Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

A technology of circulating fluidized bed and combustion method, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in molten state, etc. It can solve the problems of sticking and slagging on the heating surface, so as to prevent sticking, Guarantee boiler output and improve working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

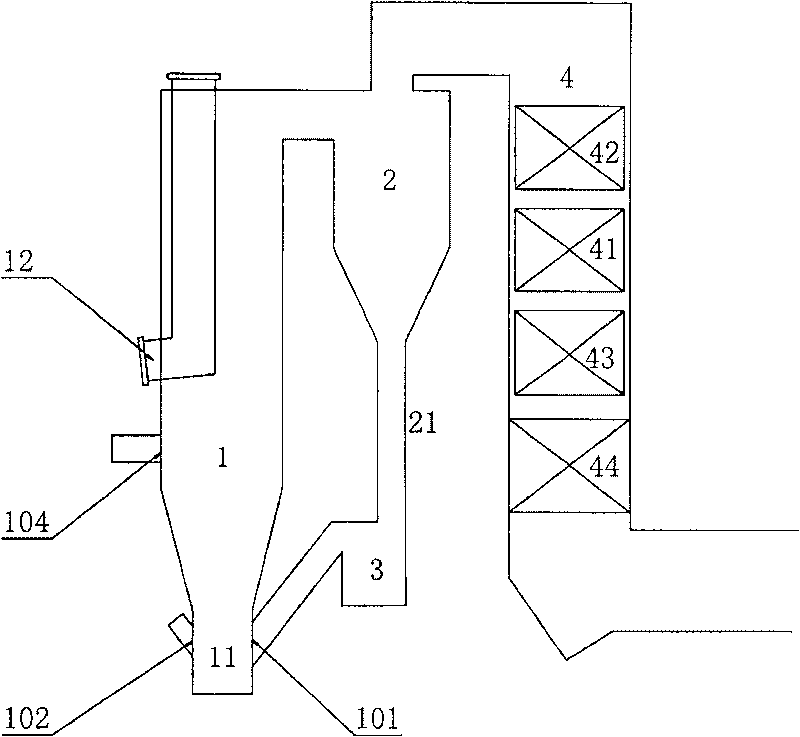

[0059] According to the present invention, if figure 1 The biomass circulating fluidized bed boiler shown includes a furnace 1, a separator 2, a feeding device 3, and a tail flue 4, with a straight section 11, a feeding port 101, a coal feeding port 102, and a biomass feeding port 104 , superheater high temperature section 12, separator dipleg 21, superheater low temperature section 41, evaporation heating surface 42, economizer 43 and air preheater 44;

[0060] The fuel used is corn stalks and rice stalks, and a small amount of coal is mixed with it. The steam parameters are high temperature and high pressure.

[0061] The upper part of the furnace 1 is equipped with a two-stage steam-cooled screen-type heating surface as the high-temperature section 12 of the superheater, which absorbs the heat of the flue gas at the upper part of the furnace 1, and reduces the temperature of the flue gas at the outlet of the furnace 1 to 700-800 ° C; Heating surface 42, low-temperature sec...

Embodiment 2

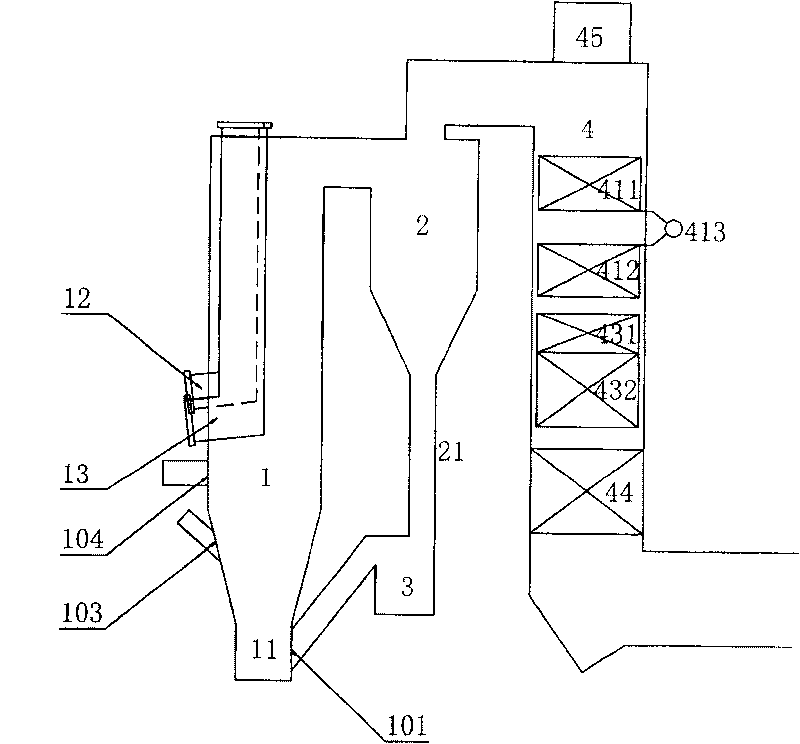

[0064] According to the present invention, if figure 2 The biomass circulating fluidized bed boiler shown includes a furnace 1, a separator 2, a feeder 3, and a tail flue 4, with a straight section 11, a feed return port 101, a bed material feed port 103, and a biomass feed port 104. High temperature section 12 of superheater, panel water cooling heating surface 13, separator material leg 21, air preheater 44, particle ash removal device 45, first stage 411 of low temperature section of superheater, second stage 412 of low temperature section of superheater , Inter-stage setting desuperheating device 413, economizer boiling section 431 and non-boiling section 432;

[0065] The fuel used is straw, and the steam parameters are medium temperature and medium pressure.

[0066] Since the ash melting point of wheat straw is lower than 700°C, the water-cooled panel-type heating surface 13 on the upper part of the furnace 1 and the steam-cooled panel-type heating surface as the high...

Embodiment 3

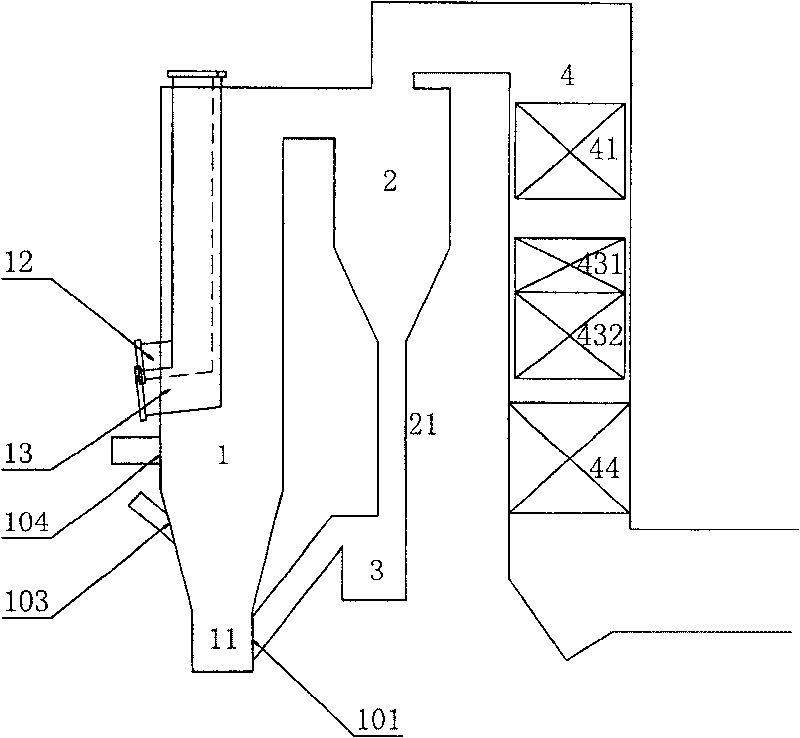

[0070] According to the present invention, if image 3 The biomass circulating fluidized bed boiler shown includes a furnace 1, a separator 2, a feeder 3, and a tail flue 4, with a straight section 11, a feed return port 101, a bed material feed port 103, and a biomass feed port 104. High temperature section 12 of superheater, panel water cooling heating surface 13, separator feed leg 21, air preheater 44, low temperature section 41 of superheater, boiling section 431 and non-boiling section 432 of economizer;

[0071] The fuel used is corn stalks, and the steam parameters are sub-high temperature and sub-high pressure.

[0072]The upper part of the furnace 1 is equipped with a water-cooled panel-type heating surface 13 and a steam-cooled panel-type heating surface as the high-temperature section 12 of the superheater to absorb the heat of the flue gas at the upper part of the furnace 1 and reduce the temperature of the flue gas at the outlet of the furnace 1 to 600-700 °C; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com