Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve steelmaking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for smelting vanadium iron from calcium vanadate

A production of ferrovanadium concerned with calcium vanadate is carried out by smelting calcium vanadate, Al and ferrous powder at weight ratio of 100: (23-28): (23-27). The said calcium vanadate is selected from m-calcium vanadate, p-calcium vanadate or o-calcium vanadate, one of them at least, with V content of 24-43%. It has high recovery rate and no wastewater pollution.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

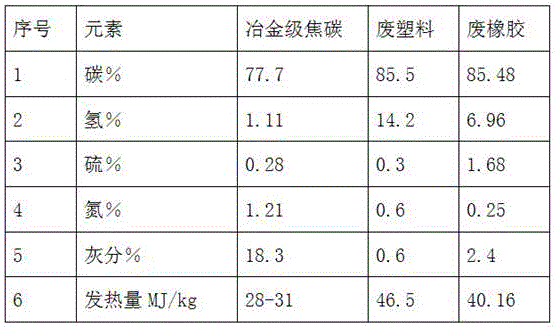

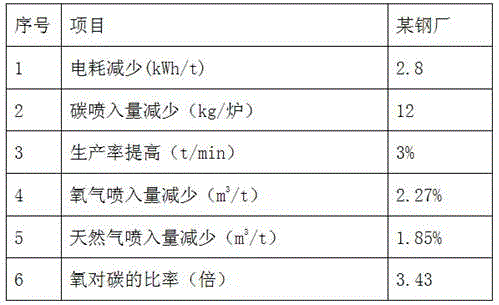

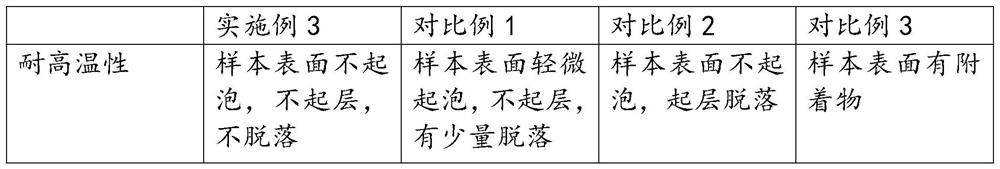

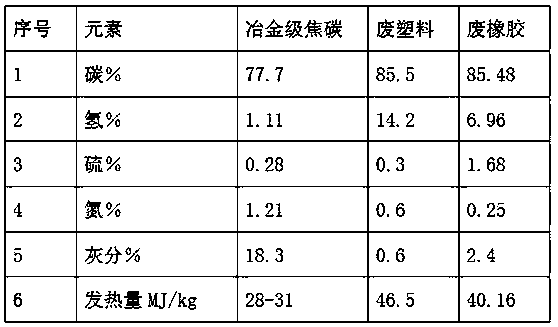

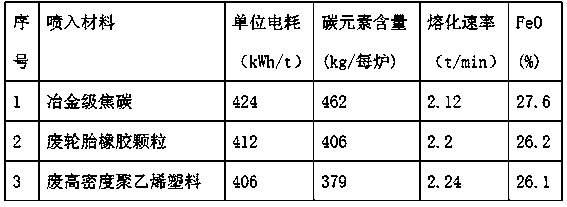

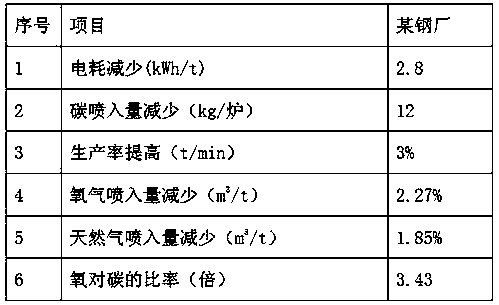

Method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber

ActiveCN106350635ASolve pollutionReduce pollutionElectric furnaceProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber, wherein the steps are as follows: The waste plastic and the waste rubber are to be crushed. When the temperature of the slag reaches 1600-1650oC and the limestone is completely dissolved, the pulverized waste plastic and waste rubber and metallurgical grade coke are injected into the slag. At this time, there is a large amount of FeO in the slag layer, and then FeO is reduced by waste plastics and waste rubber and C in metallurgical grade coke to produce Fe and CO gas, and CO gas is trapped by slag to form foam slag. In order to produce a large amount of foaming slag, oxygen-enriched operation is carried out for feeding oxygen. When the O2 content in the slag exceeds the CO equilibrium curve, excessive CO gas is generated. After the CO gas is captured by the slag, a large amount of foam slag is formed. By mixing the waste plastics, waste rubber and metallurgical grade coke, the foaming slag is characterized by improvement of the electric arc furnace steelmaking efficiency, cost reduction of electric arc furnace steel and less environmental pollution.

Owner:HENAN TAIHANG QUANLI HEAVY IND

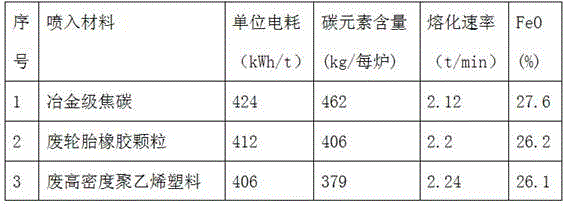

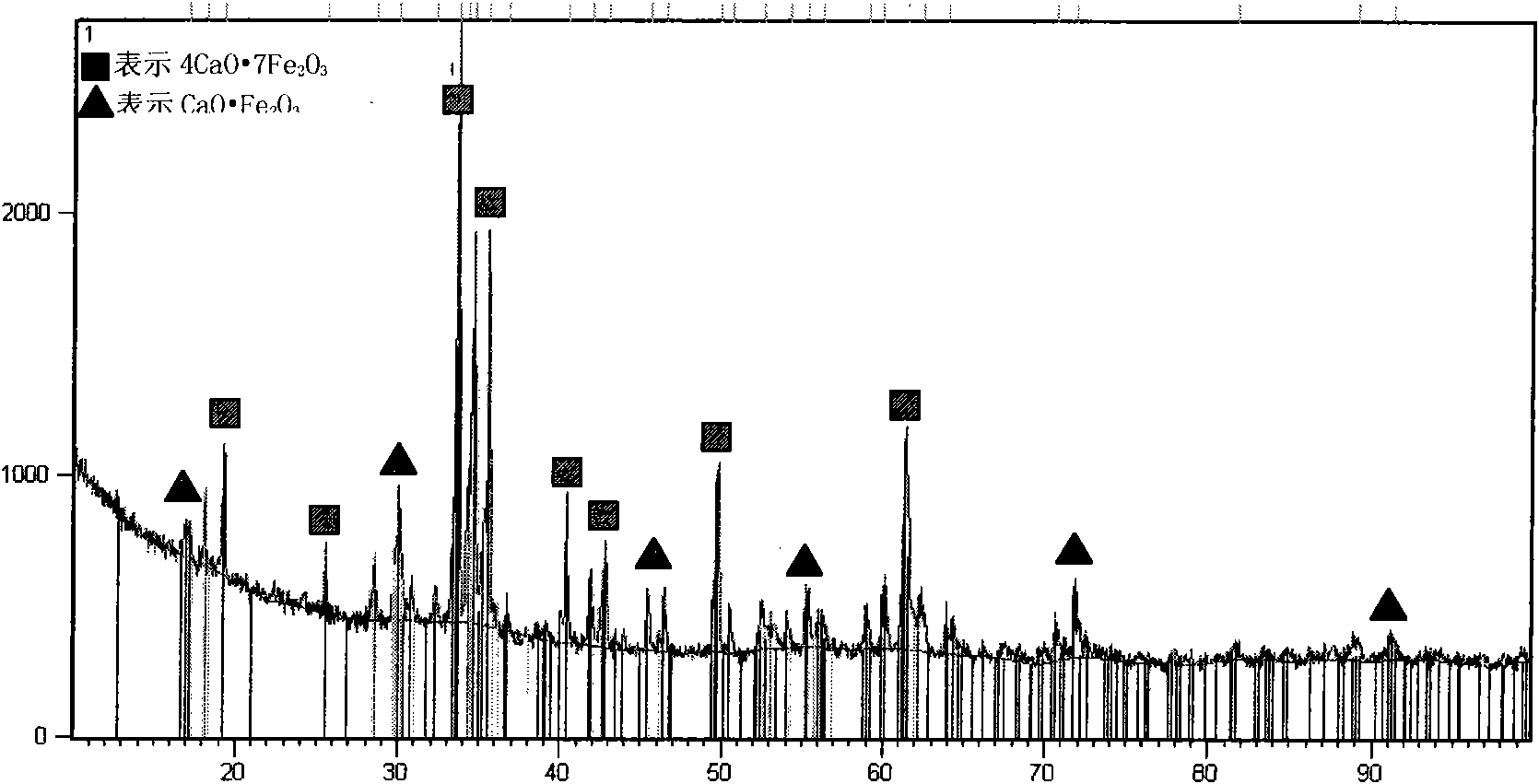

Fluxing agent for smelting steel as well as preparation and use methods thereof

InactiveCN102146500AOriginalityLow melting pointManufacturing convertersProcess efficiency improvementCupola furnaceMassicot

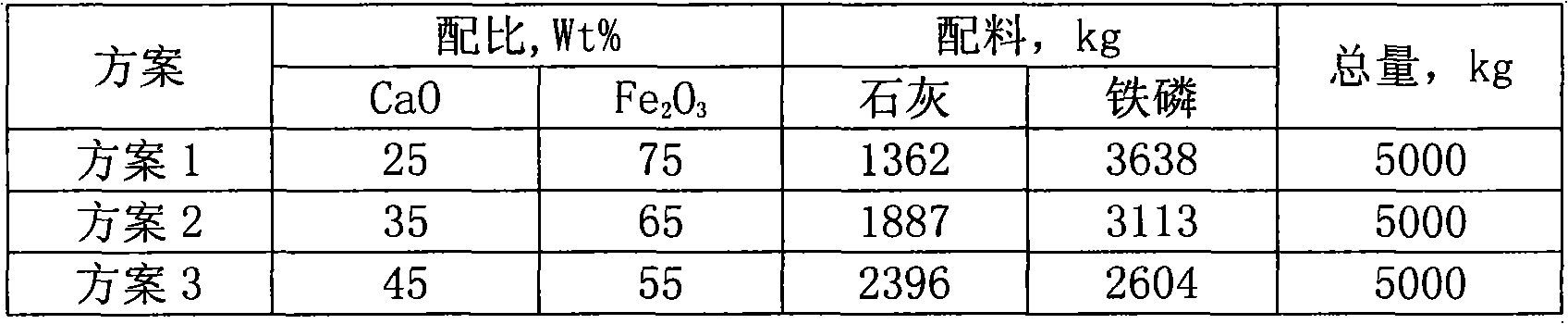

The invention discloses a fluxing agent for smelting steel as well as preparation and use methods thereof. The fluxing agent comprises the following components by weight percent: 70%-90% of 4CaO 7Fe2O3, 5%-20% of CaO Fe2O3, 1%-5% of SiO2, 0-3% of Al2O3, 0-3% of MgO and 0-5% of impurities. The preparation method comprises the following steps: evenly mixing an iron-containing waste material and a CaO-containing lime material in a ratio of ferric oxide to calcium oxide of 55%-75% to 25%-45%; pressing to form a sphere-shaped mixture with a diameter of phi 30-60mm; putting the sphere-shaped mixture in a cupola furnace for smelting, wherein the smelting temperature is controlled to 1200-1300 DEG C; in the smelting process, discharging a premelting material once per 8-12 minutes, and crushing the cooled premelting material in to blocks with a diameter of 40 mm below. The fluxing agent is used in a converter and a finery, and the addition amount of the fluxing agent is 0.3%-0.5% of loading amount of metals; and the fluxing agent is added once along with the first batch of slagging materials or is added along with the slagging materials in batch. The fluxing agent has the advantages of low melting point and good continuous slagging effect, can be used for alleviating corrosion on furnace lining and improving quality of molten steel, is beneficial to environment conservation, and the like.

Owner:ANGANG STEEL CO LTD

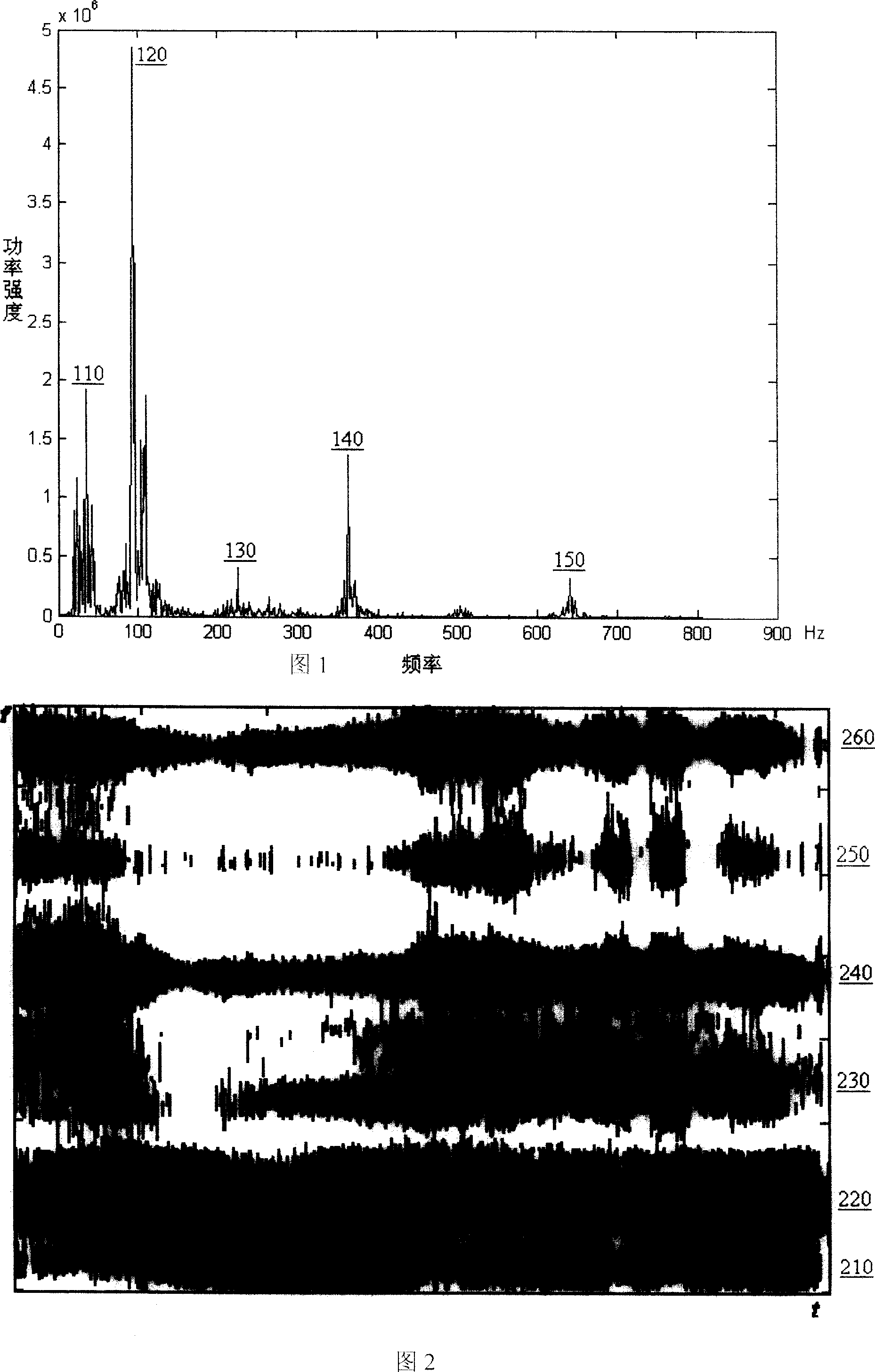

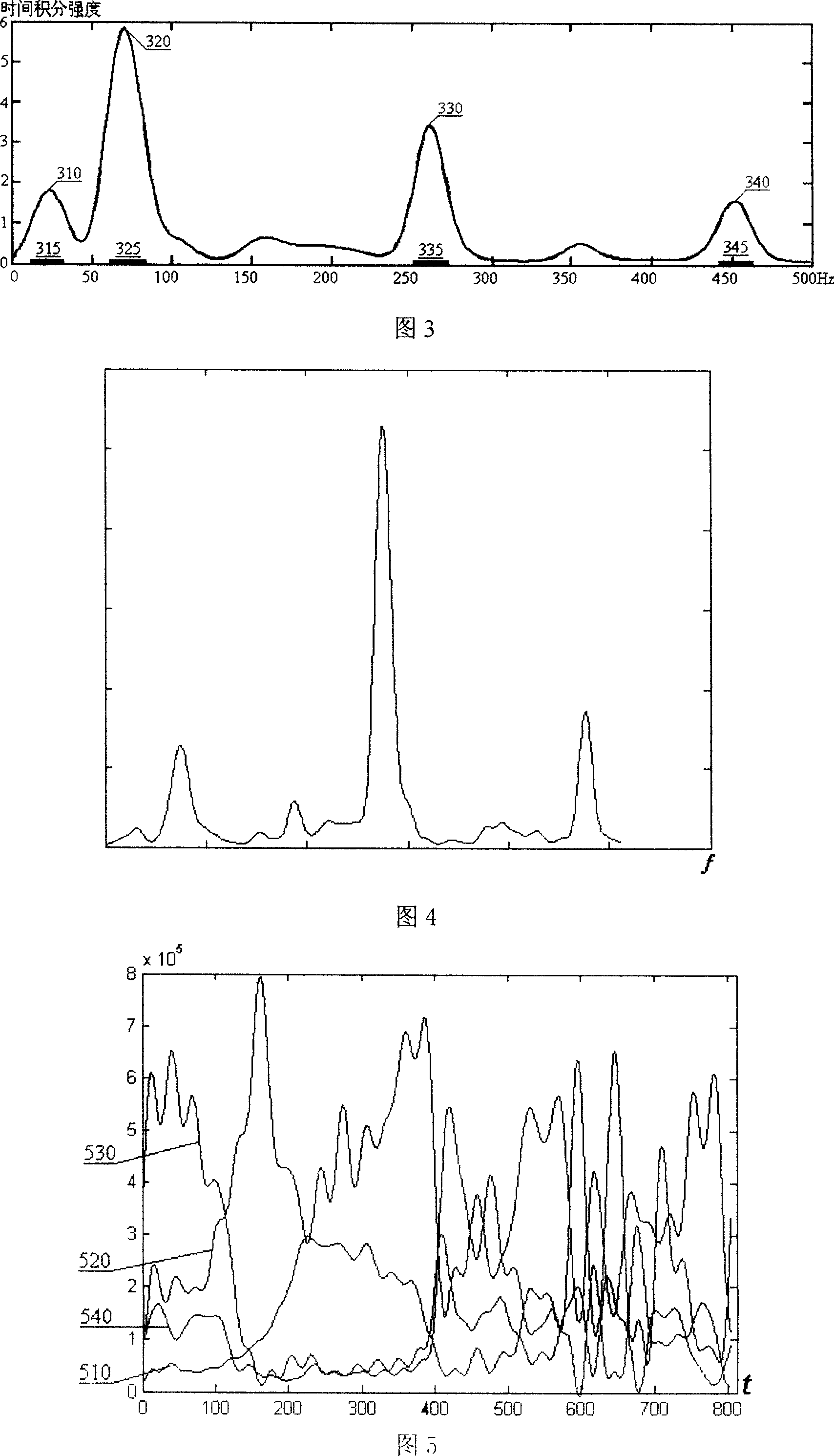

Method for investigating noise character of converter steelmaking blowing slag-making

InactiveCN101000326AShorten the steelmaking cycleImprove steelmaking efficiencyUltrasonic/sonic/infrasonic wave generationProcessing detected response signalSteelmakingUltimate tensile strength

The invention discloses converter steel and slag making air refining noise feature detecting method. It includes the following steps: sampling air refining noise; calculating out the data reflected the slag making state to guide steel making; using Blackman window corrected Welch arithmetic to compute power spectrum; finding out each feature frequency band and its main one to confirm positive and negative ones; processing linear combination for each feature frequency band strength to gain the data reflected current slag making to guide frequency slag making, judging spurting, and dry returning. The result is more exact.

Owner:SHANDONG JIANZHU UNIV

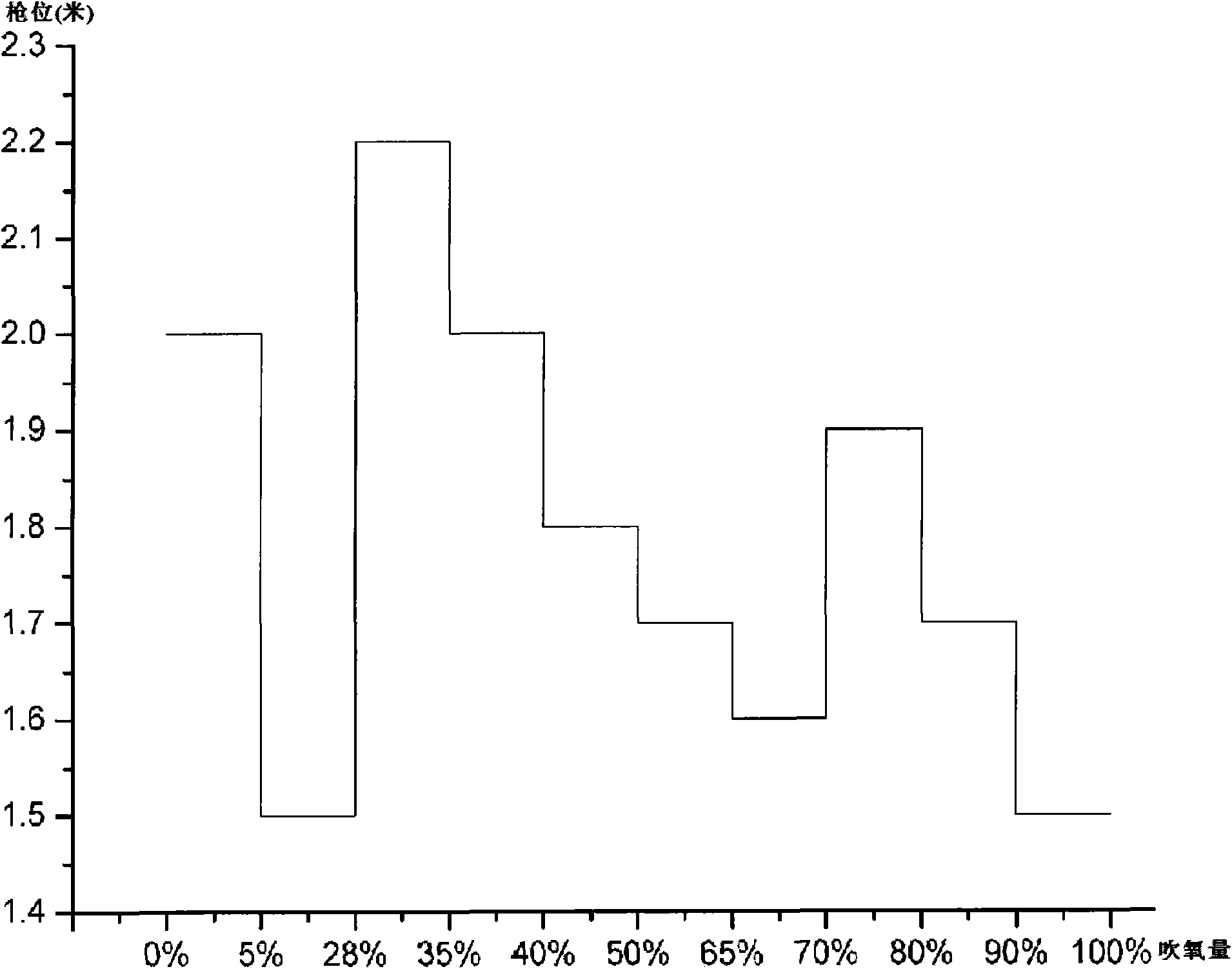

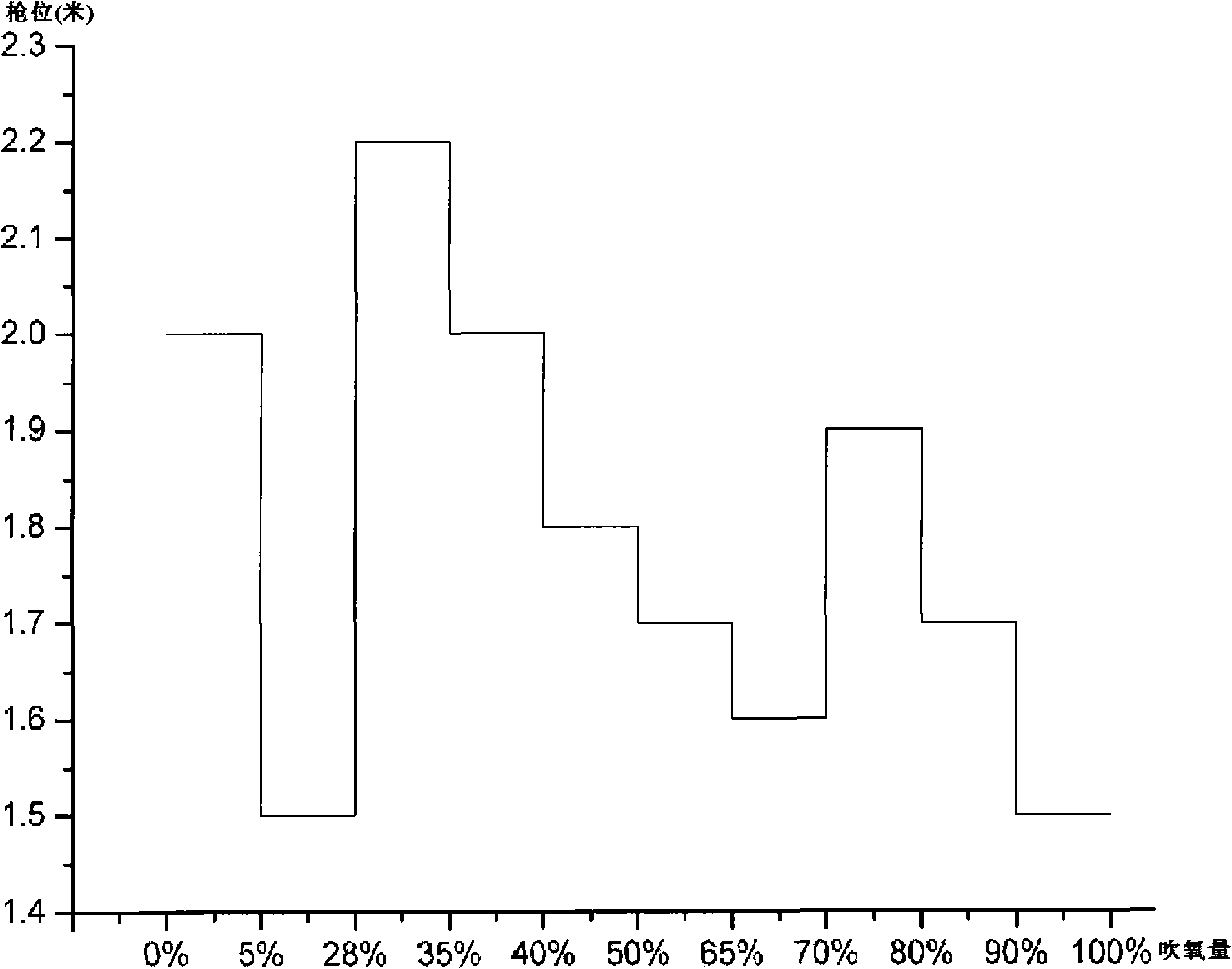

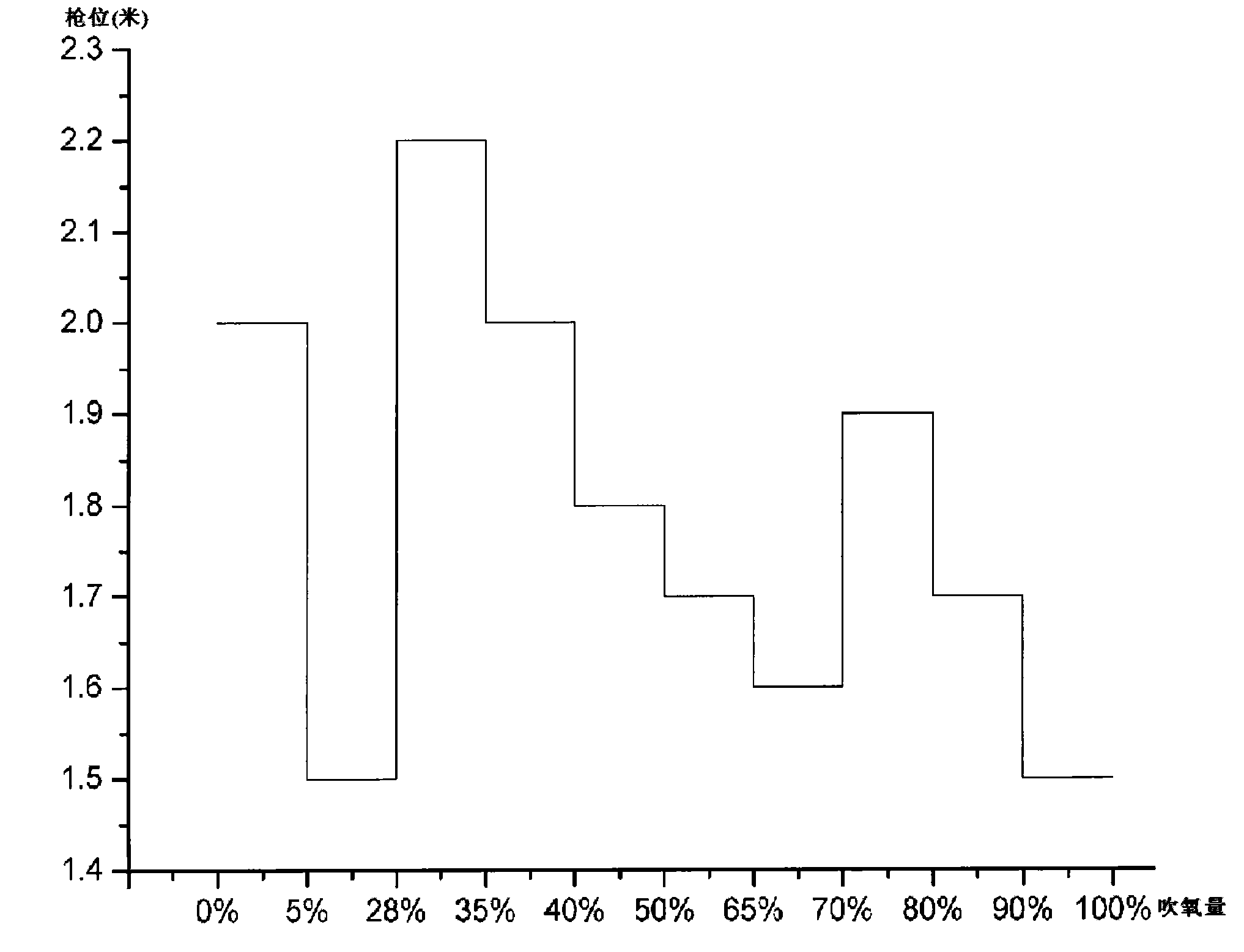

Oxygen top blown converter steel making method

InactiveCN101575656APrevent splashPrevent re-dryingManufacturing convertersHigh magnesiumSteelmaking

The invention relates to an oxygen top blown converter steel making method, comprising the following steps: the steel material is added to a converter, oxygen is blown into the converter by an oxygen lance and auxiliary materials are added into the furnace by stages in the process of oxygen blowing; wherein the steel material comprises semisteel; lance position of the oxygen lance moves within 1.5-2.2m above molten steel liquid surface in the converter, wherein blowing beginning lance position is 1.95-2.05m, blowing lance position is 1.5-2.2m and catch carbon lance position is 1.7-1.75m; wherein, the auxiliary materials comprise compound slag, lime and high-magnesium lime; in every ton of semisteel, 17-20kg of the compound slag is used, 30-34.5kg of lime is used, 30-34.5kg of high-magnesium lime is used, a total of 43-53 cubic meters of oxygen is blown into the furnace; with the total content of the blown oxygen as a benchmark, the first batch of auxiliary materials are added when the oxygen blowing content is 0.8-2%; with the method of the invention adopted, steelmaking time can be reduced and slag splashing and drying can be effectively avoided in the process of steelmaking.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Method for smelting ultra-low carbon steel

ActiveCN106929633AIncrease temperatureHigh target temperatureManufacturing convertersLiquid steelOxygen

The invention discloses a method for smelting ultra-low carbon steel. The method comprises a desulfurization procedure, a converter blowing procedure, an RH vacuum treatment procedure and a continuous casting procedure. After converter blowing, the temperature of tapping is 1680 DEG C-1700 DEG C, then ferroaluminum is added into liquid steel so that the liquid steel is subjected to preliminary deoxygenation; then the temperature is measured, oxygen activity is determined, and the liquid steel is fed with an aluminium wire according to a determined oxygen activity result, so that the oxygen activity is fine-tuned, and it is ensured that the oxygen activity is at 550 ppm-650 ppm; and the liquid steel meeting conditions enters the RH vacuum treatment procedure directly. A high target temperature of the converter tapping, with the partial ferroaluminum deoxygenation conducted after the converter tapping, enables the liquid steel to be kept at a high temperature level, and the temperature level meets the requirement for the temperature when the liquid steel enters the RH vacuum treatment procedure, so that an existing electric heating procedure is omitted; and the liquid steel can enter the RH vacuum treatment procedure directly, so that energy consumption in the steel making process is reduced greatly, and steel making efficiency is enhanced effectively after the heating procedure is omitted.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

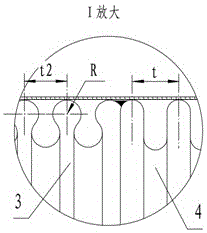

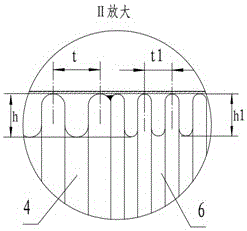

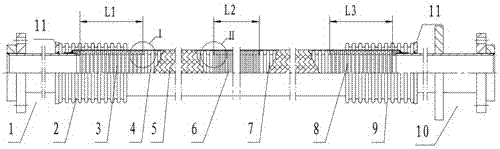

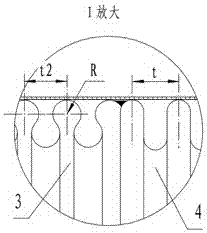

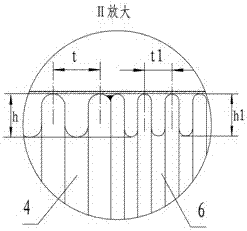

Oxygen blowing metal hose long in service life

ActiveCN105673980AExtended service lifeImprove flexibilityPipeline expansion-compensationWave shapeEngineering

An oxygen blowing metal hose long in service life comprises a corrugated pipe, and a first joint and a second joint are arranged at the two ends of the corrugated pipe; the outer side of the corrugated pipe is wrapped with a metal net body, and the corrugated pipe is of a five-segment type structure formed by sequentially connecting a first pressure-resisting segment, a first transition segment, a high-flexibility segment, a second transition segment and a second pressure-resisting segment; the first pressure-resisting segment and the second pressure-resisting segment on the two sides of the corrugated pipe are in omega shapes; and the high-flexibility segment located in the middle portion of the corrugated pipe is in a deep-U-shaped wave shape, and the first transition segment and the second transition segment are in U-shaped wave shapes. According to the characteristics that the two sides of the corrugated pipe are bad in working condition and large in bearing pressure, the pressure-resisting segments in the omega shapes are arranged on the two sides of the corrugated pipe; according to the characteristic that due to insufficient flexibility, the dynamic bending portion of the middle segment of the corrugated pipe is prone to being damaged, the middle segment of the corrugated pipe is designed to be the high-flexibility segment in the deep-U-shaped wave shape; and through the improvement, the service life of the oxygen blowing metal hose is greatly prolonged, the maintenance and replacement time is greatly shortened, and improvement of steel smelting efficiency is facilitated.

Owner:石家庄巨力科技股份有限公司

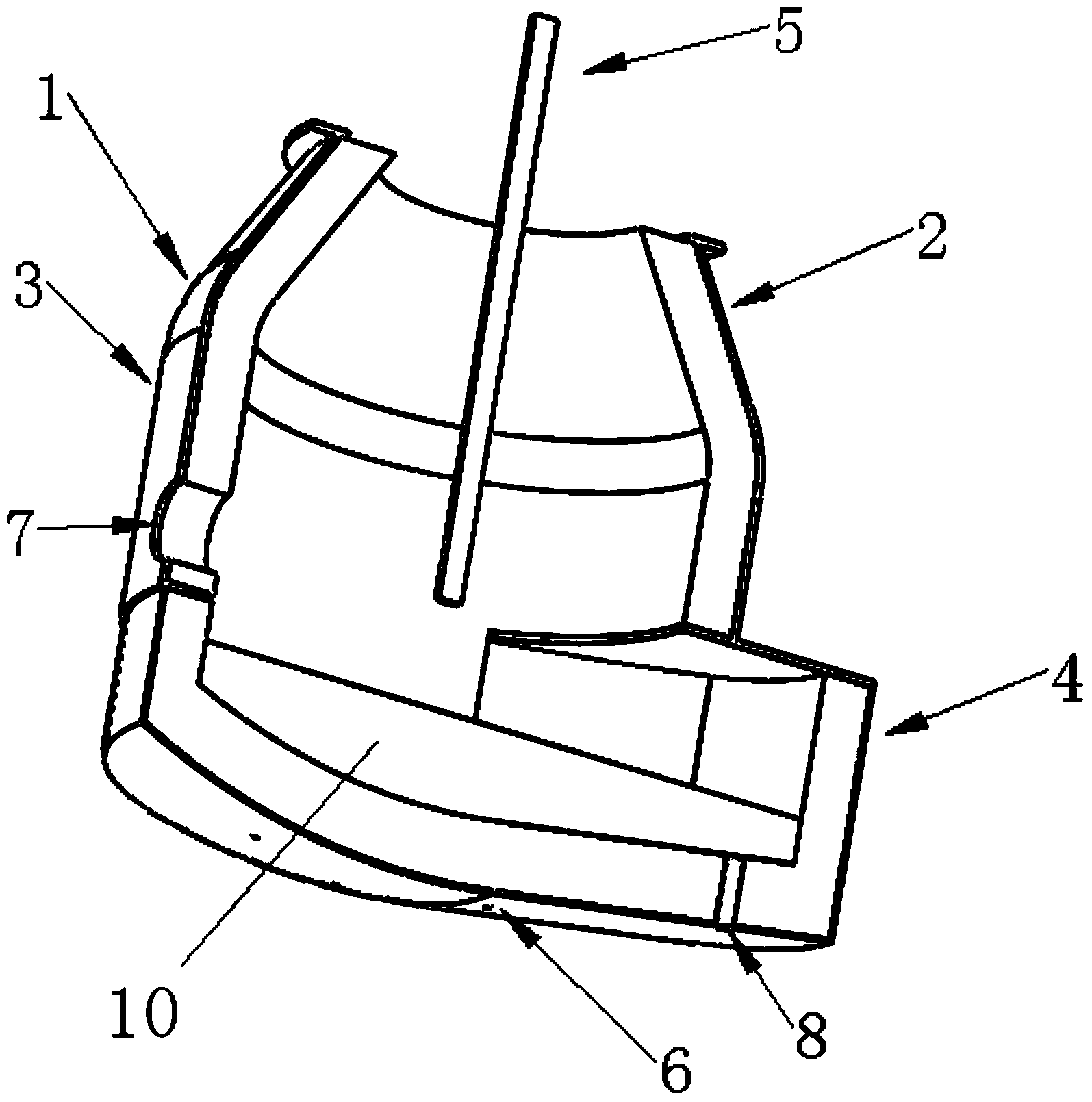

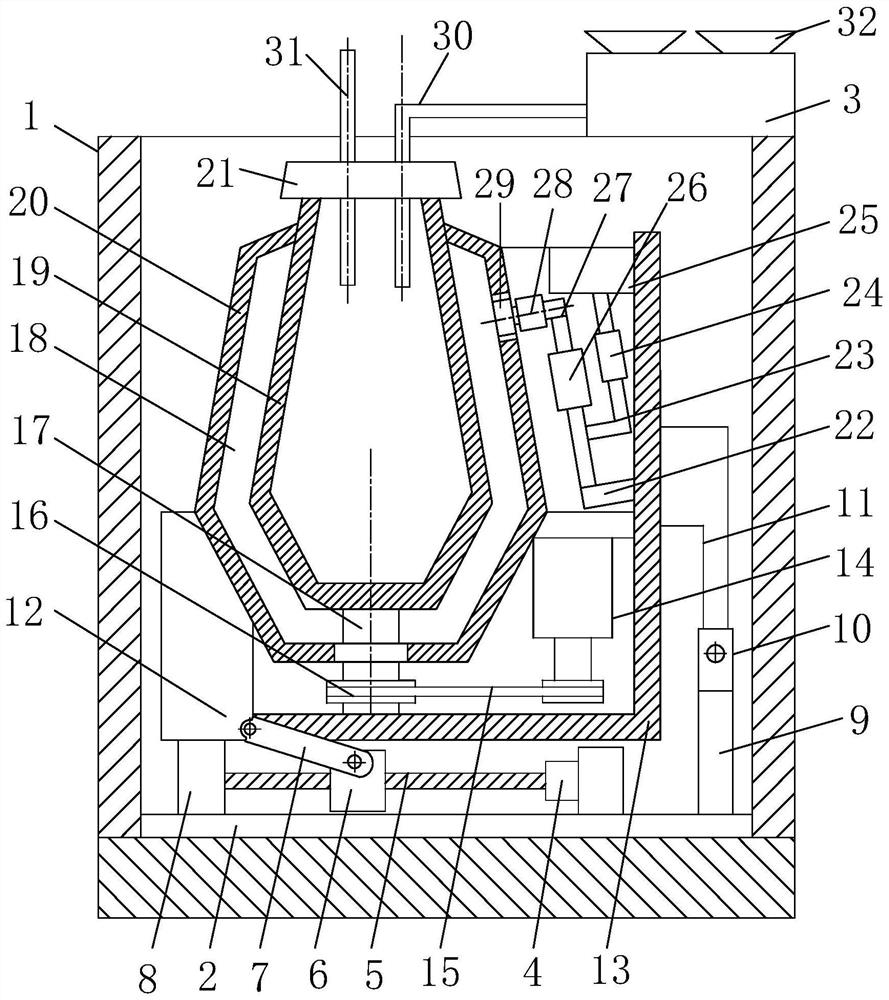

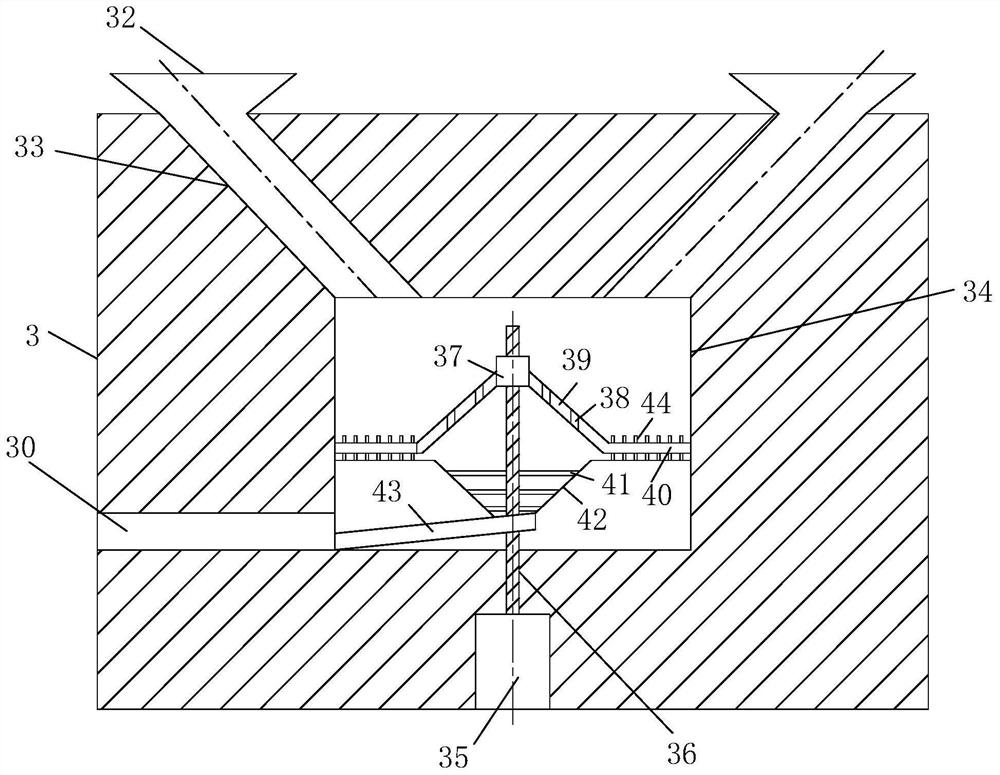

High-efficiency and energy-saving converter

ActiveCN110157850AReduce consumptionIncrease contactManufacturing convertersBackflow prevention deviceEngineering

The invention discloses a high-efficiency and energy-saving converter. The high-efficiency and energy-saving converter comprises a converter body. A converter body port lantern ring is fixedly installed on the upper surface of the converter body. An oxygen pipe fixing base is fixedly installed on the inner side of the converter body port lantern ring. An oxygen injection pipe is arranged on the inner side of the oxygen pipe fixing base. A backflow prevention device is fixedly installed on the outer surface of the upper end of the oxygen injection pipe. An oxygen input pipe is fixedly installedon the outer surface of one side of the backflow prevention device. A converter body inner chamber is arranged inside the converter body. A rotary threaded block is arranged on the inner wall of theconverter body. A molten iron pouring nozzle is fixedly installed on the outer surface of one side of the converter body. A molten iron pouring outlet is formed in the inner side of the molten iron pouring nozzle. A pull rod connecting rod is fixed to the outer surface of the other side of the converter body. With the high-efficiency and energy-saving converter, energy consumption is reduced, theefficiency of steel making is improved, the converter body is prevented from shaking, and the converter body is more convenient to use.

Owner:浙江琰大新材料有限公司

Environment-friendly water-based large fabric for converter fettling

The invention relates to an environment-friendly water-based large fabric for converter fettling. The fabric comprises the following components in parts by weight: 80-90 parts of magnesia, 6-10 partsof binding agent, 0.5-1 part of slaked lime and 0.5-1 part of bentonite. The preparation method comprises the steps: adding water into the supplementary material, stirring to form porridge, pouring the stirred material into a position needing to be repaired in the converter, burning for 15-25 minutes at 800-1350 DEG C, and finishing the repair when the supplementary material is large and the surface material turns red. Compared with a common converter large-area fettling material, the sintering time is shortened by about 30 minutes; during sintering, no smoke, no odor and no harmful volatile matter exist, and no harm is caused to human bodies and the environment; and during sintering, gunning operation can be carried out so that the steelmaking efficiency is improved.

Owner:鞍山赛诺新材料有限公司

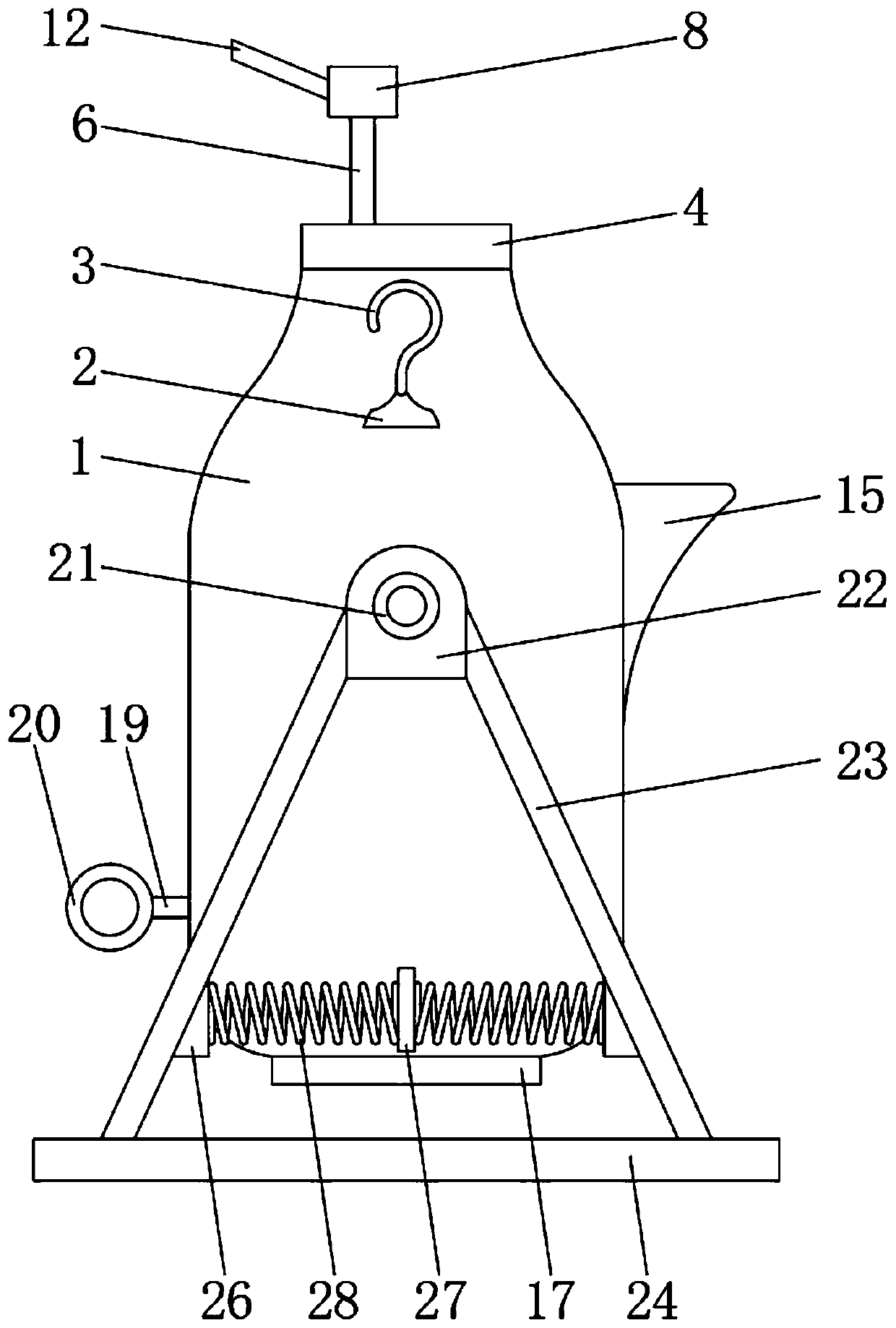

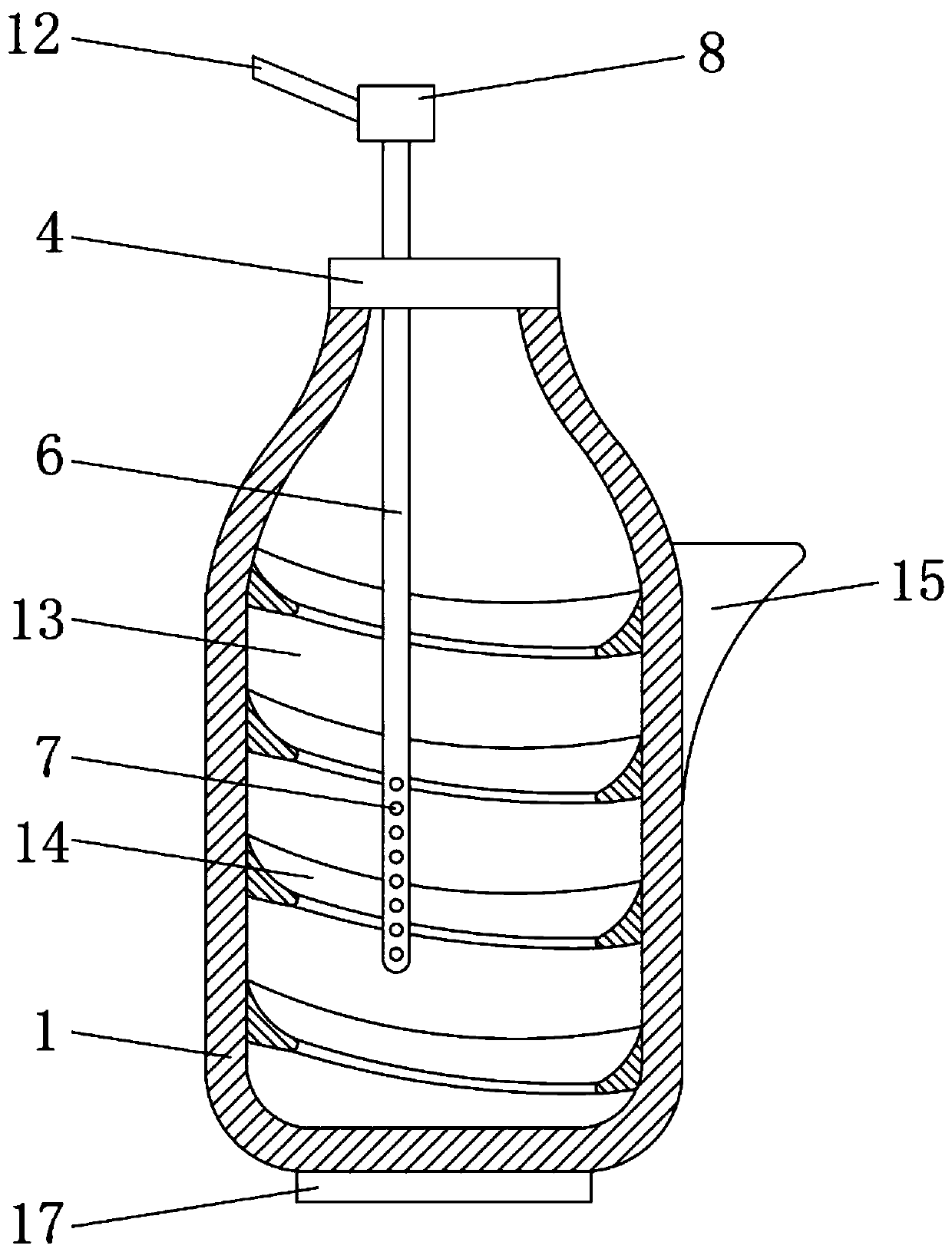

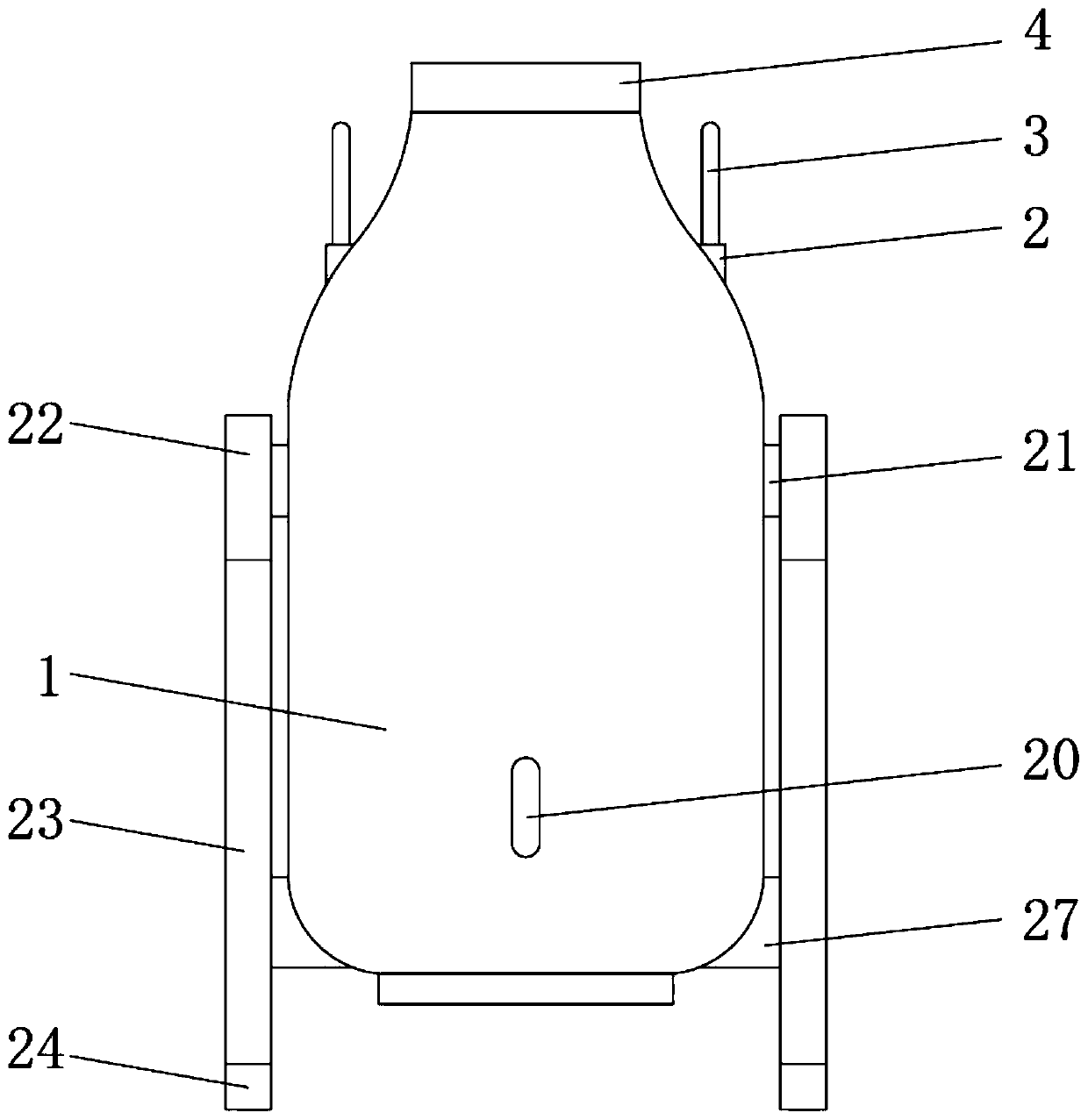

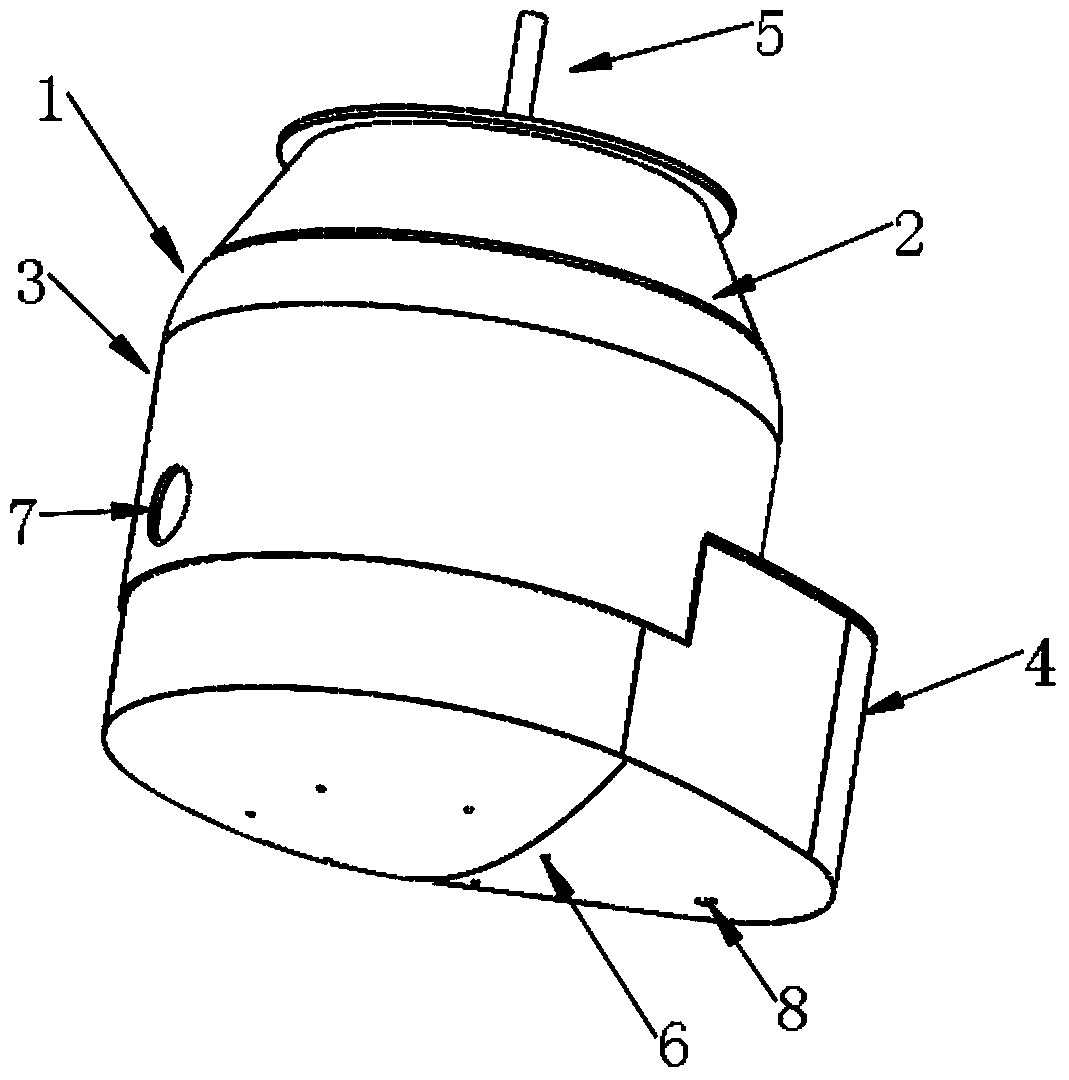

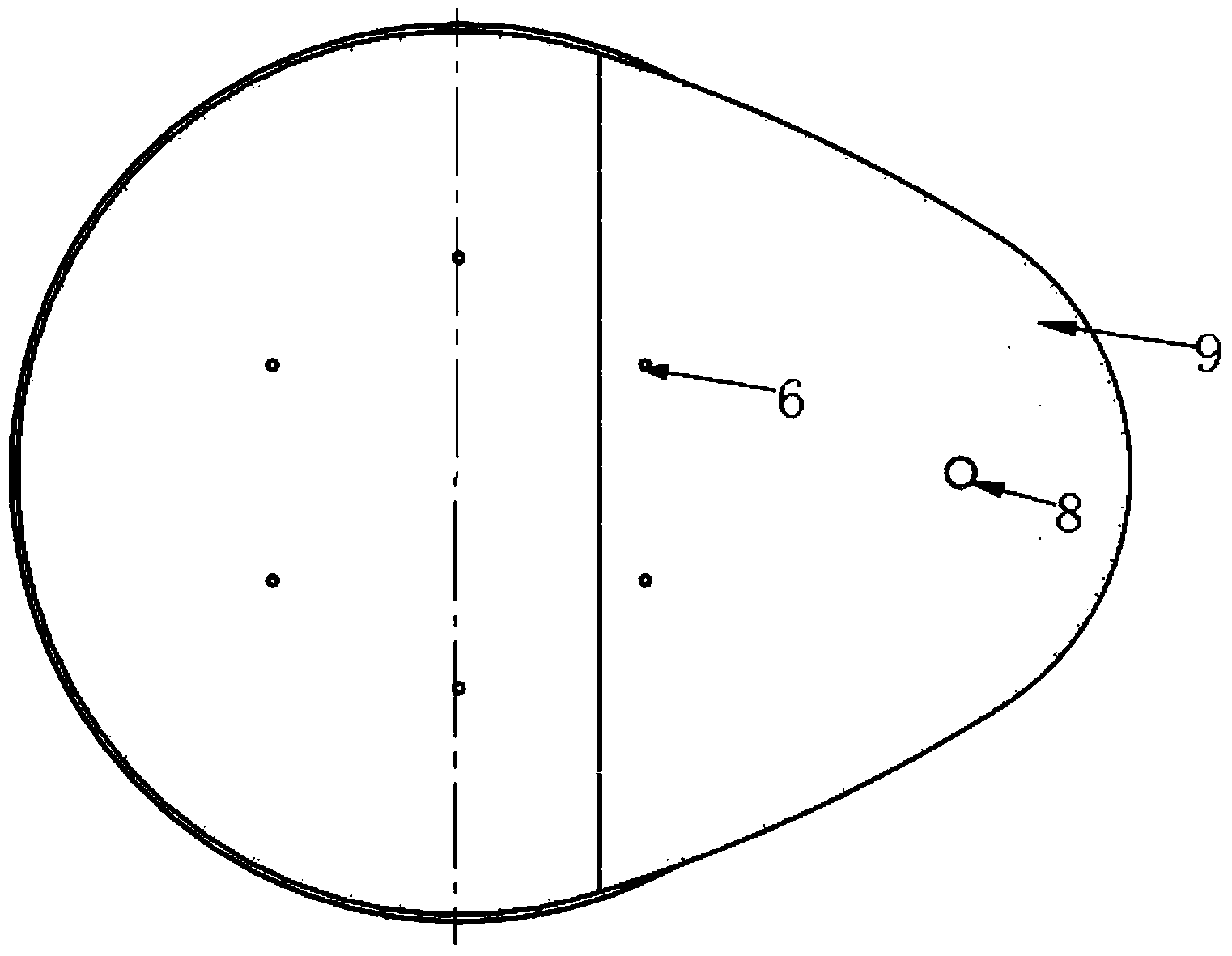

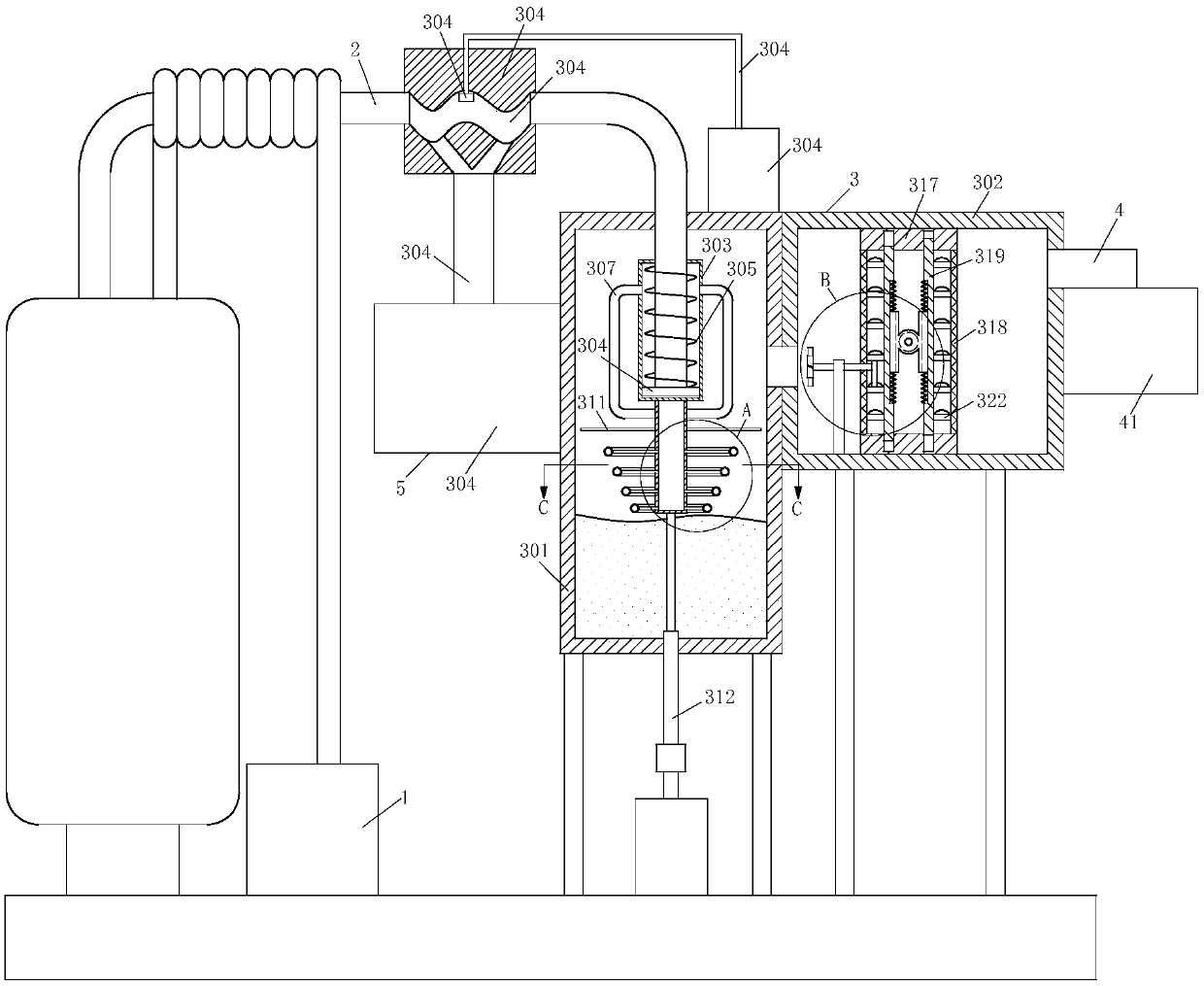

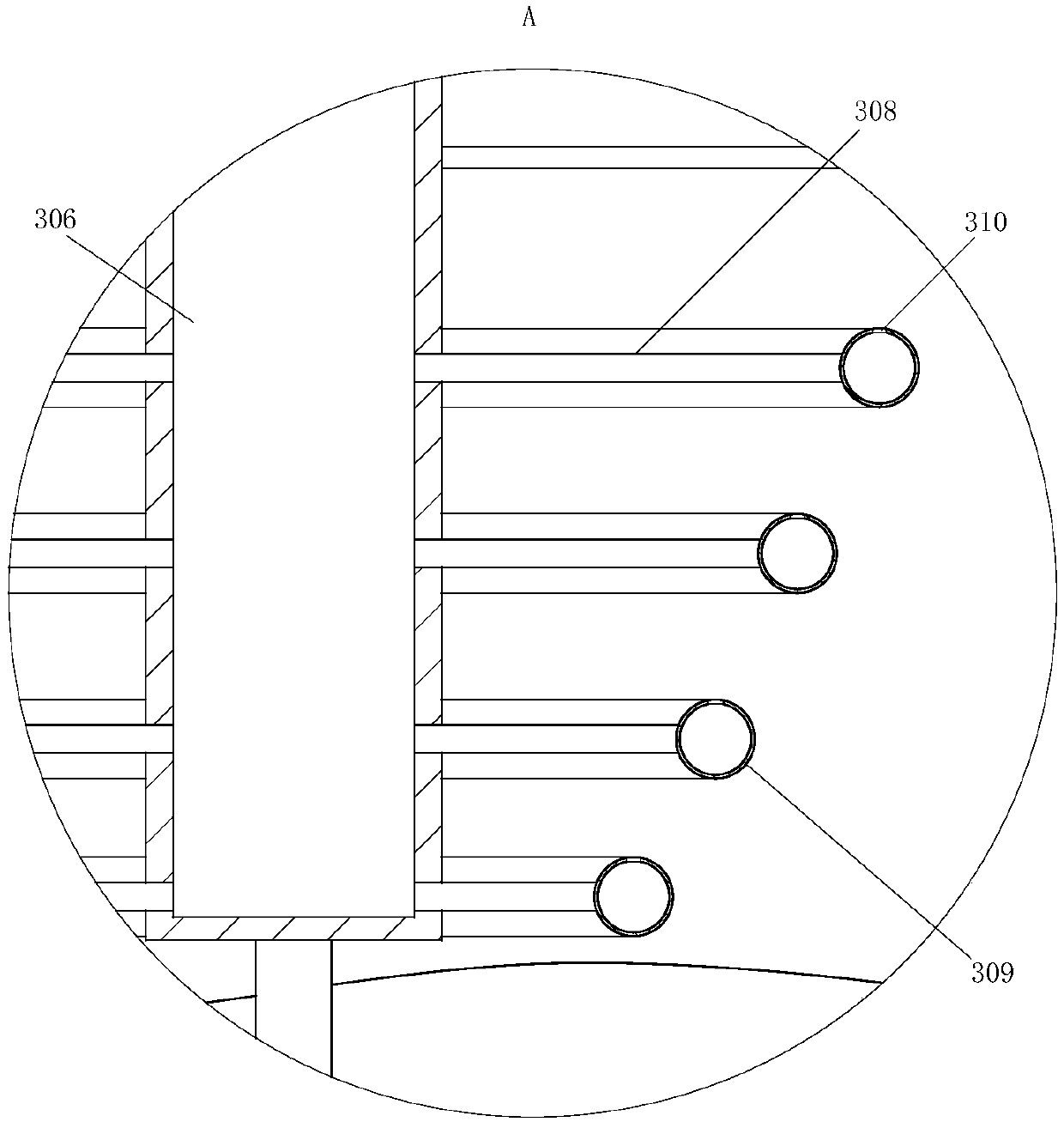

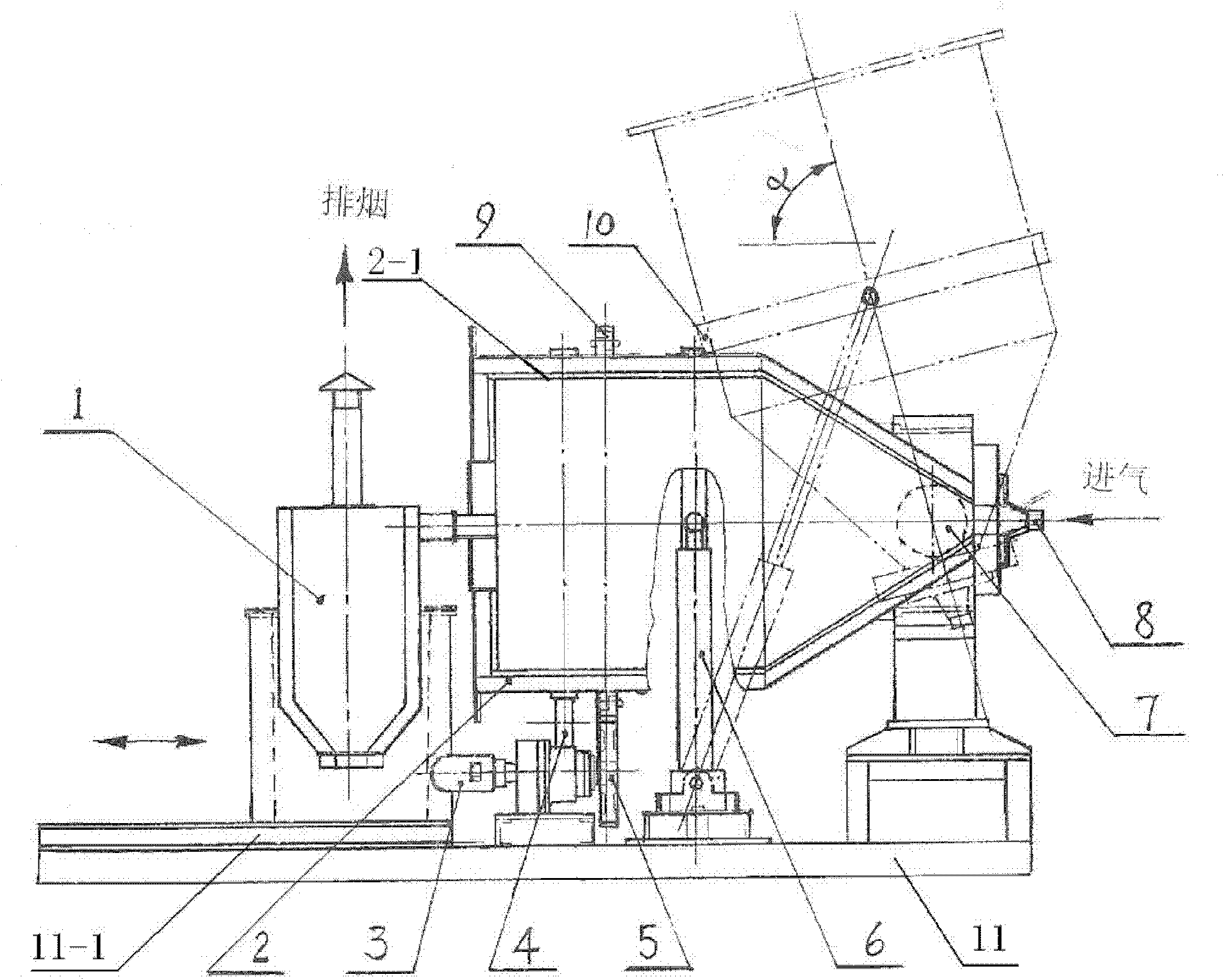

Steel-smelting furnace and smelting process

InactiveCN103952510AHigh yieldReduce consumptionProcess efficiency improvementSmelting processHeating furnace

The invention provides a steel-smelting furnace and a smelting process. The steel-smelting furnace comprises a furnace body (3) and an eccentric furnace bottom (4), wherein a slag hole (7) is formed in the furnace body (3); the projection of the center of gravity of the cross section of the eccentric furnace bottom (4) in the vertical direction deviates from the projection of the center of gravity of the cross section of the furnace body (3) in the vertical direction; the cross-sectional area of the eccentric furnace bottom (4) is larger than that of the furnace body (3); a steel outlet (8) is formed in the bottom of the eccentric furnace bottom (4). The smelting process can adopt a one-time slagging process or a two-time slagging process, and can be used for shortening the smelting time by 2-5 minutes, improving the steel smelting efficiency, realizing less slag smelting, reducing the consumption of a slagging material, reducing the consumption of a deoxidizer, improving the metal yield, and avoiding furnace slag carried out by a conventional steel-smelting furnace in steel tapping from polluting a molten steel, thereby meeting the technical requirements of efficient steel smelting.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

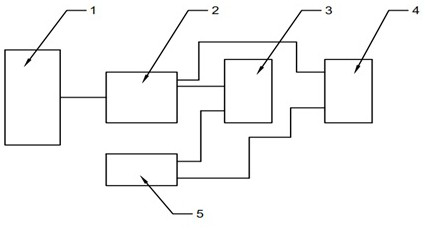

Production process method for converter steelmaking

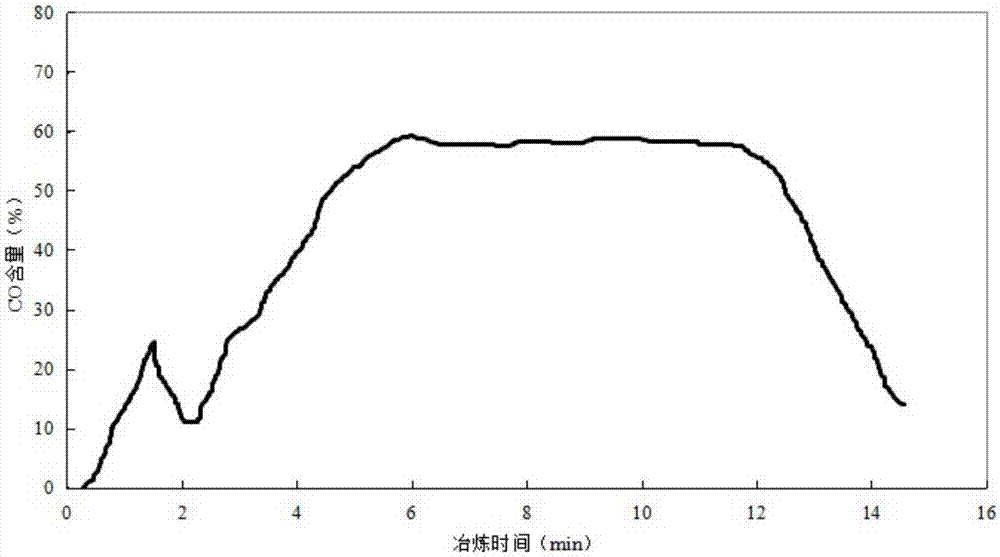

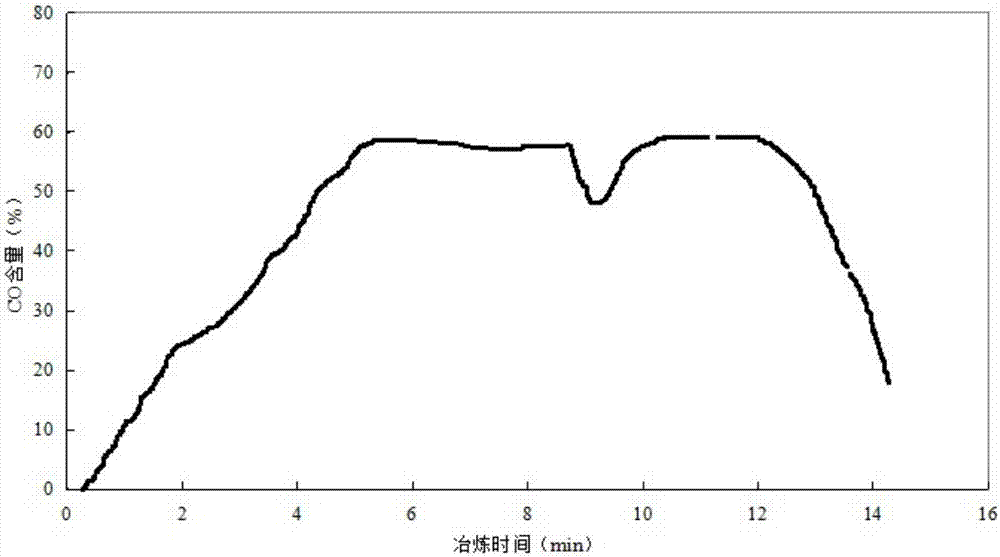

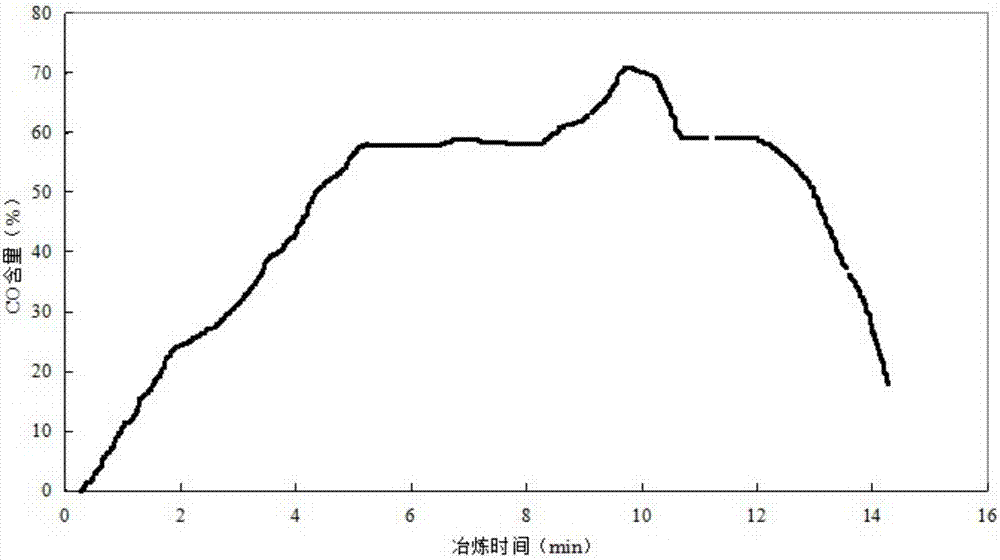

InactiveCN107385140APrevent splashPrevent re-dryingManufacturing convertersSteelmakingCommunications system

The invention belongs to the field of production processes for converter steelmaking, relates to a production process method for converter steelmaking, and mainly solves the problems of instability of carbon-oxygen reaction in a converter, and caused splashing, drying and the like in a converter steelmaking process. In the production process method for converter steelmaking, a dynamic converter steelmaking system, a data communication system and a coal gas analyzer are used, wherein the coal gas analyzer is connected with a converter flue in the dynamic converter steelmaking system through a pipe, and is used for collecting smoke in the converter flue and analyzing the content of carbon monoxide in the smoke; data are transmitted to a converter front operation platform of the dynamic converter steelmaking system through the data communication system; the trend chart of CO in the converter is drawn in real time by the dynamic converter steelmaking system; and materials in converter steelmaking are adjusted by the conventional method according to the trend chart of CO.

Owner:山西新泰钢铁有限公司

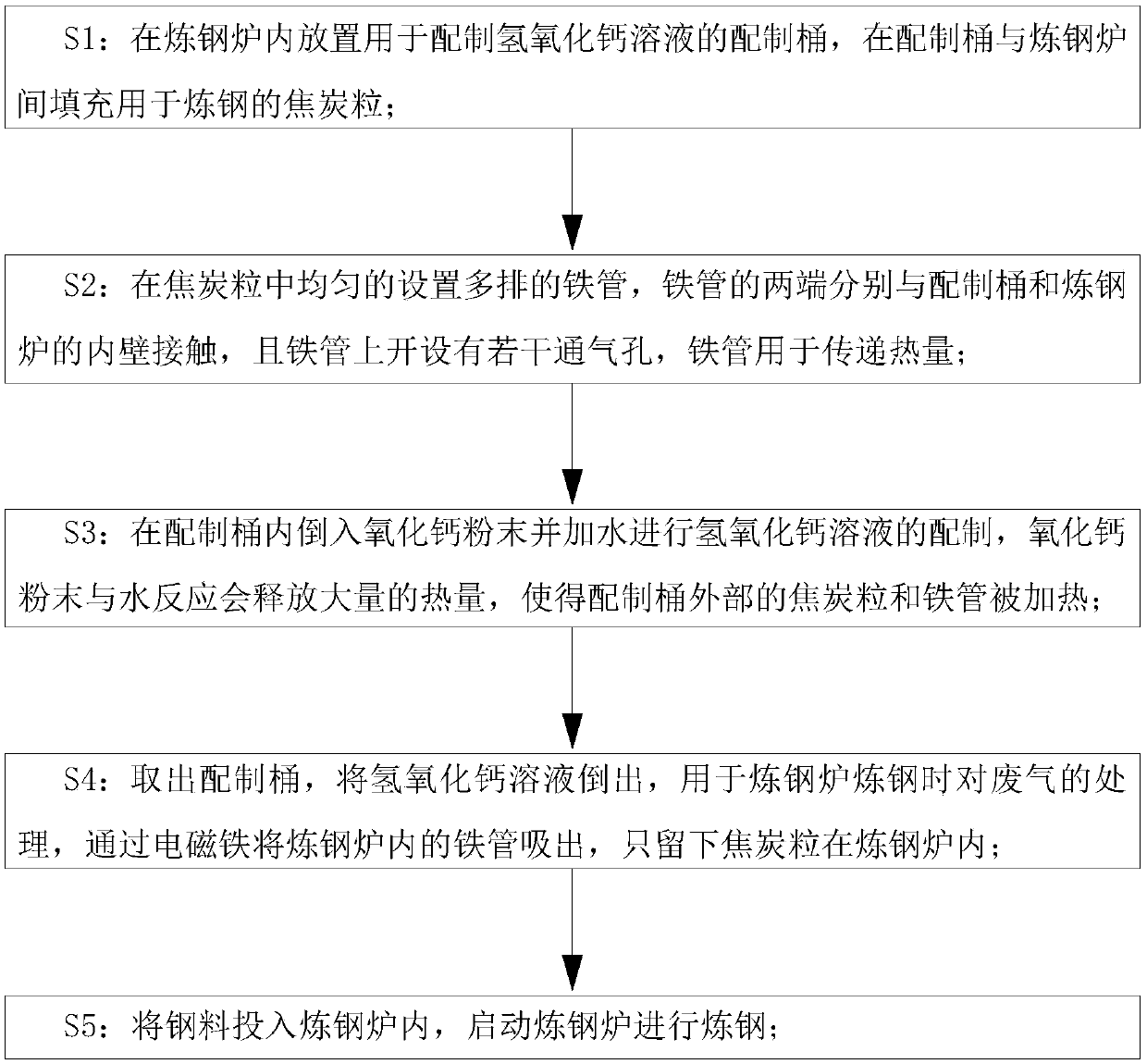

High-efficiency steelmaking process for steelmaking furnace

ActiveCN109517936AImprove steelmaking efficiencyEfficient heating and dryingIncreasing energy efficiencyWaste heat treatmentSteelmakingCALCIUM HYDROXIDE SOLUTION

The invention belongs to the technical field of steelmaking, in particular to a high-efficiency steelmaking process for a steelmaking furnace. The steelmaking furnace used in the high-efficiency steelmaking process comprises a base and a steelmaking furnace body arranged on the base; an oxygenator, a smoke exhaust pipe, a treatment absorption unit, an air outlet pipe, a motor and a controller areincluded; the controller is used for controlling the steelmaking furnace to work; the oxygenator is arranged on the base, the oxygenator communicates with the steelmaking furnace body through an oxygen conveying pipe, and the oxygenator is used for oxygenation to the interior of the furnace body; and one end of the smoke exhaust pipe is arranged at the top of the steelmaking furnace body, a preparation barrel is placed in the steelmaking furnace, and a calcium hydroxide solution is prepared in the preparation barrel. Efficient heating and drying are carried out on coke particles by using heatgenerated by preparing the calcium hydroxide solution, and the contact area between the coke particles and hot air is greatly increased, so that the coke particles are efficiently heated and dried, and the steelmaking efficiency of the steelmaking furnace is greatly improved.

Owner:临沂钢铁投资集团不锈钢有限公司

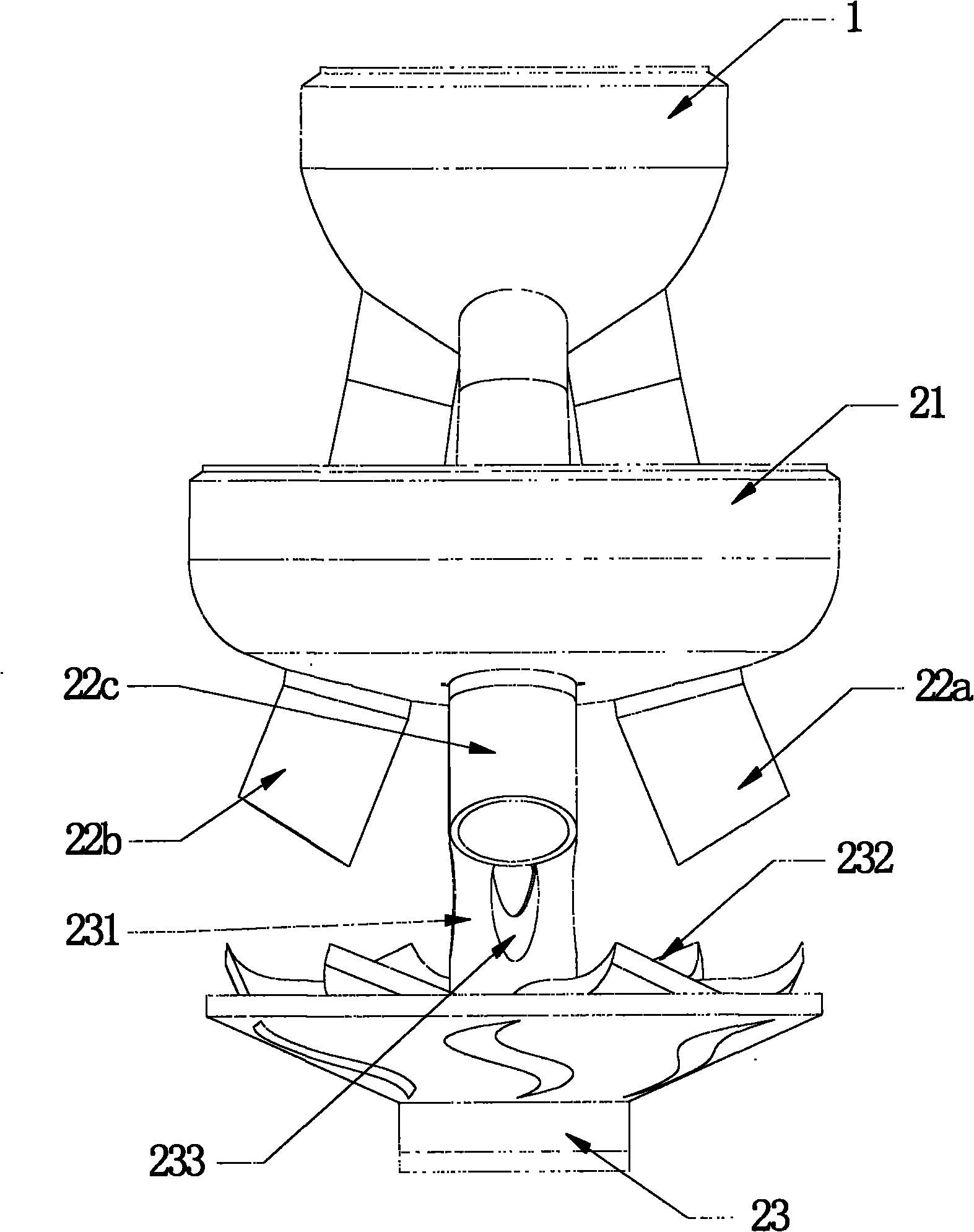

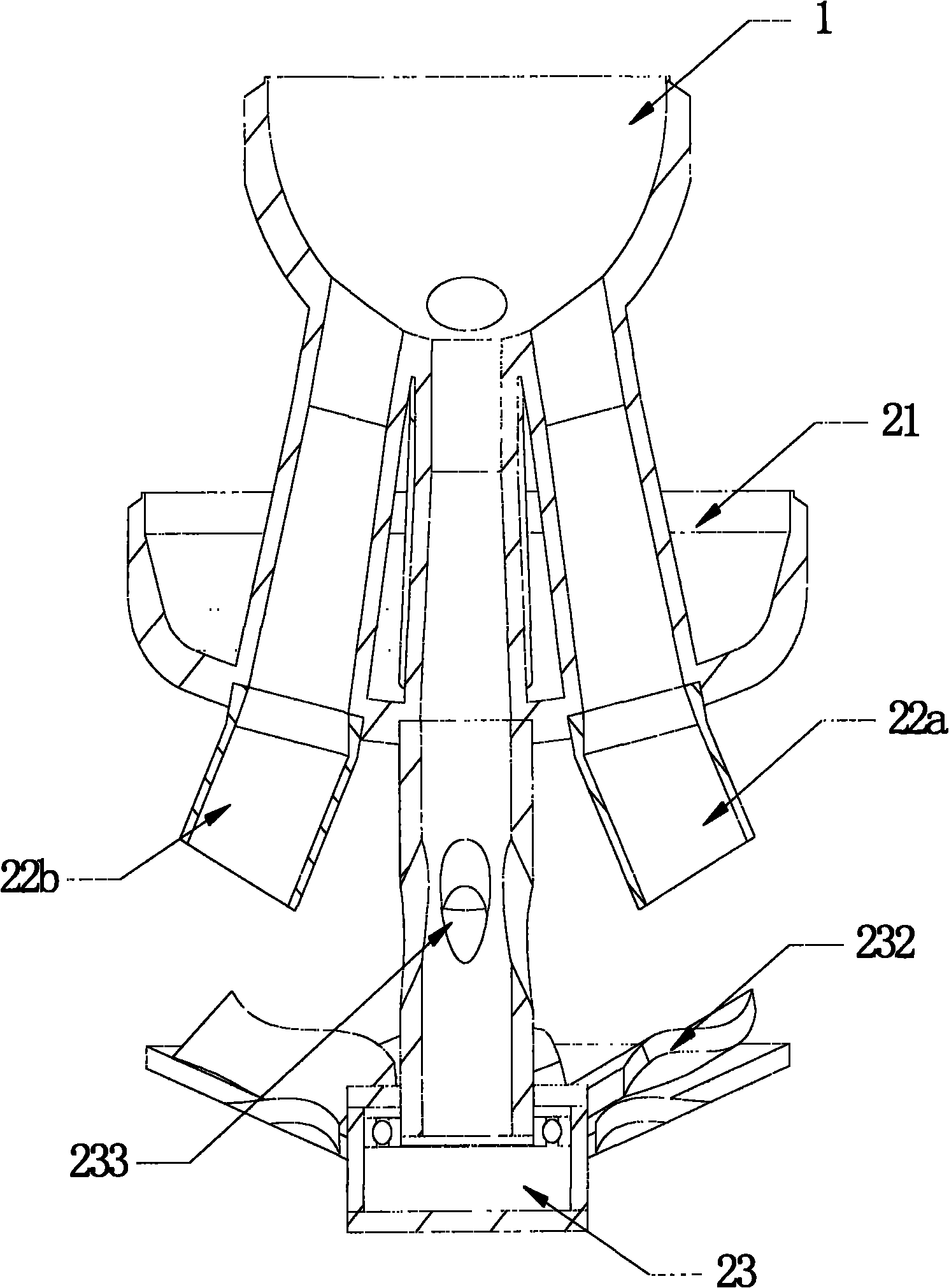

Oxygen lance spray nozzle for converter

The invention discloses an oxygen lance spray nozzle for a converter, which is assembled at the air nozzle part of the rear end of an oxygen lance, and is characterized in that the oxygen lance spray nozzle comprises a spray nozzle main body communicated with the air nozzle part, a plurality of nitrogen spray pipes detachably spliced on the spray nozzle main body and a spiral vane device, wherein a straight spray pipe and at least two side nozzles around the straight spray pipe are positioned in the center of the spray nozzle main body, the spiral vane device is a dish-shaped tray having a hollow cylinder with the rear end being closed, meanwhile, the upper end of the hollow cylinder is connected with the straight spray pipe in a sealing way, the lower end of the hollow cylinder is connected with the dish-shaped tray through a bearing, and 3 to 6 blade-shaped inclined steel sheets are arranged on the upper surface of the dish-shaped tray and rotate relative to the hollow cylinder. Through conveniently changing parts, the multifunctional oxygen lance spray nozzle can easily complete three different technological operations, greatly improves the steel-making frequency in converter steel making, relieves the labor intensity of workers, simultaneously has certain especially good effects of energy saving and environmental protection, and has wide application prospect.

Owner:SUZHOU BAOLIAN HEAVY IND

A kind of smelting method of ultra-low carbon steel

ActiveCN106929633BIncrease temperatureHigh target temperatureManufacturing convertersOxygenLiquid steel

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

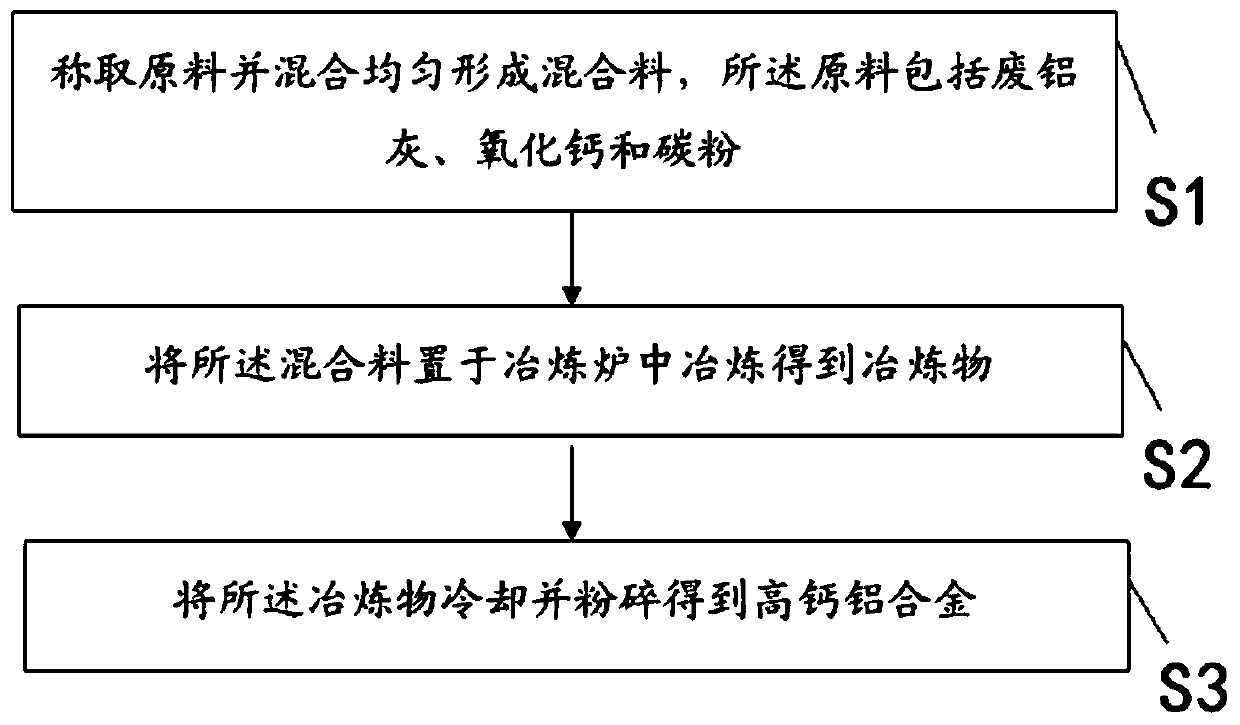

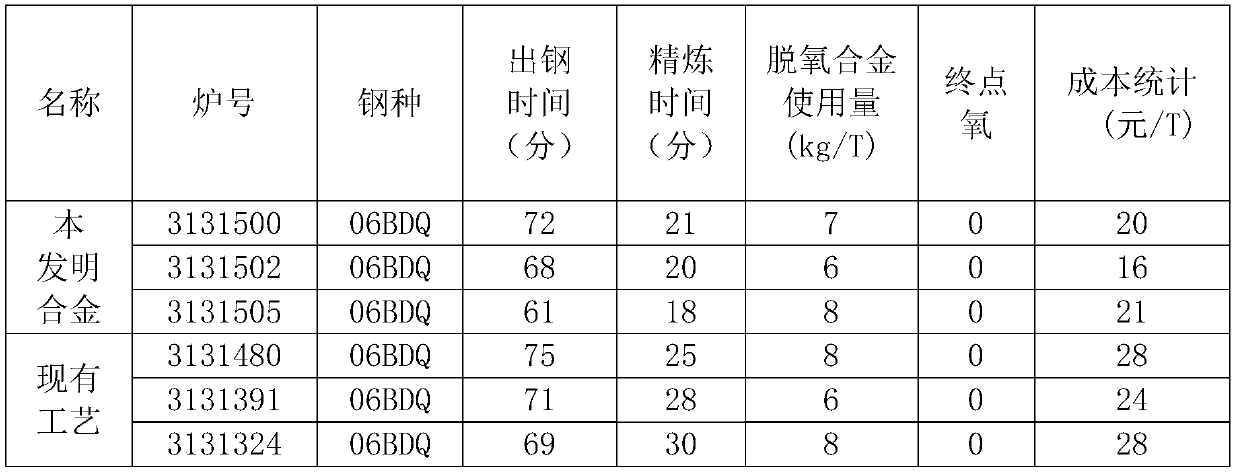

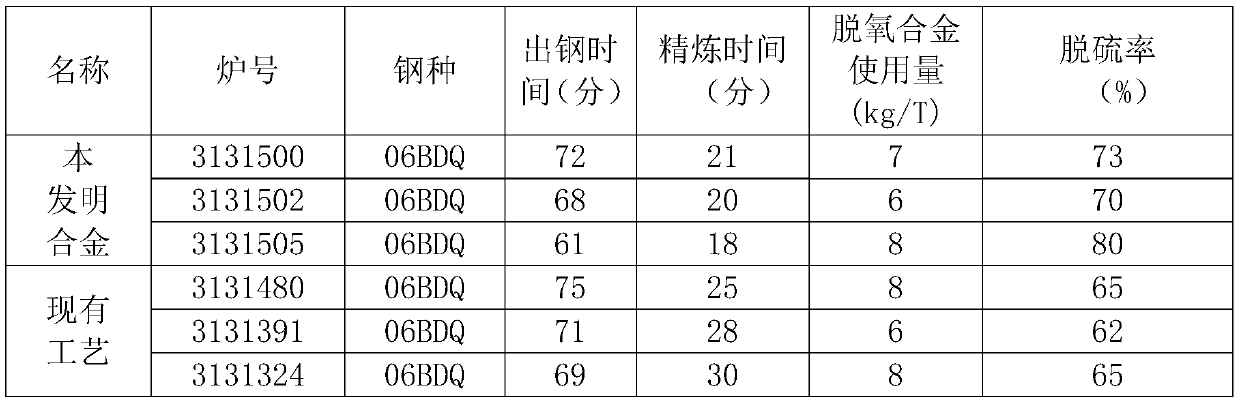

Preparation method for high calcium aluminium alloy, and high calcium aluminium alloy

The embodiment of the invention provides a preparation method for high calcium aluminium alloy, and the high calcium aluminium alloy. The preparation method comprises the steps of weighing and mixingraw materials uniformly to form mixtures, wherein the raw materials comprise aluminium scruff ash, calcium oxide and carbon powder; placing the mixtures in a smelting furnace for smelting to obtain smelting materials; and cooling and crushing the smelting materials to obtain the high calcium aluminium alloy. According to the high calcium aluminium alloy prepared with the above method, the aluminium scruff ash can be recycled, and the high calcium aluminium alloy is applied to the steel-making process; pollution can be reduced, and dust is not liable to produce at a production site; the slag forming speed is high, and the steel-making efficiency is improved; and subsequent desulfurization is not affected, and the cost is low.

Owner:肖卫学 +1

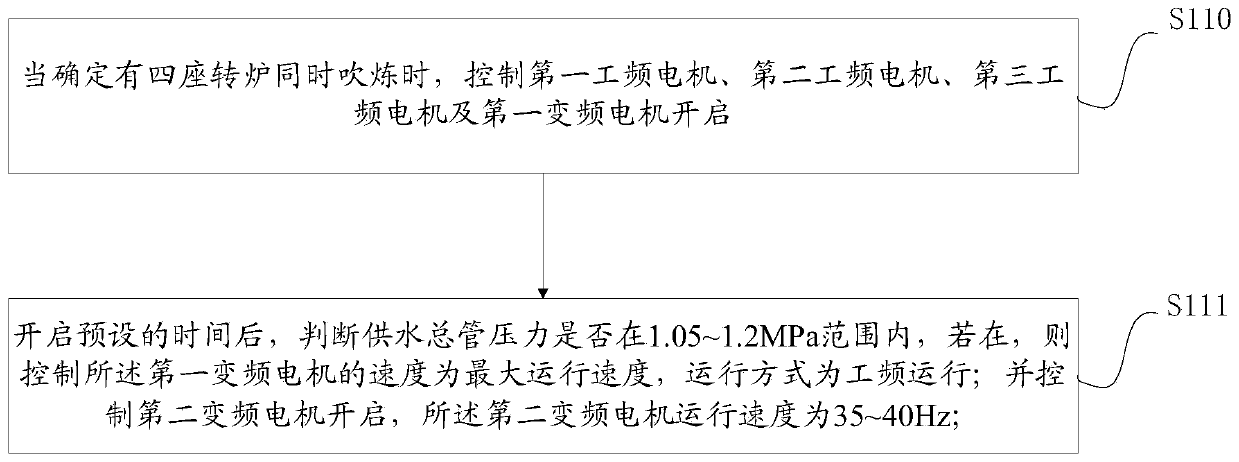

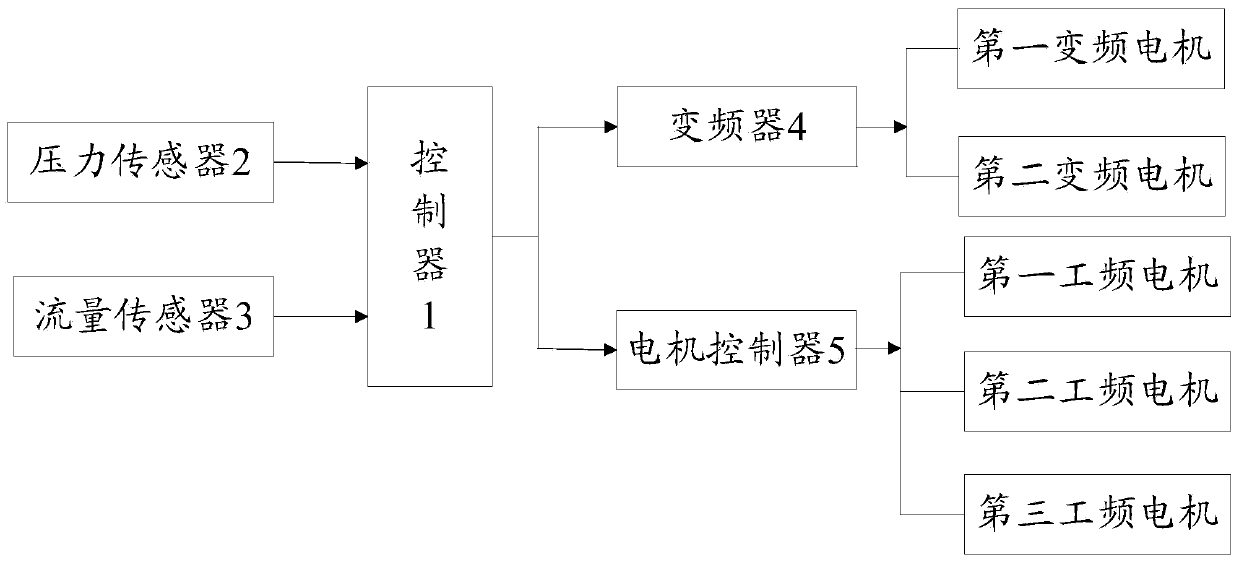

Water supplying pressure controlling method and system

ActiveCN110004266ARegulating pressureAvoiding situations where steelmaking cannot continueManufacturing convertersIncreasing energy efficiencyEvaporative coolerElectric machine

The invention provides a water supplying pressure controlling method and system. The method comprises the steps that a first power frequency motor, a second power frequency motor, a third power frequency motor and a first frequency converting motor are controlled to start when it is determined that four converters blow; whether or not the pressure of a water supplying main pipe is within the rangeof 1.05-1.2 MPa is judged after the motors are started for a preset period of time, if yes, the speed of the first frequency converting motor is controlled to be the maximum operating speed, and theoperating manner is power frequency operating; a second power converting motor is started, and the operating speed of the second frequency converting motor is 35-40 Hz; when the number of the converter is increased to four from three of less than three and a valve of an evaporating cooling device is started, four power frequency motors are controlled to start, the pressure of the water supplying main pipe can be ensured to be timely adjusted, adjusting is conducted by using a frequency converting motor so that the pressure of the water supplying main pipe can be allowed to be maintained withina normal range, the problem of the failure of making steel continuously caused by the linkage locking of the converters is prevented, and therefore the steel making efficiency is further improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

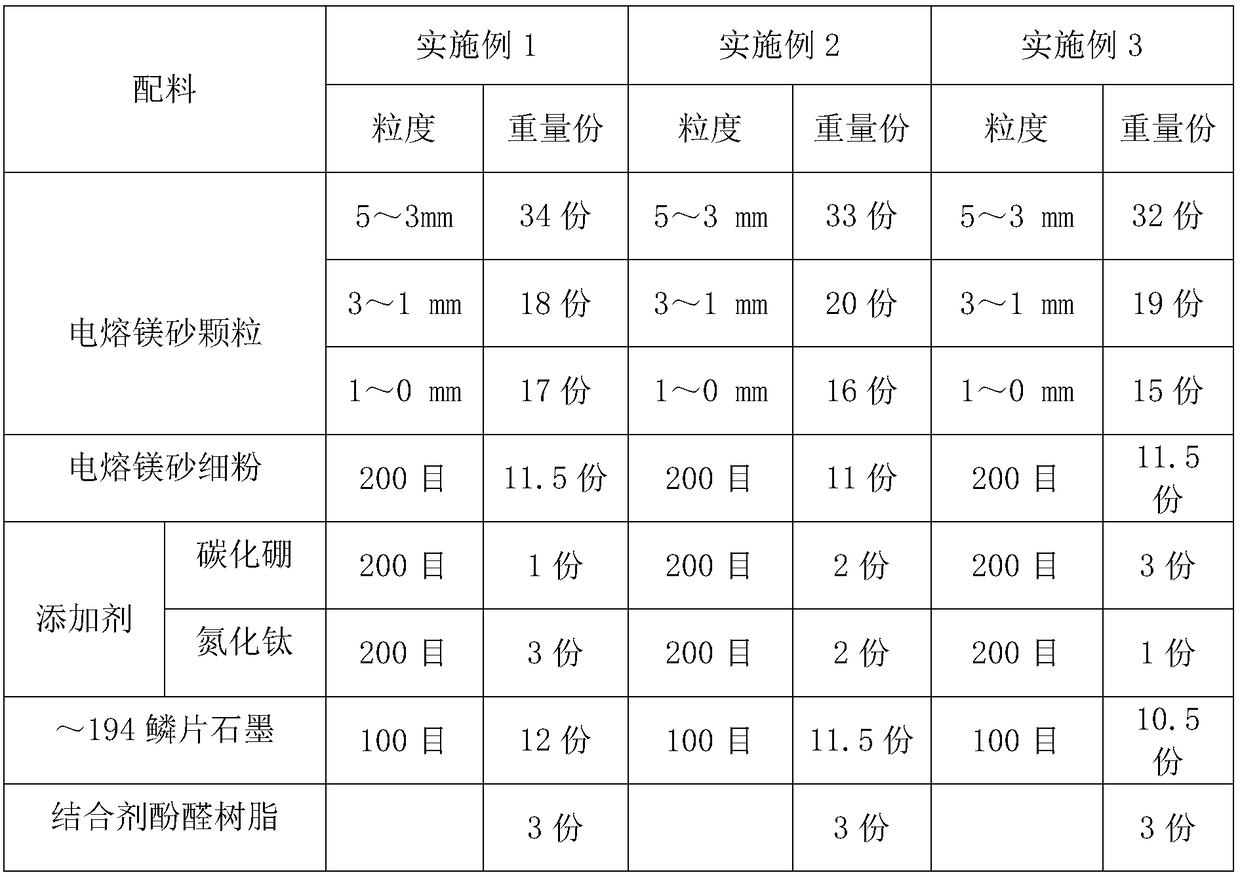

Converter body brick with titanium nitride added and preparation method thereof

InactiveCN109265144AImprove antioxidant capacityExtended service lifeManufacturing convertersPorosityBrick

The invention relates to a converter body brick with titanium nitride added. According to the physicochemical indexes of the converter body brick, MgO is greater than or equal to 75.0%, the volume density after baking at 200 DEG C is greater than or equal to 2.98 g / cm<3>, the apparent porosity is less than or equal to 4%, the compression strength is greater than or equal to 35 MPa, the linear change rate is 0-1.0%, and the high-temperature bending strength is greater than or equal to 12 MPa. The converter body brick is prepared from the following components in parts by weight: 32-34 parts of fused magnesite particles with the particle size larger than or equal to 3 mm and smaller than 5 mm, 16-20 parts of fused magnesite particles with the particle size larger than or equal to 1 mm and smaller than 3 mm, 13-17 parts of fused magnesite particles with the particle size smaller than 1 mm, 10-12 parts of 200-mesh fused magnesite fine powder, 1-3 parts of 200-mesh boron carbide fine powder,1-3 parts of 200-mesh titanium nitride fine powder, 10-13 parts of 100-mesh crystalline flake graphite and 2-4 parts of a binding agent of phenolic resin. According to the converter body brick, composite additives of boron carbide and titanium nitride are added, so that the oxidation resistance of the converter body brick is improved, the service life of the converter body brick is remarkably prolonged, and therefore the steel-making efficiency of a steel mill is improved, the steel-making cost is lowered, and the steel-making quality and safety are ensured.

Owner:海城利尔麦格西塔材料有限公司

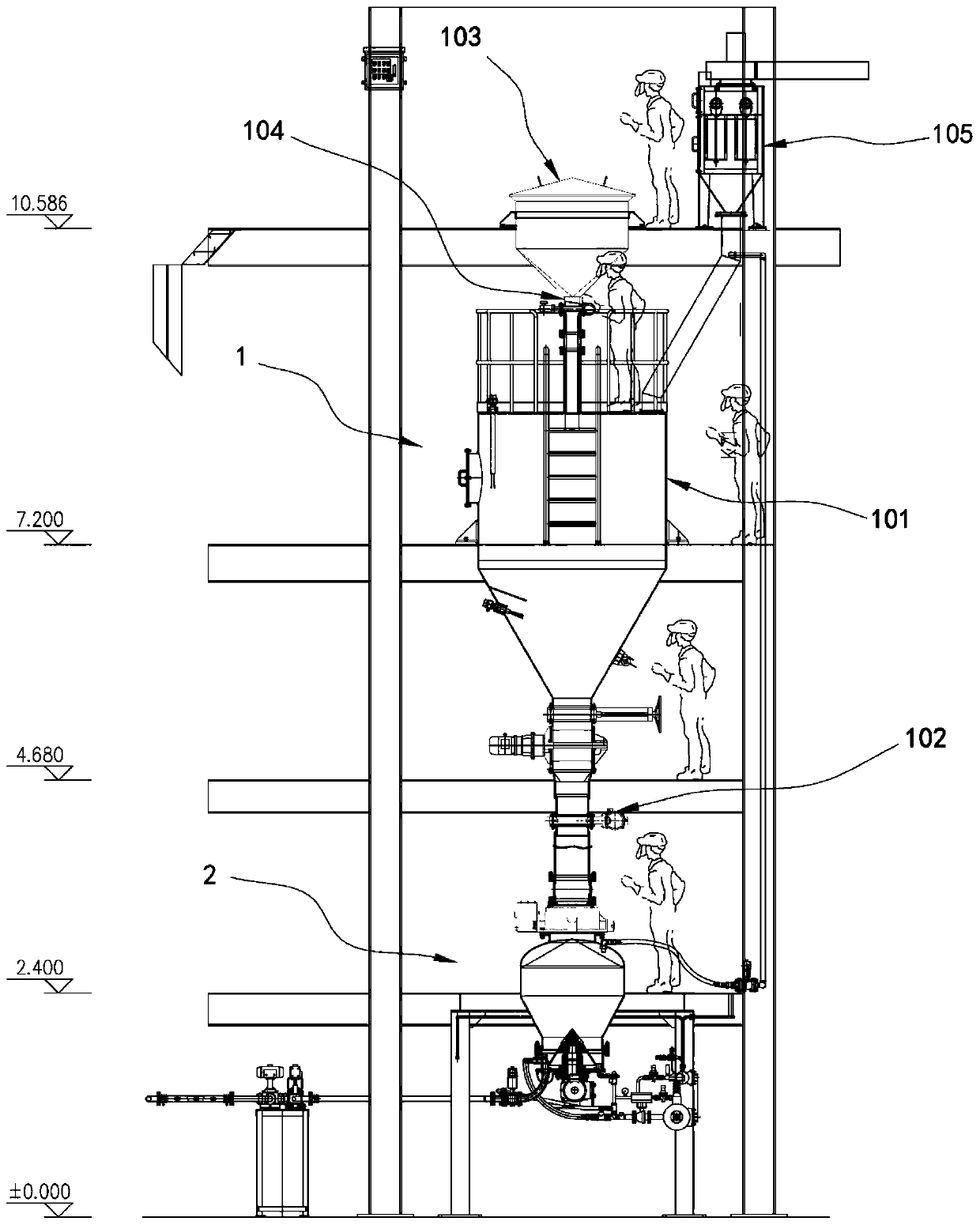

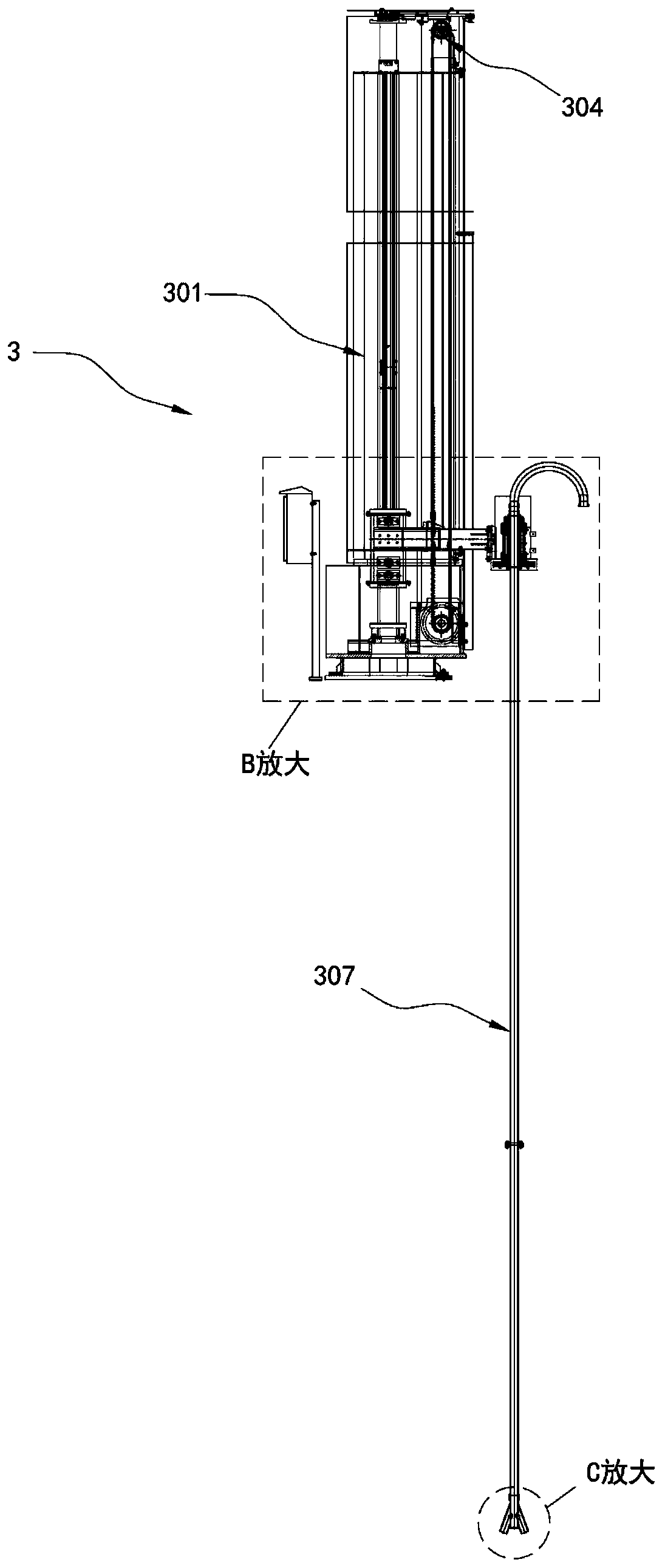

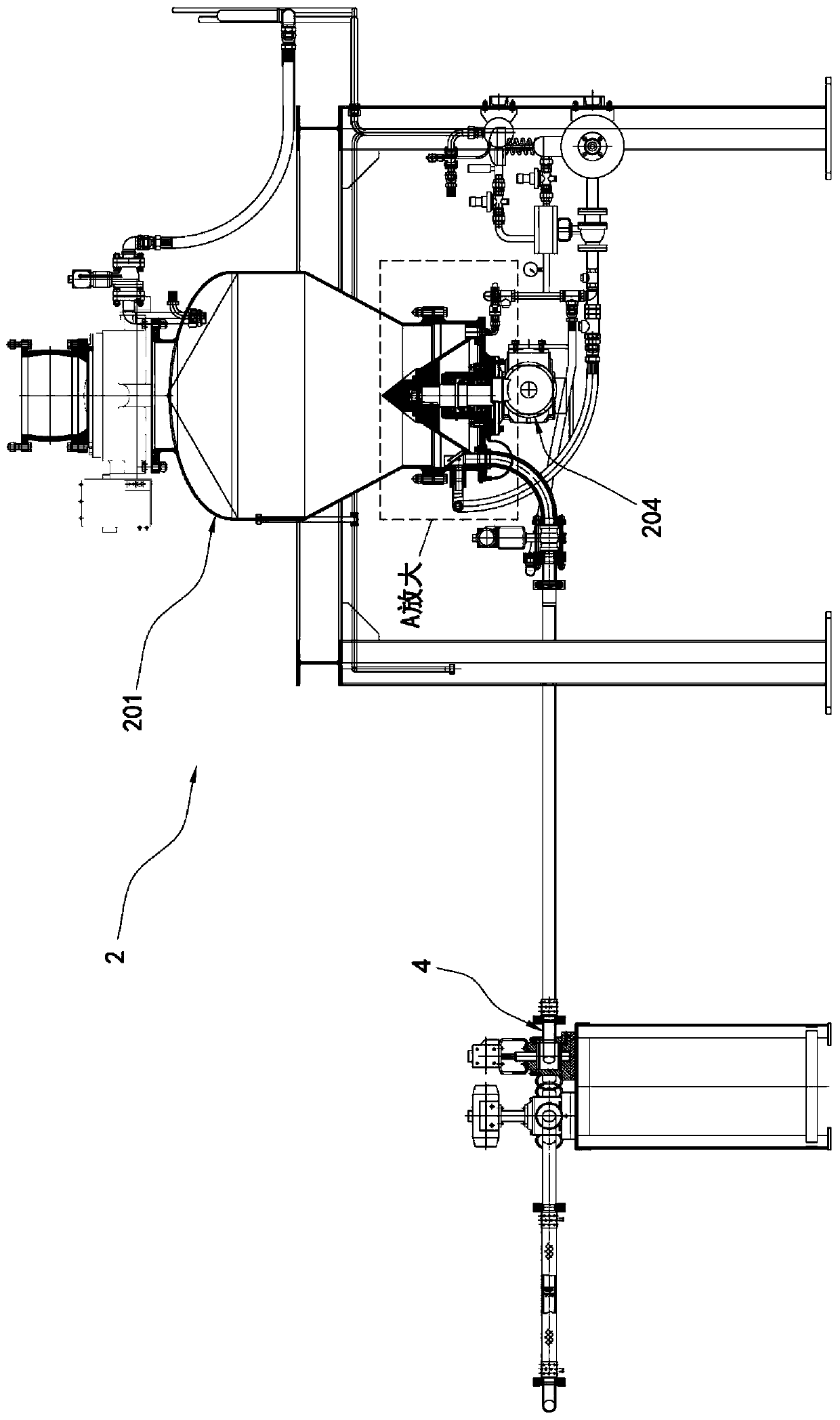

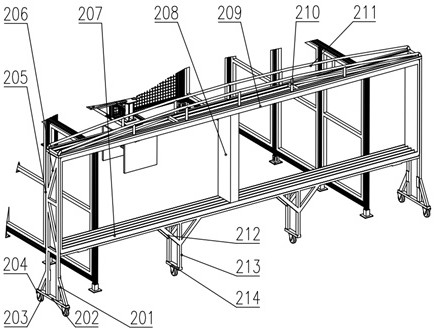

Slag conglomeration agent spraying system

The invention discloses a slag conglomeration agent spraying system comprising a material storage device, a spraying device and a nozzle component; the material storage device comprises a storage binand a first valve; the spraying device comprises a charging bucket, a baseplate, a rotating wheel component, a first driver and an air-ejecting device; the lower end of the charging bucket is open, and the opening of the lower end of the charging bucket is sealed by the baseplate; the rotating wheel component is located in the opening of the lower end of the charging bucket, and the rotating wheelcomponent is driven by the first driver to rotate; the edge of the rotating wheel component is provided with a feeding channel which is in the vertical direction and penetrates through the edge of the rotating wheel component; the surface of the charging bucket is provided with an air inlet channel, and the baseplate is provided with a discharging port; and the air inlet channel is connected withthe air-ejecting device; and the discharging port is connected with a slag conglomeration agent nozzle component. According to the slag conglomeration agent spraying system, slag conglomeration agents are stored in the storage bin, and powder slag conglomeration agents are mixed with air flow, and then conveyed to the nozzle component through the spraying device, so that mechanical spraying of the slag conglomeration agents is achieved; and the steelmaking efficiency is improved, and the labor intensity of steelworkers is reduced.

Owner:南京伊顿派克重工机械有限公司

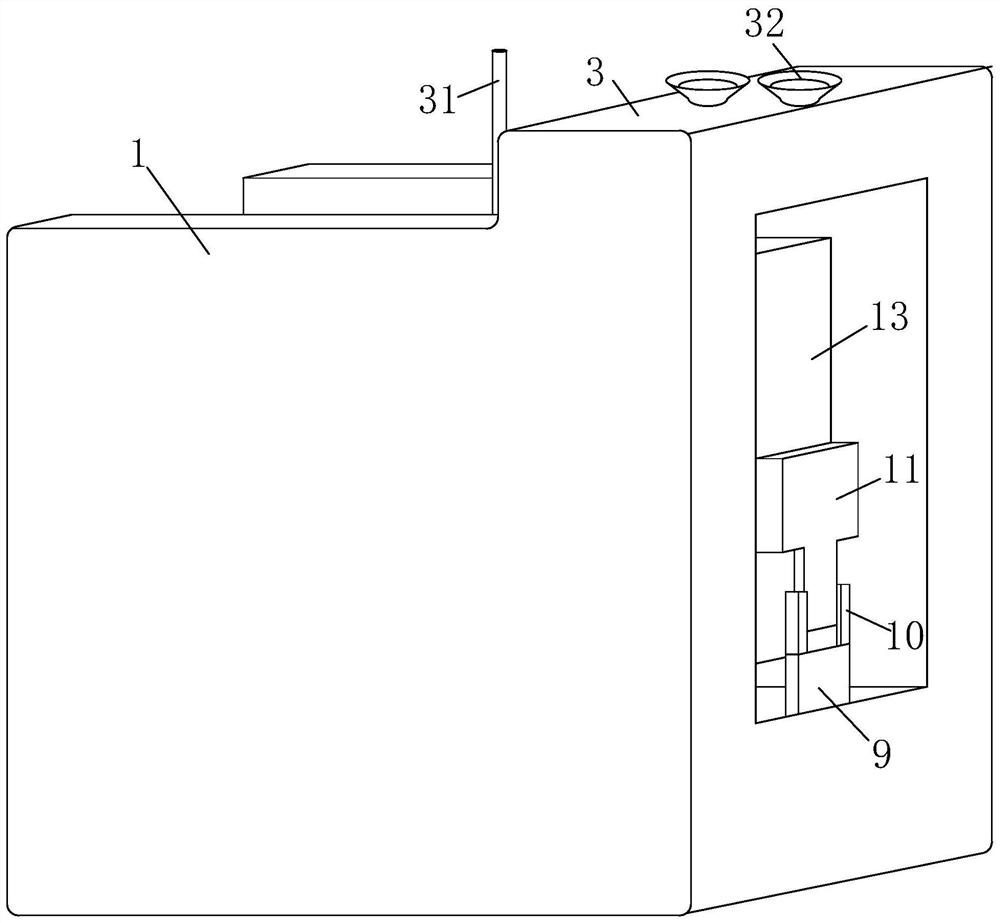

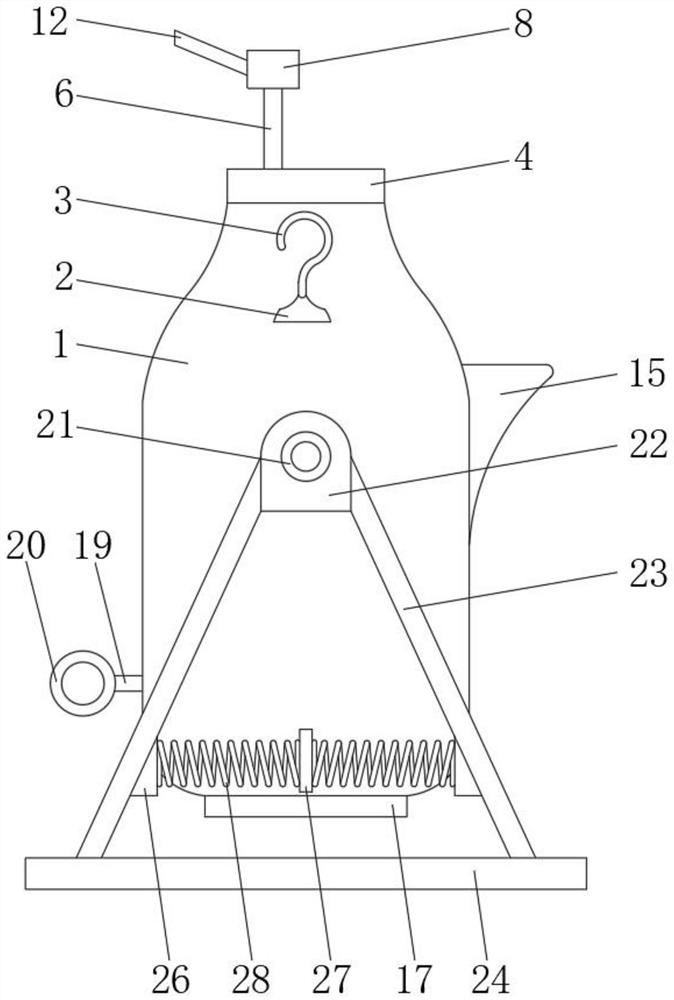

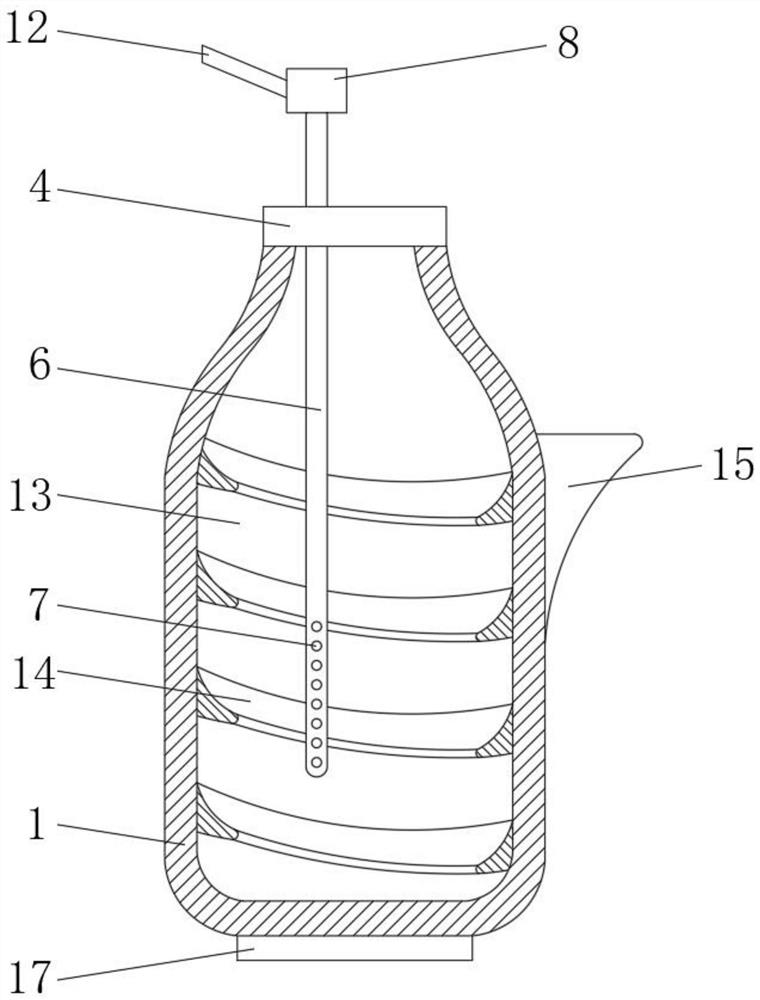

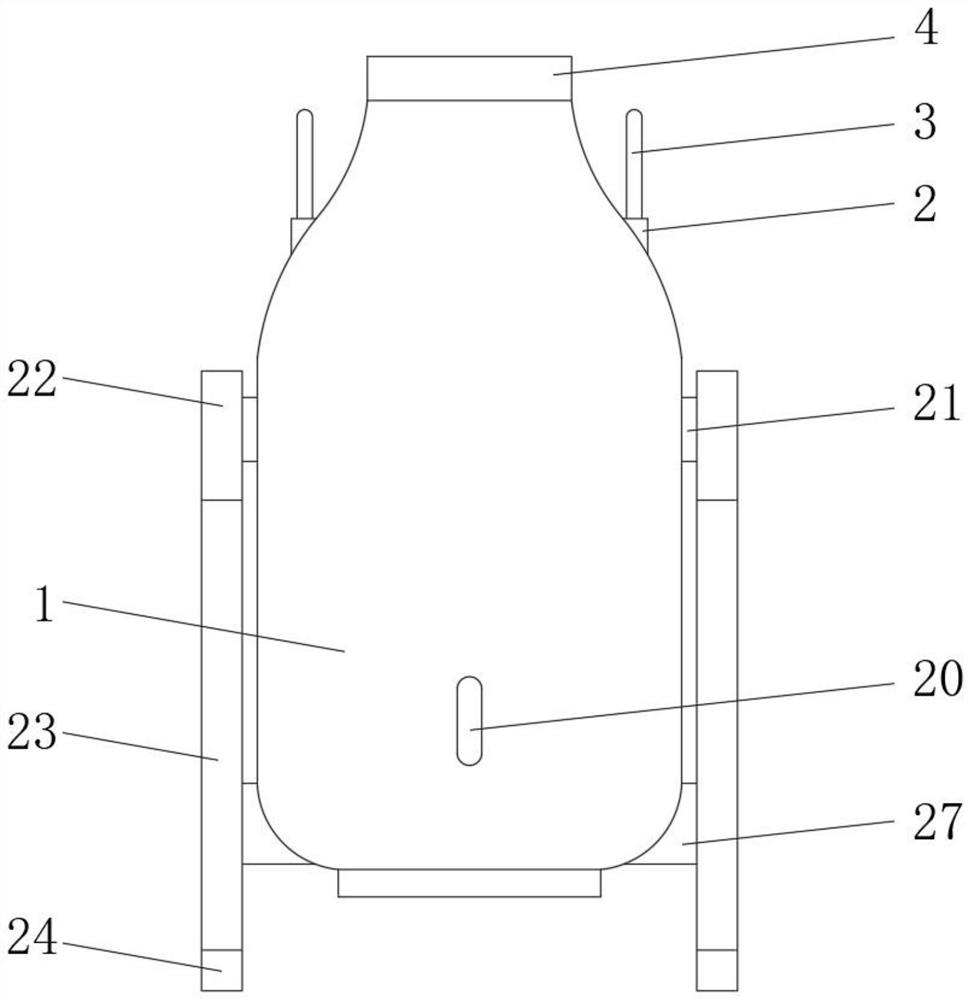

A vacuum steelmaking furnace

ActiveCN110345758BReduce lossesImprove steelmaking efficiencyCharge composition/stateCharge manipulationSteelmakingAir blower

The invention belongs to the technical field of steel smelting furnaces, and particularly relates to a vacuum steel smelting furnace. A shell, a bottom plate, a feeding box, a first motor, a lead screw, a movable block, a connecting rod, a limiting plate, a fixing plate, a movable plate, a first connecting block, a second connecting block, a fixing frame, a second motor, a belt, a belt wheel, a transmission shaft, a vacuum cavity, an inner furnace, an outer furnace, a seal furnace crown, a vacuum pump, a connecting pipe, a first air cylinder valve, a storage tank, an air blower, a communication pipe, a second air cylinder valve, an air pipe, a feeding pipe, an oxygen inlet pipe, a feeding hopper, a discharging pipe, a stirring cavity, a third motor, a stirring shaft, a casing pipe, a conical barrel, screen holes, a grinding barrel, a stirring bar, a mixing hopper, a material outlet pipe and grinding teeth are included. Through matched communication of the storage tank, the first air cylinder valve, the second air cylinder valve, the connecting pipe and the communication pipe, vacuum pumping is only conducted on the vacuum cavity through the vacuum pump and the air blower, accordingly, rapid vacuum pumping of the vacuum cavity is achieved, the steel smelting efficiency is improved, and heat losses are reduced.

Owner:山东天智信息科技有限公司

A high-efficiency and energy-saving converter

ActiveCN110157850BReduce consumptionIncrease contactManufacturing convertersSteelmakingControl engineering

Owner:浙江琰大新材料有限公司

Waste steel processing method

InactiveCN108677245AEffective isolation of contactsIsolated contactPackaging under vacuum/special atmosphereElectrochemical responseResource recovery

The invention discloses a waste steel processing method. The waste steel processing method comprises the following processes that waste steel is soaked in alkali solution and connected with the positive pole of a power supply, an electrochemical reaction is conducted, and the waste steel is picked up until the surface coating of the waste steel is removed; the waste steel is rinsed with surfactantsolution, then rinsed with deionized water and dried; and the surface of the waste steel is coated with an LDPE film, and vacuummizing is conducted after coating until the LDPE film is tightly attached to the surface of the steel. The waste steel processing method can increase the recovery rate of resources and reduce the environmental pollution.

Owner:成都兴天诚绿色建筑科技有限公司

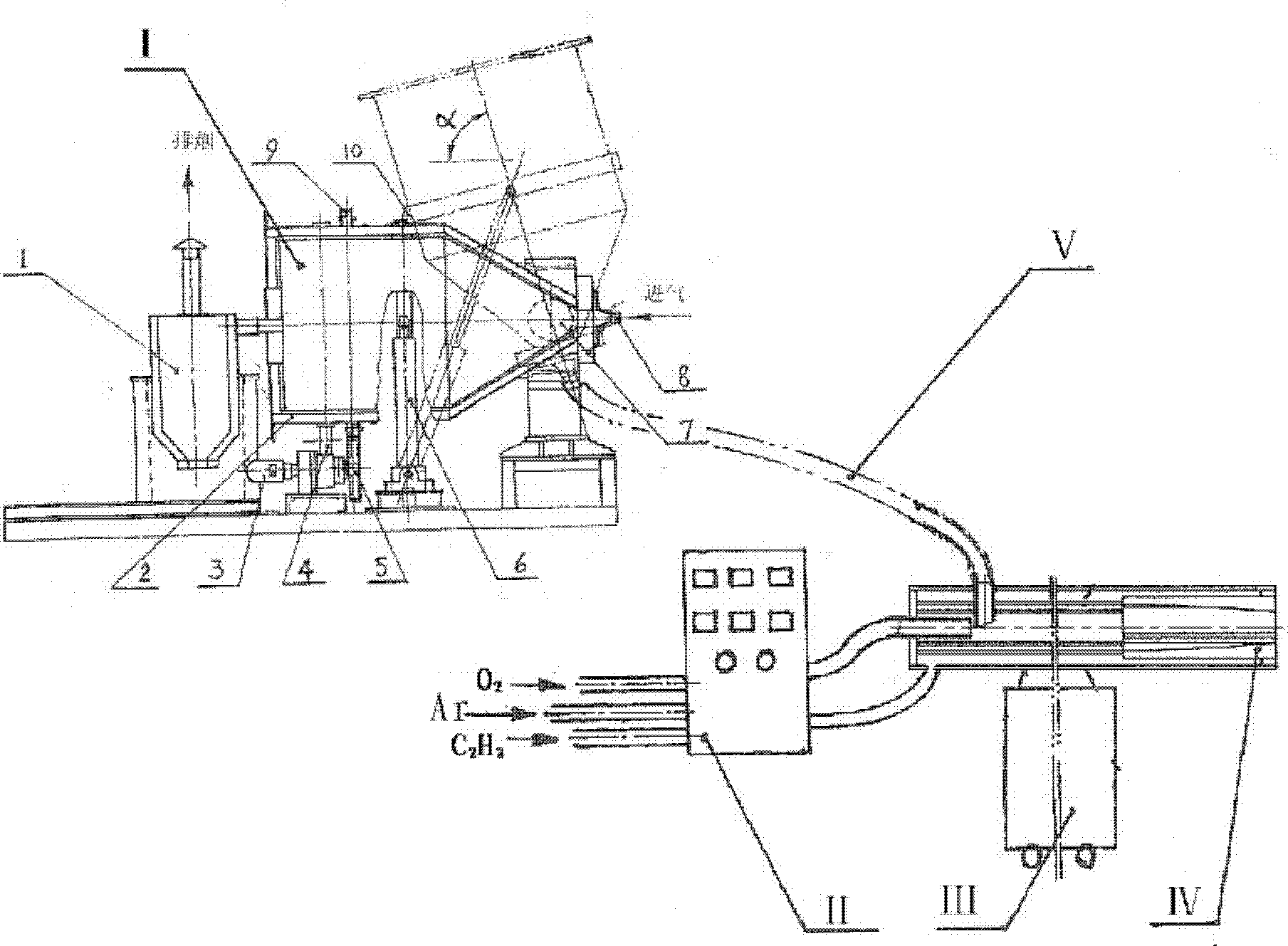

flame gunning process

InactiveCN102735060BImprove corrosion resistanceImprove anti-scourabilityLinings repairSlagMolten steel

Owner:NANTONG XINGSHI MATERIAL TRADING CO LTD

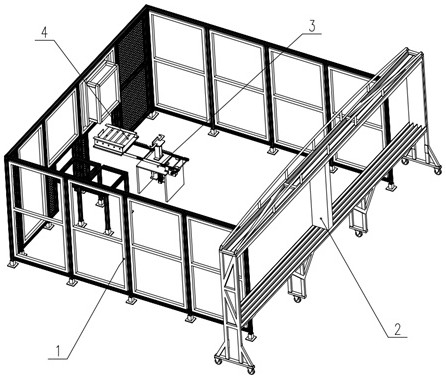

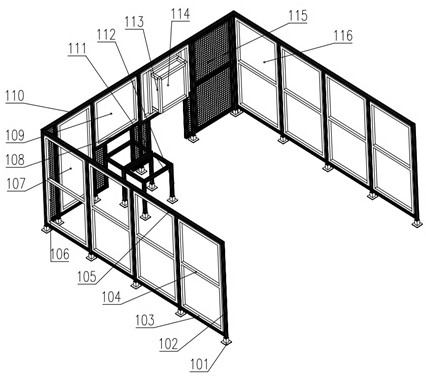

Protective guard for steel-making furnace

ActiveCN112814472AEnsure safetyEasy and direct shippingFencingBuilding constructionsSteelmakingElectric machinery

Owner:HUAYIN XINXIBEI SPECIAL STEEL CO LTD

A long-life oxygen-blowing metal hose

ActiveCN105673980BExtended service lifeImprove flexibilityPipeline expansion-compensationWave shapeEngineering

An oxygen blowing metal hose long in service life comprises a corrugated pipe, and a first joint and a second joint are arranged at the two ends of the corrugated pipe; the outer side of the corrugated pipe is wrapped with a metal net body, and the corrugated pipe is of a five-segment type structure formed by sequentially connecting a first pressure-resisting segment, a first transition segment, a high-flexibility segment, a second transition segment and a second pressure-resisting segment; the first pressure-resisting segment and the second pressure-resisting segment on the two sides of the corrugated pipe are in omega shapes; and the high-flexibility segment located in the middle portion of the corrugated pipe is in a deep-U-shaped wave shape, and the first transition segment and the second transition segment are in U-shaped wave shapes. According to the characteristics that the two sides of the corrugated pipe are bad in working condition and large in bearing pressure, the pressure-resisting segments in the omega shapes are arranged on the two sides of the corrugated pipe; according to the characteristic that due to insufficient flexibility, the dynamic bending portion of the middle segment of the corrugated pipe is prone to being damaged, the middle segment of the corrugated pipe is designed to be the high-flexibility segment in the deep-U-shaped wave shape; and through the improvement, the service life of the oxygen blowing metal hose is greatly prolonged, the maintenance and replacement time is greatly shortened, and improvement of steel smelting efficiency is facilitated.

Owner:石家庄巨力科技股份有限公司

High temperature resistant material for tea machinery

ActiveCN112300607BQuality improvementImprove antioxidant capacityFireproof paintsFibre chemical featuresSteelmakingCrack resistance

The invention discloses a high-temperature-resistant material for tea machinery. The high-temperature-resistant material includes high-temperature-resistant steel and a high-temperature-resistant paint coated on the surface of the steel. The high-temperature-resistant steel includes the following raw materials: carbon, iron, and high-purity silicon carbide , titanium, chromium, molybdenum, vanadium, niobium, boron, the high temperature resistant coating includes the following raw materials: inorganic silicone resin, titanium dioxide, modified mica powder, tungsten powder, dispersant, primary antioxidant, auxiliary antioxidant, disinfectant Foaming agent, deionized water. Adding high-purity silicon carbide synthesized by metal silicon and monochloromethane into steel not only improves the quality of steel but also speeds up steelmaking, saves energy, reduces the consumption of raw and auxiliary materials, and is used in the production of high-temperature resistant coatings. During the process, silane coupling agent and polypropylene are used to modify the mica powder, so that the modified mica powder not only improves the weather resistance of the coating film, delays pulverization, and discoloration, but also improves the water resistance, corrosion resistance, and penetration resistance of the coating film. properties, mechanical properties, crack resistance and high temperature resistance.

Owner:安徽宣城华阳茶叶机械股份有限公司

A method for making foamed slag for electric arc furnace steelmaking by using waste plastics and waste rubber

ActiveCN106350635BSolve pollutionReduce pollutionElectric furnaceProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber, wherein the steps are as follows: The waste plastic and the waste rubber are to be crushed. When the temperature of the slag reaches 1600-1650oC and the limestone is completely dissolved, the pulverized waste plastic and waste rubber and metallurgical grade coke are injected into the slag. At this time, there is a large amount of FeO in the slag layer, and then FeO is reduced by waste plastics and waste rubber and C in metallurgical grade coke to produce Fe and CO gas, and CO gas is trapped by slag to form foam slag. In order to produce a large amount of foaming slag, oxygen-enriched operation is carried out for feeding oxygen. When the O2 content in the slag exceeds the CO equilibrium curve, excessive CO gas is generated. After the CO gas is captured by the slag, a large amount of foam slag is formed. By mixing the waste plastics, waste rubber and metallurgical grade coke, the foaming slag is characterized by improvement of the electric arc furnace steelmaking efficiency, cost reduction of electric arc furnace steel and less environmental pollution.

Owner:HENAN TAIHANG QUANLI HEAVY IND

Technique for smelting vanadium iron from calcium vanadate

A production of ferrovanadium concerned with calcium vanadate is carried out by smelting calcium vanadate, Al and ferrous powder at weight ratio of 100: (23-28): (23-27). The said calcium vanadate is selected from m-calcium vanadate, p-calcium vanadate or o-calcium vanadate, one of them at least, with V content of 24-43%. It has high recovery rate and no wastewater pollution.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Preheating material tank of flame gunning machine

InactiveCN102735059AHigh densityImprove corrosion resistanceLinings repairHydraulic cylinderMolten state

A preheating material tank relates to a device used for steelmaking furnace lining spraying. The preheating material tank comprises an exhaust collector, a material tank, a motor, a supporting roller, a driving gear, a hydraulic cylinder, a shaft, a gear ring, a positioning sleeve ring and a base. The material tank bottom is hinged with a frame on the base through the horizontally disposed shaft, and the supporting roller for supporting the material tank is arranged on the base. A discharge port is provided in the material tank bottom. The positioning sleeve ring is sleeved on the material tank. The hydraulic cylinder bottom is hinged with the base, and a piston rod of the hydraulic cylinder is hinged with the positioning sleeve ring. Stretching and shrinking of the hydraulic cylinder piston rod make the material tank rotate around the shaft. The base is provided with a horizontal track and the exhaust collector is arranged on the horizontal track. When the material tank is horizontally arranged, the exhaust collector is connected with an exhaust port on top of the material tank. The gear ring is fixed on the material tank. The base is provided with the motor. The driving gear is provided on the motor rotary shaft. The driving gear is engaged with the gear ring. The material tank of the invention solves the problem of an unsatisfactory gunning effect as refractory powder cannot be burnt into a molten state in the prior gunning method.

Owner:常君辰

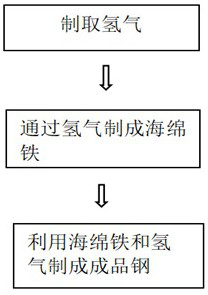

Carbon neutralization method for smelting steel and iron by using iron ore, hydrogen and oxygen

PendingCN113355474AReduce pollutionEmission reductionManufacturing convertersProcess efficiency improvementSteelmakingParticulates

The invention relates to the field of steelmaking, in particular to a carbon neutralization method for smelting steel by using iron ore, hydrogen and oxygen. The carbon neutralization method for smelting the steel by using the iron ore, the hydrogen and the oxygen comprises the steps of adding combustible energy into a smelting gasification device to be gasified into mixed gas containing the hydrogen, and extracting the hydrogen; the iron ore, the hydrogen, the oxygen and biological particles are added into a heating furnace to react to generate sponge iron; and adding the sponge iron and other steelmaking materials into a steelmaking furnace for steelmaking, and using gasification of the hydrogen and the oxygen to achieve carbon neutralization. The steelmaking method is low in cost and energy consumption, the steelmaking time is saved, the carbon emission in the steelmaking process is reduced, and the problem of air pollution in the steelmaking process is solved.

Owner:JIANGYIN SHANGFENG NEW ENERGY TECH DEV

Oxygen top blown converter steel making method

InactiveCN101575656BPrevent splashPrevent re-dryingManufacturing convertersSteelmakingHigh magnesium

The invention relates to an oxygen top blown converter steel making method, comprising the following steps: the steel material is added to a converter, oxygen is blown into the converter by an oxygen lance and auxiliary materials are added into the furnace by stages in the process of oxygen blowing; wherein the steel material comprises semisteel; lance position of the oxygen lance moves within 1.5-2.2m above molten steel liquid surface in the converter, wherein blowing beginning lance position is 1.95-2.05m, blowing lance position is 1.5-2.2m and catch carbon lance position is 1.7-1.75m; wherein, the auxiliary materials comprise compound slag, lime and high-magnesium lime; in every ton of semisteel, 17-20kg of the compound slag is used, 30-34.5kg of lime is used, 30-34.5kg of high-magnesium lime is used, a total of 43-53 cubic meters of oxygen is blown into the furnace; with the total content of the blown oxygen as a benchmark, the first batch of auxiliary materials are added when theoxygen blowing content is 0.8-2%; with the method of the invention adopted, steelmaking time can be reduced and slag splashing and drying can be effectively avoided in the process of steelmaking.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com