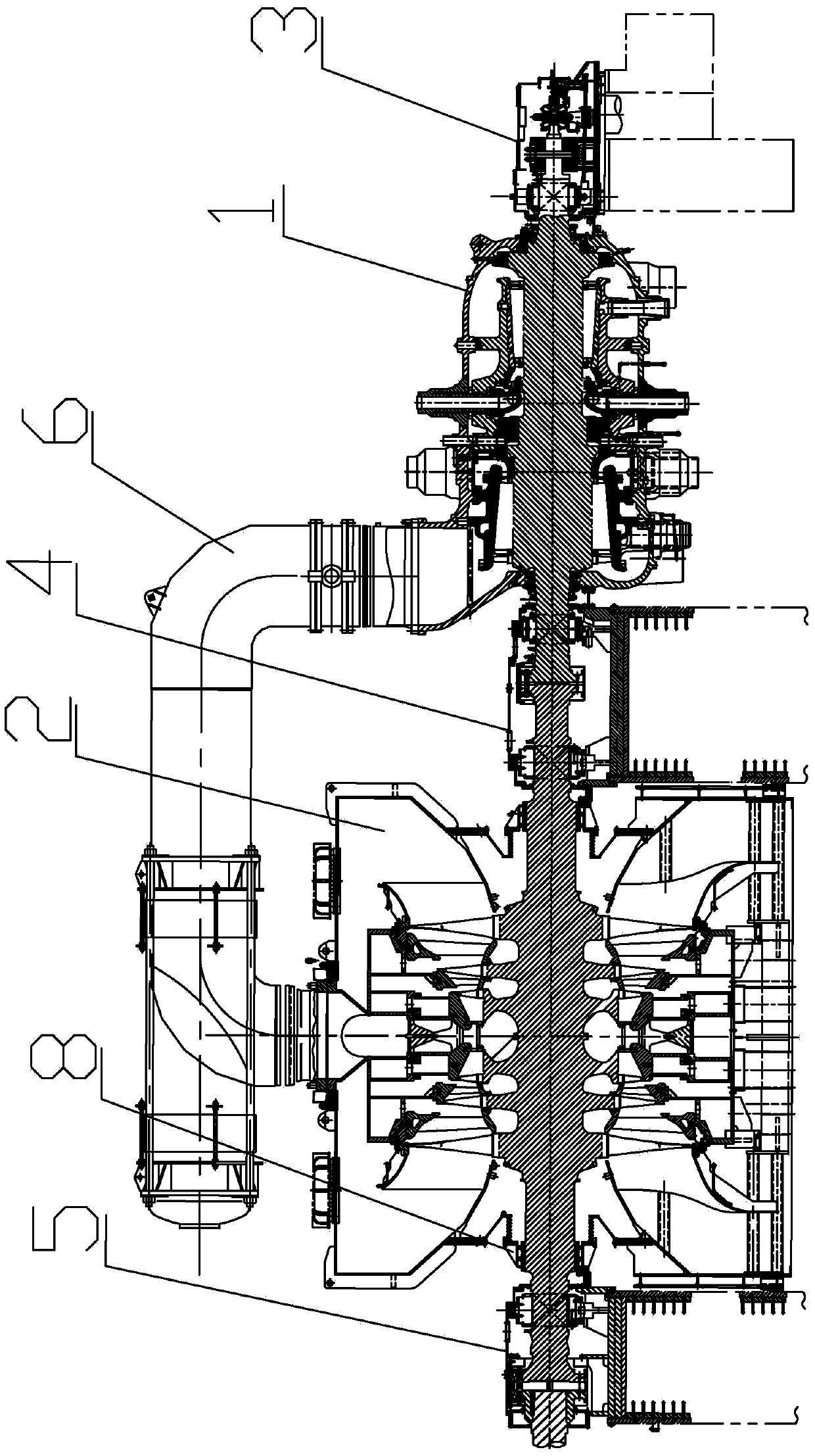

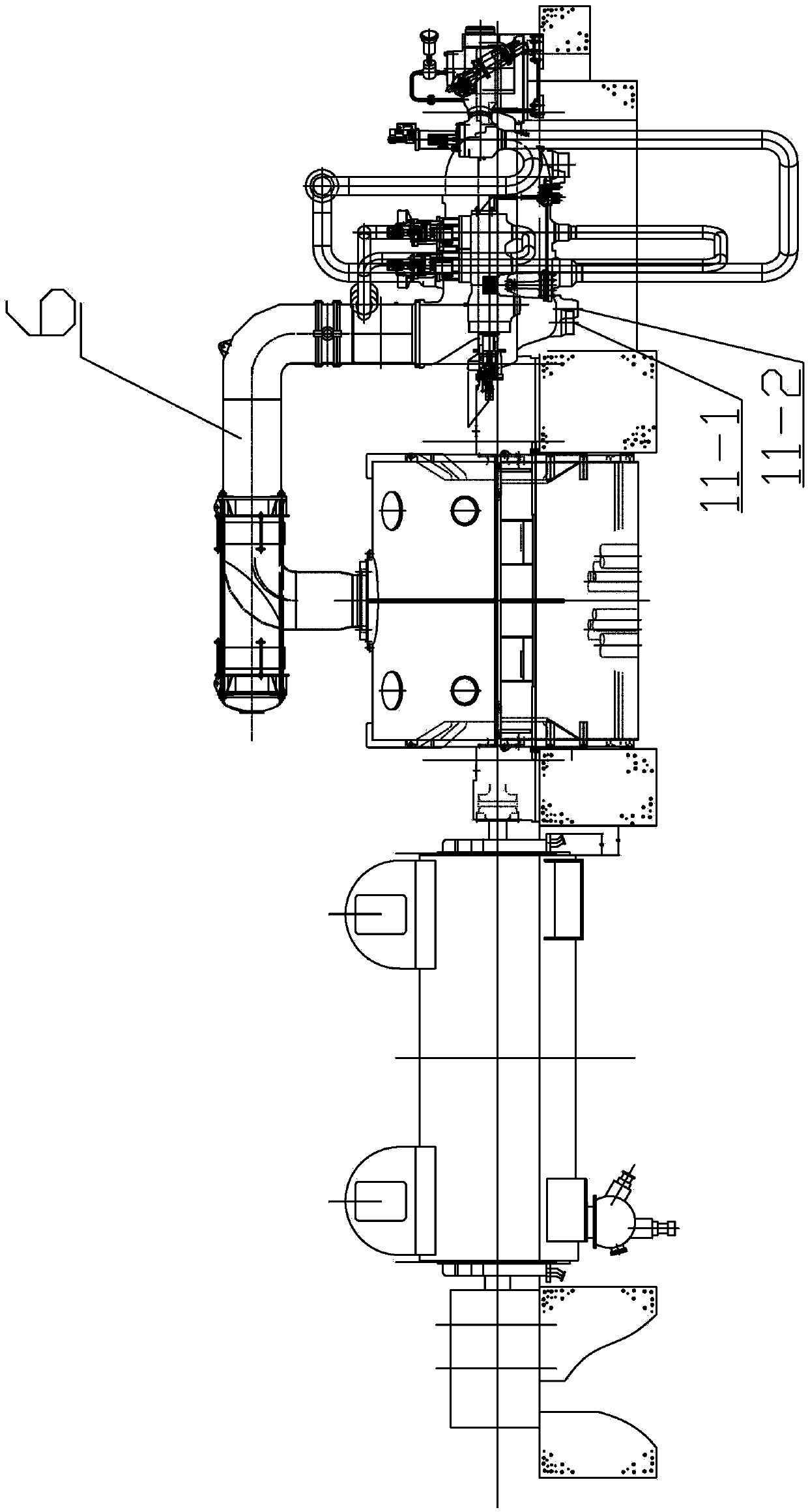

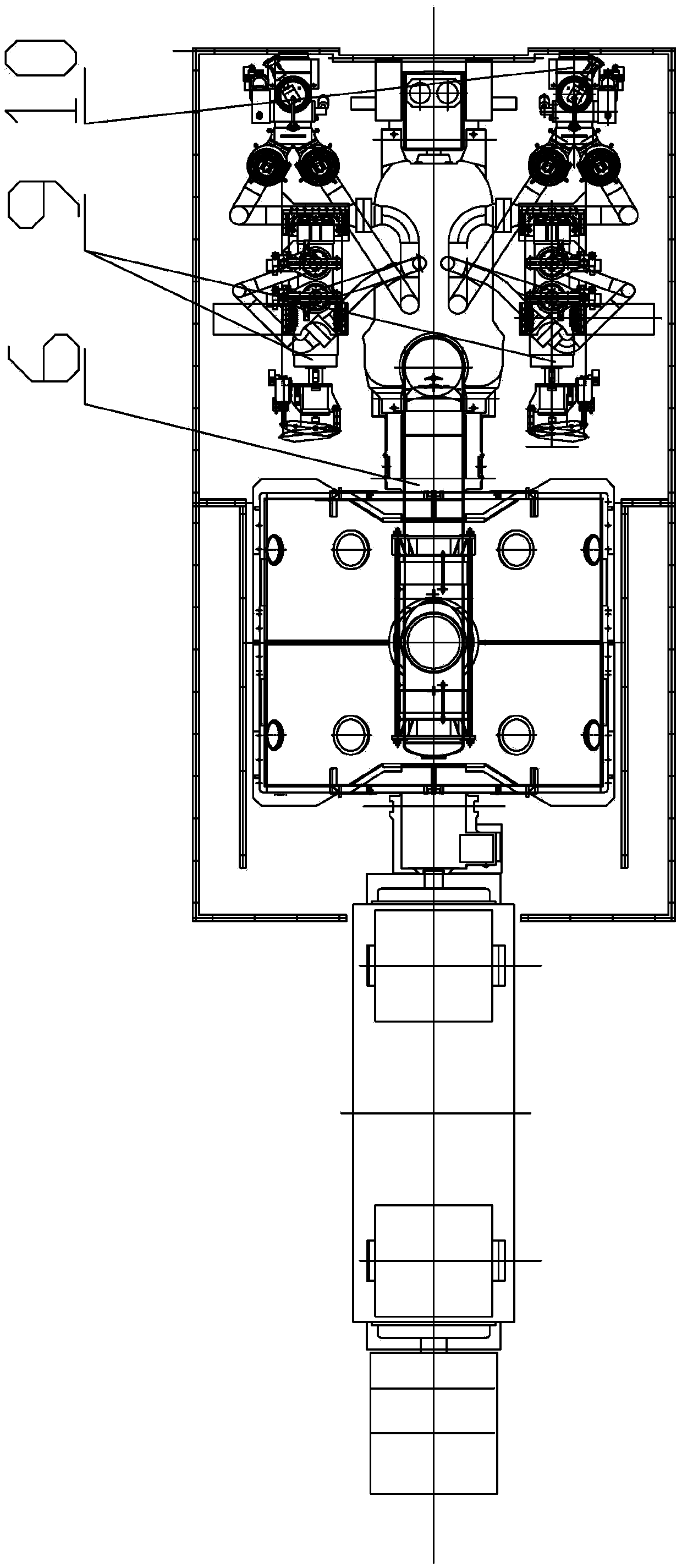

[0019] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, a 660MW class once intermediate reheat extraction steam turbine unit in this embodiment, which includes high and medium pressure cylinder 1, low pressure cylinder 2, front bearing box 3, 2# bearing box 4, 3# bearing box 5 , medium and low pressure connecting pipe 6, hydraulic control butterfly valve 7 and elastic end seal assembly 8,

[0020] Front bearing box 3, high and medium pressure cylinder 1, 2# bearing box 4, low pressure cylinder 2 and 3# bearing box 5 are arranged in sequence from right to left; medium and low pressure connecting pipe 6 guides the middle exhaust steam of high and high pressure cylinder 1 into Low-pressure cylinder 2 (viewed from the governor end to the motor end), the hydraulic control butterfly valve 7 is installed on the medium-low pressure communication pipe 6, two low-pressure heating and extraction ports 11-1 and one medium-pressure steam supply and ...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 Describe this embodiment, the front bearing housing 3, 2# bearing housing 4 and 3# bearing housing 5 of this embodiment are all floor bearing housings. Such a setting can avoid the misalignment of the low-pressure dynamic and static parts of the unit caused by the high back pressure and large change of the back pressure of the block-cylinder bearing box of the existing model, resulting in the problem of dynamic and static friction of the unit. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1 to Figure 2 To illustrate this embodiment, this embodiment also includes two high-pressure main steam control valves 9 and two medium-pressure reheat control joint valves 10, the two high-pressure main steam control valves 9 and two medium-pressure reheat control joint valves 10 are both It is symmetrically installed on the left and right sides of the high and medium pressure cylinder 1. Such setting can realize the joint start-up of high and medium pressure of the unit. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com