High-parameter waste heat boiler suitable for garbage incinerator grate

A technology of waste incinerator and waste heat boiler, which is applied in the field of high-parameter waste heat boiler and can solve the problems of reducing the power generation efficiency of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

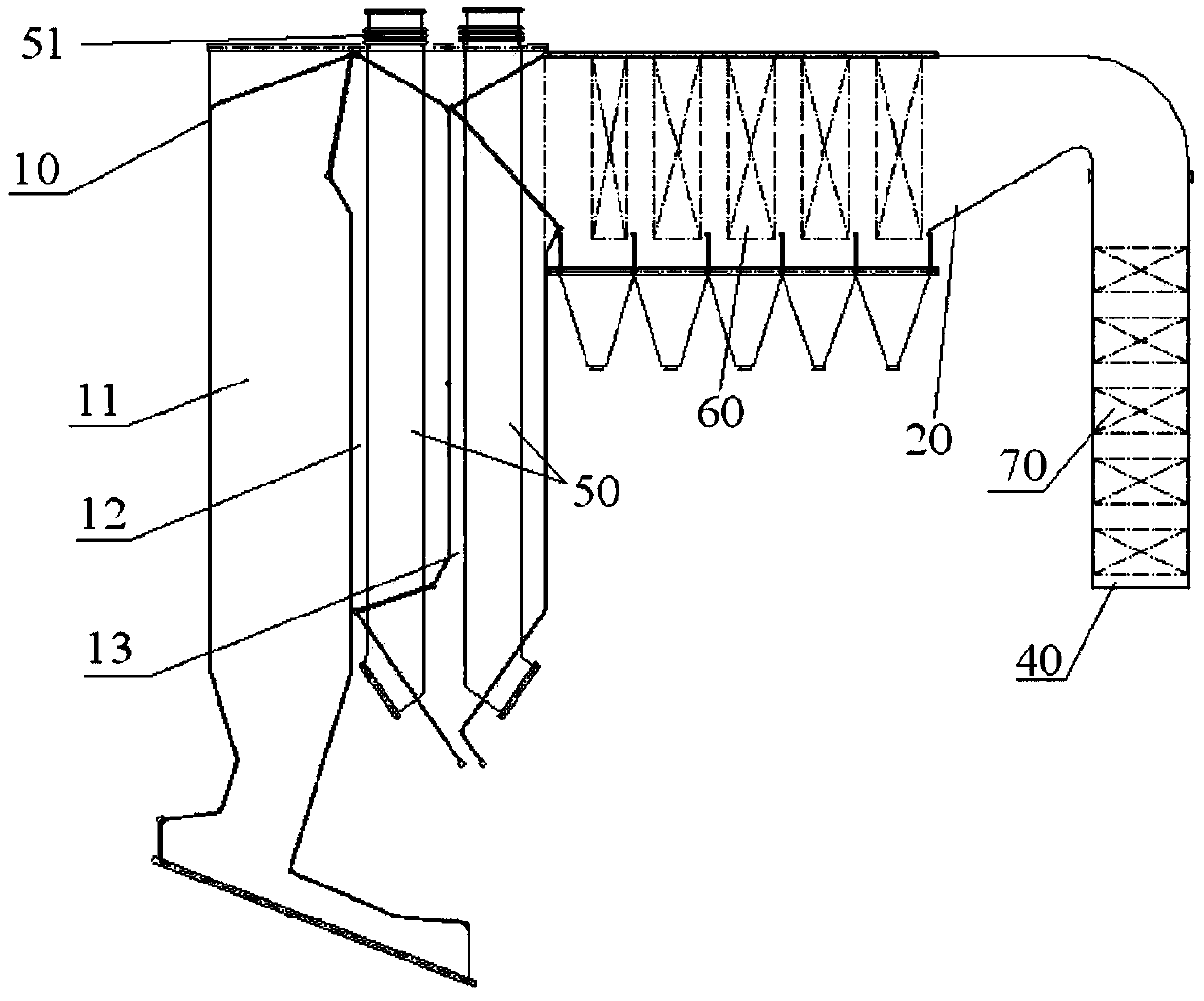

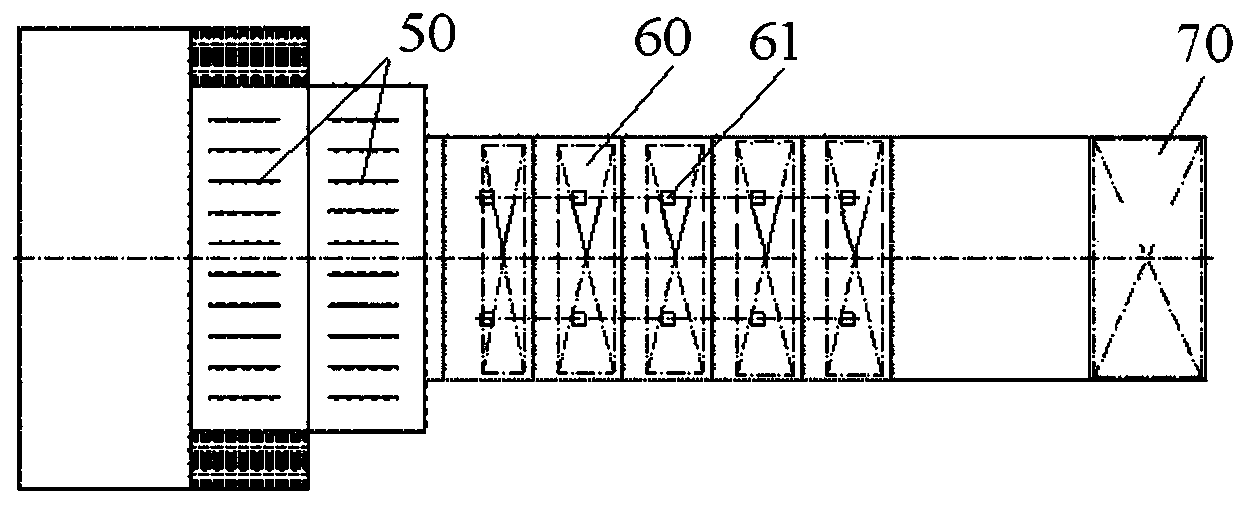

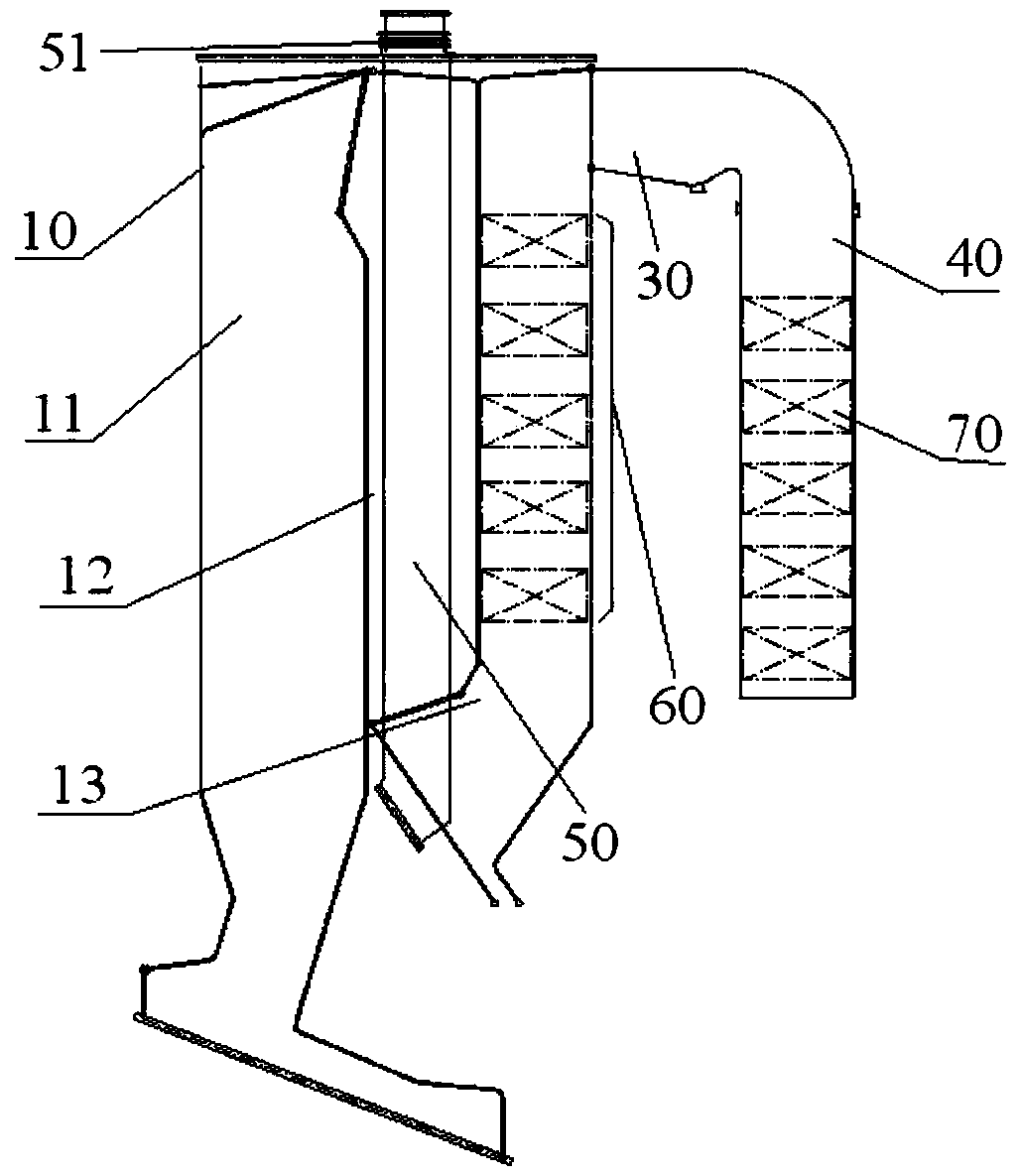

Image

Examples

Embodiment Construction

[0023] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0024] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

[0025] At present, in order to alleviate the corrosion problem of high-temperature flue gas in existing waste incinerator grate furnace waste heat boilers at home and abroad, the steam parameters at the boiler outlet are basically controlled not to exceed 4MPa / 400°C. As the pressure and temperature decrease, the working efficiency of the steam turbine will decrease accordingly, and the economic benefits of the waste-to-energy plant will decrease accordingly.

[0026] In order to achieve the purpose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com