Circuit board grinding production system

A production system and circuit board technology, applied in the direction of grinding machines, printed circuit, printed circuit manufacturing, etc., can solve the problems of inability to clean the board surface, inconvenient use, and inability to adjust the grinding position, so as to achieve the effect of improving the effect and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

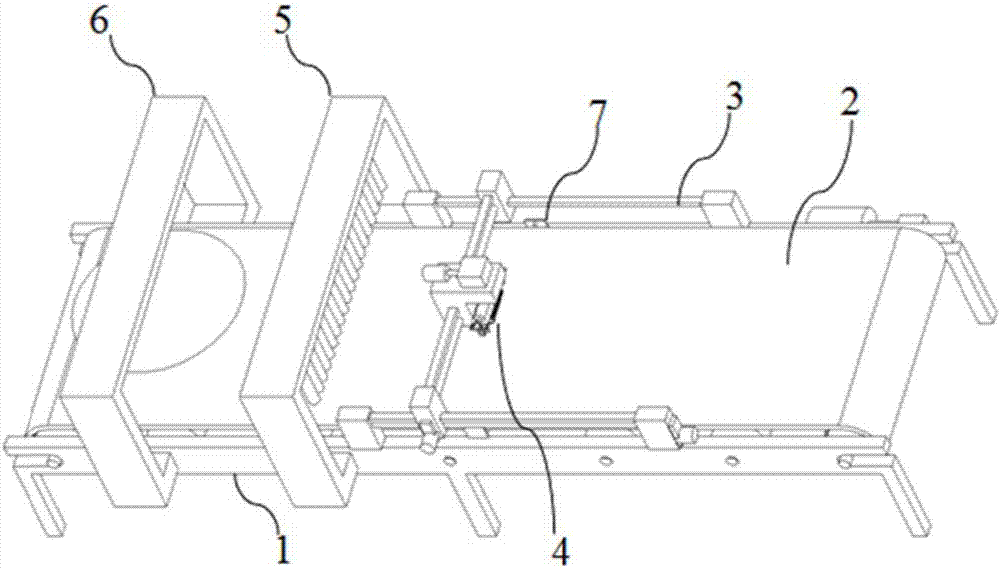

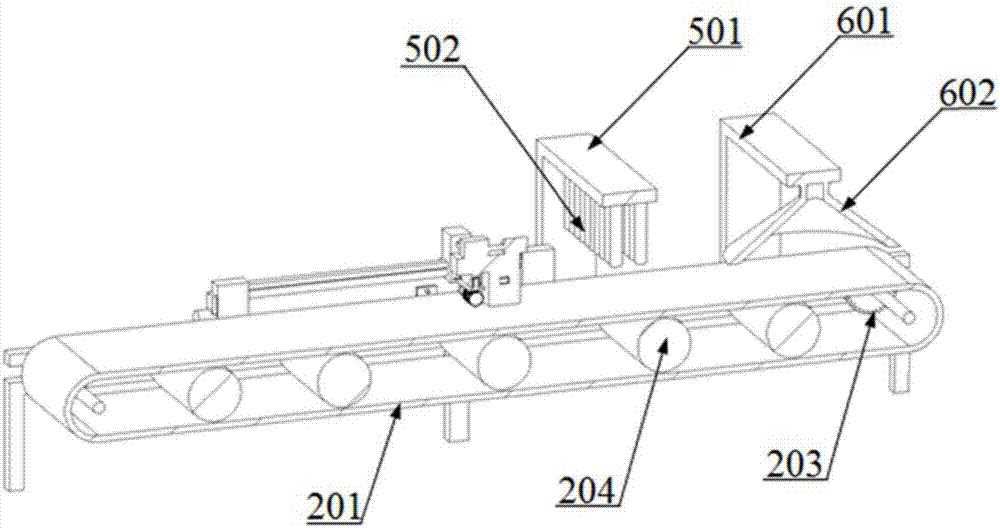

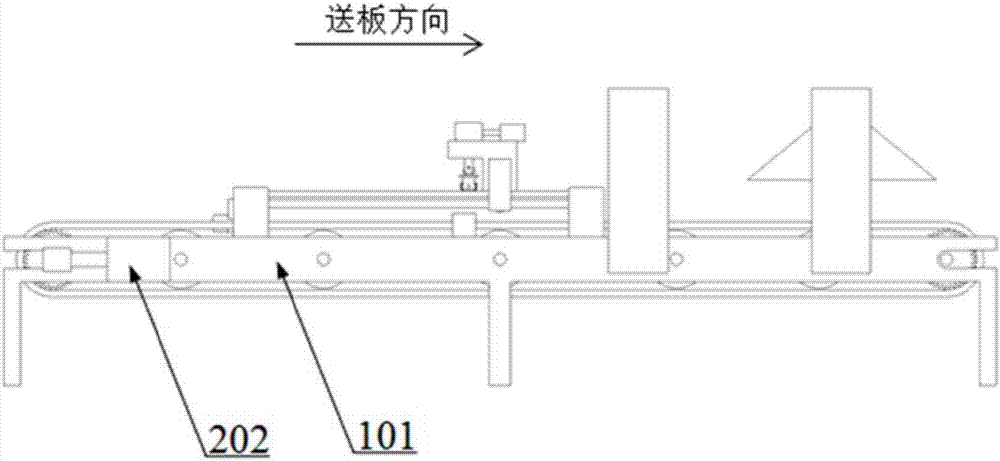

[0036] refer to Figure 1 to Figure 6 , a circuit board grinding plate production system, comprising a grinding plate frame 1, a plate feeding mechanism 2, a grinding head position adjustment mechanism 3, a polishing mechanism 4, a cleaning mechanism 5 and a drying mechanism 6, the grinding plate frame includes a support side Plate 101, the plate feeding mechanism is arranged between the supporting side plates 101 of the grinding plate frame;

[0037] The position adjustment mechanism of the grinding head includes an X-direction movement assembly, a Y-direction movement assembly and a Z-direction movement assembly. On the X-direction motion assembly, the Y-direction motion assembly includes a Z-direction motion base 305, the Z-direction motion assembly includes a Z-direction motion motor 308, and a Z-direction lifting rod 309 connected to the Z-direction motion motor 308 through a coupling , the Z-direction movement motor 308 is fixedly arranged on the top edge of the Z-direc...

Embodiment 2

[0042] refer to Figure 1 to Figure 6 , a circuit board grinding plate production system, comprising a grinding plate frame 1, a plate feeding mechanism 2, a grinding head position adjustment mechanism 3, a polishing mechanism 4, a cleaning mechanism 5 and a drying mechanism 6, the grinding plate frame includes a support side Plate 101, the plate feeding mechanism is arranged between the supporting side plates 101 of the grinding plate frame;

[0043] The position adjustment mechanism of the grinding head includes an X-direction movement assembly, a Y-direction movement assembly and a Z-direction movement assembly. On the X-direction motion assembly, the Y-direction motion assembly includes a Z-direction motion base 305, the Z-direction motion assembly includes a Z-direction motion motor 308, and a Z-direction lifting rod 309 connected to the Z-direction motion motor 308 through a coupling , the Z-direction movement motor 308 is fixedly arranged on the top edge of the Z-direc...

Embodiment 3

[0050] In this embodiment, a laser sensor and sandpaper are added on the basis of the second embodiment.

[0051] join figure 1 , a laser sensor 7 is arranged at the opposite position on the top edge of the support side plate 101 on both sides of the grinding plate frame, the optical sensor is located at the position of the grinding head position adjustment mechanism 3, and the laser sensor 7 is connected to the conveying motor 202. A laser sensor 7 is added, and when the circuit board to be polished moves to a set position, the conveying motor 202 is controlled to stop moving, which is convenient for the stable grinding work of the polishing mechanism 4 on the circuit board.

[0052] In this preferred embodiment, sandpaper (not shown in the figure) is pasted on the grinding roller 401 . By adopting the above technical scheme, by using the pasted sandpaper, it is easy to replace and the portability of the equipment is improved.

[0053] The circuit board grinding plate prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com