Alarm current-limiting type waste-heat power generation system based on submerged-arc furnace

A waste heat power generation and submerged arc furnace technology, applied in control/regulation systems, emergency protection circuit devices for limiting overcurrent/overvoltage, furnaces, etc., can solve problems such as low flue gas temperature, waste of heat energy, and environmental pollution , to achieve the effect of protecting the environment, reducing energy consumption, and strong waste heat power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

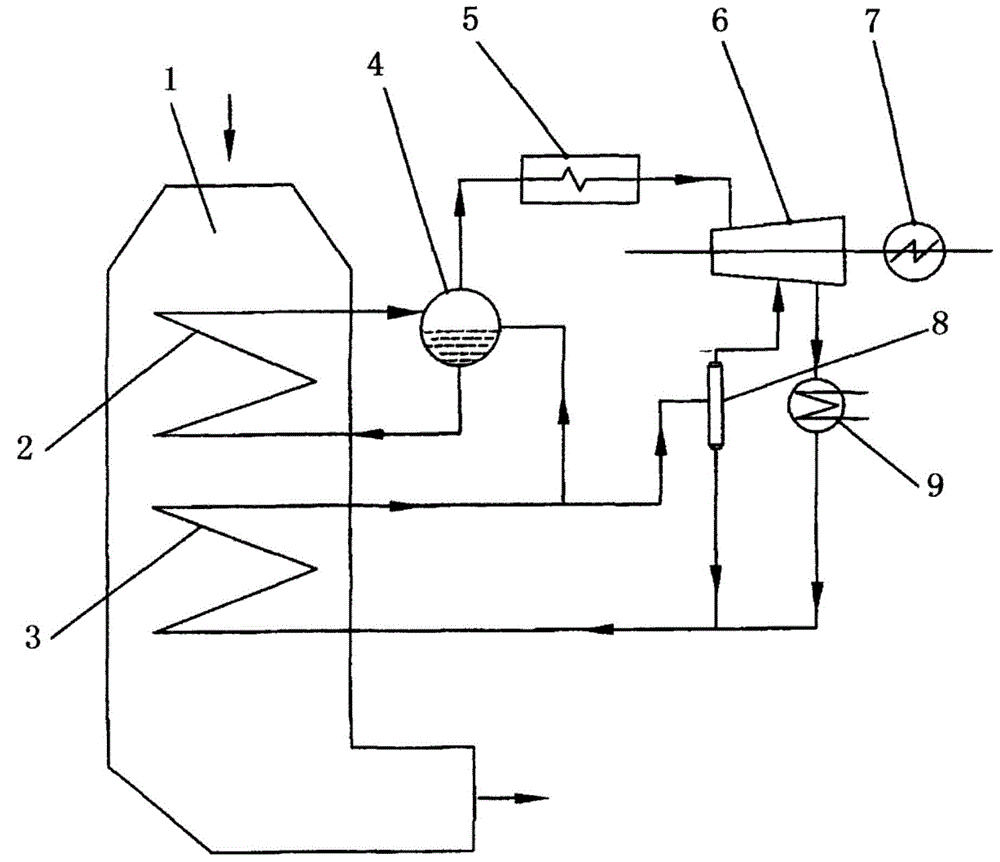

[0025] Such as figure 1 As shown, the present invention includes waste heat boiler 1 , evaporation heating surface 2 , economizer 3 , steam drum 4 , steam superheater 5 , steam turbine 6 , generator 7 , flasher 8 and condenser 9 . The main shaft of the steam turbine 6 is connected to the rotating shaft of the generator 7, the waste heat boiler 1 has exhaust gas inlet and exhaust gas outlet, the economizer 3 and the evaporation heating surface 2 are arranged in the waste heat boiler 1, and the steam drum 4 is arranged in the waste heat boiler 1 And connected with the outlet end of the economizer 3, the saturated steam inlet of the steam superheater 5 is connected with the saturated steam outlet of the steam drum 4, the superheated steam output end is connected with the steam input end of the steam turbine 6, and the input end of the condenser 9 It is connected to the steam output end of the steam turbine 6, the output end is connected to the input end of the economizer 3, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com