Method and device for generating superheated steam from high-salt boiler feed water by stage evaporation

A technology of superheated steam and boiler feed water, which is applied in the direction of steam separation device, steam superheating, steam generation, etc. It can solve the problems of high salt content in boiler water, inability to generate steam, and limit the efficiency of heavy oil recovery, so as to improve steam parameters , protect the environment and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

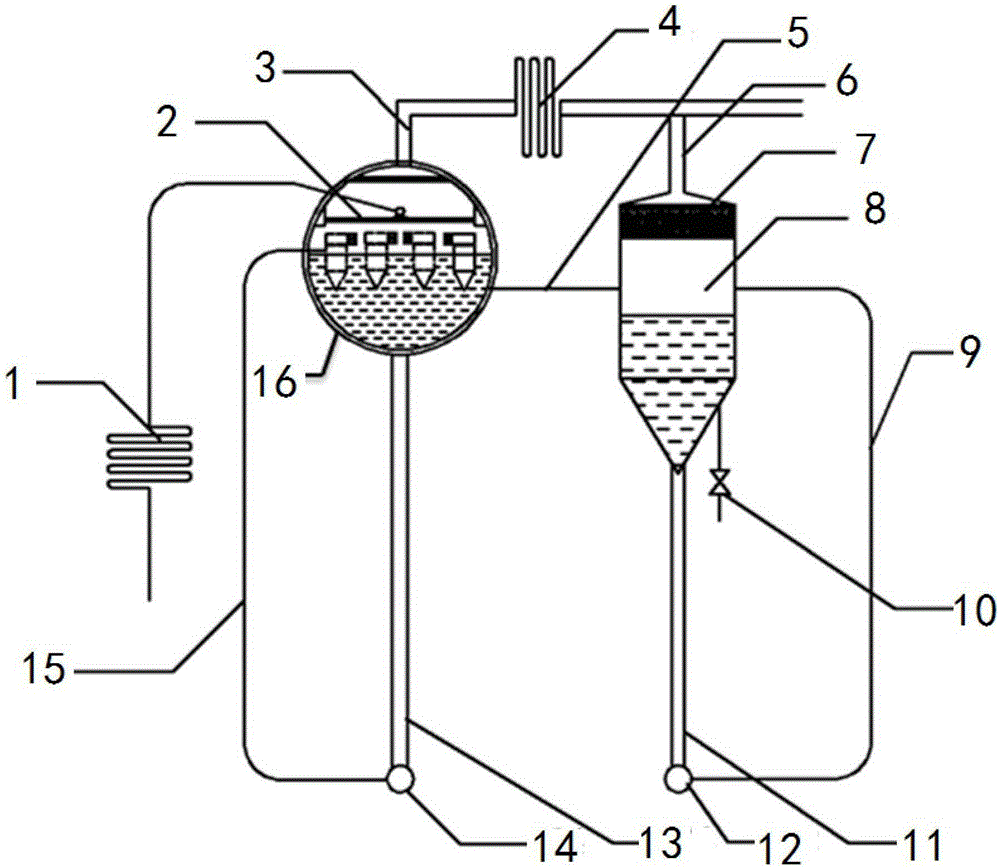

[0028] Embodiment 1: see figure 1 , high-salt boiler feed water superheated steam generation device for segmental evaporation, mainly including economizer 1, steam cleaning device 2, steam drum outlet pipe 3, superheater 4, salt section connecting pipe 5, salt section steam outlet 6, corrugated plate 7. Salt section cyclone 8, salt section ascending pipe 9, salt section sewage discharge 10, salt section descending pipe 11, salt section distribution header 12, clean section descending pipe 13, clean section distribution header 14, clean section ascending pipe 15 And net section steam drum 16.

[0029] The lower part of the salt section cyclone 8 is connected to the salt section sewage discharge 10; the bottom of the salt section cyclone 8 is connected to the salt section downcomer 11, the salt section downcomer 11 is connected to the salt section distribution header 12, and the salt section distribution header 12 is connected to the salt section The riser pipe 9, the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com