Slag conglomeration agent spraying system

A technology of spraying system and slag accumulator, which is applied in the field of mechanical equipment, can solve problems such as harsh environment, low spraying efficiency, and affecting workers' health, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

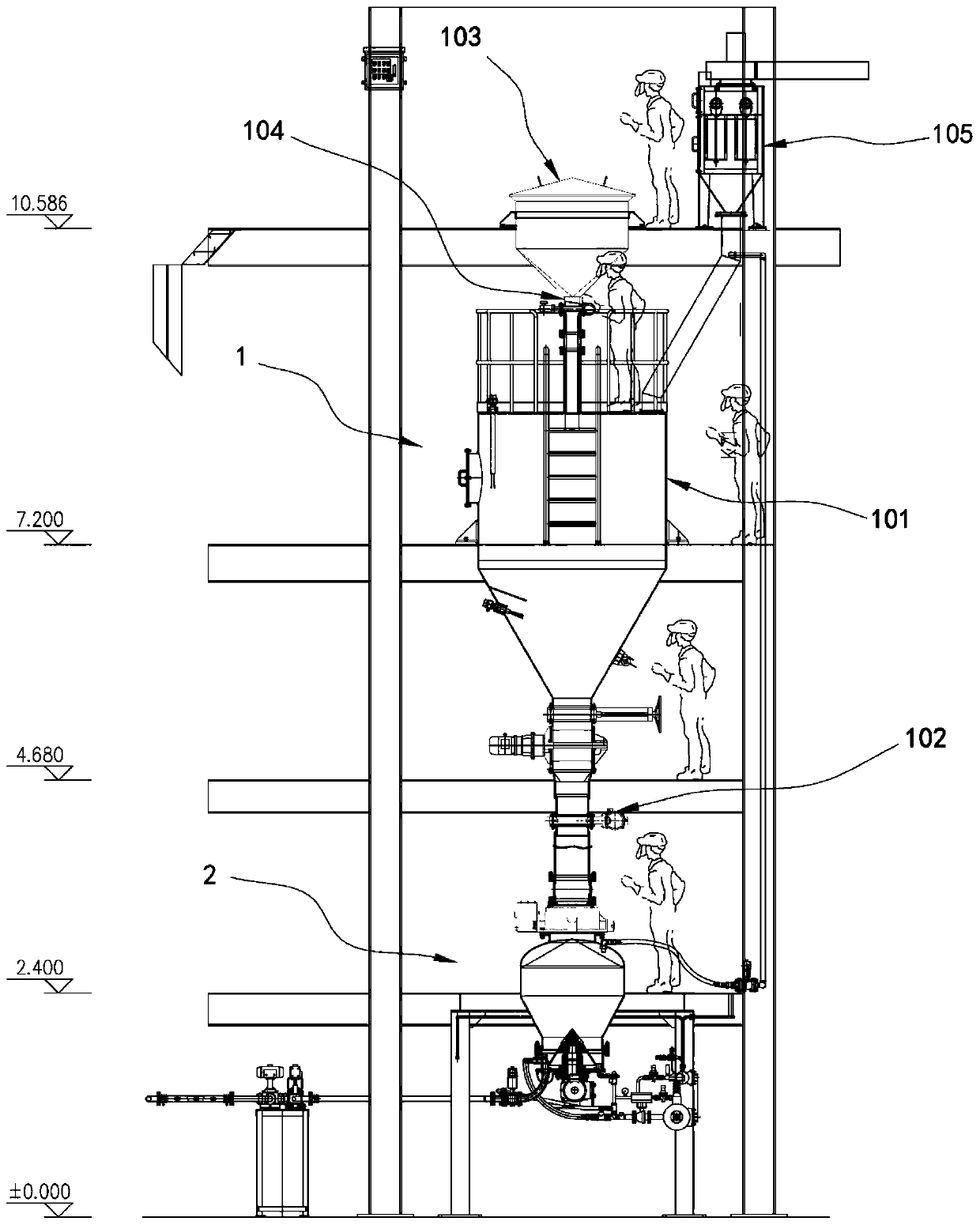

[0040] Such as figure 1 with figure 2 As shown, the slag accumulator spraying system of this embodiment includes a storage device 1, a spraying device 2, a nozzle assembly 3, a weighing device and a control center;

[0041] The storage device 1 comprises a storage bin 101, a first valve 102, a hopper 103, a second valve 104 and a dust collector 105, the storage bin 101 is located above the feed tank 201 and communicates with the feed tank 201, the storage bin 101 and the feed bin The first valve 102 is set between the tanks 201; the receiving hopper 103 is located above the storage bin 101 and communicates with the storage bin 101, and the second valve 104 is arranged between the receiving hopper 103 and the storage bin 101; the dust collector 105 and the storage bin 101 connectivity;

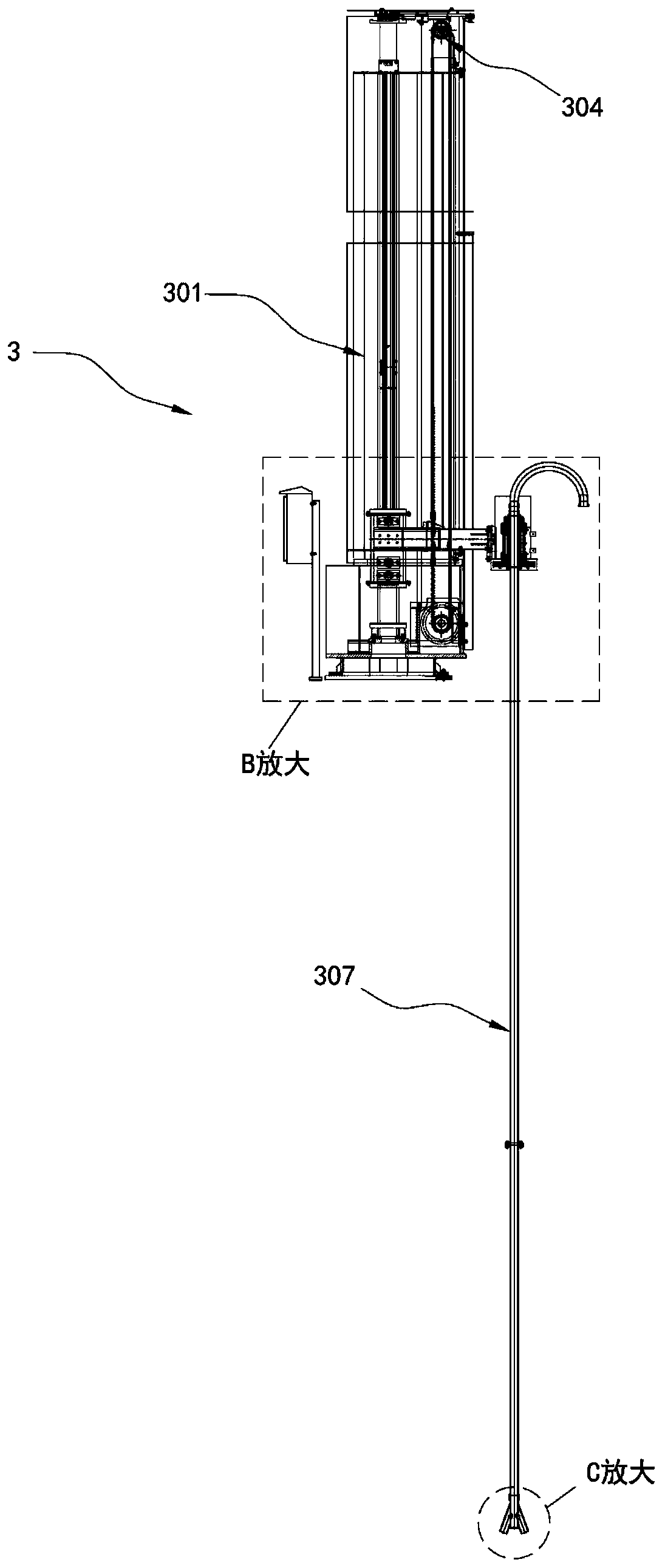

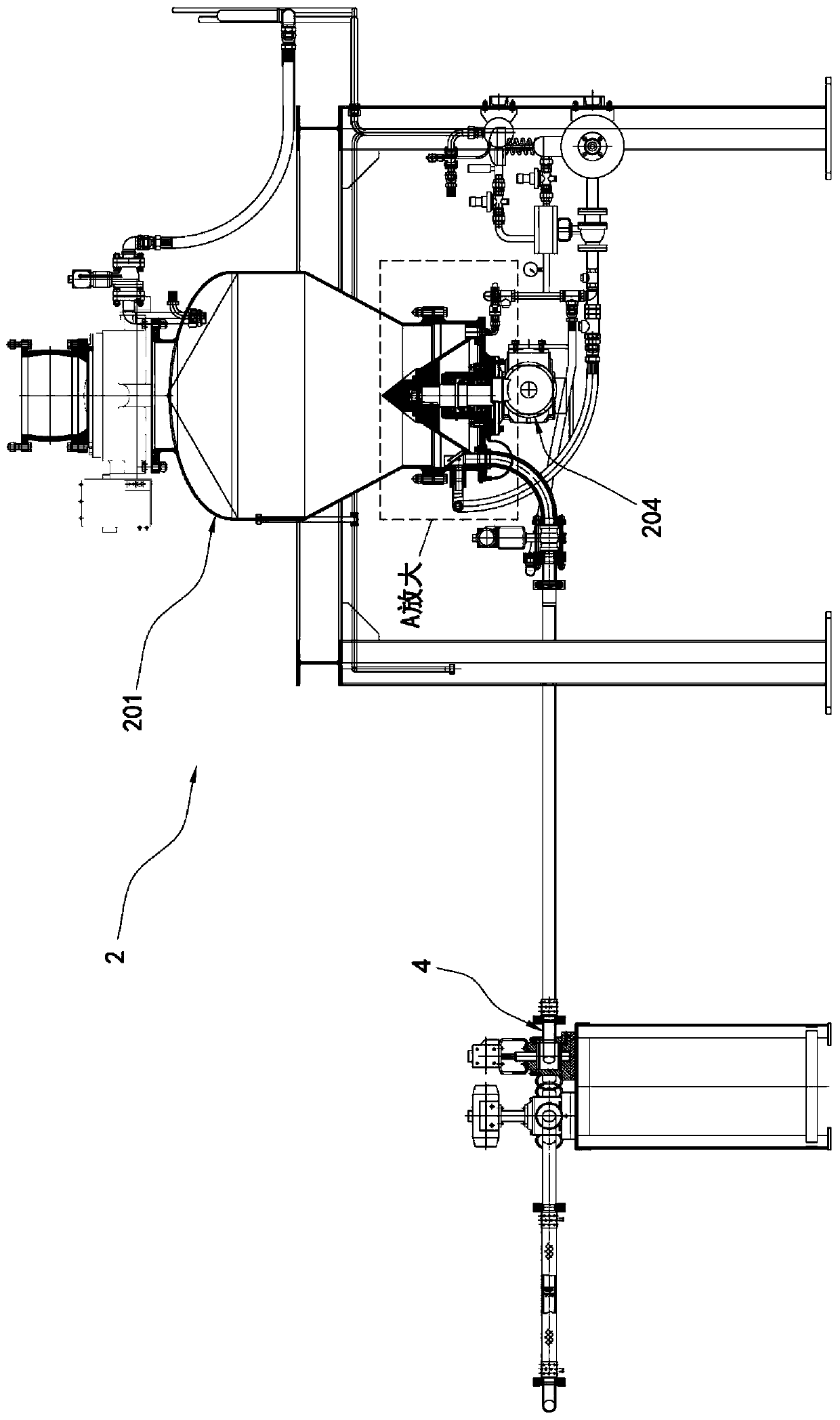

[0042] Such as Figure 3 to Figure 5 As shown, the spraying device 2 comprises a material tank 201, a bottom plate 202, a runner assembly 203, a first motor 204 and an air storage tank; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com