Protective guard for steel-making furnace

A technology for guardrails and guardrails, which is applied in the direction of fences, building types, buildings, etc., and can solve problems such as flexibility and permeability that cannot meet steelmaking plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

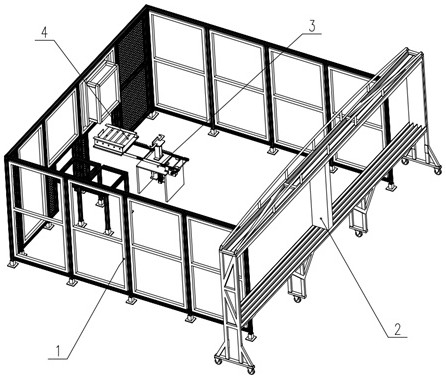

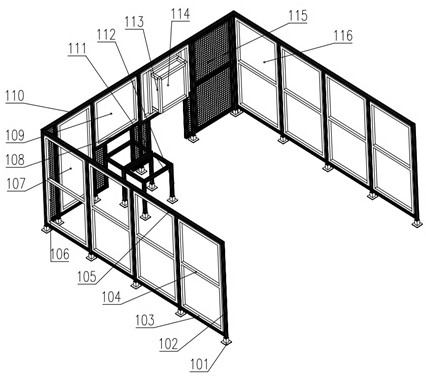

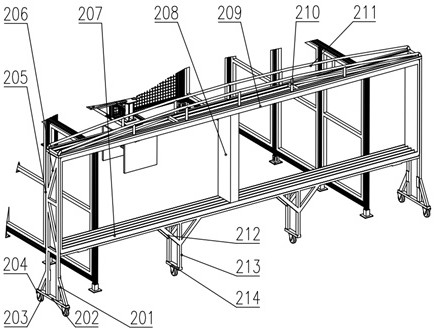

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The guardrail of a steelmaking furnace includes a guardrail 1 , a movable guardrail 2 , a lifting adjustment device 3 , and a conveying device 4 .

[0022] The specific structure of a steelmaking furnace guardrail is as follows: figure 1 As shown, the guardrail 1 is fixedly installed on the ground, the mobile guardrail 2 is fixedly installed on the ground, the lifting adjustment device 3 is fixedly installed on the ground, and the conveying device 4 is fixedly installed on the lifting adjustment device 3. A steelmaking furnace The guardrail is fixedly installed around the steelmaking furnace, wherein the guardrail 1 is directly fixed and installed on the ground as a fixed guardrail, and the lifting adjustment device 3 and the conveying device 4 are fixedly installed inside the guardrail 1 as a steelmaking material conveying structure.

[0023] The specific structure of guardrail 1 is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com