Combustion chamber and waste incineration boiler for burning waste and working method thereof

A technology of waste incineration and working methods, which is applied in the direction of combustion methods, steam generation methods using heat carriers, and combustion chambers. It can solve the problems of easy corrosion, low reliability, and low incineration efficiency of superheaters, and achieve corrosion prevention, The effect of ensuring reliability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

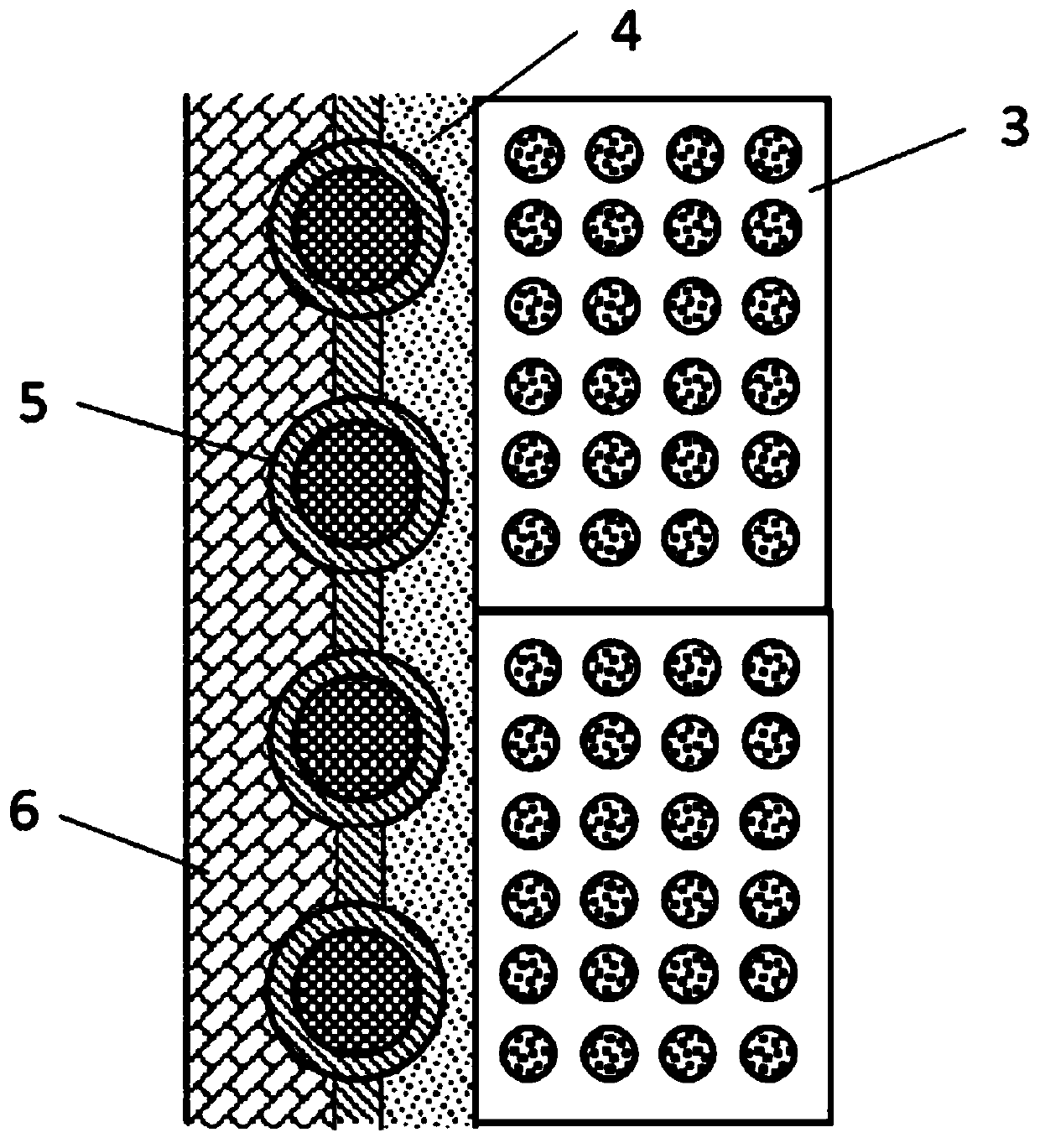

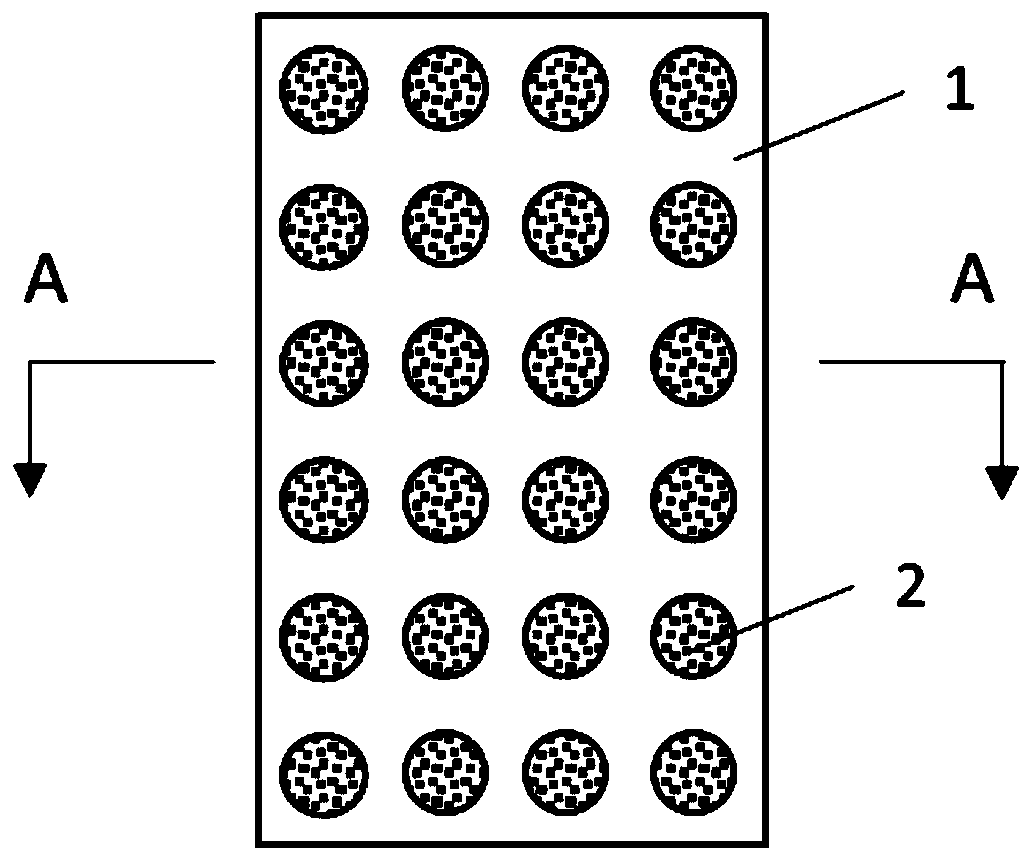

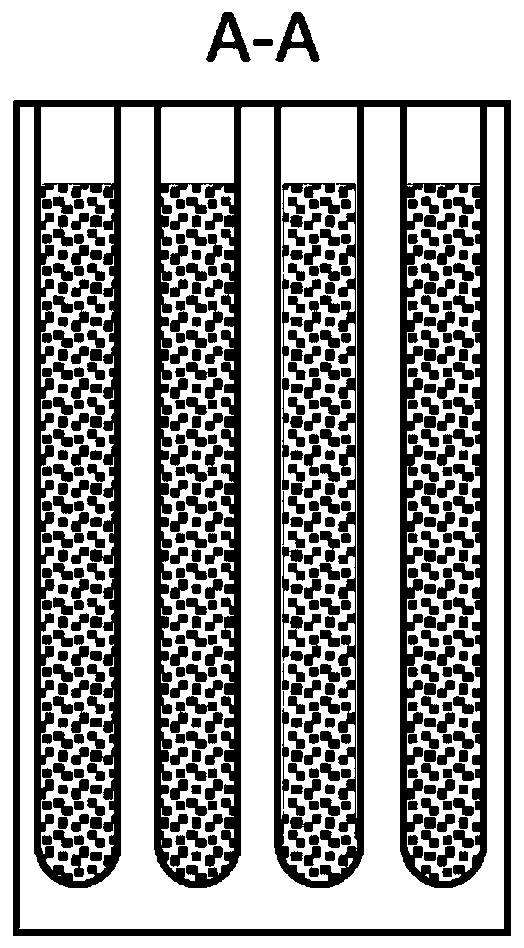

[0023] to combine figure 1 Describe this embodiment. In this embodiment, the present invention relates to a combustion chamber for incinerating garbage. The combustion chamber is composed of phase-change energy storage refractory bricks 3, mortar 4 and exterior walls 6 from inside to outside. The heat exchange tube 5 is horizontally arranged at the junction of the outer wall 6 and the mortar 4, and the mortar 4 is used to bond the phase change energy storage refractory brick 3, the heat exchange tube 5 and the outer wall 6 together. A plurality of deep holes are opened on the energy storage refractory brick 3 , and the phase change material 2 is filled in the deep holes, and the phase change energy storage refractory brick 3 is made of ceramic material 1 .

[0024] More specifically: the phase change material 2 is metal aluminum, aluminum-silicon mixture, aluminum-silicon-copper mixture, aluminum-silicon-magnesium mixture, aluminum-silicon-zinc mixture or aluminum-magnesium-zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com